Professional Documents

Culture Documents

Risk Assessment-1 PDF

Risk Assessment-1 PDF

Uploaded by

DayanandaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Risk Assessment-1 PDF

Risk Assessment-1 PDF

Uploaded by

DayanandaCopyright:

Available Formats

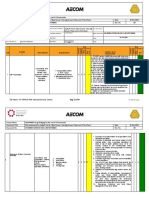

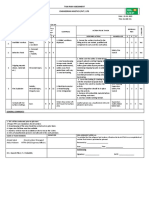

CFA SITE RISK ASSESSMENT and SPILL RESPONSE

Site Principal

Business Unit Rock & Alluvium

Address

Angle Lane, Stratford. E15 1AG

Contractor (P/C)

McAleer & Rush Con. No: 13_0375

Revision 33

HSE Assessor Sally Lloyd-Raines Operation CFA PILING Date: 07/11/13 Ref. No:

Issued 04/10/12

Notes: If any of the following situations apply, append the relevant Risk Assessment.

Adjacent to Rail: Yes Contaminated Ground: No

HAZARDS PERSONS AFFECTED RISK CONTROL MEASURES RISK

L S R (List control measures that are provided and those required) L S R

Site Specific Hazards: (additional site specific hazards identified below, if any)

Site Specific Hazards identified

upon mobilisation.

Please see next page

Ref :HS&E-FRM-H03-03 Issue: 06 Rev No.00 Page 1 of 17

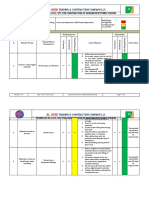

CFA SITE RISK ASSESSMENT and SPILL RESPONSE

Section

HAZARDS PERSONS AFFECTED RISK CONTROL MEASURES RISK

L S R (List control measures that are provided and those required) L S R

P/C to erect suitable pedestrian barriers to reduce the interaction between

vehicles / plant and any site operatives and/or the general public. Employ-

ees to conform to site segregation rules and not block walkways.

R&A operatives to Supervise and direct the piling rig and piling equipment

Piling Crew, visitors delivery vehicles across public footpaths and access routes.

and other operatives on 3 4 H P/C to provide security at site entrance to prevent unauthorised persons 1 4 L

1 Site Access / Egress

site gaining access to the site and supervise delivery vehicles entering and

leaving the site.

Security Container to be positioned away from traffic routes.

HS&E Standard H01 is to be complied with in full.

Piling Crew, visitors Equipment that is not required for current piling operations is to be stored

2 Congested Working and other operatives on 2 4 M outside of the piling area. Where spoil is to be loaded away, this is to be 1 4 L

site moved away from the piling rig before loading vehicles.

Foreman who uses mobile phone are only to do so in a place of safety and

when safe to do so. Mobile phones must not be used when engaged in

Use of Mobile phones or other Piling Crew, visitors

activities where distraction could pose a risk, e.g. rig manoeuvring.

3 mobile devices causing a and other operatives on 2 2 M 1 2 L

distraction from site hazards site

When using a Mobile phone, all operatives should move to a place of

safety, such as a designated area.

R&A operatives to stack piling equipment & materials in such a way as to

not become unstable when moved / used.

P/C to provide a secure site with lockable gate and provide, erect & main-

Piling Crew, visitors tain boundary fencing to prevent unauthorised access at all times.

4 Storage and Security and other operatives on 3 3 M P/C to provide site security to guard against loss/theft of property and 2 3 L

site machinery.

HS&E Standard S01 is to be complied with in full.

Ref :HS&E-FRM-H03-03 Issue: 06 Rev No.00 Page 2 of 17

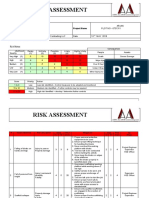

CFA SITE RISK ASSESSMENT and SPILL RESPONSE

Section

HAZARDS PERSONS AFFECTED RISK CONTROL MEASURES RISK

L S R (List control measures that are provided and those required) L S R

P/C to review service drawings

P/C to scan for, locate, expose, divert, protect as necessary all existing

underground services prior to the start of any piling operations and issue

Piling crew, visitors and

Striking services, electric "Permit to Dig".

other operatives on site

5 cables, gas mains, telecoms, 2 4 H 1 4 L

Nearby residents if gas

water supply, drainage. R&A to notify P/C of any pressure loss / anomalies whilst drilling / injecting

main

piles.

All works to cease if electric cable strike suspected - Rig operator to stay in

cab or Jump well clear,

Site and all walkways to be kept clear and tidy, with particular attention to

Piling Crew, visitors designated pedestrian routes. Materials to be stacked and stored properly.

6 Slips, trips and falls and other operatives on 2 3 L 1 3 L

site P/C to provide background safety lighting in periods of darkness in areas

used by R&A, including walkways and access routes

P/C to provide, install and maintain fencing and/or guard rails to prevent

Piling Crew, visitors

Drowning when working near R&A operatives from falling in to adjacent water. P/C to provide life jackets

7 and other operatives on 2 4 H 1 4 L

deep water and rescue plan.

site

HS&E Standard W04 is to be complied with in full.

All portable electrical equipment to be a maximum voltage of 110volts dc.

All portable electrical equipment to be checked before it is used and thor-

oughly inspected every 3 months by a competent person.

8 Electrocution

Piling Crew 3 4 H PAT testing is required see MS/047 for colour coding test schedule. 1 4 L

Damaged / Faulty equipment to be removed from use.

HS&E Standard E01 is to be complied with in full.

Ref :HS&E-FRM-H03-03 Issue: 06 Rev No.00 Page 3 of 17

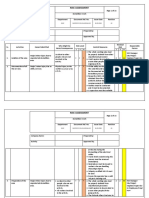

CFA SITE RISK ASSESSMENT and SPILL RESPONSE

Section

HAZARDS PERSONS AFFECTED RISK CONTROL MEASURES RISK

L S R (List control measures that are provided and those required) L S R

Lift Plan to be followed at all times (PMP Section 3)

Only Fully Trained Banksman I Slingers are to control lifting operations on

site and ensure that the loads are properly slung prior to any lift commenc-

ing.

Banksmen to ensure that the lift path I route is clear of other site operatives

and overhead services in particular H.V Cables and overhead pipe racks.

Plant Manager to ensure that all rigs receive their 12-monthly thorough

Lifting operations.

examination and that any defects are corrected

Falling plant and materials, Piling Crew, visitors Foreman to ensure rig is inspected after rigging and LOLER register

Collisions with plant, persons and other operatives on 3 4 H completed. 1 4 L

9

and Overhead services site

Failure of lifting appliance R&A foreman is to ensure that all Lifting Accessories have been given an

examination every 6 months and certificates available.

Banksman I Slinger to assess all loads before they are lifted to ensure that

the Safe W orking Load of the lifting equipment is not exceeded at any point

during the lift

Damaged slings to be cut-up and not usedIdiscarded

HS&E Standard L02 is to be complied with in full.

Foreman to check that bucket and excavator are a "matching pair" (many

systems are in use). All excavators' operators must have received training

on the type of quick hitch being used.

Use of attended excavator

Piling Crew, visitors

Accidental unlatching of bucket Driver must be competent to operate system supplied, by demonstration if

10 and other operatives on 2 4 H 1 4 L

using "quick hitch " attachment required.

site

mechanism

Where a locking pin is specified in the system, it must be in fitted in the

correct place by the excavator Operator (R&A site team to check).

HS&E Standard P01 is to be complied with in full.

Ref :HS&E-FRM-H03-03 Issue: 06 Rev No.00 Page 4 of 17

CFA SITE RISK ASSESSMENT and SPILL RESPONSE

Section

HAZARDS PERSONS AFFECTED RISK CONTROL MEASURES RISK

L S R (List control measures that are provided and those required) L S R

P/C to erect suitable signage and barriers to prevent any unauthorised site

operatives gaining access into the piling area.

R&A to cease all piling operations if any unauthorised persons enter the

piling area

Foreman to check all plant, machinery and equipment to ensure that guards

are secured in place to prevent any physical contact with moving parts.

P/C or R&A to design platform, P/C to Install & Maintain Piling Platforms to

Plant operation

Piling Crew, visitors safely support bearing pressure of piling rig in it's Working Mode.

Contact between plant and

11 and other operatives on 4 4 H 1 4 L

persons such as to cause

site The Working Platform Certificate provided by Rock & Alluvium is to be

injury.

signed by the Principal Contractor and/or the Planning Supervisor and

returned prior to Piling Operations commencing; confirming the design is in

order and the platform construction is in accordance with the design.

All excavations to remove existing foundations / underground obstructions

should be backfilled with suitable material and compacted in accordance

with the design.

HS&E Standard P01 is to be complied with in full.

Only persons holding a Competence Certificate to use saw or change

wheel.

Additional PPE. Goggles to BS EN 166 B must be worn. Suitable gloves

Use of Abrasive Wheel Cutter

Piling Crew, visitors and ear protection to be worn.

(Stihl Saw).

12 and other operatives on 2 2 M 1 2 L

site Use of this type of tool is to be limited to 1 hour per day.

Cutting Rebar only

Tools must not to be used near combustible materials. If any fuel spillage

on clothing, tool must not to be used.

HS&E Standard P01 is to be complied with in full.

Ref :HS&E-FRM-H03-03 Issue: 06 Rev No.00 Page 5 of 17

CFA SITE RISK ASSESSMENT and SPILL RESPONSE

Section

HAZARDS PERSONS AFFECTED RISK CONTROL MEASURES RISK

L S R (List control measures that are provided and those required) L S R

Working at Height

Use of Ladder/Steps (Based on

HSE Guidance)

Folding Ladder is authorised for Ladders to be Industrial Class 1 EN131 (Blue Label).

following three uses: Ladder to be inspected before use for damage

Inspection and changing auger Ladder to be adequately footed, tied or stacked.

cleaning brushes. Piling Crew, visitors Ground to be firm and consolidated

13 Attach lifting chains to corners and other operatives on 4 4 H One hand to be free at all times when climbing. Three points of contact to 2 4 M

of security container. site be maintained at all times.

Fix locking pins to Auger Top three rungs must not to be stepped on

connections.

Other Uses of Ladder/Steps to HS&E Standard PW03 is to be complied with in full.

have Foreman's Approval and

controls in place.

Movement of Rig or mast while Piling Crew, visitors Before using ladder against rig, obtain clearance from rig driver so he is

14 ladder is propped against it. and other operatives on 2 4 M aware of what is happening. No drilling or extraction work is permitted while 1 4 L

site auger cleaning brushes are being serviced.

Lifting chains to be prefixed to Containers.

Piling Equipment, Rebar or Cages to be delivered in vehicles with side rails

and pre-slung with slings easily accessible from ground level.

Piling Crew, visitors

Loading and off-loading Vehi- R&A to use unloading bay when available on site

and other operatives on 2 2 M 1 2 L

15 cles

site

Where possible, items to be slung/un-slung from ground level. W here

vehicle's flatbed is to be accessed, ladder to be used. After slinging load,

operative to dismount the vehicle's bed or stand at the headboard. Fall

protection must be used.

Ref :HS&E-FRM-H03-03 Issue: 06 Rev No.00 Page 6 of 17

CFA SITE RISK ASSESSMENT and SPILL RESPONSE

Section

HAZARDS PERSONS AFFECTED RISK CONTROL MEASURES RISK

L S R (List control measures that are provided and those required) L S R

Manual Handling is to be reduced to a minimum by the use of the attendant

excavator provided by PIC and R&A Hiab delivery vehicles or other me-

chanical means.

Should the above not be possible;-

Heavy loads are to be split into loads that the operative is comfortable with

lifting.

If this is still not possible;-

The loads are to be lifted by multiple operatives ensuring that all operatives

Manual handling muscular- are aware what is required of them and that the weight of the item does not

skeletal injuries. exceed the ability of the person lifting.

Piling Crew, visitors

and other operatives on 4 3 H 3 3 M

16 Note this applies to levering, If there are any manual handling tasks, ensure sufficient numbers of

site

pulling lifting and other manual operatives are used, to spread the load.

tasks.

Operatives to "walk the route" before they carry any loads to ensure that

there are no trip hazards I uneven surfaces I width restrictions I vehicle

crossing points that could impede the Manual Handling Operations Muddy

and slippery areas are to be avoided where possible.

Operatives to wear protective equipment provided by R&A, this includes

gloves suitable for the task being undertaken, typically to EN388: 3121.

HS&E Standard M01 is to be complied with in full.

Ref :HS&E-FRM-H03-03 Issue: 06 Rev No.00 Page 7 of 17

CFA SITE RISK ASSESSMENT and SPILL RESPONSE

Section

HAZARDS PERSONS AFFECTED RISK CONTROL MEASURES RISK

L S R (List control measures that are provided and those required) L S R

Wet Concrete can cause cement burns to the skin

Control of Substances

Hazardous to Health Operatives to avoid direct contact. PPE listed on COSHH is to be worn.

(COSHH), particularly Ready- Should any operative come into contact with wet concrete - they should

mixed Concrete. thoroughly wash skin and clothing immediately.

Piling Crew, visitors

17 and other operatives on 4 2 H 2 2 L

[Full COSHH Assessments Should there be any eye contact with dust I concrete - the affected eye

site

available as Separate Docu- should be thoroughly irrigated with cold clean water preferably a proprietary

ment.] eyewash solution.

Flammable substances (mainly fuels, oils & greases) to be securely stored,

Fire risk particularly during out of hours.

HS&E Standard H01 is to be complied with in full

Piling Crew, visitors R&A operatives are provided with hearing protection and have been

Noise

and other operatives on instructed they are to be worn when working near piling rig, pump or

[Noise Contours are available

18 site and persons 4 3 H agitator. 2 3 L

for all Piling Plant]

working nearby during Piling rig I equipment is to be kept in good working order.

working day HS&E Standard N01 is to be complied with in full

Injury from Soil falling from

auger flights

Piling Crew, visitors Mechanical Auger cleaner to be used

[Refer to FPS/HSE Guidance

19 and other operatives on 4 4 H R&A operatives are to ensure that there is no spoil I concrete I debris taken 1 4 L

on the Guarding and Clean-

site up on the flight.

ing of Augers]

When piling operations are in close proximity to the site boundary, the

Principal Contractor is responsible for providing any exclusionIprotection

Piling Crew, visitors

Piling Work - Protection of measures necessary to protect the general public. PIC to provide, erect &

and other operatives on

adjacent premises and maintain polythene sheeting I debris netting to perimeter walls I fencing to

20 site 3 2 H 2 2 L

personnel when working near prevent Mud I Concrete I Slurry splashing members of the public; strictly in

MEMBERS OF

site boundary accordance with FPS I HSE Guidance on PUW ER (Regulations 11 & 12),

PUBLIC

section 4.3 CFA Piling :Exception

HS&E Standard S01 is to be complied with in full.

Ref :HS&E-FRM-H03-03 Issue: 06 Rev No.00 Page 8 of 17

CFA SITE RISK ASSESSMENT and SPILL RESPONSE

Section

HAZARDS PERSONS AFFECTED RISK CONTROL MEASURES RISK

L S R (List control measures that are provided and those required) L S R

21 Creation of open bore caused Piling Crew, visitors 2 4 H Where a redundant bore is used to park an auger string that is not being 2 4 L

by use of additional bore to and other operatives on used, any empty bores must be covered whilst on site and backfilled before

park auger string where two site leaving site. The area must be thoroughly checked after the backfilling has

diameters being used been carried out and the area must be left at a similar level to the piling

platform to ensure that the empty bore has been suitably filled and not just

masked by spoil

22 Bursting of concrete hoses and Piling Crew, visitors 2 3 M Hoses to be inspected by pump man daily at start of shift. Damaged 1 3 L

or Hose joints causing damage and other operatives on sections are to be replaced.

and injury during concrete site All concrete hoses fitted to the mast of the piling rig must have whip checks

pumping fitted at all times. Joints to be secured by R Clips or Split Pins.

Rig "drop hoses" to be fitted with sleeved hoses for additional protection.

Newer sections of hoses are to be used adjacent to the rig and pump.

Hose runs to be planned to minimise trafficking over hoses. Hoses to be

buried under road.

23 Clearing concrete pumping Piling Crew, visitors 2 3 M All blowing out operations are to be under direct control of a trained Fore- 1 3 L

lines and auger at the end of a and other operatives on man, Foreman to remain at piling rig during procedure, banksman to control

shift by compressed air. site the compressor.

Rig lines to be blown out away from the perimeter fencing at all times.

Foreman to monitor concrete lines as the concrete moves through the lines,

when the ball passes the back of the piling rig the air flow should be turned

of and surplus air released through the exit valve.

All persons not involved in this operation to be kept at a safe distance.

Whip-checks to be used at all air hose joints including at both compressor

and the blow-out gun.

Operator to check adaptors are clear of debris before fitting to hose. Refer

to Section 5 of PMP (HS&E-RA-H03-10 Blowing-Out of CFA Piling Rig.)

Ref :HS&E-FRM-H03-03 Issue: 06 Rev No.00 Page 9 of 17

CFA SITE RISK ASSESSMENT and SPILL RESPONSE

Section

HAZARDS PERSONS AFFECTED RISK CONTROL MEASURES RISK

L S R (List control measures that are provided and those required) L S R

24 Dealing with blockages in the Piling Crew, visitors 3 3 H Where the sponge ball will exit other than down the auger, a ball catcher 2 3 M

concrete pumping lines and other operatives on must be fitted to the free end of the hose run.

site To prevent the hose end "whipping", it must be restrained by fixing a strop

to the pipe and securing it e.g. the excavator lifting point or the rig.

Holding the hose down with an excavator bucket is not effective and should

not be used as the only means of restraint, although it can be used in

addition to the strop.

Before releasing a joint, pressure should be released where possible by

back-pumping. Eye protection to BS EN 166 B goggles or a full face

protection must be worn to protect eyes from injury. Helmet visors are not

adequate for this operation.

25 Falling from rig mast Person climbing 2 4 H Rigs are only to be climbed if mast has a fixed ladder. Full body harness 1 4 L

with double lanyard and hook connected to a fall arrestor system must be

used for this operation.

[In case of operative suspended from fall arrestor, Fire Brigade to be called

immediately by dialling 999 and Rescue commenced as detailed in Method

Statement MS-013]

If no ladder fixed (CM-70 and R-312) MEW P to be used. Operator to have

IPAF or CPCS Card and wear short restraint lanyard

26 Fall from tracks. Person climbing onto/ 2 3 M Do not climb tracks unnecessarily. 1 3 L

off tracks When both climbing and descending, use proper step.

Ref :HS&E-FRM-H03-03 Issue: 06 Rev No.00 Page 10 of 17

CFA SITE RISK ASSESSMENT and SPILL RESPONSE

Section

HAZARDS PERSONS AFFECTED RISK CONTROL MEASURES RISK

L S R (List control measures that are provided and those required) L S R

27 Steelfixing of rebar cages for Piling Crew, visitors 3 3 H Steel-fixing Area to be demarked off and segregated from trafficked areas. 2 3 L

piling and other operatives on

site Heavy cages to be moved off stands or to piling area by crane or excavator.

Steelfixers

Correct lifting ring or secured helical to be used to hoist the cages into the

vertical position for insertion into the bore.

Only person qualified with an IPAF or CPCS certificate are to use MEW P.

28 Use of Mobile Elevated Work Piling Crew, visitors 3 4 H Full harness with short restrain lanyard to be used and attached to correct 2 4 L

Platform (MEWP), Risk of and other operatives on attachment point.

overturning site Only stand on the platform floor, not on the rails.

MEW P operator Check for presence of ramps, trenches, slopes, manhole covers, ground

obstructions, overhead cables, building projections, vehicles etc.

Before travelling MEW P ensure platform is in recommended travel position.

Only travel with an appointed banks-man and at correct speed

Before raising the platform, check that the machine is level and located on a

firm surface

Do not overload the platform or use it for lifting duties.

HS&E Standard P01 is to be complied with in full.

'LIVE RISKS' TO BE RECORDED B ELOW

High Risk Operation NO Temporary W orks NO The above control measures have been implemented

If Yes - refer to HS&E-STD-T01

Workplace Manager …………………………… Date ……………………

Ref :HS&E-FRM-H03-03 Issue: 06 Rev No.00 Page 11 of 17

CFA SITE RISK ASSESSMENT and SPILL RESPONSE

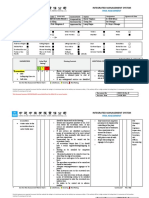

ENVIRONMENTAL RISK ASSESSMENT

Section

HAZARDS ENVIRONMENTAL IMPACT RISK CONTROL MEASURES RISK

L S R L S R

E1 Environmental Noise 2 2 L Piling Rig and ancillary equipment is to be kept in good me-

chanical order. Where damage or wear to silencing system

occurs, maintenance to receive priority.

E2 Ecological damage Damage to protected trees 2 2 L Trees needing protection to be fenced off by P/C with relevant

signeage.

E3 Water Pollution Contamination of watercourse 3 3 M P/C to install protective bunding to prevent water/slurry from

from silt laden groundwater entering watercourse.

generated by piling process

E4 Air pollution from Degeneration of air quality 2 2 L Plant to be kept in good mechanical order, machines to be 1 1 L

exhaust gasses switched off when not in use; avoid long idle times.

E5 Vandalism of hydrocar- Ground and water pollution 3 3 M All lubricants to be locked in container overnight and Weekend. 1 1 L

bons storage Bunded Diesel bowser to be lockable, including lockable hose

storage. To be locked outside site hours and when not in use

E6 Spillage of fuels and oils Ground and water pollution 3 3 M Fuel only to be stored in lockable bunded bowser or 205 litre 2 2 L

during recharging (45 gallon) drums on spillage trays. Refuelling to be via siphon

delivery hose from rig; engine to be switch off during refuelling.

Oil and lubricants to be filled by funnel.

Spill Kit to be available in case of spillage.

E7 Inadequate waste Visual Intrusion of litter 3 1 L R&A foreman to ensure that all general rubbish is placed in the 1 1 L

Management skips provided by P/C.

P/C to set up, Site W aste Management Plan, and brief to R&A

personnel

E8 Washing out ready- Ground and water contamina- 3 3 M If the subsoil is clay (impermeable) or there is an impermeable 2 2 L

mixed concrete and tion. layer of geo-textile beneath the piling platform, the wash-water

clearing out pump and may be discharged directly onto the hardcore platform.

concrete delivery hoses Where the ground is permeable and/or near to a water course,

at end of shift the P/C is to construct a lined pit/skip into which ready-mixed

concrete trucks can wash out.

An area of approximately 5m x 8m to have heavy gauge

visqueen under 300mm of crushed, to be made available for the

pump & agitator set-up.

Ref :HS&E-FRM-H03-03 Issue: 06 Rev No.00 Date: June 2011 Page 12 of 17

CFA SITE RISK ASSESSMENT and SPILL RESPONSE

Amendment Log

Revision By Amendment Date

1 to 28 WL Various Revisions 03-11-08 to 04-08-09

29 ND Various sections re-worded and formatting fixed 06-11-09

30 MG Revised section 23 blowing out 14-01-11

31 ND Document Reviewed. Various sections revised. Additional lines added for 16-05-11

'live risks' to be recorded.

32 ND Document Review 23-02-12

33 ND Revised section 21 on Open Bores 04-10-12

Ref :HS&E-FRM-H03-03 Issue: 06 Rev No.00 Date: June 2011 Page 13 of 17

CFA SITE RISK ASSESSMENT and SPILL RESPONSE

Likelihood

How often could the hazard occur? Consider the task, fre-

quency, duration, method of work,

employees involved.

Severity

How serious would the hazard's effects be if

realised? Consider the type of hazard, biological, ergonomic,

physical and chemical.

Risk = Likelihood x Severity

E.g. Likelihood (4) X Severity (3) = 12 HIGH RISK

Ref :HS&E-FRM-H03-03 Issue: 06 Rev No.00 Date: June 2011 Page 14 of 17

SPILL RESPONSE PLAN

5.1 Site Address Angle Lane, Stratford. E15 1AG

5.2 Location(s) of Spill Response Equipment

Spill Kit Site Security Container

5.3 Spill Response Equipment Trained I Competent Person(s)

All site crew

5.4 Frequency of Spill

NIA Issue Date: NIA

Tests:

Completed by: - Position: -

Client I Landowner Principal Contractor

5.5 Spill Response Con- 0800-592-827 Membership Number: CM191

tractor Adler & Allan Ltd.

5.6 Environment Agency 0800 80 70 60 (24 hr Emergency Hotline)

Local EA I SEPA Office Refer to Rock and Alluvium Area Office

5.7 Local Authority Not Applicable

5.8 Additional Contact(s) Sally Lloyd-Raines, HSE Advisor, 01372 389 333

Peter Ward, Plant Manager, 07966 562317

Contract Supervisor, see documentation

5.9 Rock and Alluvium I Galliford Try Contacts

Operations Manager Nick Dewey: 07843 328 141

Regional Office Head Office - Leatherhead: 01372 389 333

Regional HS&E Advisor Sally Lloyd-Raines: 01372 389 333

Regional Environment Advisor Amit Patel: 07976 361 119

Ref: HS&E-FRM-E04-01 Issue: 06 Rev No.00 Date: June 2011 Page 15 of 17

SPILL RESPONSE PLAN

Assess Release

Are there Injuries YES Get Medical Attention

NO

Safe to Approach & NO or UNSURE Consult Site Management

Capable to Contain

YES Safe to Approach &

Capable to Contain

CLEAN UP PROCEDURE

NO

ISOLATE

Control access to spill area

Stop flow or emissions, if safe to do so

Extinguish naked flames - NO Smoking

Turn off electrical equipment

Mobilise Spill

CONTAIN Response

Use correct PPE Contractor

Stop spill entering drains I watercourses

Use spill kits, sand or earth to contain spill

ABSORB

Use spill response equipment to absorb spill

Sand I earth may be used, temporarily

CLEAN UP Consider Site I

Place contaminated materials in leak-proof containers I bags Neighbouring

DO NOT wash down spilled materials into drainage systems Property Evacuation

DISPOSE

Apply waste management procedures

REORDER

Replenish used spill response equipment

Report to Senior Site Manager & HS&E Advisor

Report to Business Unit Management; Complete Environmental

REA; and EA I SEPA I Water Company Incident Report Form

Ref: HS&E-FRM-E04-01 Issue: 06 Rev No.00 Date: June 2011 Page 16 of 17

SPILL RESPONSE PLAN

IF IN DOUBT OR YOU REQUIRE ASSISTANCE CONTACT YOUR REGIONAL

ENVIRONMENTAL ADVISOR

Assess Release - Determine the size of the spill and whether there are any injuries to any person(s)

involved.

o If there are injuries medical attention should be sought and the most senior person on site in-

formed

o If there are no injuries, an assessment should be made as to whether the spillage is safe to

approach and contain. If there is doubt, the most senior person on site should be consulted

o Consideration should be given of the need to evacuate the site and I or neighbouring buildings.

If necessary, the police and I or fire service should be contacted

o If the competent or trained person cannot handle the hazardous material spill then the Com-

pany's spill response contractor should be contacted.

Isolate

o Control access to spill

o Do not allow unauthorised access to spillage area

o Identify the source of pollution and stop the flow or emissions as quickly as possible, if it does

not endanger the health and safety of people

o Switch off or suppress any potential sources of ignition

o Extinguish naked flames and ensure there is no smoking

o Turn off electrical equipment.

Contain

o Ensure the correct PPE is used

o If the incident involves liquids, steps should be taken to stop it spreading, using earth, sand, or

impervious material such as polythene

o If the incident involves liquids, the flow should be diverted from drains and I or watercourses

o Consideration should be given to the use of absorbent materials and I or booms, as a precau-

tion, in environmentally sensitive locations

o Use absorbent materials (sand or earth, as an alternative) to assist spill containment.

Absorb

o Spill response pads, sheets, booms and granules should be used to absorb the spilt material

o Sand and earth may be used, as a temporary alternative.

Clean Up

o Contaminated sand, earth or absorbent materials should be placed into sacks or leak-proof

containers, as appropriate

o Spilled materials should not be washed into the drainage system.

Dispose

o Waste contaminated materials should be disposed of appropriately, refer to HS&E-PRO-W 01;

Waste Management

o All used absorbent materials are classified as hazardous waste.

Reorder

o Replace used spill response equipment supplies.

Client specific spill response procedures should be adhered to when working on client site(s) or when

stipulated in the contract.

Ref: HS&E-FRM-E04-01 Issue: 06 Rev No.00 Date: June 2011 Page 17 of 17

You might also like

- AHA Roofing SystemDocument8 pagesAHA Roofing SystemLawrence adeleke Omisakin100% (2)

- Ladders, Hop Ups Risk AssessmentDocument8 pagesLadders, Hop Ups Risk AssessmentRebecca Winter100% (2)

- 03 - Risk Assessment-Material ShiftingDocument4 pages03 - Risk Assessment-Material Shifting287No ratings yet

- Risk Assessment Distribution Board DB Junction Box Junction Box InstallationDocument6 pagesRisk Assessment Distribution Board DB Junction Box Junction Box InstallationAnonymous HeA9HEbtDmNo ratings yet

- Risk Assessment - Wall & Floor Tiling: April 2010Document2 pagesRisk Assessment - Wall & Floor Tiling: April 2010wahyu nugroho100% (1)

- RA-for Glass Installation 30-04-2022Document6 pagesRA-for Glass Installation 30-04-2022Muideen Oyedele100% (2)

- Demolition Risk AssessmentsDocument9 pagesDemolition Risk Assessmentssamar0% (1)

- Risk Assessment Template For Combo Roof Waterproofing Work.Document14 pagesRisk Assessment Template For Combo Roof Waterproofing Work.Majaga MabhenaNo ratings yet

- Qrc-Ra-001-00-Road and Footpath Modification WorksDocument27 pagesQrc-Ra-001-00-Road and Footpath Modification WorksKallem RajashekarNo ratings yet

- Risk Assessment Sheet For Installation of Wooden DoorsDocument3 pagesRisk Assessment Sheet For Installation of Wooden Doorsrajat100% (1)

- RA - Block Work RevisedDocument14 pagesRA - Block Work RevisedCarlus RieraNo ratings yet

- RA - For Precast ChambersDocument5 pagesRA - For Precast ChambersKallem RajashekarNo ratings yet

- RA For Stone Work Rev0Document5 pagesRA For Stone Work Rev0yahiya0% (1)

- Diesel Generator Hazard Assessment PDF Master HireDocument6 pagesDiesel Generator Hazard Assessment PDF Master HireMuhammad MalikNo ratings yet

- Risk Assessment ForkliftDocument2 pagesRisk Assessment Forkliftmohamed ghaly100% (2)

- Risk Assessment For FlushingDocument9 pagesRisk Assessment For FlushingABDUL BASITHNo ratings yet

- Risk AssessmentDocument3 pagesRisk AssessmentSam HodgsonNo ratings yet

- Risk Assessment: Act/Hse/Ra 001: Use of Suspended Access Cradles and Platforms (Temporary Works)Document2 pagesRisk Assessment: Act/Hse/Ra 001: Use of Suspended Access Cradles and Platforms (Temporary Works)Saravana0% (1)

- Risk Assessment-Earth & Backfilling Work-Sent To HibaDocument14 pagesRisk Assessment-Earth & Backfilling Work-Sent To Hibasamer8saifNo ratings yet

- Risk Assessment For DemolitionDocument10 pagesRisk Assessment For Demolitionadeniyi abiolaNo ratings yet

- Risk Assessment For Refurbishment of Civil Assets in Pump Station Rev 00Document12 pagesRisk Assessment For Refurbishment of Civil Assets in Pump Station Rev 00Sachwin SachuNo ratings yet

- Deshuttering WorkDocument1 pageDeshuttering WorkAhmed AbdulfatahNo ratings yet

- Risk Assessment For Erection of Steel GirderDocument11 pagesRisk Assessment For Erection of Steel GirderNirajan MarwaitNo ratings yet

- HSE-F-NEOM-014 - General Risk AssessmentDocument32 pagesHSE-F-NEOM-014 - General Risk AssessmentAhmed Mohamed100% (1)

- Risk Assessment - Elie SabDocument8 pagesRisk Assessment - Elie SabMuhammad FaizalNo ratings yet

- Risk Assessment - Site Establishment - 2021Document6 pagesRisk Assessment - Site Establishment - 2021Asakundwi Mukhwa100% (2)

- Screeding WorksDocument2 pagesScreeding WorksSaleem Basha100% (1)

- Risk Assessment Construction of Lighting Pole at Site OfficeDocument9 pagesRisk Assessment Construction of Lighting Pole at Site OfficeSinaNo ratings yet

- Ra For Fire Protection Piping Installation WorksDocument7 pagesRa For Fire Protection Piping Installation WorksprinceNo ratings yet

- 003 Material HandlingpdfDocument4 pages003 Material Handlingpdfghada gattouchNo ratings yet

- Risk Assessment-Pnuematic Test. DraftDocument3 pagesRisk Assessment-Pnuematic Test. DraftKono Nor AtanNo ratings yet

- Persons at Risk (Groups) Risk Assessor Appointment Tel. No. Description of Task or ActivityDocument8 pagesPersons at Risk (Groups) Risk Assessor Appointment Tel. No. Description of Task or ActivityAyu Wanda SaraswatiNo ratings yet

- RA - 5 - For Backfilling & CompactionDocument14 pagesRA - 5 - For Backfilling & CompactionIbrahim EsmatNo ratings yet

- 18 - RA Roadworks Risk AssessmentDocument1 page18 - RA Roadworks Risk AssessmentkumarNo ratings yet

- Risk Assessment For Concrete Repair WorkDocument11 pagesRisk Assessment For Concrete Repair WorkSaeed AhmadNo ratings yet

- Risk Assessment Roller Shutter DoorDocument4 pagesRisk Assessment Roller Shutter DoorphoenixsafetyconsultantNo ratings yet

- Focus Audit Temp WorksDocument2 pagesFocus Audit Temp WorksArunKumar GanesanNo ratings yet

- PCR-LP-362-Tower Crane Dismantling (LTM1450-8.1)Document17 pagesPCR-LP-362-Tower Crane Dismantling (LTM1450-8.1)Geethika SandaruwanNo ratings yet

- Builder Hoist OperationDocument2 pagesBuilder Hoist OperationDhananjai TiwariNo ratings yet

- Risk Assessment - Hand ToolsDocument2 pagesRisk Assessment - Hand ToolsRoy Chandra Sekar JeyapaulNo ratings yet

- Risk Assessment Template BathroomDocument2 pagesRisk Assessment Template BathroomRNo ratings yet

- Block WorkDocument4 pagesBlock WorkAbdul GhaffarNo ratings yet

- IM-08-B HSE Wall Grinding For Finishing WorkDocument2 pagesIM-08-B HSE Wall Grinding For Finishing WorkAnsari HarisNo ratings yet

- QHSEDOCS-Demolition Work Activities Risk AssessmentDocument14 pagesQHSEDOCS-Demolition Work Activities Risk AssessmentLawrence adeleke OmisakinNo ratings yet

- Risk Assessment:: Corresponding Permit To Work NoDocument4 pagesRisk Assessment:: Corresponding Permit To Work NoNaseemandson TeamNo ratings yet

- 002 Excavation & TrenchingpdfDocument3 pages002 Excavation & Trenchingpdfghada gattouch100% (1)

- RA For Snake BiteDocument5 pagesRA For Snake Biteshamroz khan100% (1)

- Risk Assessment - Installation of Exhaust FansDocument4 pagesRisk Assessment - Installation of Exhaust FansehteshamNo ratings yet

- RA 002 - Mechanical ExcavationDocument2 pagesRA 002 - Mechanical ExcavationZaki Abdullah ALQweaenNo ratings yet

- 12 (1) HIRA - PaintingDocument6 pages12 (1) HIRA - PaintingSk younus0% (1)

- Risk Assessment Steel FixingDocument1 pageRisk Assessment Steel Fixingmohamed ghalyNo ratings yet

- Brazing (Oxygen and Acetylene)Document6 pagesBrazing (Oxygen and Acetylene)My Zain100% (1)

- 02 - R.A. Working On ScaffoldsDocument2 pages02 - R.A. Working On ScaffoldspremNo ratings yet

- AHA-007, Concrete PouringDocument4 pagesAHA-007, Concrete PouringBuddhikaNo ratings yet

- PTW272 - Asphalt Paving 17-01-2023Document22 pagesPTW272 - Asphalt Paving 17-01-2023Shah Muzzamil0% (1)

- Ref: Section / Dept: Civil Activity: Risk Assessment For False CeilingDocument1 pageRef: Section / Dept: Civil Activity: Risk Assessment For False CeilingJack P100% (2)

- Task Risk Assessment Engineering Kinetics (PVT.) LTD: Risk Evaluation (Refer To Evaluation Form)Document2 pagesTask Risk Assessment Engineering Kinetics (PVT.) LTD: Risk Evaluation (Refer To Evaluation Form)andreNo ratings yet

- CSCEC HSE-F-01 Risk Assessment Form - Excavation& Backfilling - RA-02Document12 pagesCSCEC HSE-F-01 Risk Assessment Form - Excavation& Backfilling - RA-02Dan SarmientoNo ratings yet

- Block Work and PlasteringDocument7 pagesBlock Work and Plasteringmohammed sohail100% (1)

- Safe Use of Site Dumpers On Construction SitesDocument4 pagesSafe Use of Site Dumpers On Construction SitesMusharaf ShahNo ratings yet

- Heat Load Calculations For Server RoomDocument1 pageHeat Load Calculations For Server RoomDayanandaNo ratings yet

- Relationship Between Temperature and HumidityDocument2 pagesRelationship Between Temperature and HumidityDayanandaNo ratings yet

- ABT - Tariff Explaination With Examples PDFDocument33 pagesABT - Tariff Explaination With Examples PDFDayanandaNo ratings yet

- Design Boundaries For Metro Rail ProjectDocument3 pagesDesign Boundaries For Metro Rail ProjectDayanandaNo ratings yet

- ABT - Tariff Explaination With Examples PDFDocument33 pagesABT - Tariff Explaination With Examples PDFDayanandaNo ratings yet

- SwotDocument13 pagesSwotDayanandaNo ratings yet

- ServicesDocument33 pagesServicesDayanandaNo ratings yet

- Site AnalysisDocument7 pagesSite Analysispussy CathNo ratings yet

- Guidelines For Evaluation and RepairDocument73 pagesGuidelines For Evaluation and RepairValquir Pacheco NetoNo ratings yet

- Ladder Self Inspection ChecklistDocument3 pagesLadder Self Inspection ChecklistRajkumsr VNo ratings yet

- Grab Research Final Report ENDocument28 pagesGrab Research Final Report ENThiviya A/P NarayananNo ratings yet

- Use of Leadership and Managerial: Ukp TGL 27 Juni 2022Document1,910 pagesUse of Leadership and Managerial: Ukp TGL 27 Juni 2022Deni PamianNo ratings yet

- Evaluation of Pavement Damage Due To NewDocument74 pagesEvaluation of Pavement Damage Due To NewsiritapeNo ratings yet

- Car Parts in Dubai PDFDocument5 pagesCar Parts in Dubai PDFPopular AutopartsNo ratings yet

- WWW - Toyotaglanza.in: Grade G MT (Manual Transmission) CVT G V G VDocument6 pagesWWW - Toyotaglanza.in: Grade G MT (Manual Transmission) CVT G V G VRahulSahujiNo ratings yet

- Mazda 3 Mazdaspeed 3 Workshop Manual 2007 Wwwmanual CarorguaDocument20 pagesMazda 3 Mazdaspeed 3 Workshop Manual 2007 Wwwmanual Carorguamaya100% (33)

- Loading and Haulage For Surface Coal MiningDocument25 pagesLoading and Haulage For Surface Coal MiningSarah Mae Ajon100% (5)

- MZ380466EX - Sensores AparcamientoDocument20 pagesMZ380466EX - Sensores AparcamientoPepe PerezNo ratings yet

- Summer Training in DMRCDocument18 pagesSummer Training in DMRCmat labNo ratings yet

- 1/4/2023 Código ComercialDocument6 pages1/4/2023 Código ComercialMhtecnical SacNo ratings yet

- 12ESH Electric Stacker Operation Manual Service ManualDocument45 pages12ESH Electric Stacker Operation Manual Service Manualmehdi100% (1)

- Titanic.1997.1080P.Bluray.Hindi.English.themoviesflix.comDocument154 pagesTitanic.1997.1080P.Bluray.Hindi.English.themoviesflix.comKing Boy GamerNo ratings yet

- Sas 7Document5 pagesSas 7Clarrinne Geralence Galo RomoNo ratings yet

- Logistics Hse l3Document18 pagesLogistics Hse l3Emmanuel AdenolaNo ratings yet

- Lossan ScheduleDocument12 pagesLossan ScheduleMetro Los AngelesNo ratings yet

- Technical Paper T-117: SEGREGATION: Causes and CuresDocument28 pagesTechnical Paper T-117: SEGREGATION: Causes and CuresraoufNo ratings yet

- LUBCON Train Rail and Wheel - EngDocument3 pagesLUBCON Train Rail and Wheel - EngMontserrat BustiosNo ratings yet

- He Va Grass Roller 63m Mounted Parts Manual 17Document48 pagesHe Va Grass Roller 63m Mounted Parts Manual 17peterbirtatNo ratings yet

- PM PML PLLDocument262 pagesPM PML PLLDave Mooney100% (1)

- Preheater Elevator Work Report 3 Check List 45NS0702Document4 pagesPreheater Elevator Work Report 3 Check List 45NS0702eliasNo ratings yet

- TDL Eol Uce350 Bsvi R2 PDFDocument2 pagesTDL Eol Uce350 Bsvi R2 PDFBarath BiberNo ratings yet

- Logistics and Spply ChainDocument74 pagesLogistics and Spply ChainJosiah GrannumNo ratings yet

- TCDS EASA R146 AH AS355 Issue 06Document35 pagesTCDS EASA R146 AH AS355 Issue 06EX919No ratings yet

- Manual Operacion Dingli Manlift en E01-18Document93 pagesManual Operacion Dingli Manlift en E01-18Juan Pablo Monardez MaluendaNo ratings yet

- Ecqb PPL 70 FPP BPL Gas at enDocument17 pagesEcqb PPL 70 FPP BPL Gas at enYasin CnkciNo ratings yet

- Europe KeysDocument10 pagesEurope KeysMarcos PauloNo ratings yet

- Victor 1 IngleseDocument15 pagesVictor 1 IngleseReijean Alexfer Dos Santos SantosNo ratings yet