Professional Documents

Culture Documents

Es0203-75640100-Spc-0002 10 PDF

Uploaded by

Anonymous vwbLPTpjOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Es0203-75640100-Spc-0002 10 PDF

Uploaded by

Anonymous vwbLPTpjCopyright:

Available Formats

4.1.

5 Fill and Fill Supports

The fill shall be of film fills and shall consist of formed PVC material. The fill material shall be capable of

withstanding temperature upto 55 Deg.C without damage or permanent distortion. The sheet thickness of the fill

media shall be uniform with a minimum of 0.25mm. The fill media shall be UV stabilized. SUPPLIER to furnish the

fill material properties and the material standards along with fill characteristics curves and pressure drop curves.

The fill shall be supported by MS HDG/GRP grid specially provided for this purpose. Movement or sagging of fill

assembly shall be prevented. The fills shall be arranged properly and of suitable size for easy erection and removal.

4.1.6 Drift Eliminators

The drift eliminators shall be designed to keep the drift loss to a maximum of 0.005 percent of the circulation rate.

The air pressure drop across the eliminators shall be kept to a minimum by providing a proper number of air flow

direction change across the eliminators. The water collected in the eliminators shall be returned to the tower basin

and shall not mix with the discharge air stream. Eliminators shall be of multipass Herring bone type or angular

honey comb arrangement or cellular type. The drift eliminators shall be of PVC material.

4.1.7 Water distribution system

The hot water shall be distributed to the fill from the PVC hot water distribution header located inside the cooling

tower. SUPPLIER to note that the air pressure drop due to the above arrangement has to be taken care in the fan

power calculation and cooling tower design. The hot water will be further distributed through PVC lateral pipes and

gets sprayed over the fills using non-clog type polypropylene spray nozzles. The PVC distribution header & lateral

pipes shall be as per the latest edition of IS: 4985. The wall thickness of the lateral pipe shall be minimum Class 3.

The lateral pipe shall be provided with plastic end plugs for inspection and cleaning. The PVC hot water distribution

header shall be provided with MS terminal flange as per ASME B 16.5 Cl 150.

4.1.8 Fan stack

The Fan stack shall be of FRP with core stiffener and safety mesh. The fan stack shall be of proper shape for

efficient operation and performance of the fan. The fan stack shall be of self supporting structure designed to

withstand the wind load without external support ties or cable brackings. The height of the stack shall be sufficient

to recover the velocity and discharge the humid air at a sufficiently high level to minimise recirculation. The

minimum clearance between the stack and the fan blades shall be maintained along the entire periphery of the

stack to prevent the rubbing of fan blades while rotating.

You might also like

- DRIP Tech ManualDocument2 pagesDRIP Tech ManualGunasridharan LakshmananNo ratings yet

- Marley M-106: / Crossflow Film FillDocument2 pagesMarley M-106: / Crossflow Film FillErnesto Sánchez GómezNo ratings yet

- N N Total: Design CriteriaDocument6 pagesN N Total: Design Criteriaprabhuanand1986No ratings yet

- Section 4 Air Handling Units - Double Skin ScopeDocument4 pagesSection 4 Air Handling Units - Double Skin ScopematzoyekNo ratings yet

- Tender Specifications-Exhaust SystemDocument6 pagesTender Specifications-Exhaust Systemgullipalli srinivasa raoNo ratings yet

- Compliance Statement ElmDocument5 pagesCompliance Statement ElmdeepakjoyinNo ratings yet

- Quantum Climate Changer Air Handling Unit Guide SpecificationDocument10 pagesQuantum Climate Changer Air Handling Unit Guide SpecificationIndra IrawanNo ratings yet

- 3.ACMV (Air Cooled Split Unit) - PDFDocument3 pages3.ACMV (Air Cooled Split Unit) - PDFIswadi Bin ZulkarnainNo ratings yet

- Compressor SpecificationDocument9 pagesCompressor Specificationcarzante100% (1)

- Technical Specifications OF Multi Purpose Tender (LCV 100 HP Chassis)Document23 pagesTechnical Specifications OF Multi Purpose Tender (LCV 100 HP Chassis)Naushad WadiaNo ratings yet

- Technical Specifications OF Multi Purpose Tender (16 Ton 150 HP Chassis)Document11 pagesTechnical Specifications OF Multi Purpose Tender (16 Ton 150 HP Chassis)Naushad WadiaNo ratings yet

- Vayhan Ahu CatalogueDocument26 pagesVayhan Ahu CatalogueAzher ANo ratings yet

- HVAC Ductwork SpecificationDocument4 pagesHVAC Ductwork SpecificationhvacwallyNo ratings yet

- Checklist Hvac p1Document16 pagesChecklist Hvac p1Aditya ChourasiaNo ratings yet

- Refinery Cooling Plant SpecificationDocument8 pagesRefinery Cooling Plant SpecificationHatem ShawkiNo ratings yet

- Plant Layout - Cooling Water TowersDocument7 pagesPlant Layout - Cooling Water TowersSouparna DuttaNo ratings yet

- Deaerator WriteupDocument12 pagesDeaerator WriteupAmit SharmaNo ratings yet

- Multy Outlet PipelineDocument3 pagesMulty Outlet Pipelinehekayat71No ratings yet

- Cooling Coil and Drain Pan Requirements For Air Handling Units August 2015 News To Use - 508 PDFDocument1 pageCooling Coil and Drain Pan Requirements For Air Handling Units August 2015 News To Use - 508 PDFkktayNo ratings yet

- Scott Air Pak 50 Bid SpecsDocument0 pagesScott Air Pak 50 Bid SpecsgshdavidNo ratings yet

- Standard S Eci Cation of Multipurpose Fire TenderDocument9 pagesStandard S Eci Cation of Multipurpose Fire TenderaravindappiNo ratings yet

- Ac1 Spilt AcDocument3 pagesAc1 Spilt AcSdferwste SrqreNo ratings yet

- Section Vii H.V.A.C Specification Packaged Type Air-Conditioning Units - Air Cooled (Data Sheet Attached Must Be Filled & Submitted With Offer)Document44 pagesSection Vii H.V.A.C Specification Packaged Type Air-Conditioning Units - Air Cooled (Data Sheet Attached Must Be Filled & Submitted With Offer)ravirawat15No ratings yet

- Energy Conservation in Cooling TowersDocument13 pagesEnergy Conservation in Cooling TowersMohamad ChaudhariNo ratings yet

- Api Plan 53Document2 pagesApi Plan 53Luis SudNo ratings yet

- Gas Filtration Sterile Micro Filtration For Bio Reactors F & S Vol 43, #4, May 06Document4 pagesGas Filtration Sterile Micro Filtration For Bio Reactors F & S Vol 43, #4, May 06michael_payne3532No ratings yet

- Air and Water Cooled Liquid Chillers: Maintenance and Operating ManualDocument20 pagesAir and Water Cooled Liquid Chillers: Maintenance and Operating ManualRick LynchNo ratings yet

- Air 3-101Document24 pagesAir 3-101753rgsNo ratings yet

- Precooler Suggested SpecificationsDocument1 pagePrecooler Suggested SpecificationsEaster KongNo ratings yet

- Api 23Document3 pagesApi 23sapu11jagat5855No ratings yet

- AHU Specification - SaiverDocument4 pagesAHU Specification - SaiverRyan Au YongNo ratings yet

- Panwater PET 300 & 400 FC Series Cooling Towers PDFDocument4 pagesPanwater PET 300 & 400 FC Series Cooling Towers PDFkingathur26681No ratings yet

- Cooling Tower Specs - Cti Certified Counter FlowDocument2 pagesCooling Tower Specs - Cti Certified Counter FlowShahab Z AhmedNo ratings yet

- 3149 Vol 2B-PACDocument12 pages3149 Vol 2B-PACvcasadoayesaNo ratings yet

- Technical Specification of GrillsDocument1 pageTechnical Specification of GrillsmishtinilNo ratings yet

- Technical Specification of GrillsDocument1 pageTechnical Specification of GrillsmishtinilNo ratings yet

- 3472 Vol 2b-Pac Tech.-Spec.Document123 pages3472 Vol 2b-Pac Tech.-Spec.Satadal LahiriNo ratings yet

- Installation Manual - Coil CoolerDocument16 pagesInstallation Manual - Coil CoolerRS100% (2)

- Operating Instructions Refrigerated Air Dryers Models D-300 Through D-7500Document13 pagesOperating Instructions Refrigerated Air Dryers Models D-300 Through D-7500janessa ilaganNo ratings yet

- Technical Specifications OF Water Bouser (16 TON 150-180 HP CHASSIS)Document11 pagesTechnical Specifications OF Water Bouser (16 TON 150-180 HP CHASSIS)Naushad WadiaNo ratings yet

- 05 CHARGE AIR COOLER MaK - 9M20CDocument14 pages05 CHARGE AIR COOLER MaK - 9M20Ccamilo.provoste.manNo ratings yet

- O & M-MannualDocument29 pagesO & M-MannualHadziq NaufalNo ratings yet

- Hygienic Air Handling Unit Technical SpecificationsDocument7 pagesHygienic Air Handling Unit Technical SpecificationsMuhammad IlyasNo ratings yet

- Overview of Cooling Tower PDFDocument79 pagesOverview of Cooling Tower PDFHamid Ariz100% (2)

- Marley Fills SP-MX75 - CDocument2 pagesMarley Fills SP-MX75 - Ckkod11No ratings yet

- BSL2 and BSL3 and Certification-10Document5 pagesBSL2 and BSL3 and Certification-10dhirajsatyam98982285No ratings yet

- Enquiry - Cassete TypesDocument9 pagesEnquiry - Cassete Typesrkpatel40No ratings yet

- Solutions For Reservoir DesignDocument7 pagesSolutions For Reservoir DesignSympatyagaNo ratings yet

- SECTION 15854 Central Station Air Handling Units Part 1 - General 1.1 General RequirementsDocument7 pagesSECTION 15854 Central Station Air Handling Units Part 1 - General 1.1 General RequirementsfatREVITNo ratings yet

- Location Clearances Installation: FORM 201.21-NM1Document11 pagesLocation Clearances Installation: FORM 201.21-NM1MOHSEN KenawyNo ratings yet

- H Im 68Document12 pagesH Im 68Maria DazaNo ratings yet

- Specification of Multipurpose Fire TenderDocument8 pagesSpecification of Multipurpose Fire TenderMd SaddamNo ratings yet

- Final Sent Technical Specification 14.03.2019Document16 pagesFinal Sent Technical Specification 14.03.2019harishNo ratings yet

- PRFD - Design ManualDocument2 pagesPRFD - Design ManualSreepathy RangarajanNo ratings yet

- Module 2 LecDocument16 pagesModule 2 LecABDULLA MOHAMED AHMED JASIM ASHOORNo ratings yet

- Specification - Screw Chiller - DraftDocument8 pagesSpecification - Screw Chiller - DraftSupriya RoyNo ratings yet

- DeviDocument53 pagesDeviFire Service PondyNo ratings yet

- Revised National Plumbing Code of The Philippines 101-225Document125 pagesRevised National Plumbing Code of The Philippines 101-225Kenneth D. PacadaNo ratings yet

- Compressed Air TipsDocument16 pagesCompressed Air Tipstaghdirim100% (3)

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- ES0203-75990100-DBR-0004 - WORKING FINAl 6Document1 pageES0203-75990100-DBR-0004 - WORKING FINAl 6Anonymous vwbLPTpjNo ratings yet

- Steamblowing Procedure (1) 2Document1 pageSteamblowing Procedure (1) 2Anonymous vwbLPTpjNo ratings yet

- Steamblowing Procedure (1) 3Document1 pageSteamblowing Procedure (1) 3Anonymous vwbLPTpjNo ratings yet

- NSPCL Steamblowing Procedure (1) 4Document1 pageNSPCL Steamblowing Procedure (1) 4Anonymous vwbLPTpjNo ratings yet

- Rev 00 - Pumps 1Document1 pageRev 00 - Pumps 1Anonymous vwbLPTpjNo ratings yet

- NSPCL Steamblowing Procedure (1) 5Document1 pageNSPCL Steamblowing Procedure (1) 5Anonymous vwbLPTpjNo ratings yet

- ES0203-75990100-DBR-0004 - WORKING FINAl 5Document1 pageES0203-75990100-DBR-0004 - WORKING FINAl 5Anonymous vwbLPTpjNo ratings yet

- ES0203-75990100-DBR-0004 - WORKING FINAl 4Document1 pageES0203-75990100-DBR-0004 - WORKING FINAl 4Anonymous vwbLPTpjNo ratings yet

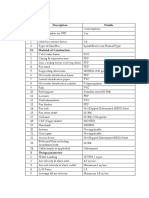

- S. No Description Value Unit Remarks Flow: 9 CTMWT Pump (Slop Cogen) Head and Flow CalculationsDocument1 pageS. No Description Value Unit Remarks Flow: 9 CTMWT Pump (Slop Cogen) Head and Flow CalculationsAnonymous vwbLPTpjNo ratings yet

- ES0203-75990100-DBR-0004 - WORKING FINAl 4Document1 pageES0203-75990100-DBR-0004 - WORKING FINAl 4Anonymous vwbLPTpjNo ratings yet

- ES0203-75990100-DBR-0004 - WORKING FINAl 5Document1 pageES0203-75990100-DBR-0004 - WORKING FINAl 5Anonymous vwbLPTpjNo ratings yet

- Technical Specification For Auxiliary Cooling Tower 5Document1 pageTechnical Specification For Auxiliary Cooling Tower 5Anonymous vwbLPTpjNo ratings yet

- S. No Description Value Unit Remarks: 10 Effluentpit - Ii Water Transfer Pump (CT Area) Head and Flow CalculationsDocument1 pageS. No Description Value Unit Remarks: 10 Effluentpit - Ii Water Transfer Pump (CT Area) Head and Flow CalculationsAnonymous vwbLPTpjNo ratings yet

- ES0203-75990100-DBR-0004 - WORKING FINAl 3Document1 pageES0203-75990100-DBR-0004 - WORKING FINAl 3Anonymous vwbLPTpjNo ratings yet

- Technical Specification For Auxiliary Cooling Tower 7 PDFDocument1 pageTechnical Specification For Auxiliary Cooling Tower 7 PDFAnonymous vwbLPTpjNo ratings yet

- S. No Spares List QTY: NotesDocument1 pageS. No Spares List QTY: NotesAnonymous vwbLPTpjNo ratings yet

- 1 MCW Pump Head and Flow Calculations: B. Sizing CalculationDocument1 page1 MCW Pump Head and Flow Calculations: B. Sizing CalculationAnonymous vwbLPTpjNo ratings yet

- 8.0 Vendor List For Major Bought Out ItemsDocument1 page8.0 Vendor List For Major Bought Out ItemsAnonymous vwbLPTpjNo ratings yet

- Es0128-75570200-Pos-0001 4Document1 pageEs0128-75570200-Pos-0001 4Anonymous vwbLPTpjNo ratings yet

- Es0128-75570200-Pos-0001 5Document1 pageEs0128-75570200-Pos-0001 5Anonymous vwbLPTpjNo ratings yet

- Technical Specification For Auxiliary Cooling Tower 6Document1 pageTechnical Specification For Auxiliary Cooling Tower 6Anonymous vwbLPTpjNo ratings yet

- Technical Specification For Auxiliary Cooling Tower 2 PDFDocument1 pageTechnical Specification For Auxiliary Cooling Tower 2 PDFAnonymous vwbLPTpjNo ratings yet

- Technical Specification For Auxiliary Cooling Tower 3 PDFDocument1 pageTechnical Specification For Auxiliary Cooling Tower 3 PDFAnonymous vwbLPTpjNo ratings yet

- S. No Spares List QTY: 10.0 Three (3) Years O & M SparesDocument1 pageS. No Spares List QTY: 10.0 Three (3) Years O & M SparesAnonymous vwbLPTpjNo ratings yet

- Technical Specification For Auxiliary Cooling TowerDocument7 pagesTechnical Specification For Auxiliary Cooling TowerAnonymous vwbLPTpj100% (2)

- Technical Specification For Auxiliary Cooling Tower 4Document1 pageTechnical Specification For Auxiliary Cooling Tower 4Anonymous vwbLPTpjNo ratings yet

- Technical Specification For Auxiliary Cooling Tower 1 PDFDocument1 pageTechnical Specification For Auxiliary Cooling Tower 1 PDFAnonymous vwbLPTpjNo ratings yet

- Pos 4 PDFDocument1 pagePos 4 PDFAnonymous vwbLPTpjNo ratings yet

- Pos 2 PDFDocument1 pagePos 2 PDFAnonymous vwbLPTpjNo ratings yet

- Tag. No 06-PSV-151: Sl. No. Description UnitDocument1 pageTag. No 06-PSV-151: Sl. No. Description UnitAnonymous vwbLPTpjNo ratings yet

- Boq - Drilling of BoreholeDocument1 pageBoq - Drilling of BoreholeAugustine BelieveNo ratings yet

- Non-Shrink Grout Application ProcedureDocument6 pagesNon-Shrink Grout Application Proceduremoytabura96No ratings yet

- Schedule of Technical Data For Water Tube BoilerDocument5 pagesSchedule of Technical Data For Water Tube BoilerMurugan MuniandyNo ratings yet

- Rr412112 Approximate Methods in Structural MechanicsDocument12 pagesRr412112 Approximate Methods in Structural MechanicsSrinivasa Rao GNo ratings yet

- To: Project: Location Labor & Materials Total Unit Cost Total Amount Item Description QTY UnitDocument18 pagesTo: Project: Location Labor & Materials Total Unit Cost Total Amount Item Description QTY UnitMarylan SalazarNo ratings yet

- Forced Draft Cooling Tower: Bachelor of TechnologyDocument9 pagesForced Draft Cooling Tower: Bachelor of TechnologySanjay NgarNo ratings yet

- Fatigue of Drillpipe: 391047887.xlsx Mitchell Engineering ProgramsDocument1 pageFatigue of Drillpipe: 391047887.xlsx Mitchell Engineering ProgramsgrabettyNo ratings yet

- 37.03.10 - Well Driller Licensing RulesDocument15 pages37.03.10 - Well Driller Licensing Rulesnick gomezNo ratings yet

- DPWH Cost Analysis PDFDocument4 pagesDPWH Cost Analysis PDFEdwin Tapit JrNo ratings yet

- SFC Catalog 2020 enDocument94 pagesSFC Catalog 2020 enதமிழன் இராமசாமிNo ratings yet

- Mechanical Drives 1 Lap 3Document77 pagesMechanical Drives 1 Lap 3j.bbarnesNo ratings yet

- Fichtner PDFDocument76 pagesFichtner PDFbacuoc.nguyen356No ratings yet

- Township Design Revised FinalDocument4 pagesTownship Design Revised FinalamityalwarNo ratings yet

- Shaliseal Ps GG: DescriptionDocument3 pagesShaliseal Ps GG: DescriptionVikas Singh ChandelNo ratings yet

- Data Sheet: Manifolds/Collectors and Hydraulic Pressure BalancersDocument4 pagesData Sheet: Manifolds/Collectors and Hydraulic Pressure BalancersHutan CatalynNo ratings yet

- CH 9 WeldingDocument18 pagesCH 9 WeldingHazim KhalilNo ratings yet

- OPI Centrifugal 4x5 Spec Sheet 2022Document1 pageOPI Centrifugal 4x5 Spec Sheet 2022Aldo Antonio Cortegana AbadNo ratings yet

- Mann Automotive Filter Stock List19052021Document3 pagesMann Automotive Filter Stock List19052021B Sathish BabuNo ratings yet

- Design A Good Road: Road Design ResourcesDocument2 pagesDesign A Good Road: Road Design ResourcesJeremiah PNo ratings yet

- Vacuum CastingDocument5 pagesVacuum CastingHarpreetSinghNo ratings yet

- ACE ACADEMY GATE Full Length Mock Test - BDocument12 pagesACE ACADEMY GATE Full Length Mock Test - BAbhilasha CIVILNo ratings yet

- lv4403 PDFDocument1 pagelv4403 PDFalvaro_arcvNo ratings yet

- Telangana State Housing Corporation Limited H# 3-6-184, STREET# 17, HIMAYATNAGAR, HYD: 500 029Document6 pagesTelangana State Housing Corporation Limited H# 3-6-184, STREET# 17, HIMAYATNAGAR, HYD: 500 029kondaNo ratings yet

- City Block in RotterdamDocument3 pagesCity Block in RotterdamDenisa BalajNo ratings yet

- BOQ Weligama PDFDocument3 pagesBOQ Weligama PDFMuhammadWazimAkramNo ratings yet

- D9R Disa and AsseDocument128 pagesD9R Disa and AsseCollins ManseloNo ratings yet

- Former Kyneton Primary School Draft Master Plan ConceptsDocument5 pagesFormer Kyneton Primary School Draft Master Plan ConceptsAnonymous TLKcJKUUWr100% (1)

- TERRAM For Pipeline and UtilitiesDocument20 pagesTERRAM For Pipeline and Utilitiessaneela bibiNo ratings yet

- Plumber or Pipe FitterDocument2 pagesPlumber or Pipe Fitterapi-76974390No ratings yet