Professional Documents

Culture Documents

Handrail Railing

Uploaded by

Masiuddin AtifOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Handrail Railing

Uploaded by

Masiuddin AtifCopyright:

Available Formats

Saudi Aramco 2616-ENG (3/99) À

OPERNS.

THIS DRAWING AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL OR IN PART SHALL BE OBTAINED FROM THIS DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OWNER.

PMT

SAUDI ARAMCO OIL COMPANY

SECTION 05520

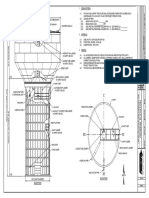

HANDRAILS RAILINGS & BOLLARD

CERT

PART 1 GENERAL

ENG’G

1.01 SECTION INCLUDES

A. Interior and exterior handrails, balustrades and railings including but not

limited to the following:-

DESCRIPTION

1. Disabled Fittings.

2. Handrails Finished as shown.

3. Balustrades as shown.

4. Fittings and Accessories.

DATE JOB/EWO

1.02 RELATED SECTIONS

A. Section 01300 Submittals.

REV.

NO.

B. Section 05510 Metal Stairs.

DISCIPLINE

ENGINEER

C. Section 08415 Interior Glass Wall Systems.

½

__ ________ _

¾ DATE: ________

PROJECT D. Section 08800 Glass and Glazing.

ENGINEER

____________

DATE E. Section 09900 Paints and Coatings: Paint finish.

CERTIFIED

1.03 REFERENCES

_ __________

DATE: ________

A. Americans with Disabilities Act Accessibility Guidelines.

CONSTRUCTION

AGENCY

________________

B. ANSI A 117.1 American National Standard for Buildings and Facilities –

DATE: Providing Accessibility and Usability for Physically Handicapped People.

OPERATIONS

______________ C. American Society for Testing and Materials (ASTM):

DATE:_________

1. ASTM A 36 M Structural Steel.

APPROVAL/CERTIFICATION REQUIREMENTS,, CONTROL NUMBER

VERIFICATION

EDSD

2. ASTM A 53 Hot-Dipped, Zinc-coated Welded and

Seamless Steel Pipe.

Date:

By:

3. ASTM A 123 Zinc (Hot-Dip Galvanized) Coatings on Iron

OF THIS DRAWING IS COVERED, FOR ALL

BY DRAWING COMPLETION CERTIFICATE

THIS INDICATES THAT REV. NO.________

(DCC) NO.: __________________________

and Steel Products.

REVISION CERTIFICATION

4. ASTM A 269 Seamless and Welded Autenistic Stainless

Steel Tubing.

SECTION 05520

CONSTRUCTION SPECIFICATIONS DWG. TYPE PLANT NO. INDEX DRAWING NO. SHT. NO. REV. NO.

KAUST TOWN CENTRE RESIDENTIAL & DOC

K55 A 1

VE-417361

. COMMUNITY SUPPORT BUILDINGS OF 00

11

RABIGH SAUDI ARABIA JOB/EWO# BI-25-00002

14-Sep-07 ¿

Saudi Aramco 2616-ENG (3/99) À

OPERNS.

THIS DRAWING AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL OR IN PART SHALL BE OBTAINED FROM THIS DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OWNER.

PMT

SAUDI ARAMCO OIL COMPANY

5. ASTM A 312M Seamless and Welded Austenitic Stainless

CERT

Steel Pipe.

ENG’G

6. ASTM A 480M General Requirements for Flat Rolled

Stainless Steel Plate, Sheet and Strip.

7. ASTM A 500 Cold-Formed Welded and Seamless

Carbon Steel Structural Tubing in Round and

DESCRIPTION

Shapes.

8. ASTM A 501 Hot-Formed Welded and Seamless

Carbon Steel Structural Tubing.

9. ASTM A 525M Galvanized Sheet Steel by Hot Dip

Process.

DATE JOB/EWO

10. ASTM E 935 Test Methods for Performance of

Permanent Metal Railing Systems and Rails for

Buildings.

REV.

NO.

11. ASTM E 985 Permanent Metal Railing Systems and

Rails for Buildings.

DISCIPLINE

ENGINEER

D. The Society for Protective Coatings (SSPC):

½

__ ________ _

¾ DATE: ________

PROJECT 1. SSPC Steel Structures Painting Manual.

ENGINEER

____________

DATE 2. SSPC Paint 20 Zinc – Rich Primers (Type I – Inorganic

CERTIFIED and Type II – Organic).

_ __________ E. National Fire Protection Association

DATE: ________

CONSTRUCTION

AGENCY

1. NFPA 101 Safety to Life from Fire in Buildings and Structures.

________________

DATE: 1.04 RELATED DOCUMENTS

OPERATIONS

______________ A. Drawings and general provisions of Contract.

DATE:_________

1.05 DESIGN REQUIREMENTS

APPROVAL/CERTIFICATION REQUIREMENTS,, CONTROL NUMBER

VERIFICATION

EDSD

A. Handrails and railing assemblies attachments and anchorages shall be

designed in accordance with the following:

Date:

By:

1. Minimum concentrated and uniformly distributed loads, for

OF THIS DRAWING IS COVERED, FOR ALL

BY DRAWING COMPLETION CERTIFICATE

THIS INDICATES THAT REV. NO.________

(DCC) NO.: __________________________

appropriate types of facilities, their point of application and

deflection criteria, as specified in ASTM E 985. Tests for

REVISION CERTIFICATION

compliance shall be in accordance with ASTM E 935.

SECTION 05520

CONSTRUCTION SPECIFICATIONS DWG. TYPE PLANT NO. INDEX DRAWING NO. SHT. NO. REV. NO.

KAUST TOWN CENTRE RESIDENTIAL & DOC

K55 A 2

VE-417361

. COMMUNITY SUPPORT BUILDINGS OF 00

11

RABIGH SAUDI ARABIA JOB/EWO# BI-25-00002

14-Sep-07 ¿

Saudi Aramco 2616-ENG (3/99) À

OPERNS.

THIS DRAWING AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL OR IN PART SHALL BE OBTAINED FROM THIS DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OWNER.

PMT

SAUDI ARAMCO OIL COMPANY

2. The maximum bending moment resulting from the application of a

concentrated load of 1.112 kN, in accordance with the

CERT

requirements of ADAAG. For bridge railings, methods prescribed

in AASHTO 1996 shall be used.

ENG’G

B. The height and configuration of handrails shall meet the requirements of

ASTM E 985, ADAAG and NFPA 101. For bridge railings, the minimum

requirement for the railing height shall be as per AASHTO 1995 unless

otherwise instructed by the Engineer.

DESCRIPTION

1.06 SUBMITTALS

A. Comply with Section 01300.

B. Shop Drawings: Indicate profiles, sizes, connection attachments,

anchorage, size and type of fasteners, and accessories.

DATE JOB/EWO

C. Samples: Submit one 300 mm long samples of handrail. Submit two

samples, of elbow Tee wall bracket escutcheon and end stop. For bridge

railing, submit one sample for each of railing post, connection brackets

and as instructed by the Engineer.

REV.

NO.

D. Submit the railing design calculations for bridge railing as per the

DISCIPLINE

ENGINEER requirements of AASHTO 1996 and as mentioned in sub-section 1.04

above.

½

__ ________ _

¾ DATE: ________

PROJECT 1.07 FIELD MEASUREMENTS

ENGINEER

____________

DATE A. Verify field measurements prior to fabrication.

CERTIFIED

1.08 MOCKUP

_ __________

DATE: ________

A. Provide mock up of each handrail and railings under provision of Section

CONSTRUCTION

AGENCY

01400.

________________

DATE: B. Construct in-situ mock-up three meter length including jointings, bonds,

OPERATIONS attachments and finishes where instructed by the Engineer.

______________

DATE:_________

C. Locate where directed.

APPROVAL/CERTIFICATION REQUIREMENTS,, CONTROL NUMBER

VERIFICATION

D. Mock up may NOT remain as part of work.

EDSD

Date:

By:

OF THIS DRAWING IS COVERED, FOR ALL

BY DRAWING COMPLETION CERTIFICATE

THIS INDICATES THAT REV. NO.________

(DCC) NO.: __________________________

REVISION CERTIFICATION

SECTION 05520

CONSTRUCTION SPECIFICATIONS DWG. TYPE PLANT NO. INDEX DRAWING NO. SHT. NO. REV. NO.

KAUST TOWN CENTRE RESIDENTIAL & DOC

K55 A 3

VE-417361

. COMMUNITY SUPPORT BUILDINGS OF 00

11

RABIGH SAUDI ARABIA JOB/EWO# BI-25-00002

14-Sep-07 ¿

Saudi Aramco 2616-ENG (3/99) À

OPERNS.

THIS DRAWING AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL OR IN PART SHALL BE OBTAINED FROM THIS DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OWNER.

PMT

SAUDI ARAMCO OIL COMPANY

PART 2 PRODUCTS

CERT

2.01 MANUFACTURERS

ENG’G

A. Available Manufacturers: Subject to compliance with requirements,

manufacturers offering products that may be incorporated into the Work

include, but are not limited to, the following:

1. Aluminum Pipe and Tube Railings:

DESCRIPTION

Alumaguard or approved and equal under Project

Manufacturers List..

Aluminum Tube Railings, Inc. or approved and equal

under Project Manufacturers List.

Architectural Art Mfg., Inc. or approved and equal under

Project Manufacturers List.

DATE JOB/EWO

Blum: Julius Blum & Co., Inc. or approved and equal

under Project Manufacturers List.

Braun: J.G. Braun Co. or approved and equal under

Project Manufacturers List.

REV.

NO.

CraneVeyor Corp. or approved and equal under Project

Manufacturers List.

DISCIPLINE

ENGINEER Substitution: Under provisions of Section 01630.

½

__ ________ _

¾ DATE: ________ 2. Stainless-Steel Pipe and Tube Railings:

PROJECT

ENGINEER

Alumaguard or approved and equal under Project

____________

DATE Manufacturers List.

CERTIFIED Architectural Art Mfg., Inc. or approved and equal under

Project Manufacturers List.

_ __________ Blum: Julius Blum & Co., Inc. or approved and equal

DATE: ________

under Project Manufacturers List.

CONSTRUCTION

AGENCY

CraneVeyor Corp. or approved and equal under Project

________________

Manufacturers List.

DATE: KDI Paragon, Inc. or approved and equal under Project

OPERATIONS Manufacturers List.

______________ Stainless Fabricators, Inc. or approved and equal under

DATE:_________

Project Manufacturers List.

Substitution: Under provisions of Section 01630.

APPROVAL/CERTIFICATION REQUIREMENTS,, CONTROL NUMBER

VERIFICATION

EDSD

3. Steel Pipe and Tube Railings:

Date:

By:

Arabian Metal Industries or approved and equal under

Project Manufacturers List.

OF THIS DRAWING IS COVERED, FOR ALL

BY DRAWING COMPLETION CERTIFICATE

THIS INDICATES THAT REV. NO.________

(DCC) NO.: __________________________

Armetal or approved and equal under Project

Manufacturers List.

REVISION CERTIFICATION

Sendan Metal Works or approved and equal under

Project Manufacturers List.

SECTION 05520

CONSTRUCTION SPECIFICATIONS DWG. TYPE PLANT NO. INDEX DRAWING NO. SHT. NO. REV. NO.

KAUST TOWN CENTRE RESIDENTIAL & DOC

K55 A 4

VE-417361

. COMMUNITY SUPPORT BUILDINGS OF 00

11

RABIGH SAUDI ARABIA JOB/EWO# BI-25-00002

14-Sep-07 ¿

Saudi Aramco 2616-ENG (3/99) À

OPERNS.

THIS DRAWING AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL OR IN PART SHALL BE OBTAINED FROM THIS DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OWNER.

PMT

SAUDI ARAMCO OIL COMPANY

Khalil Bahman Tading Est. or approved and equal under

Project Manufacturers List.

CERT

Gulf Stainless Steel or approved and equal under Project

Manufacturers List.

ENG’G

Al Muhalab Cont. & Trad. Co. or approved and equal

under Project Manufacturers List.

Substitution: Under provisions of Section 01630.

2.02 STEEL RAILING SYSTEM COMPONENTS

DESCRIPTION

A. Steel Tubing: ASTM A 500, Grade B ASTM A 501.

B. Steel Pipe: ASTM A 53, Grade B Schedule 40.

C. Stainless Steel Tubing: ASTM A 269.

D. Stainless Steel Pipe: ASTM A 312 M.

DATE JOB/EWO

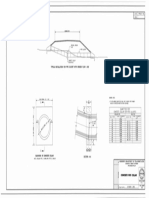

E. Rails and Posts: 50 mm diameter steel tubing pipe; welded joints.

F. Posts: 50 mm diameter steel tubing pipe; welded joints.

REV.

NO.

G. Fittings: Elbows, T-shapes, wall brackets, escutcheons; cast machined

DISCIPLINE

ENGINEER steel.

½

__ ________ _

¾ DATE: ________ H. Mounting: Adjustable brackets and flanges, for bolting to concrete and

PROJECT masonry.

ENGINEER

____________

DATE I. Exposed Fasteners: Flush countersunk screws or bolts; consistent with

CERTIFIED design of railing.

_ __________ J. Splice Connectors: Steel welding collars.

DATE: ________

CONSTRUCTION

AGENCY

K. Galvanizing: To ASTM A 123, provide minimum 360 g/sq m galvanized

________________

coating.

DATE:

OPERATIONS 1. Touch-up Primer for Galvanized Surfaces: SSPC Paint 20 Type I

______________ Inorganic zinc rich.

DATE:_________

L. Stainless Steel: To ASTM A 480; Type 304, 306.

APPROVAL/CERTIFICATION REQUIREMENTS,, CONTROL NUMBER

VERIFICATION

EDSD

M. Handrail: 50 mm diameter polished stainless steel and 38 mm diameter

stainless steel.

Date:

By:

N. Bollard: 100 mm diameter epoxy coated steel.

OF THIS DRAWING IS COVERED, FOR ALL

BY DRAWING COMPLETION CERTIFICATE

THIS INDICATES THAT REV. NO.________

(DCC) NO.: __________________________

O. Fixings: To manufacturer's detail, polished stainless steel covering where

REVISION CERTIFICATION

exposed.

SECTION 05520

CONSTRUCTION SPECIFICATIONS DWG. TYPE PLANT NO. INDEX DRAWING NO. SHT. NO. REV. NO.

KAUST TOWN CENTRE RESIDENTIAL & DOC

K55 A 5

VE-417361

. COMMUNITY SUPPORT BUILDINGS OF 00

11

RABIGH SAUDI ARABIA JOB/EWO# BI-25-00002

14-Sep-07 ¿

Saudi Aramco 2616-ENG (3/99) À

OPERNS.

THIS DRAWING AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL OR IN PART SHALL BE OBTAINED FROM THIS DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OWNER.

PMT

SAUDI ARAMCO OIL COMPANY

P. Bridge railing components: As per design submitted and approved by the

Engineer.

CERT

2.03 FABRICATION

ENG’G

A. Fit and shop assemble components in largest practical sizes for delivery

to site.

B. Fabricate components with joints tightly fitted and secured. Provide

DESCRIPTION

spigots and sleeves to accommodate site assembly and installation.

C. Provide anchors, plates angles required for connecting railings to

structure.

D. Exposed Mechanical Fastenings: Flush countersunk screws or bolts;

unobtrusively located; consistent with design of component, except

where specifically noted otherwise.

DATE JOB/EWO

E. Supply components required for anchorage of fabrications. Fabricate

anchors and related components of same material and finish as

fabrication, except where specifically noted otherwise.

REV.

NO.

F. Exterior Components: Continuously seal joined pieces by intermittent

DISCIPLINE

ENGINEER welds and plastic filler. Continuous welds. Drill condensate drainage

holes at bottom of members at locations that will not encourage water

½

__ ________ _

¾ DATE: ________ intrusion.

PROJECT

ENGINEER

G. Interior Components: Continuously seal joined pieces by intermittent

____________

DATE welds and plastic filler. Continuous welds.

CERTIFIED

H. Grind exposed joints flush and smooth with adjacent finish surface. Make

_ __________ exposed joints butt tight, flush, and hairline. Ease exposed edges to

DATE: ________

small uniform radius.

CONSTRUCTION

AGENCY

________________

I. Accurately form components to suit stairs and landings, to each other and

DATE: to building structure.

OPERATIONS

______________ J. Accommodate for expansion and contraction of members and building

DATE:_________

movement without damage to connections or members.

APPROVAL/CERTIFICATION REQUIREMENTS,, CONTROL NUMBER

VERIFICATION

K. Use factory formed bends and elbows free from necking and distortions.

EDSD

2.04 FINISHES

Date:

By:

A. GENERAL

OF THIS DRAWING IS COVERED, FOR ALL

BY DRAWING COMPLETION CERTIFICATE

THIS INDICATES THAT REV. NO.________

(DCC) NO.: __________________________

1. Comply with NAAMM's "Metal Finishes Manual for Architectural

REVISION CERTIFICATION

and Metal Products" for recommendations for applying and

designating finishes.

SECTION 05520

CONSTRUCTION SPECIFICATIONS DWG. TYPE PLANT NO. INDEX DRAWING NO. SHT. NO. REV. NO.

KAUST TOWN CENTRE RESIDENTIAL & DOC

K55 A 6

VE-417361

. COMMUNITY SUPPORT BUILDINGS OF 00

11

RABIGH SAUDI ARABIA JOB/EWO# BI-25-00002

14-Sep-07 ¿

Saudi Aramco 2616-ENG (3/99) À

OPERNS.

THIS DRAWING AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL OR IN PART SHALL BE OBTAINED FROM THIS DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OWNER.

PMT

SAUDI ARAMCO OIL COMPANY

2. Protect mechanical finishes on exposed surfaces from damage

CERT

by applying a strippable, temporary protective covering before

shipping.

ENG’G

B. ALUMINUM FINISHES

1. Finish designations prefixed by AA comply with system

DESCRIPTION

established by the Aluminum Association for designating

aluminum finishes.

2. Mechanical Finish: AA-M12 (Mechanical Finish: nonspecular

as fabricated).

3. Class I, Color Anodic Finish: AA-M12C22A42/A44 (Mechanical

Finish: nonspecular as fabricated; Chemical Finish: etched,

medium matte; Anodic Coating: Architectural Class I, integrally

colored or electrolytically deposited color coating 0.018 mm or

DATE JOB/EWO

thicker) complying with AAMA 606.1 or AAMA 608.1.

a. Color: As selected by Engineer from the full range of

industry colors and color densities.

REV.

NO.

4. Powder Coated Finish: Shall be electrostatically applied finish to

DISCIPLINE

ENGINEER AAMA 2603.; and to AAMA 2604/2605 for superdurable

electrostatically applied polyester powder coating finish; 60 - 80

½

__ ________ _

¾ DATE: ________ micron thick. Color shall be as selected and approved

PROJECT

ENGINEER

5. PVDF: Two-coat, shop-applied, high performance, Polyvinylidene

____________

DATE Fluoride coating; color as selected by the Engineer from

CERTIFIED

manufacturer’s full range of finishes.

_ __________

DATE: ________

C. STAINLESS-STEEL FINISHES

CONSTRUCTION

AGENCY

1. Remove or blend tool and die marks and stretch lines into finish.

________________

DATE: 2. Grind and polish surfaces to produce uniform, directionally

OPERATIONS textured polished finish indicated, free of cross scratches. Run

______________

grain with long dimension of each piece.

DATE:_________ 3. Bright, Directional Polish: No. 4 finish.

4. When polishing is completed, passivate and rinse surfaces.

APPROVAL/CERTIFICATION REQUIREMENTS,, CONTROL NUMBER

VERIFICATION

Remove embedded foreign matter and leave surfaces

EDSD

chemically clean.

Date:

By:

D. STEEL FINISHES

OF THIS DRAWING IS COVERED, FOR ALL

BY DRAWING COMPLETION CERTIFICATE

THIS INDICATES THAT REV. NO.________

(DCC) NO.: __________________________

1. Galvanized Handrails and Railings: Hot-dip galvanize steel and

iron handrails and railings to comply with ASTM A 123. Hot-dip

REVISION CERTIFICATION

galvanize hardware for exterior steel and iron handrails and

railings to comply with ASTM A 153/A 153M.

SECTION 05520

CONSTRUCTION SPECIFICATIONS DWG. TYPE PLANT NO. INDEX DRAWING NO. SHT. NO. REV. NO.

KAUST TOWN CENTRE RESIDENTIAL & DOC

K55 A 7

VE-417361

. COMMUNITY SUPPORT BUILDINGS OF 00

11

RABIGH SAUDI ARABIA JOB/EWO# BI-25-00002

14-Sep-07 ¿

Saudi Aramco 2616-ENG (3/99) À

OPERNS.

THIS DRAWING AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL OR IN PART SHALL BE OBTAINED FROM THIS DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OWNER.

PMT

SAUDI ARAMCO OIL COMPANY

2. Galvanizing: Hot-dip galvanize items as indicated to comply

with applicable standard listed below:

CERT

a. ASTM A 123, for galvanizing steel and iron products.

ENG’G

b. ASTM A 153/A 153M, for galvanizing steel and iron

hardware.

3. Fill vent and drain holes that will be exposed in finished Work,

unless indicated to remain as weep holes, by plugging with zinc

DESCRIPTION

solder and filing off smooth.

4. For galvanized handrails and railings, provide galvanized fittings,

brackets, fasteners, sleeves, and other ferrous components.

5. Preparation for Shop Priming: After galvanizing, thoroughly

clean handrails and railings of grease, dirt, oil, flux, and other

foreign matter, and treat with metallic-phosphate process.

6. Apply shop primer to prepared surfaces of handrail and railing

DATE JOB/EWO

components, unless otherwise indicated. Comply with

requirements in SSPC-PA 1, "Paint Application Specification

No. 1," for shop painting. Primer need not be applied to surfaces

to be embedded in concrete or masonry.

REV.

NO.

7. Baked-Enamel Finish: AA-C12C42R1x (Chemical Finish:

DISCIPLINE

ENGINEER cleaned with inhibited chemicals; Chemical Finish: acid-

chromate-fluoride-phosphate conversion coating; Organic

½

__ ________ _

¾ DATE: ________ Coating: as specified below). Apply baked enamel complying

PROJECT with paint manufacturer's specifications for cleaning, conversion

ENGINEER

coating, and painting.

____________

DATE

CERTIFIED Organic Coating: Thermosetting, modified-acrylic

enamel primer/topcoat system complying with

_ __________ AAMA 603.8 except with a minimum dry film thickness of

DATE: ________

1.5 mils (0.04 mm), medium gloss.

CONSTRUCTION

AGENCY

________________

Color: As selected by Engineer from manufacturer's full

DATE: range.

OPERATIONS

______________ PART 3 EXECUTION

DATE:_________

3.01 EXAMINATION

APPROVAL/CERTIFICATION REQUIREMENTS,, CONTROL NUMBER

VERIFICATION

EDSD

A. Examine plaster and gypsum board assemblies, where reinforced to

receive anchors, to verify that locations of concealed reinforcements

Date:

By:

have been clearly marked for Installer. Locate reinforcements and mark

locations if not already done.

OF THIS DRAWING IS COVERED, FOR ALL

BY DRAWING COMPLETION CERTIFICATE

THIS INDICATES THAT REV. NO.________

(DCC) NO.: __________________________

3.02 INSTALLATION, GENERAL

REVISION CERTIFICATION

A. Fit exposed connections together to form tight, hairline joints.

SECTION 05520

CONSTRUCTION SPECIFICATIONS DWG. TYPE PLANT NO. INDEX DRAWING NO. SHT. NO. REV. NO.

KAUST TOWN CENTRE RESIDENTIAL & DOC

K55 A 8

VE-417361

. COMMUNITY SUPPORT BUILDINGS OF 00

11

RABIGH SAUDI ARABIA JOB/EWO# BI-25-00002

14-Sep-07 ¿

Saudi Aramco 2616-ENG (3/99) À

OPERNS.

THIS DRAWING AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL OR IN PART SHALL BE OBTAINED FROM THIS DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OWNER.

PMT

SAUDI ARAMCO OIL COMPANY

B. Perform cutting, drilling, and fitting required to install handrails and

CERT

railings. Set handrails and railings accurately in location, alignment,

and elevation; measured from established lines and levels and free from

ENG’G

rack.

1. Do not weld, cut, or abrade surfaces of handrail and railing

components that have been coated or finished after fabrication

and that are intended for field connection by mechanical or other

DESCRIPTION

means without further cutting or fitting.

2. Set posts plumb within a tolerance of 1/16 inch in 3 feet (2 mm

in 1 m).

3. Align rails so variations from level for horizontal members and

from parallel with rake of steps and ramps for sloping members

do not exceed 1/4 inch in 12 feet (5 mm in 3 m).

DATE JOB/EWO

C. Corrosion Protection: Coat concealed surfaces of aluminum that will be

in contact with grout, concrete, masonry, wood, or dissimilar metals with

a heavy coat of bituminous paint.

REV.

NO.

D. Adjust handrails and railings before anchoring to ensure matching

DISCIPLINE

ENGINEER alignment at abutting joints. Space posts at interval indicated, but not

less than that required by structural loads.

½

__ ________ _

¾ DATE: ________

PROJECT E. Fastening to In-Place Construction: Use anchorage devices and

ENGINEER

fasteners where necessary for securing handrails and railings and for

____________

DATE properly transferring loads to in-place construction.

CERTIFIED

3.03 RAILING CONNECTIONS

_ __________

DATE: ________

A. Nonwelded Connections: Use mechanical or adhesive joints for

CONSTRUCTION

AGENCY

permanently connecting railing components. Use wood blocks and

________________

padding to prevent damage to railing members and fittings. Seal

DATE: recessed holes of exposed locking screws using plastic cement filler

OPERATIONS colored to match finish of handrails and railings.

______________

DATE:_________

B. Welded Connections: Use fully welded joints for permanently

connecting railing components. Comply with requirements for

APPROVAL/CERTIFICATION REQUIREMENTS,, CONTROL NUMBER

VERIFICATION

welded connections in "Fabrication" Article whether welding is

EDSD

performed in the shop or in the field.

Date:

By:

C. Expansion Joints: Install expansion joints at locations indicated but not

farther apart than required to accommodate thermal movement. Provide

OF THIS DRAWING IS COVERED, FOR ALL

BY DRAWING COMPLETION CERTIFICATE

THIS INDICATES THAT REV. NO.________

(DCC) NO.: __________________________

slip-joint internal sleeve extending 2 inches (50 mm) beyond joint on

either side, fasten internal sleeve securely to one side, and locate joint

REVISION CERTIFICATION

within 6 inches (150 mm) of post.

SECTION 05520

CONSTRUCTION SPECIFICATIONS DWG. TYPE PLANT NO. INDEX DRAWING NO. SHT. NO. REV. NO.

KAUST TOWN CENTRE RESIDENTIAL & DOC

K55 A 9

VE-417361

. COMMUNITY SUPPORT BUILDINGS OF 00

11

RABIGH SAUDI ARABIA JOB/EWO# BI-25-00002

14-Sep-07 ¿

Saudi Aramco 2616-ENG (3/99) À

OPERNS.

THIS DRAWING AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL OR IN PART SHALL BE OBTAINED FROM THIS DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OWNER.

PMT

SAUDI ARAMCO OIL COMPANY

3.04 ANCHORING POSTS

CERT

A. Use steel pipe sleeves preset and anchored into concrete for installing

posts. After posts have been inserted into sleeves, fill annular space

ENG’G

between post and sleeve with the following anchoring material, mixed

and placed to comply with anchoring material manufacturer's written

instructions:

1. Nonshrink, nonmetallic grout.

DESCRIPTION

B. Cover anchorage joint with flange of same metal as post, attached to

post as follows:

2. By set screws.

C. Leave anchorage joint exposed; wipe off surplus anchoring material;

and leave 1/8-inch (3-mm) build-up, sloped away from post.

DATE JOB/EWO

Anchor posts to metal surfaces with oval flanges, angle type, or floor

type as required by conditions, connected to posts and to metal

supporting members as follows:

REV.

NO.

For aluminum pipe railings, attach posts as indicated using

DISCIPLINE

ENGINEER fittings designed and engineered for this purpose.

For stainless-steel pipe railings, weld flanges to post and bolt to

½

__ ________ _

¾ DATE: ________ metal supporting surfaces.

PROJECT 3. For steel pipe railings, weld flanges to post and bolt to metal

ENGINEER

supporting surfaces.

____________

DATE

CERTIFIED Install removable railing sections, where indicated, in slip-fit metal

sockets cast in concrete.

_ __________

DATE: ________

3.05 ANCHORING RAILING ENDS

CONSTRUCTION

AGENCY

________________

A. Anchor railing ends into concrete and masonry with round flanges

DATE: connected to railing ends and anchored into wall construction with

OPERATIONS postinstalled anchors and bolts.

______________

DATE:_________

B. Anchor railing ends to metal surfaces with flanges bolted to metal

surfaces.

APPROVAL/CERTIFICATION REQUIREMENTS,, CONTROL NUMBER

VERIFICATION

EDSD

4. Connect flanges to railing ends using nonwelded connections.

Date:

By:

3.06 ATTACHING HANDRAILS TO WALLS

OF THIS DRAWING IS COVERED, FOR ALL

BY DRAWING COMPLETION CERTIFICATE

THIS INDICATES THAT REV. NO.________

(DCC) NO.: __________________________

A. Attach handrails to wall with wall brackets. Provide bracket with 1-1/2-

REVISION CERTIFICATION

inch (38-mm) clearance from inside face of handrail and finished wall

surface.

SECTION 05520

CONSTRUCTION SPECIFICATIONS DWG. TYPE PLANT NO. INDEX DRAWING NO. SHT. NO. REV. NO.

KAUST TOWN CENTRE RESIDENTIAL & DOC

K55 A 10

VE-417361

. COMMUNITY SUPPORT BUILDINGS OF 00

11

RABIGH SAUDI ARABIA JOB/EWO# BI-25-00002

14-Sep-07 ¿

Saudi Aramco 2616-ENG (3/99) À

OPERNS.

THIS DRAWING AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL OR IN PART SHALL BE OBTAINED FROM THIS DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OWNER.

PMT

SAUDI ARAMCO OIL COMPANY

B. Locate brackets as indicated or, if not indicated, at spacing required to

CERT

support structural loads.

ENG’G

D. Secure wall brackets to building construction as follows:

1. For concrete and solid masonry anchorage, use drilled-in

expansion shields and hanger or lag bolts.

2. For hollow masonry anchorage, use toggle bolts.

DESCRIPTION

3. For wood stud partitions, use hanger or lag bolts set into wood

backing between studs. Coordinate with carpentry work to

locate backing members.

4. For steel-framed gypsum board assemblies, use hanger or lag

bolts set into wood backing between studs. Coordinate with

stud installation to locate backing members.

3.07 CLEANING

DATE JOB/EWO

A. Clean aluminum and stainless steel by washing thoroughly with clean

water and soap and rinsing with clean water.

REV.

NO.

B. Touchup Painting: Immediately after erection, clean field welds, bolted

connections, and abraded areas of shop paint, and paint exposed areas

DISCIPLINE

ENGINEER with same material.

½

__ ________ _

¾ DATE: ________ C. Galvanized Surfaces: Clean field welds, bolted connections, and

PROJECT abraded areas and repair galvanizing to comply with ASTM A 780.

ENGINEER

____________

DATE 3.08 PROTECTION

CERTIFIED

A. Protect finishes of handrails and railings from damage during

_ __________ construction period with temporary protective coverings approved by

DATE: ________

railing manufacturer. Remove protective coverings at the time of

CONSTRUCTION

AGENCY

Substantial Completion.

________________

DATE: B. Restore finishes damaged during installation and construction period so

OPERATIONS no evidence remains of correction work. Return items that cannot be

______________ refinished in the field to the shop; make required alterations and refinish

DATE:_________

entire unit, or provide new units.

APPROVAL/CERTIFICATION REQUIREMENTS,, CONTROL NUMBER

VERIFICATION

END OF SECTION 05520

EDSD

Date:

By:

OF THIS DRAWING IS COVERED, FOR ALL

BY DRAWING COMPLETION CERTIFICATE

THIS INDICATES THAT REV. NO.________

(DCC) NO.: __________________________

REVISION CERTIFICATION

SECTION 05520

CONSTRUCTION SPECIFICATIONS DWG. TYPE PLANT NO. INDEX DRAWING NO. SHT. NO. REV. NO.

KAUST TOWN CENTRE RESIDENTIAL & DOC

K55 A 11

VE-417361

. COMMUNITY SUPPORT BUILDINGS OF 00

11

RABIGH SAUDI ARABIA JOB/EWO# BI-25-00002

14-Sep-07 ¿

You might also like

- Saudi Aramco Oil Company: SECTION 05520 Handrails Railings & Bollard Part 1 GeneralDocument12 pagesSaudi Aramco Oil Company: SECTION 05520 Handrails Railings & Bollard Part 1 GeneralAbid HussainNo ratings yet

- Saudi Aramco Oil Company: SECTION 05050 Metal Fastenings Part 1 GeneralDocument10 pagesSaudi Aramco Oil Company: SECTION 05050 Metal Fastenings Part 1 GeneralAbid HussainNo ratings yet

- Saudi Aramco Oil Company: SECTION 07820 Skylights Part 01 - General 1.01 Section IncludesDocument8 pagesSaudi Aramco Oil Company: SECTION 07820 Skylights Part 01 - General 1.01 Section Includessaneela bibiNo ratings yet

- Saudi Aramco Oil Company: SECTION 08111 Metal Frames Part 1 - General 1.01 Section IncludesDocument7 pagesSaudi Aramco Oil Company: SECTION 08111 Metal Frames Part 1 - General 1.01 Section Includessaneela bibiNo ratings yet

- Saudi Aramco Oil Company: SECTION 08100 Metal DoorsDocument9 pagesSaudi Aramco Oil Company: SECTION 08100 Metal Doorssaneela bibiNo ratings yet

- Saudi Aramco Oil Company: SECTION 07620 Sheet Metal Flashing and TrimDocument4 pagesSaudi Aramco Oil Company: SECTION 07620 Sheet Metal Flashing and Trimsaneela bibiNo ratings yet

- Mortar & Masonry GroutDocument7 pagesMortar & Masonry GroutTito GarciaNo ratings yet

- Reinforced Masonry Unit SystemDocument12 pagesReinforced Masonry Unit SystemTito GarciaNo ratings yet

- Saudi Aramco Oil Company: SECTION 03200Document6 pagesSaudi Aramco Oil Company: SECTION 03200saneela bibiNo ratings yet

- SECTION 07720 Roof Accessories Rev 0Document22 pagesSECTION 07720 Roof Accessories Rev 0Azhar AliNo ratings yet

- Handrail RailingDocument11 pagesHandrail RailingphilipyapNo ratings yet

- Unit MasonryDocument14 pagesUnit MasonryTito GarciaNo ratings yet

- Saudi Aramco Oil Company: SECTION 07920 Sealants and CaulkingDocument8 pagesSaudi Aramco Oil Company: SECTION 07920 Sealants and Caulkingsaneela bibiNo ratings yet

- Saudi Aramco Oil Company: SECTION 03300 Cast-In-Place Concrete Part 1 - General 1.01 Section IncludesDocument13 pagesSaudi Aramco Oil Company: SECTION 03300 Cast-In-Place Concrete Part 1 - General 1.01 Section Includessaneela bibiNo ratings yet

- SECTION 10115 Markerboards Rev 0Document15 pagesSECTION 10115 Markerboards Rev 0NabzNo ratings yet

- SECTION 10110 Chalkboards Rev 0Document12 pagesSECTION 10110 Chalkboards Rev 0NabzNo ratings yet

- Specifications - Aluminum, Glazing, Metal - Part-02Document28 pagesSpecifications - Aluminum, Glazing, Metal - Part-02omar ayeshNo ratings yet

- Saudi Aramco Oil Company: SECTION 03210 Epoxy Coated Concrete ReinforcementDocument8 pagesSaudi Aramco Oil Company: SECTION 03210 Epoxy Coated Concrete Reinforcementsaneela bibiNo ratings yet

- 2500 SpecificationDocument5 pages2500 SpecificationMelissa ArandaNo ratings yet

- SECTION 10 28 00 Toilet, Bath, and Laundry AccessoriesDocument17 pagesSECTION 10 28 00 Toilet, Bath, and Laundry AccessoriesClarice Delos ReyesNo ratings yet

- SECTION 02820 Fences and Gates Rev 0Document41 pagesSECTION 02820 Fences and Gates Rev 0Abdul HannanNo ratings yet

- SECTION 16130 Raceway and Boxes Rev 0Document19 pagesSECTION 16130 Raceway and Boxes Rev 0Ahmed HashimNo ratings yet

- Saudi Aramco Oil Company: SECTION 03100Document9 pagesSaudi Aramco Oil Company: SECTION 03100saneela bibiNo ratings yet

- SECTION 02891 Traffic Signs Rev 0Document37 pagesSECTION 02891 Traffic Signs Rev 0Azhar Ali100% (1)

- 1500m CompositeDocument1 page1500m Compositekheang mengNo ratings yet

- GRATINGS Rev.1Document7 pagesGRATINGS Rev.1mohdNo ratings yet

- Section 07 4000 - Metal Panel SystemDocument20 pagesSection 07 4000 - Metal Panel SystemMuhammad AbuBakarNo ratings yet

- SECTION 10350 Flagpoles Rev 0Document13 pagesSECTION 10350 Flagpoles Rev 0NabzNo ratings yet

- CompositeJoistStandardSpecifications PDFDocument8 pagesCompositeJoistStandardSpecifications PDFcorrokokoNo ratings yet

- Handrails and Railings Picket BalustersDocument11 pagesHandrails and Railings Picket Balusterspraveen0907No ratings yet

- Division 5Document15 pagesDivision 5hari banggaNo ratings yet

- SECTION 16510 Interior Luminaires Rev 0Document23 pagesSECTION 16510 Interior Luminaires Rev 0Ahmed HashimNo ratings yet

- Saudi Aramco Oil Company: SECTION 07724 Roof Hatches Part 1 - General 1.01 Section IncludesDocument3 pagesSaudi Aramco Oil Company: SECTION 07724 Roof Hatches Part 1 - General 1.01 Section Includessaneela bibiNo ratings yet

- 400m Toro EllipsoidalDocument1 page400m Toro EllipsoidalJorge León IllanesNo ratings yet

- SECTION 05 36 00 Composite Metal DeckingDocument9 pagesSECTION 05 36 00 Composite Metal DeckingJuanPaoloYbañezNo ratings yet

- Handrail & PlatformDocument58 pagesHandrail & Platformvhung TranNo ratings yet

- SECTION 05 12 00 Structural Steel FramingDocument9 pagesSECTION 05 12 00 Structural Steel FramingJuanPaoloYbañezNo ratings yet

- SECTION 08 90 00 Louvers and VentsDocument10 pagesSECTION 08 90 00 Louvers and VentsJuanPaoloYbañezNo ratings yet

- Section 02651 - Steel Pipe, Lined and Coated City of San Diego, CWP GuidelinesDocument23 pagesSection 02651 - Steel Pipe, Lined and Coated City of San Diego, CWP GuidelinesMohammed HarrisNo ratings yet

- SpecsDocument34 pagesSpecsAhmed GhariebNo ratings yet

- Structural Steel ErectionDocument8 pagesStructural Steel ErectionMiguel A. CondeNo ratings yet

- SECTION 05 50 00 Metal Fabrications Spec Writer NoteDocument35 pagesSECTION 05 50 00 Metal Fabrications Spec Writer NoteJuanPaoloYbañezNo ratings yet

- Hy Safe Fab Posts and Tie Backs With SpecificsDocument4 pagesHy Safe Fab Posts and Tie Backs With SpecificsabheypriyaNo ratings yet

- Va 05 36 00Document9 pagesVa 05 36 00Tâm TrầnNo ratings yet

- SECTION 09960 High-Performance Coatings Rev 0Document48 pagesSECTION 09960 High-Performance Coatings Rev 0rachedNo ratings yet

- Section 05500 Metal FabricationsDocument7 pagesSection 05500 Metal FabricationsMØhãmmed ØwięsNo ratings yet

- Concrete Driven PilesDocument11 pagesConcrete Driven PilesAmalNo ratings yet

- SECTION 07 71 00 Roof SpecialtiesDocument12 pagesSECTION 07 71 00 Roof SpecialtiesJuanPaoloYbañezNo ratings yet

- ETFE SINGLE FILM SYSTEM SpecDocument18 pagesETFE SINGLE FILM SYSTEM SpecM. Murat ErginNo ratings yet

- Metal Stairs and LaddersDocument7 pagesMetal Stairs and Laddersrizkboss8312No ratings yet

- 09 22 16.13mbaDocument11 pages09 22 16.13mbaHanamanthNo ratings yet

- BS 1139 Scaffold TubeDocument8 pagesBS 1139 Scaffold TubeTito GarciaNo ratings yet

- Staff HousingDocument5 pagesStaff HousingSyed AliNo ratings yet

- Material Submittal HANDRAILDocument6 pagesMaterial Submittal HANDRAILManu Mohan0% (1)

- Building No. SC#Document7 pagesBuilding No. SC#ephremNo ratings yet

- 8430 Entrances&StorefrontsDocument3 pages8430 Entrances&Storefrontsiwd_smNo ratings yet

- This Product Masterspec Section Modifies The Original Masterspec Text and Does Not Include The Full Content of The Original Masterspec SectionDocument13 pagesThis Product Masterspec Section Modifies The Original Masterspec Text and Does Not Include The Full Content of The Original Masterspec SectionEltonNo ratings yet

- 60 41 Ab SPC 00002Document39 pages60 41 Ab SPC 00002Vineet RungtaNo ratings yet

- SECTION 07 72 00 Roof AccessoriesDocument8 pagesSECTION 07 72 00 Roof AccessoriesJuanPaoloYbañezNo ratings yet

- Brittle Fracture in Steel StructuresFrom EverandBrittle Fracture in Steel StructuresG.M. BoydNo ratings yet

- Review On Feasibility of Bamboo in ModerDocument5 pagesReview On Feasibility of Bamboo in ModerEg EdNo ratings yet

- Secretary For Development Distribution DEVB (W) 516/71/01 3509 8385 2524 9308 29 September 2017 3 + EnclDocument85 pagesSecretary For Development Distribution DEVB (W) 516/71/01 3509 8385 2524 9308 29 September 2017 3 + EnclJacky_LEOLEONo ratings yet

- Efaz Et Al 2022 Combined Load Test and Nde Novel Method To Diagnose and Load Rate Prestressed Concrete Girder BridgesDocument16 pagesEfaz Et Al 2022 Combined Load Test and Nde Novel Method To Diagnose and Load Rate Prestressed Concrete Girder BridgesTONY VILCHEZ YARIHUAMANNo ratings yet

- Iapex PresDocument19 pagesIapex PresAamirSaghirNo ratings yet

- Installation Instructions: DB M 1 150 (FM)Document2 pagesInstallation Instructions: DB M 1 150 (FM)Irving GuatemalaNo ratings yet

- CementDocument21 pagesCementTHE BEST GAMERNo ratings yet

- Pengusaha Kuari Malaysia Bagi Tahun 2019Document27 pagesPengusaha Kuari Malaysia Bagi Tahun 2019Friendly LondonNo ratings yet

- Industry Standard (Vic), Precast and Tilt-Up Concrete For BuildingsDocument87 pagesIndustry Standard (Vic), Precast and Tilt-Up Concrete For BuildingsAbdullah NafiNo ratings yet

- Upright: Bussman Alphabetical Table of ContentsDocument26 pagesUpright: Bussman Alphabetical Table of Contentsluis tocoraNo ratings yet

- 2005-10-DIAVIK Mine A418 - Dike Techical Reference SheetDocument2 pages2005-10-DIAVIK Mine A418 - Dike Techical Reference SheetSalvatore MirandaNo ratings yet

- Historic Masonry StructuresDocument155 pagesHistoric Masonry Structuresp jNo ratings yet

- Irjet - Effect of Addition of Crumb Rubbe PDFDocument5 pagesIrjet - Effect of Addition of Crumb Rubbe PDFKlisman A. Flores DurandNo ratings yet

- 32 322 Dc2 Groheminta™ Single-Lever Sink Mixer 1/2": Product DescriptionDocument2 pages32 322 Dc2 Groheminta™ Single-Lever Sink Mixer 1/2": Product DescriptionCesar Alfredo TrejoNo ratings yet

- Bisaya Fire Safety Prevention TipsDocument1 pageBisaya Fire Safety Prevention Tipsmar cor67% (3)

- Mechanical Characteristics of Pumice Stone As Light Weight Aggregate in ConcreteDocument3 pagesMechanical Characteristics of Pumice Stone As Light Weight Aggregate in ConcreteFrances GalangNo ratings yet

- ST7016 Prefabricated StructuresDocument128 pagesST7016 Prefabricated Structurescse udtNo ratings yet

- Types of Bricks - Detail Classification of Bricks - Civil EngineeringDocument6 pagesTypes of Bricks - Detail Classification of Bricks - Civil EngineeringPrajith AdNo ratings yet

- Projection: Figure 1:the Six Principal ViewsDocument12 pagesProjection: Figure 1:the Six Principal ViewsetilaNo ratings yet

- Highway and Railway Engineering IntroductionDocument19 pagesHighway and Railway Engineering IntroductionMichael Martinez MercolitaNo ratings yet

- Dha Multan Study TourDocument9 pagesDha Multan Study TourSAADULLAH malikNo ratings yet

- FR2 SoS For BIM Modelling (GBC Engineering) P01Document10 pagesFR2 SoS For BIM Modelling (GBC Engineering) P01ramatchatNo ratings yet

- Provisional Sum and Prime Cost ItemsDocument4 pagesProvisional Sum and Prime Cost Itemsizyan_zulaikha100% (2)

- Technical Drawing Worksheet: Teacher: Mrs. Di SclafaniDocument4 pagesTechnical Drawing Worksheet: Teacher: Mrs. Di SclafaniEarl Caesar100% (1)

- TNR Lifts-G+3, MRL, Collapsible Gates - V Raja SwamyDocument8 pagesTNR Lifts-G+3, MRL, Collapsible Gates - V Raja SwamytnrgenuineNo ratings yet

- 2016 Moffatt&Nichol SouthTerminalEngineeringReDocument48 pages2016 Moffatt&Nichol SouthTerminalEngineeringReran2315570No ratings yet

- Structural Calc Analysis of in Patient BLDG Facade Rev003Document67 pagesStructural Calc Analysis of in Patient BLDG Facade Rev003عزة الإسلامNo ratings yet

- Eta-20 0728Document24 pagesEta-20 0728Tom YeeNo ratings yet

- Jabas, Aaron Qarl M.: ObjectivesDocument2 pagesJabas, Aaron Qarl M.: ObjectivesRome GalosoNo ratings yet

- Resident Engineering ServicesDocument13 pagesResident Engineering ServicesjuhiNo ratings yet

- Concrete Collar For Pipe Culverts: Typical Installation For Pipe Culvert With Broken Flow LineDocument1 pageConcrete Collar For Pipe Culverts: Typical Installation For Pipe Culvert With Broken Flow LineTumulak IanNo ratings yet