Professional Documents

Culture Documents

31220098

Uploaded by

Muhammad AliCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

31220098

Uploaded by

Muhammad AliCopyright:

Available Formats

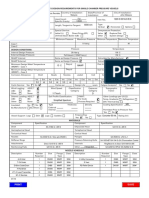

PRESSURE VESSELS – ASME –

USER’S DESIGN SPECIFICATION

PAGE 1 OF 8

General Service Pressure Vessel

Engineered Pressure Vessel

Issued For: Proposal Purchase As-Built

Operating Unit: Refinery Location: Refinery Location: Chemical Plant Loc:

Service: Item No: P&ID No: Project No:

PO No: Manufactured by: Serial No:

National Board Reg. Reqd: Jurisdictional Reg. Reqd: Jurisdiction:

Yes No Yes No Not Applicable

ENGINEERING REQUIREMENTS

TO BE SUPPLIED TO MANUFACTURER

Design Condition Vessel Jacket Coil

Specified Internal

Design Pressure kPa

Internal Design Temp.

(ºF) (ºC)

Specified External

Design Pressure kPa

External Design

Temperature)

(ºC ) (ºF )

MDMT

(ºC ) (ºF) @ ( kPa)

Low Temperature Due

Process Excursion Normal Process Low Ambient

To:

Design Specific

Gravity:

MAWP Basis:

Calculated Same as Design Pressure

Construction Code: ASME Section VIII

Division __

Edition Addenda

Lethal Service

Other Markings: Code Case(s)

(Division 1 only) Other:

See Certification Page

No. Date Description By Check Appv

DEP 31.22.00.98-Gen., January 2009

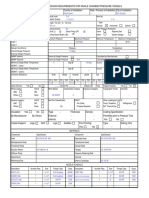

PRESSURE VESSELS – ASME –

PAGE 2 OF 8

USER’S DESIGN SPECIFICATION

Capacity

I.D. (m) O.D. (m)

(m3)

Installed Position: Maximum Liquid Level: (m)

Vertical

Vessel Interior Vessel Exterior Nozzles Internals Corrosive

Service?

Corrosion

Allowance Yes No

Vessel

Seal Weld

in. Jacket Internal Jacket External Coil

Supports

Internals to

Pressure

Boundary?

Yes No

Cyclic Service Annual Cycles – Vessel Annual Cycles – Jacket Annual Cycles – Coil

Yes No

Fatigue Analysis by Mfg. Fatigue Analysis Not Requred

Design Life: Years Structural Stress Method based on comparable equipment

Permitted Yes No experience

Wind Loading Wind Speed Classification Exposure Topographic Elevation

(ASCE7) (km/h) Category Category Factor (m)

Seismic Loading

Soil Profile Classification:

(ASCE7)

Other Loadings

(See UG-22 or Part 4,

Table 4.1.1 or Part 5,

Tables 5.1 and 5.2)

Head Types Top: 2:1 Ellipsoidal Bottom:2:1 Ellipsoidal Ends: 2:1 Ellipsoidal

Body Flange Type: ____ Facing: ____

Body Flange Finish Process Side: Service Side:

(Ra) (μm) (μ-in) (μm) (μ-in)

Vortex Breaker: Projection: Type:

Yes No ____ ____

Hardness Control: Max Hardness Value:

Yes No Brinell

Joint Efficiency: 1.0 PWHT: Per Code

No. Date Description By Check Appv

DEP 31.22.00.98-Gen., January 2009

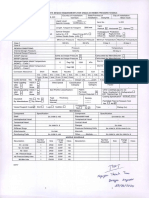

PRESSURE VESSELS – ASME –

PAGE 3 OF 8

USER’S DESIGN SPECIFICATION

Shop Coat: Primer Specification: Top Coat Specification:

Fireproofing: Type: Thickness:

By Mfg.

Insulation: Thickness: Density:

Type:

Yes No mm (kg/m3)

By Others

Vessel Supports

Type :Legs Lifting Lugs: Tailing Lugs:

OPERATING DATA

Case 1 Case 2 Case 2

Min Pressure (kPa)

Max Pressure (kPa)

Min Temp

(ºC ) (ºF )

Max Temp

(ºC ) (ºF )

Gradients and/or

Hi

st

or

Pres Temp Other Pres Temp Other Pres Temp Other

gr

a

m

s

Future Hydrostatic Pressure Shop Field

Test Vertical Vertical

Requirement

s

Shop Field

Future PWHT Cycle

1st Cycle after years 1st Cycle after years

Requirements

2nd Cycle after years 2nd Cycle after years

Additional Operational

Comments

No. Date Description By Check Appv

DEP 31.22.00.98-Gen., January 2009

PRESSURE VESSELS – ASME –

PAGE 4 OF 8

USER’S DESIGN SPECIFICATION

MATERIALS

ALL MATERIALS SHALL COMPLY WITH ASME BPVC SECTION II AND SECTION VIII

Component Material Type ASME Specification Comments

Shell

Clad Lining

Heads

Jacket

Reinforcing Pads

Vessel Nozzle Neck

Jacket Nozzle Neck

Vessel Nozzle Flanges

Jacket Nozzle Flanges

Manway Neck

Manway Flange

Manway Cover

Supports

Lifting / Tailing Lugs

Body Flanges

Jacket Closure Ring

Stiffening Rings

Insulation Supt. Rings

Ladder & Pltfm Clips

Coil

Other Internals

Internal Bolts

Internal Nuts

External Bolts

External Nuts

Vessel Gaskets

Jacket Gaskets

Coil Gaskets

No. Date Description By Check Appv

DEP 31.22.00.98-Gen., January 2009

PRESSURE VESSELS – ASME –

PAGE 5 OF 8

USER’S DESIGN SPECIFICATION

NOZZLE SCHEDULE

PURCHASER SHALL ORIENT AND LOCATE NOZZLES ON MANUFACTURER’S APPROVAL

DRAWINGS

No. Proj

Mark Size Rating Type Description

Req’d (mm)

GENERAL NOTES

No. Date Description By Check Appv

DEP 31.22.00.98-Gen., January 2009

PRESSURE VESSELS – ASME –

PAGE 6 OF 8

USER’S DESIGN SPECIFICATION

WELDED PRESSURE JOINT REQUIREMENTS

ALL MATERIALS MUST COMPLY WITH ASME BPV SECTION II AND SECTION VIII

Joint NDE Requirements

Component Type Joint

Efficiency (See also Division 2, Part 7, Table 7.2)

Head Type Extent Type Extent PMI

• Category A 1.0 Type 1 RT 100% MT 100% 100%

• Category B 1.0 Type 1 RT 100% RT 100% 100%

• Category C 1.0 Type 1 RT 100% RT 100% 100%

• Category D 1.0 Type 1 RT 100% RT 100% 100%

• Category E 1.0 Type 1 RT 100% RT 100% 100%

Other

Requirements

Shell Type Extent Type Extent PMI

• Category A 1.0 Type 1 RT 100% RT 100% 100%

• Category B 1.0 Type 1 RT 100% RT 100% 100%

• Category C 1.0 Type 1 RT 100% RT 100% 100%

• Category D 1.0 Type 1 RT 100% RT 100% 100%

• Category E 1.0 Type 1 RT 100% RT 100% 100%

Other

Requirements

Cone Type Extent Type Extent PMI

• Category A 1.0 Type 1 RT 100% RT 100% 100%

• Category B 1.0 Type 1 RT 100% RT 100% 100%

• Category C 1.0 Type 1 RT 100% RT 100% 100%

• Category D 1.0 Type 1 RT 100% RT 100% 100%

• Category E 1.0 Type 1 RT 100% RT 100% 100%

Other

Requirements

Other Type Extent Type Extent PMI

• Skirt 1.0 Type 1 RT 100% RT 100% 100%

• 1.0 Type 1 RT 100% RT 100% 100%

• 1.0 Type 1 RT 100% RT 100% 100%

No. Date Description By Check Appv

DEP 31.22.00.98-Gen., January 2009

PRESSURE VESSELS – ASME –

PAGE 7 OF 8

USER’S DESIGN SPECIFICATION

REFERENCE SPECIFICATIONS

THE FOLLOWING ADDITIONAL SPECIFICATIONS ARE INCLUDED

(Add others as applicable)

Check if Check if

Spec No. Title Spec No. Title

Applicable Applicable

Annex III General Service

Annex IV Engineered

Annex VI Storage Spheres

Annex IX Wet H2S Service

Annex I Cr-Mo Steels

S10.010 Vortex Breaker

S10.070 Davit for Blind Flange

S10.114 Nameplate and bracket

S20.001 Lifting Trunnion

S20.003 Support Skirts

S20.004 Anchor Bolt Ring or Lugs

S22.001 Saddle Supports – Small

S22.002 Saddle Supports – Large

S22.003 Sliding Plate

No. Date Description By Check Appv

DEP 31.22.00.98-Gen., January 2009

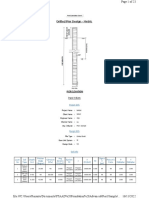

PRESSURE VESSELS – ASME –

PAGE 8 OF 8

USER’S DESIGN SPECIFICATION

SKETCH

OUTLINES OF EQUIPMENT AND DIMENSIONS THAT MANUFACTURER SHALL MEET

Attach additional sheets as necessary.

CERTIFICATE OF COMPLIANCE

I (We), the undersigned, being experienced and competent in the applicable field of design related to

pressure vessel requirements relative to this User’s Design Specification, certify that to the best of my (our)

knowledge and belief it is correct and complete with respect to the Design and Service Conditions given and

provides a complete basis for construction in accordance with Part 2 of ASME Section VIII, Division 2, and

all applicable requirements therein included in the Edition with Addenda and the listed Code

Cases.

; ; ; ; ; ; ; ; ; ; ; ; ;

This certification is made on behalf of the organization that will operate this (these) vessel(s):

(Company Name)

The statements made in this form are accurate and represent all details of design per the owner/operator or the designated agent.

Certified by: Certified by: Certified by:

Title and areas of responsibility: Title and areas of responsibility: Title and areas of responsibility:

Professional Engineer's Seal Professional Engineer's Seal Professional Engineer's Seal

or engineer's signature: or engineer's signature: or engineer's signature:

Date: Date: Date:

No. Date Description By Check Appv

DEP 31.22.00.98-Gen., January 2009

You might also like

- Pressuremeter Testing: Methods and InterpretationFrom EverandPressuremeter Testing: Methods and InterpretationRating: 5 out of 5 stars5/5 (2)

- HAJ-AR-UDR-001 Rev.0 - 1.08.2023Document4 pagesHAJ-AR-UDR-001 Rev.0 - 1.08.2023divakar.panigrahiNo ratings yet

- U Stamp - KK Form - SampleDocument5 pagesU Stamp - KK Form - SampleshazanNo ratings yet

- FORM U-DR-2 USER REQUIREMENTSDocument2 pagesFORM U-DR-2 USER REQUIREMENTSCarlos Anibal OrtizNo ratings yet

- Udr 1Document2 pagesUdr 1shazanNo ratings yet

- Form U-1 Design Requirements for Pressure VesselDocument5 pagesForm U-1 Design Requirements for Pressure VesselshazanNo ratings yet

- Bpvc Viii 1 u Dr 1Document2 pagesBpvc Viii 1 u Dr 1gahaind0518No ratings yet

- Form U-Dr-1 User, S Design Requirement For Single Chamber Pressure VesselsDocument4 pagesForm U-Dr-1 User, S Design Requirement For Single Chamber Pressure VesselsAmit SharmaNo ratings yet

- Company UDR Format - REV.0Document3 pagesCompany UDR Format - REV.0Shaheen Andre ChikkuNo ratings yet

- Form U-Dr-1 User'S Design Requirements For Single Chamber Pressure VesselsDocument2 pagesForm U-Dr-1 User'S Design Requirements For Single Chamber Pressure VesselsAmit Sharma100% (1)

- Mechanical Data SheetDocument7 pagesMechanical Data SheetktejankarNo ratings yet

- Operating Conditions:: Form Kk3-U-DrDocument2 pagesOperating Conditions:: Form Kk3-U-DrshazanNo ratings yet

- Form U-Dr-1 User'S Design Requirements For Single Chamber Pressure VesselsDocument3 pagesForm U-Dr-1 User'S Design Requirements For Single Chamber Pressure VesselsssNo ratings yet

- Visual Inspection Report SummaryDocument4 pagesVisual Inspection Report SummaryIntan AyuNo ratings yet

- BPVC - Viii-1 - U-Dr - GASDocument2 pagesBPVC - Viii-1 - U-Dr - GASRodolfoNo ratings yet

- Specification For Adsorbent Bed Accumulator Item No: V-05202Document3 pagesSpecification For Adsorbent Bed Accumulator Item No: V-05202amlanfacebookNo ratings yet

- Tank Manual CalculationsDocument19 pagesTank Manual Calculationsbhavanamadhuri itapuNo ratings yet

- Air Eliminator Datasheet PDFDocument2 pagesAir Eliminator Datasheet PDFbecpavanNo ratings yet

- Air Eliminator Datasheet PDFDocument2 pagesAir Eliminator Datasheet PDFbecpavanNo ratings yet

- Ngurv Ter - : de en Ow06/002.0Document2 pagesNgurv Ter - : de en Ow06/002.0tranhonghakd5533No ratings yet

- Foundation 1 Design ReportDocument7 pagesFoundation 1 Design ReportEdwinBastidasNo ratings yet

- SESMACOL BPVC - Viii-1 - U-Dr-1 ASME Rev 0Document2 pagesSESMACOL BPVC - Viii-1 - U-Dr-1 ASME Rev 0Jairo Andres Romero QuirogaNo ratings yet

- Air Eliminator DatasheetDocument2 pagesAir Eliminator DatasheetbecpavanNo ratings yet

- Foundation 1 Design Report (8 Metros)Document7 pagesFoundation 1 Design Report (8 Metros)EdwinBastidasNo ratings yet

- Pipe Stress AnalysisDocument19 pagesPipe Stress AnalysisJosuaNo ratings yet

- Scope of Work and Repair Process for Thumbler PartDocument7 pagesScope of Work and Repair Process for Thumbler PartEngineering ProductionNo ratings yet

- Design Notes and AssumptionsDocument19 pagesDesign Notes and AssumptionsDarshan PanchalNo ratings yet

- Air Vessel (Final Sent To AI) - 1Document38 pagesAir Vessel (Final Sent To AI) - 1hgagselim2012No ratings yet

- CA LPG 5b STD 0 RepairedDocument27 pagesCA LPG 5b STD 0 RepairedMadiaw NajaNo ratings yet

- Anexo 4 - Dimensionamiento PSV-7004 1Document2 pagesAnexo 4 - Dimensionamiento PSV-7004 1JairoVidalNo ratings yet

- API Monogram Gate Valve Design CalculationsDocument20 pagesAPI Monogram Gate Valve Design CalculationsMahendra PatilNo ratings yet

- PDE-EQS-3100-EC-00006 - 00 Technical Specification of Safety VesselDocument9 pagesPDE-EQS-3100-EC-00006 - 00 Technical Specification of Safety Vesselhgag selimNo ratings yet

- Foundation 1 Design ReportDocument7 pagesFoundation 1 Design ReportEdwinBastidasNo ratings yet

- SSGC'S Design Requirements For 60 MT LPG Tank As Per Asme Section Viii Div. 1 Edition 2013Document2 pagesSSGC'S Design Requirements For 60 MT LPG Tank As Per Asme Section Viii Div. 1 Edition 2013MuhammadShabbirNo ratings yet

- Foundation 1 Design ReportDocument7 pagesFoundation 1 Design Report“Lava Gamers” ahmet akmanNo ratings yet

- MD PV ASME v0.1Document34 pagesMD PV ASME v0.1nileshNo ratings yet

- M 6.340 LPDC Functional Validation of Equipment at SupplierDocument69 pagesM 6.340 LPDC Functional Validation of Equipment at SupplierJesus ValdezNo ratings yet

- AZ Safety Pressure Valve (Design)Document2 pagesAZ Safety Pressure Valve (Design)ZangNo ratings yet

- AssistantDocument2 pagesAssistantnana arya sumardjaNo ratings yet

- AutoPIPE Nozzle Report for sss.Noz ModelDocument8 pagesAutoPIPE Nozzle Report for sss.Noz ModelRrrrrrrNo ratings yet

- Machining Cyl Surface 1 Sisi & Skim 1 Sisi Machining ID Groove & ID Contact BushingDocument3 pagesMachining Cyl Surface 1 Sisi & Skim 1 Sisi Machining ID Groove & ID Contact BushingEngineering ProductionNo ratings yet

- Calculation Cover SheetDocument8 pagesCalculation Cover SheetYogesh PangareNo ratings yet

- Ab 028 MDR For Indirect Fired Heat CoilsDocument1 pageAb 028 MDR For Indirect Fired Heat CoilsCubzlookNo ratings yet

- Foundation 1 Design ReportDocument6 pagesFoundation 1 Design ReportDinesh RajaNo ratings yet

- Line List: Project: Date Rev. No. Serial No. Doc. Type Discipline Phase Unit Plan/Project/SubDocument1 pageLine List: Project: Date Rev. No. Serial No. Doc. Type Discipline Phase Unit Plan/Project/SubAli AsadiNo ratings yet

- Approval Drawing Control Valve For Fire Line - KORVAL DATA SHEETDocument5 pagesApproval Drawing Control Valve For Fire Line - KORVAL DATA SHEETMusholla BaiturrahimNo ratings yet

- Calculation Cover Sheet: ClientDocument9 pagesCalculation Cover Sheet: Clientanamaria ursuNo ratings yet

- API-650 Water Storage Tank TK-2Document27 pagesAPI-650 Water Storage Tank TK-2Athira ZahraNo ratings yet

- Saudi Pipe System Co. Mold Final Inspection ReportDocument8 pagesSaudi Pipe System Co. Mold Final Inspection ReportNADEEM AHMEDNo ratings yet

- 6.FM-JEC - Chilled Water Fan Coil Unit (F)Document4 pages6.FM-JEC - Chilled Water Fan Coil Unit (F)Thi Ha NaingNo ratings yet

- DatasheetDocument2 pagesDatasheetnirmalNo ratings yet

- QAP N2 Generator & N2 VesselDocument2 pagesQAP N2 Generator & N2 VesselVijay - Spantech EngineersNo ratings yet

- Mechanical Design Report - EX-3340 - R00Document75 pagesMechanical Design Report - EX-3340 - R00Aditya JainNo ratings yet

- 019-02 - 50 KL Mee Feed Storage Tank 21ST-017 & 21ST-018Document26 pages019-02 - 50 KL Mee Feed Storage Tank 21ST-017 & 21ST-018Bhaumik BhuvaNo ratings yet

- r2b p2 203 03 H HD 51062 - Rev.b - Data Sheet SRV PSV 61152 A B 1st Stage DischargeDocument17 pagesr2b p2 203 03 H HD 51062 - Rev.b - Data Sheet SRV PSV 61152 A B 1st Stage Dischargedavid perezNo ratings yet

- STAAD20 Foundation 20 AdvanceDocument23 pagesSTAAD20 Foundation 20 AdvanceKenneth SalvadorNo ratings yet

- Column Data Sheet Distillation Column (T-2010)Document12 pagesColumn Data Sheet Distillation Column (T-2010)John Patrick Sanay NunezNo ratings yet

- Design Cal - Feed PreheaterDocument61 pagesDesign Cal - Feed PreheaterIrshad HussainNo ratings yet

- Flow Measurement: By Square-Edged Orifice Plate Using Corner TappingsFrom EverandFlow Measurement: By Square-Edged Orifice Plate Using Corner TappingsRating: 5 out of 5 stars5/5 (1)

- Digital Citizenship RubricDocument1 pageDigital Citizenship Rubricapi-300964436No ratings yet

- HTTP API - SMS Help GuideDocument8 pagesHTTP API - SMS Help Guideaksh11inNo ratings yet

- ASTM C186 - 15a Standard Test Method For Heat of Hydration of Hydraulic CementDocument3 pagesASTM C186 - 15a Standard Test Method For Heat of Hydration of Hydraulic CementKalindaMadusankaDasanayakaNo ratings yet

- Receiving of Packaging Material SOPDocument4 pagesReceiving of Packaging Material SOPanoushia alviNo ratings yet

- Oracle® Database: Administrator's Reference 11g Release 1 (11.1) For Linux and UNIX-Based Operating Sys-TemsDocument174 pagesOracle® Database: Administrator's Reference 11g Release 1 (11.1) For Linux and UNIX-Based Operating Sys-TemsPrakash MohantyNo ratings yet

- Trigonometry Ted Sundstrom and Steven SchlickerDocument430 pagesTrigonometry Ted Sundstrom and Steven SchlickerhibiskusologjiaNo ratings yet

- SQ3R Is A Reading Strategy Formed From Its LettersDocument9 pagesSQ3R Is A Reading Strategy Formed From Its Letterschatura1989No ratings yet

- Lesson Exemplar On Contextualizing Science Lesson Across The Curriculum in Culture-Based Teaching Lubang Elementary School Science 6Document3 pagesLesson Exemplar On Contextualizing Science Lesson Across The Curriculum in Culture-Based Teaching Lubang Elementary School Science 6Leslie SolayaoNo ratings yet

- Lesson Plan-Brainstorming Session For The Group Occupational Report-Jmeck Wfed495c-2 V4a7Document2 pagesLesson Plan-Brainstorming Session For The Group Occupational Report-Jmeck Wfed495c-2 V4a7api-312884329No ratings yet

- MATHMATICAL Physics Book Career EndaevourDocument293 pagesMATHMATICAL Physics Book Career EndaevourSwashy Yadav100% (1)

- Newsletter April.Document4 pagesNewsletter April.J_Hevicon4246No ratings yet

- District Plan of ActivitiesDocument8 pagesDistrict Plan of ActivitiesBrian Jessen DignosNo ratings yet

- Soal Biokim IDocument9 pagesSoal Biokim INuraMalahayatiNo ratings yet

- Sap CRM Web - UiDocument7 pagesSap CRM Web - UiNaresh BitlaNo ratings yet

- The Cultural Diversity Phenomenon in Organisations and Different Approaches For Effective Cultural Diversity Management - A Literary Review PDFDocument21 pagesThe Cultural Diversity Phenomenon in Organisations and Different Approaches For Effective Cultural Diversity Management - A Literary Review PDFeugene123No ratings yet

- Lighthouse Case Study Solution GuideDocument17 pagesLighthouse Case Study Solution Guidescon driumNo ratings yet

- Wave Hydro Dynamics Prof. V. Sundar Department of Ocean Engineering Indian Institute of Technology, MadrasDocument32 pagesWave Hydro Dynamics Prof. V. Sundar Department of Ocean Engineering Indian Institute of Technology, MadrasMuralidhar YarakalaNo ratings yet

- Learning by LivingDocument5 pagesLearning by LivingPaul SchumannNo ratings yet

- Cloud Computing Vs Traditional ITDocument20 pagesCloud Computing Vs Traditional ITgarata_java100% (1)

- Components of GMP - Pharma UptodayDocument3 pagesComponents of GMP - Pharma UptodaySathish VemulaNo ratings yet

- Week3 Communication Skill Part 1 Student GuideDocument10 pagesWeek3 Communication Skill Part 1 Student GuideZoe FormosoNo ratings yet

- Project SELF Work Plan and BudgetDocument3 pagesProject SELF Work Plan and BudgetCharede BantilanNo ratings yet

- Guia de Manejo Sdra 2019Document27 pagesGuia de Manejo Sdra 2019Jorge VidalNo ratings yet

- Constructed Wetland Design Guidelines for DevelopersDocument32 pagesConstructed Wetland Design Guidelines for DevelopersBere QuintosNo ratings yet

- Wjec A Level Maths SpecificationDocument50 pagesWjec A Level Maths SpecificationastargroupNo ratings yet

- SINGLE OPTION CORRECT ACCELERATIONDocument5 pagesSINGLE OPTION CORRECT ACCELERATIONShiva Ram Prasad PulagamNo ratings yet

- Controversial Aquatic HarvestingDocument4 pagesControversial Aquatic HarvestingValentina RuidiasNo ratings yet

- IEEE TRANSACTIONS ON COMMUNICATIONS, VOL. COM-34, NO. 5 , MAY 1986A BPSK/QPSK Timing-Error DetectorDocument7 pagesIEEE TRANSACTIONS ON COMMUNICATIONS, VOL. COM-34, NO. 5 , MAY 1986A BPSK/QPSK Timing-Error DetectorFahmi MuradNo ratings yet

- Fisica Básica 3er Año SantillanaDocument66 pagesFisica Básica 3er Año SantillanaElifrnak91% (22)

- Variable frequency drives for electric submersible pumpsDocument34 pagesVariable frequency drives for electric submersible pumpshermit44535No ratings yet