100% found this document useful (5 votes)

6K views3 pagesPre-Shutdown Safety Planning Checklist

This document outlines a pre-planning safety checklist for a major shutdown at a site/location. It includes sections for pre-shutdown administrative planning, pre-shutdown safety planning, and safety planning for the day of the shutdown. The checklist covers reviewing work plans and procedures, ensuring proper training and qualifications for on-site workers, planning lockout/tagout procedures, acquiring necessary equipment and protective gear, and conducting pre-job meetings to review safety protocols.

Uploaded by

Abiram VSCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

100% found this document useful (5 votes)

6K views3 pagesPre-Shutdown Safety Planning Checklist

This document outlines a pre-planning safety checklist for a major shutdown at a site/location. It includes sections for pre-shutdown administrative planning, pre-shutdown safety planning, and safety planning for the day of the shutdown. The checklist covers reviewing work plans and procedures, ensuring proper training and qualifications for on-site workers, planning lockout/tagout procedures, acquiring necessary equipment and protective gear, and conducting pre-job meetings to review safety protocols.

Uploaded by

Abiram VSCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

- Pre-Shutdown Administrative Planning

- Pre-Shutdown Safety Planning

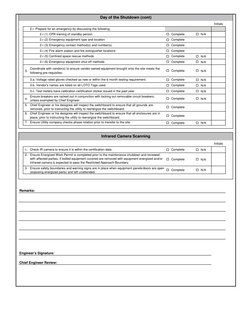

- Day of the Shutdown

- Safety Planning (cont)

- Infrared Camera Scanning