Professional Documents

Culture Documents

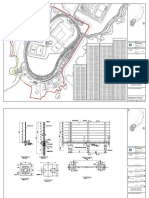

R2 - TYPICAL SLAB LVL (3rd, 4th, 5th, 7th & 8th Floor Slab LVL.) - HOTEL HYATT PLACE - Bharuch - 27.12.19-Model

Uploaded by

Nachiketa MithaiwalaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

R2 - TYPICAL SLAB LVL (3rd, 4th, 5th, 7th & 8th Floor Slab LVL.) - HOTEL HYATT PLACE - Bharuch - 27.12.19-Model

Uploaded by

Nachiketa MithaiwalaCopyright:

Available Formats

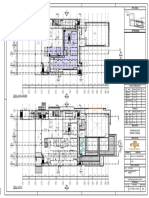

1 1' OWNER:

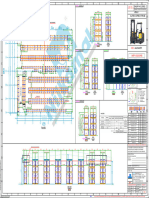

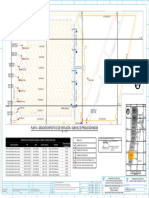

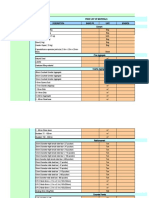

Schedule for Beams & Brackets (M35)

1

Top Steel Top Steel

LC

7

B1 B17 Top Steel

C

2 -16 T

Q 2 -16 T

Q Top Steel Top Steel

BR1

Shree Amitbhai Prajapati

790

2 -20 T

Q

2 -16 T

Q 2 -16 T

Q

LB1(LB @ Landing lvl)

size reinforcement extra adj. stirrups

1 1' Pin 16 T

Q sr no. top remark

Pin 20 T

Q bxd bottom top beam A B

600

Extra Top B1 230 x 600 4 - 16 Q

T 2 - 16 T

Q 2 - 16 T

Q B17 -8T

Q @ 150 c/c thro - Fig:-1

600

600

Extra Top ARCHITECT :

600

600

STAIRWAY AS PER 2 -16 T

Q

B2 2 - 20 T 1 - 20 T Fig:-2

3 - 20 T

Q 150 x 600 2 - 20 Q

T Q Q End Support -8T

Q @ 115 c/c thro -

DRG. No. STR-2a

B2

B3 230 x 600 3 - 20 TQ + 3 -16 T 2 - 16 T 3 - 20 T End Support -8T

Q @ 125 c/c thro - Fig:-3

Pin 16 T

Q Pin 16 T

Q

Pin 20 T

Q Pin 20 T

Q

B4

Q Q Q

DESIGN STUDIO

Bottom Steel 230 x 600 4 - 16 Q

T 2 - 16 T

Q 2 - 16 T

Q B5,End Support -8T

Q @ 150 c/c thro - Fig:-4 G.F. 17 UNIQUE PARK

14 Bottom Steel Bottom Steel 2 -20 T Bottom Steel Bottom Steel

14' 4 - 16 T

Q 4 - 16 Q

T 150 Q B5 230 x 600 2 - 16 T + 2 -10 T

Q Q 2 - 12 T

Q 2 - 16 T

Q End Support -8T

Q @ 150 c/c thro - Fig:-5 OPP. ISRO

3' 3 230 230

7

B14 230 3 - 20 TQ + 3 -16 TQ 230 3 - 20 T

Q + 3 -16 T

Q AHMEDABAD-15.

C

B3

8

B6 230 x 600 4 - 12 Q

T 2 - 12 T

Q 1 - 16 T

Q End Support -8T

Q @ 150 c/c thro - Fig:-6

C

PHONE : 26745020

H

BR3 3 - 16 TQ 3' 3 PTS1 14' 14 10' 10' BR3

J B1(Fig:-1) B1 B2(Fig:-2) B3(Fig:-3) B3 B7 150 x 600 3 - 20 Q

T 2 - 16 T

Q -8T

Q @ 115 c/c thro - Fig:-7 E MAIL : designstudio.shah@gmail.com

B10

STR-9 STR-9

LC (675 x 600)

225 th. PTS1 10 10 2 - 16 T 4 - 20 T Fig:-8

PTB8A

(Typical) B8 230 x 600 6 - 20 Q

T Q Q End Support -8TQ @ 115 c/c thro -

D K Section-1-1 Section-1'-1' Section-3-3 Section-3'-3'

F2

225 th.

BR3

C

BR3

BR3

K

920

F1

1220

F1 F1 F1 F1 F1 F1

STR-9

5 STR-9 B9 300 x 600 8 - 16 T

Q 4 - 16 T

Q 3 - 20 T

Q B10,End Support - 10 T

Q @ 115 c/c thro - Fig:-9 CONSULTANT :

BR3

13' 13 S1 4' 4 STR-9 STR-9

ER

600

11

B4 B5 5' 3 - 12 Q

T 2 - 12 T 1 - 12 T -8TQ @ 150 c/c thro - Fig:-10

B10 300 x 600 Q Q End Support

G

C

AN

PTB1 PTB2 CPTB2 B11 230 x 600 4 - 20 Q

T 2 - 16 T -8T Fig:-11

Aashutosh. A. Desai

B13 6' Q Q @ 115 c/c thro -

)H

B13 5

2

4' 4 6 5'

(H

13' 13 (600 x 600) (600 x 600) (600 x 600) Fig:-12

1

D B12 230 x 600 2 - 25 T 4 - 25 T B11,End Support

15

6 - 25 T

Q Q Q

- 10 T

Q @ 115 c/c thro -

15

18

C

Top Steel Top Steel Top Steel Top Steel Top Steel

C

B6

C

K

C

C

STR-9

6' 9' K 2 -16 T

Q 2 -16 T

Q 2 -12 T

Q 2 -12 T

Q 2 -12 TQ Alternate B12a 230 x 600 6 - 25 T

Q 2 - 32 T

Q 2 - 32 T

Q

B11,End Support - 10 T

Q @ 115 c/c thro - Fig:-12a

6 9'

STR-9 STR-9

B18

R2 B13 230 x 880 5 - 20 Q

T 2 - 20 T

Q 3 - 20 T

Q B13,End Support - 10 T

Q @ 125 c/c thro - Fig:-13(Surface r/f) 201 , Spentha Complex , Opp.Vanijya Bhavan,

SB1

Pin 16 T

Q Pin 16 T

Q

SB1

SB1

PTS1 PTS1 PTS1 5 - 12 Q

T 3 - 12 T 2 - 16 T Fig:-14

PTB11 (675 x 600)

PTB13 (675 x 600)

B14 300 x 600 Q Q End Support -8TQ @ 150 c/c thro - Race Course Circle (E),Vadodara.

PTB8 (675 x 600)

PTB4 (675 x 600)

PTB6 (675 x 600)

PTS1

STAIRWAY AS PER

225 th. 225 th. 225 th. Extra Top Extra Top

600

600

600

600

600

B15 230 x 880 6 - 20 Q

T 2 - 20 T

Q 4 - 20 T

Q B16,End Support -8TQ @ 115 c/c thro - Fig:-15(Surface r/f) Tele Fax :- 0265 - 2340032

DRG. No. STR-5a

BR2 225 th. 2 -16 T

Q 2 -16 T

Q

9

B8

9 E - Mail :- aashutoshdesai@gmail.com

B16 230 x 880 6 - 20 Q

T 2 - 20 T

Q 4 - 20 T

Q B16 -8TQ @ 115 c/c thro - Fig:-16(Surface r/f)

B9

PTS1 PTS1 Pin 16 T

Q Pin 16 T

Q Pin 16 T

Q Pin 16 T

Q Pin 12 T Q B17 230 x 600 3 - 10 Q

T 2 - 10 T

Q -8TQ @ 180 c/c thro - Fig:-17

B7

SB1 B SB1 225 th. 225 th. 8 8 HB SB1 SB1 230 x 225 2 - 12 Q

T 2 - 12 T

Q -8TQ @ 150 c/c thro - Fig:-18

Bottom Steel

4 -16 T

Bottom Steel

4 -16 T

Bottom Steel

2 - 16 T

Q + 2 -10 T

Bottom Steel

2 - 16 T

Q + 2 -10 T

Bottom Steel

F1 120 x 600 2 - 10 T

Q 2 - 12 T

Q -8TQ @ 150 c/c thro - Fig:-19

PROJECT MANAGEMENT

H 230 Q

230 Q

230 Q

230 Q 230 4 - 12 QT

STR-9 PTS3 BR2

J

PTS3 F2 120 x 600 2 - 16 Q

T 2 - 12 T

Q -8TQ @ 150 c/c thro - Fig:-20 CONSULTANTS

Details 'A' PTS3 150 th.

HB

STR-9

150 th.

Details 'A' B4(Fig:-4) B4 B5(Fig:-5) B5 B6(Fig:-6) B18 230 x 600 3 - 16 Q

T 2 - 16 T

Q -8TQ @ 115 c/c thro - Fig:-24

19

150 th.

2

Section-4-4 Section-4'-4' Section-5-5 Section-5'-5' Section-6-6

C

R2

C

PTS3

8' 8'

10

150 th.

HB HB HB Lift Wall Fig:-21

16

BR1 230 x 600 - 3 - 12 T

Q Chipiya - - -8T

Q @ 150 c/c thro -

5

C

C

C

12

12' 12

HB HB HB B11 B11 HB HB BR2 150 x 600 - 2 - 16 T

Q Chipiya - - Lift Wall -8T

Q @ 115 c/c thro - Fig:-22

C

B12 BR3 230 x 600 - 3 - 16 T

Q Chipiya - 2 - 16 T

Q SB1,PTB -8T

Q @ 115 c/c thro - Fig:-23

3

12'

LC

12 C Top Steel Top Steel Top Steel Top Steel Top Steel PTB1 600 X 600 PT Beam

PTS2 PTS2 PTS2 PTS2 PTS2

STR-9 2 -12 T

Q 2 -16 T

Q

2 -16 T

Q 2 -16 T

Q 4 -16 T

Q PTB2 600 X 600 PT Beam

175 th. 175 th. 175 th. 175 th. 175 th.

CPTB2 600 X 600 PT Beam

Pin 20 T

Q

MEP CONSULTANTS

PTB9 (675 x 600)

PTB3 675 X 600 PT Beam

PTB5 (675 x 600)

Extra Top

600

Extra Top

600

600

600

600

PTB4 675 X 600 PT Beam

HB HB HB HB HB HB HB HB HB HB 1 -16 TQ 4 - 20 T

Q

PTB5 675 X 600 PT Beam

HB HB HB HB HB T-1

Pin 12 T

Q Pin 20 T

Q Pin 20 T

Q Pin 20 T

Q Pin 16 T

Q G- PT Beam

PTB6 675 X 600 TS

PTS3 PTS3 PTS3 PTS3 PTS3 -P

PTB10 (675 x 600)

PTB12 (675 x 600)

150 th. PTB7 675 X 600 NO PT Beam

PTB3 (675 x 600)

PTB7 (675 x 600)

150 th. 150 th. 150 th. 150 th. Bottom Steel Bottom Steel Bottom Steel Bottom Steel Bottom Steel

Details 'B' RG

Details 'B' H J J H 230 4 - 12 T

Q 150 3 -20 T

Q 230 6 - 20 T

Q

230 6 - 20 TQ 300 8 -16 T

Q

PTB8 675 X 600

PT

D PT Beam

R

FE

STR-9 STR-9 STR-9 STR-9

PTB8A 675 X 600 PT Beam

B6 B7(Fig:-7) B8(Fig:-8) B8 B9(Fig:-9) RE SPECIFIC NOTES:

SB1 SB1 SB1 SB1 SB1 PTB9 675 X 600 PT Beam

B Section-6'-6' Section-8-8 Section-8'-8' Section-9-9 PTB10 675 X 600 PT Beam 1. All R.C.C. works should be carried out as per I.S. 456-2000

2. All steel Structural works should be done as per I.S. 800-1984

PTB11 675 X 600 PT Beam Q

PTB12 675 X 600 PT Beam 4. Structural and Architectural drawings should be followed in relation to

PTS1

SB1

SB1

SB1

SB1

SB1

each other & any Ambiguity if found should be reported in writing before

PTS1 PTS1 225 th. PTS1 PTS1 PTB13 675 X 600 PT Beam execution.

225 th. 225 th. 225 th. 225 th. Top Steel Top Steel Top Steel Top Steel 5. Structural Engineer is not responsible for Centering, Curing,

Top Steel 2 - 12 T

Q 2 - 12 T

Q Top Steel

4 -16 T

Q 2 -16 T

Q 2 -25 T

Q Fabrication, Welding, Misunderstanding of drawings & Quality of Materials.

D 2 -25 T

Q 6. This drawing is property of A.A. DESAI & should not be used without

D STR-9 D permission.

13

6 Pin 20 T

Q

17

STR-9

14

16 STR-9

C

16' Pin 25 T

Q

3

15' 15 C Schedule for Slabs (M35) 7. Follow this drg. with respect to Std. drg.

C

20

C

B15 Extra Top

600

600

B15 B16 B16 B16 8.All Concreting to be done using Concrete Machine mixer & Vibrator Only.

600

C

600

Extra Top

600

1 - 12 T

Q Extra Top reinforcement 9. All Center Line Dimensions as per Architects dgrs./details.

600

3 - 20 T

Q

4 - 25 T remark 10.All Mix proportion for Concrete to be as per approved Mix design.

BR3

BR3

BR3

BR3

BR3

BR3

BR3

BR3

Q

16' D

BR3

D 16 sr no. tk.

1220

15' 15 Main

D STR-9 STR-9

Pin 16 T

Q Pin 20 T

Q Pin 25 T

Q secondary 11. R/F Cover for Column -40,Beam -25, Slab- 12.5 .

STR-9 Pin 25 T

Q 12. Steel Denoted as TQConforming to IS:1786 Fe500 Grade.

H J J H Bottom Steel Bottom Steel 13. Grade of concrete M35 unless specified.

Bottom Steel Bottom Steel Bottom Steel

STR-9 STR-9 STR-9 STR-9 300 3 - 12 Q

T 300 3 - 12 T

Q

6 - 25 T

Q Bottom Steel 14. This Drawing is Part of a set of Drawing for this Project and shall not be

300 8 -16 T

Q 230 4 - 20 T

Q 230

Considered valid unless it is accompanied by the complete set of Drawing.

230 6 - 25 T

Q

PTS1 225 PT Slab

B9 B10(Fig:-10) B10 B11(Fig:-11) B12(Fig:-12) 15. The site execution based on these structure drawings to be carried out

on availing building permission from concerned Authority and as per

B12 PTS2 175 REFER PT DRG NO - PTSG-T-1 PT Slab

approved Plan only.

8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 Section-9'-9' Section-10-10 Section-10'-10' Section-12-12 PTS3 150 PT Slab These shall be sole responsibility of the Client/Developer. The Structure

Section-12'-12' Engineer is not Directly/Indirectly responsible for any legal deviation what so

ever.

16. All Dimension Are in mm unless mentioned otherwise.

R1 Top Steel Top Steel R2 17. 75 mm Sunk Slab (Light weight filling - 8.5kn/m3 max.Density.)

Top Steel Top Steel Top Steel Top Steel

2 -20 T

Q 2 -20 T

Q 2 -20 T

Q 2 -20 T

Q 2 -20 T

Q 2 -20 T

Q

Top Steel

180

180

Pin 20 T

Q

180

180

180

180

Top Steel Slab lvl. Slab lvl. Top Steel Top Steel Slab lvl. Pin 20 T

Q

Slab lvl. Slab lvl. Pin 20 T

Q

Slab lvl. Top Steel Top Steel

2 -32 T

Q

2 -32 T

Q Extra Top 3 - 12 T

Q 3 - 12 T

Q 2 -10 T

Q 2 -16 T

Q

Extra Top Extra Top

3 - 20 T

Q 4 -20 T

Q 4 -20 T

Q

Pin 32 T

Q Pin 16 T

Q

880

880

Surface r/f

880

880

880

880

Surface r/f Surface r/f

700

700

600

8TQ @ 150 c/c

700

700

700

700

Slab (PTS1) Surface r/f Slab (PTS1) 8TQ @ 150 c/c 8TQ @ 150 c/c

600

Extra Top

600

Extra Top Slab (PTS1) Surface r/f Slab (PTS1) Slab (PTS1) Surface r/f Slab (PTS1)

600

600

600

2 - 32 T

Q 8TQ @ 150 c/c

2 - 16 T

Q 8TQ @ 150 c/c 8TQ @ 150 c/c

Pin 25 T

Q

Pin 25 T

Q Pin 20 T

Q Pin 20 T

Q

Pin 12 T

Q Pin 12 T

Q Pin 20 T

Q Pin 20 T

Q Pin 20 T

Q Pin 20 T

Q

Bottom Steel

6 - 25 T

Q Bottom Steel Bottom Steel Bottom Steel Bottom Steel Bottom Steel Bottom Steel Bottom Steel Bottom Steel Bottom Steel Bottom Steel Bottom Steel

230 5 - 20 Q

T

230 6 - 25 T

Q 230 5 - 20 Q

T 230

300 5 - 12 T

Q 300 5 - 12 T

Q 230 6 - 20 Q

T 230 6 - 20 Q

T 230 6 - 20 Q

T 230 6 - 20 Q

T 230 3 - 10 Q

T 230 3 - 16 T

Q

B12a(Fig:-12a)

B12a B13(Fig:-13) B13 B14(Fig:-14) B14 B15(Fig:-15) B15 B16(Fig:-16) B16 B17(Fig:-17) B18(Fig:-24)

Section-12-12

Section-12'-12' Section-13-13 Section-13'-13' Section-14-14 Section-14'-14' Section-15-15 Section-15'-15' Section-16-16 Section-16'-16'

Top Steel Top Steel

2 -12 T

Q 2 -12 T

Q

Chipiya Chipiya Chipiya

3 -12 T

Q

2 -16 T

Q 3 -16 T

Q

Top Steel

2 -12 T

Q Pin 16 T

600

600

180

Chipiya + Extra Top PTS1

75mm

SUNK

Extra Top Top Steel

225

600

600

600

3 -16 T

Q + 2 -16 T

Q PTS3

2 -16 T

Q Bearing = 2 Times To Cantilever (2400 min) Slab lvl. 2 -12 T

Q

Sunk Slab lvl.

180

Bottom Steel Bottom Steel Slab lvl.

225

Bottom Steel

1

SB1

150

SB

230 2 -12 T

Q 120 2 -10 T

Q 120 2 -16 T

Q

225

150

880

230 230

600

PTB1 Bracket(BR3)

700

2. 27.12.19 Lift Opening & Beam(B18) Added.

5

880 Bottom Steel

SB1(Fig:-18) F1(Fig:-19) F2(Fig:-20) BR1(Fig:-21) BR2(Fig:-22) BR3(Fig:-23)

B1

PTB2

600

700

300 min.` L' 2 -12 T

Q

Slab (PTS1) 1. 16.12.19 Beam (B12a) Alternate

CPTB2 Slab (PTS1)

Detail Revised.

PT BEAM

75mm

SUNK

PTS1 PTS1

PTS3 1220 230

PTS2 PTS3 8T

Q @ 150 c/c

230 Section:- H-H(Typical) Sr.No. Date

100

Beam (B13,B15,B16) 2 -10 T

Q

230

175

REVISION

225

225

1

600

1

SB

150

150

SB

Section:- D-D Section:- K-K(Typical)

CUTOUT SECTION - BB CUTOUT PRINT ISSUED (SOFT COPY)

Column DATE TO WHOM TO WHOM

DATE

ISSUED ISSUED

Column G 22.01.19 Arch 19.10.19 P.T.S.I / Arch

G Chipiya + Extra Top

STR-6

STR-6 Bearing = 2 Times To Cantilever (2400 min) 22.02.19 P.T.S.I 21.10.19 P.T.S.I / Arch

230 3 -16 T

Q + 2 -16 T

Q

27.02.19 Arch

ON

06.11.19 P.T.S.I / Arch

50 Eq 50 16.03.19 P.T.S.I 16.11.19 P.T.S.I / Arch

TI

Slab Lvl. 230x550x10 mm tk, M.S. Plate Slab Lvl. 230x550x10 mm tk, M.S. Plate

50

230x550x10 mm tk, M.S. Plate 20.03.19 Arch 25.11.19 P.T.S.I / Arch

UC

600

75 Bracket(BR3) PTBEAM 14.05.19 Arch 04.12.19 P.T.S.I / Arch

PT Slab PT Slab

Eq Eq Eq

L 75x75x6mm

TR

ISMB200 ISMB200 75 300 min.` L' 11.06.19 P.T.S.I / Arch 16.12.19 P.T.S.I / Arch

550

ISMB200

NS

09.10.19 P.T.S.I / Arch 27.12.19 P.T.S.I / Arch

ISMB200 ISMB200 ISMB200

PT Beam PT Beam

CO

L 75x75x6mm L 75x75x6mm 6mm tk. continuous fillet welding 1220

PRINT ISSUED (HARD COPY)

600 6mm tk. continuous fillet welding 6mm tk. continuous fillet welding

R

50

600 DATE TO WHOM TO WHOM

(8 No.)10 mm wide , 4mm tk. & DATE

FO

3 - 12 TQ Column ISSUED ISSUED

100mm Long Flat to be Split 2 - 16 T

Q

G G 04.12.19 Client-3

Section:- J-J(Typical)

OD

Column STR-6

& Welded as Hold fastener

STR-6

Section:- G-G(Typical) 230

GO

(8 No.)10 mm wide , 4mm tk. & (8 No.)10 mm wide , 4mm tk. &

100mm Long Flat to be Split 100mm Long Flat to be Split

& Welded as Hold fastener & Welded as Hold fastener 2 - 16 T

Q

3 - 12 TQ

750

Details 'A' Details 'B' (H)HANGER

Chipiya

Bearing = 1.5 times to Cantilever APPROVED BY:

All PT Beam / Slab to be in M35.

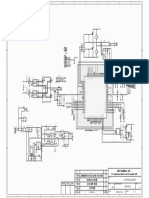

Section:- A-A

All RCC Beam / Slab to be in M35. Slab lvl.

10th Floor.Lvl CHECKED BY: A.A.Desai

Bracket

Refer to PT Vendor Drawing/Instructions Prior to Pouring Concrete. BR1 150 min.` L'

300

BR2 300

9th Floor.Lvl DRAWN BY: BRP

Note:- Extra bottom r/f for PT beam & extra top and

bottom r/f for PT Slab as per PTSG-T-1 drg./detaits. PTB12 PTB13 150 min.` L' 8th Floor.Lvl

DATE: 30-11-18

PROVIDE OPEN STIRRUPS UPTO L/4 DISTANCE FROM

FACE OF COLUMN AND CLOSE STIRRUPS AT R.C.C.Wall 2 -10 T

Q 7th Floor.Lvl

Cantilever

REMAINING PORTION OF MIDSPAN Beam JOB No. ; A.A.D. 2017 A2

Beam 6th Floor.Lvl

IMP NOTE:-

(1) Reshoring for slab/beam for two levels below to be done prior to pouring concrete. PROJECT :

A A Typical Section For Brackets 5th Floor.Lvl

Column (C19) STR-8 STR-8

HOTEL HYATT PLACE

150x150 10 TQ ring 4th Floor.Lvl

2-16 # FOR STIRRUPS IN 150 OFFSET 230x230 10 T

Q ring

PERIPHERAL PT/RCC BEAM

1-16 # TOP + 1-16 # BOTTOM FOR STIRRUPS IN 6" OFFSET

CONTINUOUS TOP BARS Chipiya 3rd Floor.Lvl LOCATION:

50 d

0 Y Top Steel

CONTINUOUS BOTTOM BARS EXTRA TOP BARS 10 (H)HANGER(230 X 750) X Extra Top Top Steel Y BHARUCH

50 d

150 300

15

0 End Support

EXTRA BOTTOM BARS Min. TENDONS

150 300 Bearing = 1.5 Times To Cantilever Extra Top (Extra Top) 2nd Floor.Lvl

3D View vert. r/f 4 - 16 T

Q + 6 - 12 T

Q Z

BEAM DEPTH

Min. TENDONS

3D View

BEAM WIDTH

Ties 8 T

Q @ 150 c/c

Top Steel

Service Floor.Lvl DRAWING TITLE:

L2/4

d

L1/4 L2/4

d

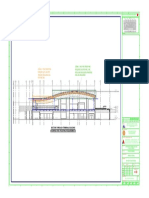

150min.` L' 150min.` L' 1st Floor.Lvl 1st Floor.Lvl DETAIL OF TYPICAL FLOOR

Stirrups Slab lvl.

EXTRA BOTTOM BARS

Beam SLAB LVL.

Slab lvl. b b b Ground Floor.Lvl Ground Floor.Lvl

CONTINUOUS BOTTOM BARS

CONTINUOUS BOTTOM BARS

2-16 # FOR STIRRUPS IN 6" OFFSET X-X Y-Y

Cantilever

Bottom Steel Adj. Beam Z-Z (3rd,4th,5th,7th & 8th floor slab Lvl.)

50 d

1-16 # TOP + 1-16 # BOTTOM FOR STIRRUPS IN 6" OFFSET MAIN STEEL IN COLUMN (d: STEEL DIAMETER)

Bottom Steel PTB12 PTB13 Bottom Steel 1st Basement Floor.Lvl 1st Basement Floor.Lvl 1st Basement Floor.Lvl

COLUMN STEEL (d: STEEL DIAMETER) X

PERIPHERAL BEAM STEEL

NOTE : (1) STIRRUPS ARE NOT SHOWN FOR CLARITY PURPOSE 230x230 8T

Q ring

cutout for spout 150x150 L1

Y Z Y DRG. CODE REVISION

(2) THIS DETAIL SHALL NOT BE ADOPTED FOR BEAM ENDS L2 2nd Basement Floor.Lvl 2nd Basement Floor.Lvl 2nd Basement Floor.Lvl

300

HAVING CANTILEVERS WITH SPANS MORE THAN 2 FEET. Section A B A A B A Column - C Column - SC Column - BC

Plan View Section Typical Section For all Beams wherein Spouts S T R - 0 9 R 2

Numbers of Floor

are to be connected as per architect/plumbing detail Typical Section For Beams & Brackets

Typical Detail at Anchorage of a Beam Section:- C-C SCALE: N.T.S.

You might also like

- Instant Assessments for Data Tracking, Grade 1: MathFrom EverandInstant Assessments for Data Tracking, Grade 1: MathRating: 4 out of 5 stars4/5 (1)

- MR-KCP-1 & 4-026 - Birco Drain ChannelDocument1 pageMR-KCP-1 & 4-026 - Birco Drain ChannelUsman SandhuNo ratings yet

- 22.06.13 Pekerjaan PagarDocument3 pages22.06.13 Pekerjaan PagarsanusiNo ratings yet

- Electrical System C32 Generator Set With EMCP3: Harness and Wire Electrical Schematic SymbolsDocument4 pagesElectrical System C32 Generator Set With EMCP3: Harness and Wire Electrical Schematic Symbolsyasser eljabaliNo ratings yet

- Planta de Cimentación: Tabla de Datos Tecnicos Del ProyectoDocument1 pagePlanta de Cimentación: Tabla de Datos Tecnicos Del ProyectoMārco RēyesNo ratings yet

- EDG LCP Wiring MARINEDocument14 pagesEDG LCP Wiring MARINEHeni HasanahNo ratings yet

- SWR UpdatedDocument1 pageSWR Updatedram prasad meenaNo ratings yet

- 4217-Pbg-A-1101-Rc Denah - Lantai 1 Dan 1 MezaninDocument1 page4217-Pbg-A-1101-Rc Denah - Lantai 1 Dan 1 MezaninAdi PriyapurnatamaNo ratings yet

- B Side: N7Tw - Power.Pcb 1LG4B10Y04300Document2 pagesB Side: N7Tw - Power.Pcb 1LG4B10Y04300Dario EzequielNo ratings yet

- Mz-04-00001-00-05-Ar-Aed-Dg-011209 (03) - Mzfw-Elevations Part 5 - 1Document1 pageMz-04-00001-00-05-Ar-Aed-Dg-011209 (03) - Mzfw-Elevations Part 5 - 1AMR ABDALHNo ratings yet

- Maintenance Hangar: DepartureDocument2 pagesMaintenance Hangar: DepartureJoshua RegilmeNo ratings yet

- Conexiones Domiciliarias Ploteo-Layout1Document1 pageConexiones Domiciliarias Ploteo-Layout1Jim MartinezNo ratings yet

- Hualañe 2 OficialDocument1 pageHualañe 2 OficialJair MoralesNo ratings yet

- Dry Street Lighting Network Layout Ci SL LP 104Document1 pageDry Street Lighting Network Layout Ci SL LP 104Ahmed BoraeyNo ratings yet

- 402 00 PL DWG 0009.001Document1 page402 00 PL DWG 0009.001Krishnan KrishNo ratings yet

- 03 12000 48000441 Boc Inf DRG 000010 - 02Document1 page03 12000 48000441 Boc Inf DRG 000010 - 02Yasir Nisar SyedNo ratings yet

- Esquema Excavacion A-6Document1 pageEsquema Excavacion A-6Sebastian SalazarNo ratings yet

- Ec1-02a Second Floor Fdas LayoutDocument1 pageEc1-02a Second Floor Fdas LayoutSEDFREY DELA CRUZNo ratings yet

- 03 12000 48000441 Boc Inf DRG 000011 - 02Document1 page03 12000 48000441 Boc Inf DRG 000011 - 02Yasir Nisar SyedNo ratings yet

- DM Architectural Set 14.12.2023Document22 pagesDM Architectural Set 14.12.2023VinodNo ratings yet

- Avenza BPP 3-4 (2) 10-02-2023 PDFDocument1 pageAvenza BPP 3-4 (2) 10-02-2023 PDFyusuf alpianNo ratings yet

- 640-0762 (Inversora) - SURT7500,8000,10000Document7 pages640-0762 (Inversora) - SURT7500,8000,10000Helder RizziNo ratings yet

- A B C D E: Planta Estructural Ne 3.80M ESCALA 1:40Document1 pageA B C D E: Planta Estructural Ne 3.80M ESCALA 1:40jpenalozaicNo ratings yet

- MDB-Sanhour A2Document1 pageMDB-Sanhour A2ahmad.yasser.workNo ratings yet

- Siteplan 2Document1 pageSiteplan 2muhammadulil abrorNo ratings yet

- Siteplan 1Document1 pageSiteplan 1muhammadulil abrorNo ratings yet

- Brqva Sftleo 190923 CA-RAW-QSF3.8 Confidential CA25/30/35 T3 - 1 A SFT190537 13 ProductionDocument13 pagesBrqva Sftleo 190923 CA-RAW-QSF3.8 Confidential CA25/30/35 T3 - 1 A SFT190537 13 ProductionMauro PerezNo ratings yet

- 18 606000 1100001344 Asb Civ SHD 115152 - 01Document2 pages18 606000 1100001344 Asb Civ SHD 115152 - 01Mahmudul Alam kanakNo ratings yet

- POCVN-MF-SD-CON-M-SEW-06 07 - Rev03 - Septic TankDocument3 pagesPOCVN-MF-SD-CON-M-SEW-06 07 - Rev03 - Septic TankTôn Huỳnh ĐoànNo ratings yet

- Controle Remoto Controle Remoto: Keila KeilaDocument1 pageControle Remoto Controle Remoto: Keila KeilaRudyXPNo ratings yet

- North: Service Bay Service BayDocument1 pageNorth: Service Bay Service BaymateojullieanneNo ratings yet

- OAK-PL-GA-F3XX-N04-10-S-002-MUROS-VERDE-PANTALLAS-S1-V20_00[1]-ModeloDocument1 pageOAK-PL-GA-F3XX-N04-10-S-002-MUROS-VERDE-PANTALLAS-S1-V20_00[1]-ModeloEnergia TotalNo ratings yet

- Ubic - Loc 3DDocument1 pageUbic - Loc 3DRolan Yañez ParionaNo ratings yet

- 3) Plano Clave-Plano ClaveDocument1 page3) Plano Clave-Plano ClaveCesar Roman MuñozNo ratings yet

- E-500 Telephone Layout-E-500Document1 pageE-500 Telephone Layout-E-500mahmoud mohamedNo ratings yet

- 3W-200697-01 R12-AREA-01 Roquette India Pvt. Ltd. Belgaum (200502) COFFE...Document1 page3W-200697-01 R12-AREA-01 Roquette India Pvt. Ltd. Belgaum (200502) COFFE...Dk WatranaNo ratings yet

- S-03710 P42118-Rev. 3-P18-Steam DrumDocument1 pageS-03710 P42118-Rev. 3-P18-Steam Drumwylie01No ratings yet

- Control Board Circuit Diagram For AJEX2000HDocument1 pageControl Board Circuit Diagram For AJEX2000HGirayNo ratings yet

- TP.V56.PC821 SchematicDocument8 pagesTP.V56.PC821 SchematicSubhash.2084 S75% (8)

- 11Document1 page11FabianoNo ratings yet

- Audio Micro: CA+ CA-Vol+ Vol - Tv/Av MenuDocument2 pagesAudio Micro: CA+ CA-Vol+ Vol - Tv/Av MenuJosé Alberto Pérez CabreraNo ratings yet

- Cat G3516BDocument2 pagesCat G3516BSam SamNo ratings yet

- Dry-Street Lighting Network Layout-Ci-Sl-Lp-101Document1 pageDry-Street Lighting Network Layout-Ci-Sl-Lp-101Ahmed BoraeyNo ratings yet

- DENON AVR-1905 SchematicDocument13 pagesDENON AVR-1905 SchematicGuillaume HubertNo ratings yet

- Schematic diagrams and input/volume board details for AVR-1905/785 AVC-1590 audio equipmentDocument13 pagesSchematic diagrams and input/volume board details for AVR-1905/785 AVC-1590 audio equipmentWinger ZsNo ratings yet

- Controle Remoto RC-206 - 1027241190 Controle Remoto RC-206 - 1027241190Document1 pageControle Remoto RC-206 - 1027241190 Controle Remoto RC-206 - 1027241190Enrique HerreraNo ratings yet

- Scubber Seal Tank (6a25-T12) 12kl-MasterDocument2 pagesScubber Seal Tank (6a25-T12) 12kl-MasterJayan VKNo ratings yet

- Electrica Puerta de Riel: Dell Dell DellDocument1 pageElectrica Puerta de Riel: Dell Dell DellJ Antonio ZamudioNo ratings yet

- XC2003 Controller Notes:: X2:1 X2:6 X2:7 X2:8 X2:9 X2:6 X2:14 X2:15 X2:11 X2:17 X2:20 X2:21 X2:22 X2:24 X2:26 X2:25 X2:18Document1 pageXC2003 Controller Notes:: X2:1 X2:6 X2:7 X2:8 X2:9 X2:6 X2:14 X2:15 X2:11 X2:17 X2:20 X2:21 X2:22 X2:24 X2:26 X2:25 X2:18percyctba FilhoNo ratings yet

- Igebsts1 17Document3 pagesIgebsts1 17hal9000_mark1No ratings yet

- Surat Airport SAS - Section For Vermiculite - 19.08.2020Document1 pageSurat Airport SAS - Section For Vermiculite - 19.08.2020Tanmay GorNo ratings yet

- N14MS03 223500 100VC 00002Document1 pageN14MS03 223500 100VC 00002Rigo McFly Casanova ArmijoNo ratings yet

- S31 - Axis A1 - Warehouse 02Document1 pageS31 - Axis A1 - Warehouse 02CoralSun CravensickNo ratings yet

- SKEMA - TV - LG - 21FU3RL - Pdffilename - UTF-8SKEMA-20TV-20LG-2021FU3RLDocument1 pageSKEMA - TV - LG - 21FU3RL - Pdffilename - UTF-8SKEMA-20TV-20LG-2021FU3RLyusrianto Nusamaine windewani100% (2)

- Supatá-ALC-ALT 1-COMBINADO-Versión 1 AutoCAD-Presentación4Document1 pageSupatá-ALC-ALT 1-COMBINADO-Versión 1 AutoCAD-Presentación4Andres Bonilla RNo ratings yet

- Design Data: Saudi Arabian Oil CompanyDocument15 pagesDesign Data: Saudi Arabian Oil Companysuria qaqcNo ratings yet

- Alangilan Site Dev-1Document1 pageAlangilan Site Dev-1andreimalibiran8No ratings yet

- Haroli Jajon: Earthen Shoulder EdgeDocument13 pagesHaroli Jajon: Earthen Shoulder EdgeDushyant JadaunNo ratings yet

- 4217-Pbg-A-1102-Rc Denah - Lantai 2 Dan 2 MezaninDocument1 page4217-Pbg-A-1102-Rc Denah - Lantai 2 Dan 2 MezaninAdi PriyapurnatamaNo ratings yet

- ALA-OEP Topics Sem 8 1Document8 pagesALA-OEP Topics Sem 8 1Nachiketa MithaiwalaNo ratings yet

- Elective Entry For 8th Sem StudentsDocument6 pagesElective Entry For 8th Sem StudentsNachiketa MithaiwalaNo ratings yet

- Characteristics of Construction ManagementDocument2 pagesCharacteristics of Construction ManagementNicole Santillan100% (1)

- Stakeholder Management in Construction Projects - A Life Cycle Based FrameworkDocument313 pagesStakeholder Management in Construction Projects - A Life Cycle Based FrameworkshaiNo ratings yet

- Ih April 2021Document56 pagesIh April 2021Nachiketa MithaiwalaNo ratings yet

- ContentDocument3 pagesContentNachiketa MithaiwalaNo ratings yet

- FE Manual Sem 6 New CourseDocument26 pagesFE Manual Sem 6 New CourseNachiketa MithaiwalaNo ratings yet

- Final Advt 04 2021 0UAKDocument25 pagesFinal Advt 04 2021 0UAKNachiketa MithaiwalaNo ratings yet

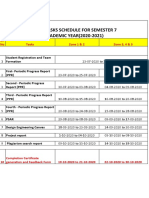

- Pmms Tasks Schedule For Semester 7 ACADEMIC YEAR (2020-2021)Document1 pagePmms Tasks Schedule For Semester 7 ACADEMIC YEAR (2020-2021)Nachiketa MithaiwalaNo ratings yet

- Characteristics of Construction ManagementDocument2 pagesCharacteristics of Construction ManagementNicole Santillan100% (1)

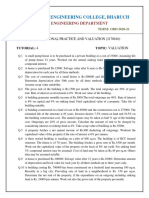

- Tutorial Estimation Numericals PDFDocument3 pagesTutorial Estimation Numericals PDFNachiketa MithaiwalaNo ratings yet

- GTU Environmental Engineering SyllabusDocument4 pagesGTU Environmental Engineering SyllabusNachiketa MithaiwalaNo ratings yet

- Analysis and Design of G+3 Residential Building Using STRUDSDocument5 pagesAnalysis and Design of G+3 Residential Building Using STRUDSDinesh SenNo ratings yet

- 18.engg Aptitude-2021 PDFDocument21 pages18.engg Aptitude-2021 PDFNachiketa MithaiwalaNo ratings yet

- SolidEdge ch9 Titleblock and Borders PDFDocument12 pagesSolidEdge ch9 Titleblock and Borders PDFNachiketa MithaiwalaNo ratings yet

- Eneral Bility Q. No. 1 - 5 Carry One Mark Each: - CE, GATE-2020, Paper-IDocument23 pagesEneral Bility Q. No. 1 - 5 Carry One Mark Each: - CE, GATE-2020, Paper-ISuman.SNo ratings yet

- TandC Rupay Card PDFDocument1 pageTandC Rupay Card PDFNachiketa MithaiwalaNo ratings yet

- Notice Regarding SSC Exam InstructionDocument1 pageNotice Regarding SSC Exam Instructiondebabratrath786No ratings yet

- Flat Slab DesignDocument76 pagesFlat Slab Designyunuswsa97% (36)

- Rclect10 12Document25 pagesRclect10 12Abera MamoNo ratings yet

- Defect Remedy Management PlanDocument6 pagesDefect Remedy Management PlanAndrew ReidNo ratings yet

- Solid Waste ManagementDocument16 pagesSolid Waste ManagementAshish AroraNo ratings yet

- m4l08-ENERGY DISSIPATOR IITDocument75 pagesm4l08-ENERGY DISSIPATOR IITRajendra Shah Shah100% (1)

- Tutorial Valuation PDFDocument1 pageTutorial Valuation PDFNachiketa MithaiwalaNo ratings yet

- Government Engineering College, BHARUCHDocument1 pageGovernment Engineering College, BHARUCHNachiketa MithaiwalaNo ratings yet

- Defect Remedy Management PlanDocument6 pagesDefect Remedy Management PlanAndrew ReidNo ratings yet

- Use of Ceramic Waste Powder in Cement ConcreteDocument7 pagesUse of Ceramic Waste Powder in Cement ConcreteIJIRSTNo ratings yet

- Earth Work by MechDocument5 pagesEarth Work by MechJaneshaNo ratings yet

- Talha ReportDocument8 pagesTalha ReportNachiketa MithaiwalaNo ratings yet

- Design of Bridges Using Limit State by IRC-112 CodeDocument45 pagesDesign of Bridges Using Limit State by IRC-112 CodeTIRTH100% (1)

- Deck 762Document2 pagesDeck 762Rubel MorolNo ratings yet

- Brickwork ApparatusDocument4 pagesBrickwork ApparatusRoslie AbdullahNo ratings yet

- S3-0-0 - Typical Slab On Grade Details PDFDocument1 pageS3-0-0 - Typical Slab On Grade Details PDFVictor Miranda AcuñaNo ratings yet

- Improve roadway drainage and safety with crash barriersDocument1 pageImprove roadway drainage and safety with crash barriersyedidiNo ratings yet

- Andrea Palladio PDFDocument324 pagesAndrea Palladio PDFNelson Zamorano100% (2)

- Denah Pile Cap (Pondasi) DrawingDocument1 pageDenah Pile Cap (Pondasi) DrawingKhaerun SolehNo ratings yet

- Construction Manual MI MP 38Document61 pagesConstruction Manual MI MP 38Mohanakrishnan SNo ratings yet

- Mitsubishi MXZ sm48 Hyper Heat Specifications SheetDocument5 pagesMitsubishi MXZ sm48 Hyper Heat Specifications SheetRoshNo ratings yet

- Stability Analysis of Possible Embankment Construction For Placement of Granite Capstone On Brihadeeshwara Temple, TanjavurDocument8 pagesStability Analysis of Possible Embankment Construction For Placement of Granite Capstone On Brihadeeshwara Temple, TanjavurDinesh Kumar JNo ratings yet

- Architecture Anomaly - Saul KimDocument4 pagesArchitecture Anomaly - Saul Kimdaat.incNo ratings yet

- LEGEND DESCRIPTIONDocument1 pageLEGEND DESCRIPTIONcrescente galendezNo ratings yet

- Westgate Pavimentaatqueemblemata 2000Document22 pagesWestgate Pavimentaatqueemblemata 2000EmilyNo ratings yet

- Ramp Details (Section A & B)Document1 pageRamp Details (Section A & B)Rajesh ShindeNo ratings yet

- 302-KG - Nirup - Residence 2bed - Type 2 - 2BRS - DD - King Room Bathroom-303Document1 page302-KG - Nirup - Residence 2bed - Type 2 - 2BRS - DD - King Room Bathroom-303hari alfandiNo ratings yet

- ZulfalahDocument11 pagesZulfalahAbrar AhmadNo ratings yet

- Saiver ReportDocument29 pagesSaiver Reportmohamed yehiaNo ratings yet

- Urban design-urban planning relationship gap analysisDocument11 pagesUrban design-urban planning relationship gap analysisMelanie CabforoNo ratings yet

- Literature Case Study: ARCHITECT:keywowDocument9 pagesLiterature Case Study: ARCHITECT:keywowgayathriNo ratings yet

- Tunnel specification and quantity calculationDocument1 pageTunnel specification and quantity calculationRavi Kumar100% (1)

- Masonry Design Guide PDFDocument29 pagesMasonry Design Guide PDFdawitgggNo ratings yet

- Catalogue MaderaDocument212 pagesCatalogue Maderaabelardo garciaNo ratings yet

- Typ Wall Detail DetailDocument1 pageTyp Wall Detail DetailJuanCarlosOrtizDradaNo ratings yet

- B.1 Passive House Building Envelope - Types of ConstructionDocument50 pagesB.1 Passive House Building Envelope - Types of ConstructionDoru FecheteNo ratings yet

- VITI LIGHT BLUE - MOSAIC - Jubin Cantik 2Document1 pageVITI LIGHT BLUE - MOSAIC - Jubin Cantik 2chiangshirongjasmineNo ratings yet

- Post-tensioning technology of the "MoračicaDocument5 pagesPost-tensioning technology of the "MoračicaKenan KajosevicNo ratings yet

- Price List of Construction MaterialsDocument259 pagesPrice List of Construction Materialsosei kwadwoNo ratings yet

- Final - Samsung Irex MRP Catalouge - 01-03-2023-1Document28 pagesFinal - Samsung Irex MRP Catalouge - 01-03-2023-1ESCAP- Holiday Inn CochinNo ratings yet

- Retaining Wall Design Based On ACI 318-19: Input Data & Design SummaryDocument6 pagesRetaining Wall Design Based On ACI 318-19: Input Data & Design SummaryEdu D. Bocanegra LopezNo ratings yet

- Ethio Telecom Regional Office Building Construction ProjectDocument34 pagesEthio Telecom Regional Office Building Construction ProjectFreedom Love Nabal100% (1)

![OAK-PL-GA-F3XX-N04-10-S-002-MUROS-VERDE-PANTALLAS-S1-V20_00[1]-Modelo](https://imgv2-2-f.scribdassets.com/img/document/725688346/149x198/838c40216d/1713837999?v=1)