Professional Documents

Culture Documents

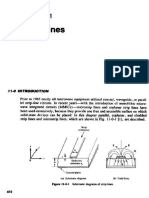

0 1 2 Raffreddamento R9: Jacketed Vessel Heat Transfer 223 XX

Uploaded by

Phượng Nguyễn0 ratings0% found this document useful (0 votes)

15 views1 pageOriginal Title

RP-AG-Heat Calculate-30rpm-1

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

15 views1 page0 1 2 Raffreddamento R9: Jacketed Vessel Heat Transfer 223 XX

Uploaded by

Phượng NguyễnCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

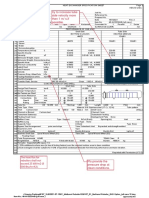

JACKETED VESSEL HEAT TRANSFER

CLIENT EQUIP. NO PAGE

223 xx

REV PREPARED BY DATE APPROVAL W.O. REQUISITION NO. SPECIFICATION NO.

0 AV Jan-06-21 xx

1 UNIT AREA PROCURED BY INSTALLED BY

2 R9 xx

RAFFREDDAMENTO R9

1 Vessel Data

2 Orientation vertical, cylindrical Contents Chili sauce

3 Total working volume 1,500 liters Bulk Temperature 45 °C

4 Inside diameter 1250 millimeters Thermal Conductivity 2.30 W/m-°C

5 Tangent-to-tangent 1150 millimeters Specific Heat 2,130 joules/kg-°C

6 Heads ASME Torispherical Dished Density 1.12 g/cc

7 Material of construction 316 SS Viscosity 35.00000 Pa-sec

8 Thickness 4 millimeters

9 Lining None 34.26015 Pa-sec

10 Thickness 0 millimeters

11 Internal surface roughness 0.0013 millimeters Agitator Type Helical Ribbon

12 Outside surface roughness 0.1778 millimeters Impeller Diameter 1160 millimeters

13 Internal fouling factor 0 m²-°C/W Speed 30 rpm

14 Outside fouling factor (jacket) 9E-05 m²-°C/W

15 Vessel is baffled

16 Jacket Fluid

17 Method for determining flow rate in jacket or coil: Fluid Name Steam

18 Specified Flowrate Pressure, absolute 400 kPa

19 Value 100000 liters/min Thermal Conductivity 0.03 W/m-°C

20 Flow computed for single sidewall zone used for bttm jacket Latent Heat of Vap 2,140 kJ/kg

21 Steam Density 0.00 g/cc

22 Viscosity 0.00001 Pa-sec

23

24 Prandtl Number 1.07 dimensionless

25

26 Jacket and Coil Data

27 Sidewall Jacket Type Dimple Annular space: 5.00 millimeters; 2 zones

28 89.5 millimeters diameter dimples; square pitch; 89.0 x 90.0 millimeters spacing

29 Bottom Jacket Type Dimple Annular space: 5.00 millimeters; piped in series with sidewall

30 89.5 millimeters diameter dimples; square pitch; 89.0 x 90.0 millimeters spacing

31 Internal Coil Type No Coil

32

33

34 Calculated Results

35 Heat Transfer Coefficients hi hw ho Overall U

36 From Vessel to Sidewall Jacket 366 4,181 5,110 307 W/m²-°C

37 From Vessel to Bottom Jacket 366 4,181 5,110 307 W/m²-°C

38 From Vessel to Coil -- -- -- -- W/m²-°C

39

40 Fluid Flow Flow Rate Velocity Pressure Drop

41 Sidewall Jacket (each zone) 110.0 kg/hr 5,981.8 m/sec ######## kPa

42 Sidewall Jacket (combined) 220.0 kg/hr 5,981.8 m/sec ######## kPa

43 Bottom Jacket (in series with sidewall) 61.4 kg/hr 3,335.9 m/sec 46,106.1 kPa

44 Internal Coil -- kg/hr -- m/sec -- kPa

45

46 Temperature Effects Inlet Outlet Heat Transferred

47 Sidewall Jacket 141.4 141.4 °C 130,265 W

48 Bottom Jacket 141.4 141.4 °C 36,323 W

49 Internal Coil -- -- °C -- W

50 Vessel Contents 45.0 °C 166,588 W

51 Vessel contents will heat at a rate of 2.80 °C/minute

52 NOTE: Pressure Drop calculation for dimple jacket is imprecise; consult manufacturer

You might also like

- Handbook of Heating, Ventilating and Air ConditioningFrom EverandHandbook of Heating, Ventilating and Air ConditioningRating: 4 out of 5 stars4/5 (6)

- Iq, Oq, PQ, DQDocument17 pagesIq, Oq, PQ, DQsiruslara649167% (3)

- Chiller Data SheetDocument3 pagesChiller Data SheetMoriyasuNguyenNo ratings yet

- 1000TR Entravac Centrifugal Chiller Product ReportDocument2 pages1000TR Entravac Centrifugal Chiller Product ReportEdwin CalpitoNo ratings yet

- Heat Transfer in Jacketed Vessels: Customary US SIDocument60 pagesHeat Transfer in Jacketed Vessels: Customary US SIDHAVALESH AMNo ratings yet

- Condensate Water Tank Data Sheet (1000 m3)Document13 pagesCondensate Water Tank Data Sheet (1000 m3)GunturMudaAliAkbarNo ratings yet

- Jacketed Vessel Heat Transfer (Half Pipe Coil) : MM Inch MM RPM MM M /HDocument30 pagesJacketed Vessel Heat Transfer (Half Pipe Coil) : MM Inch MM RPM MM M /Hmanoj67% (3)

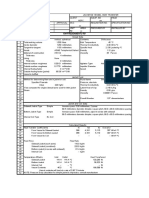

- Technical Data Sheet For Shell and Tube Heat Exchager Design SpecificationDocument5 pagesTechnical Data Sheet For Shell and Tube Heat Exchager Design SpecificationSakthi VelNo ratings yet

- Condenser 7.5 (RATING)Document1 pageCondenser 7.5 (RATING)Madelyn BelbesNo ratings yet

- VG 320 Oil CoolerDocument32 pagesVG 320 Oil CoolergsdaundhNo ratings yet

- Heat Exchanger Specification Sheet SI 2 Units: D:/HE/PLN/SHE - HtriDocument1 pageHeat Exchanger Specification Sheet SI 2 Units: D:/HE/PLN/SHE - HtrivikzefgNo ratings yet

- Shell&Tube TEMAsheet 1Document1 pageShell&Tube TEMAsheet 1Rikiya FebriyanNo ratings yet

- Steam HXDocument1 pageSteam HXrajachemNo ratings yet

- VSEP-Calc: Vertical Gas/Liquid Separator Design Calculations (2 Phase)Document7 pagesVSEP-Calc: Vertical Gas/Liquid Separator Design Calculations (2 Phase)rudi 010% (1)

- Pressurisation and Depressurization ResultsDocument8 pagesPressurisation and Depressurization ResultsQayyum KhanNo ratings yet

- TankJkt ExampleDocument16 pagesTankJkt ExamplesioanniNo ratings yet

- SQ8167 - 01 - Methanol Reboiler - BKU Option - (Alt Case 10 Deg Approach) .HTRI 6th Aug 21-CmtdDocument4 pagesSQ8167 - 01 - Methanol Reboiler - BKU Option - (Alt Case 10 Deg Approach) .HTRI 6th Aug 21-CmtdSRINo ratings yet

- Iso 178Document19 pagesIso 178Chris Kořán100% (1)

- Atmospheric Tank Loadsheet AnalysisDocument13 pagesAtmospheric Tank Loadsheet AnalysisGunturMudaAliAkbar100% (1)

- Half Pipe Coil AgitatedDocument1 pageHalf Pipe Coil AgitatedNITINNo ratings yet

- TEMA Spec SheetDocument1 pageTEMA Spec SheetvikzefgNo ratings yet

- SQ8167 - 01 - Methanol Reboiler - BKU Option - (Alt Case 10 Deg Approach) .HTRI 6th Aug 21Document4 pagesSQ8167 - 01 - Methanol Reboiler - BKU Option - (Alt Case 10 Deg Approach) .HTRI 6th Aug 21SRINo ratings yet

- Heat Exchanger - Preliminary Data SheetDocument4 pagesHeat Exchanger - Preliminary Data SheetgksakthiNo ratings yet

- Jacketed vessel heat transfer analysisDocument2 pagesJacketed vessel heat transfer analysisPhượng NguyễnNo ratings yet

- Tankjkt (Reparado)Document93 pagesTankjkt (Reparado)carlos batistaNo ratings yet

- Air Heater Process Data Sheet: Design Conditions Shell SideDocument4 pagesAir Heater Process Data Sheet: Design Conditions Shell SideAnonymous tDeb8M0SyNo ratings yet

- Heat exchanger specification sheetDocument1 pageHeat exchanger specification sheetSonya LoveraNo ratings yet

- CRF214 - 5 - 40 TR at 7°C - R134a - WATER COOLED SCREW WATER CHILLER - CONDENSERDocument1 pageCRF214 - 5 - 40 TR at 7°C - R134a - WATER COOLED SCREW WATER CHILLER - CONDENSERkartikkhatri1188No ratings yet

- EXCHANGER SPECIFICATION SHEET Hoja EspecificacionesDocument2 pagesEXCHANGER SPECIFICATION SHEET Hoja EspecificacionesDaniel SalasNo ratings yet

- CH-RA3 Page 1Document1 pageCH-RA3 Page 1Sonya LoveraNo ratings yet

- A307 Ius Uv DS 1201Document2 pagesA307 Ius Uv DS 1201smartravi222No ratings yet

- NSDocument1 pageNSXemtintuc Xem TinNo ratings yet

- A307 Ius FV DS 1311Document2 pagesA307 Ius FV DS 1311Ravi KumarNo ratings yet

- Heat exchanger specification sheetDocument2 pagesHeat exchanger specification sheetDycka Anugerah PuryantoroNo ratings yet

- PHL 1000Document4 pagesPHL 1000kamlesheicNo ratings yet

- 42 Mab 191Document5 pages42 Mab 191false mailNo ratings yet

- WTS Sample PrintoutDocument21 pagesWTS Sample Printoutsaka dewaNo ratings yet

- Anexo 2 - Hoja de Datos Valvula de Diagragma (30-XV-4069)Document1 pageAnexo 2 - Hoja de Datos Valvula de Diagragma (30-XV-4069)Antezana RodriguezNo ratings yet

- Crf271 6 CondenserDocument1 pageCrf271 6 Condenserkartikkhatri1188No ratings yet

- CCTV - CVHG780-CN123 - Product ReportDocument2 pagesCCTV - CVHG780-CN123 - Product ReportTân NguyễnNo ratings yet

- 2002 Room Air Conditioner Service ManualDocument62 pages2002 Room Air Conditioner Service Manualespagnita100% (2)

- Installation, Commissioning & Start-Up ProcedureDocument9 pagesInstallation, Commissioning & Start-Up ProcedureMudassir RafiqNo ratings yet

- CONDENSER - Performance Heat Exchanger: B10Tx20: SSP G7Document2 pagesCONDENSER - Performance Heat Exchanger: B10Tx20: SSP G7Goran PanticNo ratings yet

- 30 TR IG Tube PDFDocument1 page30 TR IG Tube PDFshree awateNo ratings yet

- Aspen Exchanger Design and Rating Plate V9Document4 pagesAspen Exchanger Design and Rating Plate V9samara navasNo ratings yet

- MULTI-V - INDOOR - 36k-48k - Common Exploded - View 2015.11.11 EU and LATDocument8 pagesMULTI-V - INDOOR - 36k-48k - Common Exploded - View 2015.11.11 EU and LATfhelfenstellerNo ratings yet

- Inter Cambiado RDocument2 pagesInter Cambiado RmilenarixNo ratings yet

- TECH DATADocument12 pagesTECH DATANazar KhanNo ratings yet

- Heat exchanger specification sheet vibration analysisDocument3 pagesHeat exchanger specification sheet vibration analysisSRINo ratings yet

- Example 1Document1 pageExample 1M. Nasikhun WahidinNo ratings yet

- Heat exchanger rating and specification dataDocument5 pagesHeat exchanger rating and specification datachemical509No ratings yet

- Heat Exchanger Specification Sheet for Renewable Naphtha Product CoolerDocument2 pagesHeat Exchanger Specification Sheet for Renewable Naphtha Product Coolershahbaz akramNo ratings yet

- Wall Mounted: Asya24Lcc Aoyr24LccDocument24 pagesWall Mounted: Asya24Lcc Aoyr24Lccmarcio carvalhoNo ratings yet

- Air Conditioner Service Manual Models LV-C3621CL/HL/AL LV-D4821CL/HL/AL LV-D6021CL/HL/ALDocument43 pagesAir Conditioner Service Manual Models LV-C3621CL/HL/AL LV-D4821CL/HL/AL LV-D6021CL/HL/ALCesar Calderon GrNo ratings yet

- 5TR CondenserDocument1 page5TR CondenserbevarsiNo ratings yet

- Process Data Sheet - Rev.01Document1 pageProcess Data Sheet - Rev.01Giannis AnastasakisNo ratings yet

- Air Conditioning - Airteach - Provision Plant, A.C PlantDocument88 pagesAir Conditioning - Airteach - Provision Plant, A.C PlantGabriel AgafiteiNo ratings yet

- Specifications: WG40 WG75 WG100 WG175 Performance Model NumberDocument1 pageSpecifications: WG40 WG75 WG100 WG175 Performance Model Numberconstantin.iacomi3837No ratings yet

- Scantling CalculationDocument16 pagesScantling Calculationfadelrifqi8No ratings yet

- E-101, Precalentador de PropanoDocument1 pageE-101, Precalentador de PropanoIsaac RodriguezNo ratings yet

- Heat Exchanger Specification SheetDocument1 pageHeat Exchanger Specification SheetRizal NajibNo ratings yet

- NexansDocument3 pagesNexansasex4uNo ratings yet

- Applsci 09 01627Document17 pagesApplsci 09 01627Phượng NguyễnNo ratings yet

- Huang Control and Design DOFDocument9 pagesHuang Control and Design DOFgatzkeNo ratings yet

- Catalysts 11 00833Document15 pagesCatalysts 11 00833Phượng NguyễnNo ratings yet

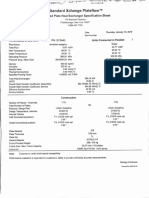

- Sondex Heat Exchangers: Danfoss Ref: SD-2019-87 Date: 23 Anh Minh Technology Trading Co., LTDDocument4 pagesSondex Heat Exchangers: Danfoss Ref: SD-2019-87 Date: 23 Anh Minh Technology Trading Co., LTDPhượng NguyễnNo ratings yet

- Applsci 09 01627Document17 pagesApplsci 09 01627Phượng NguyễnNo ratings yet

- Bơm Chiller 80m3, 5bargDocument5 pagesBơm Chiller 80m3, 5bargPhượng NguyễnNo ratings yet

- Applsci 09 01627Document17 pagesApplsci 09 01627Phượng NguyễnNo ratings yet

- Bơm Chiller 80m3, 5bargDocument5 pagesBơm Chiller 80m3, 5bargPhượng NguyễnNo ratings yet

- Energies: On The Optimization of Electrical Water Heaters: Modelling Simulations and ExperimentationDocument12 pagesEnergies: On The Optimization of Electrical Water Heaters: Modelling Simulations and ExperimentationPhượng NguyễnNo ratings yet

- S9A - Datasheet - Cooking TankDocument1 pageS9A - Datasheet - Cooking TankPhượng NguyễnNo ratings yet

- Lọc YDocument13 pagesLọc YPhượng NguyễnNo ratings yet

- Technical data for 80x65 FSGA pumpDocument5 pagesTechnical data for 80x65 FSGA pumpPhượng NguyễnNo ratings yet

- Design and Analysis of U-Shaped Ribbon Blender With Screw ConveyorDocument9 pagesDesign and Analysis of U-Shaped Ribbon Blender With Screw ConveyorPhượng NguyễnNo ratings yet

- PH Transmitter - CM444 - Endress & HauserDocument52 pagesPH Transmitter - CM444 - Endress & HauserPhượng NguyễnNo ratings yet

- Proximity - IGT205 - IFMDocument3 pagesProximity - IGT205 - IFMPhượng NguyễnNo ratings yet

- Temperature Transmitter - TMR35 - Endress & HauserDocument20 pagesTemperature Transmitter - TMR35 - Endress & HauserPhượng NguyễnNo ratings yet

- Pressure Transmitter With Ceramic Sensor, Accuracy 0,5%Document2 pagesPressure Transmitter With Ceramic Sensor, Accuracy 0,5%Phượng NguyễnNo ratings yet

- All Stainless Steel Pressure Gauge Bayonet Ring (Open Front) : Since 1971Document9 pagesAll Stainless Steel Pressure Gauge Bayonet Ring (Open Front) : Since 1971Phượng NguyễnNo ratings yet

- Industrial Bimetal Thermometer Bottom Connection: Since 1971Document6 pagesIndustrial Bimetal Thermometer Bottom Connection: Since 1971Phượng NguyễnNo ratings yet

- Calcium Silicate Insulation BrochureDocument52 pagesCalcium Silicate Insulation Brochureibson045001256No ratings yet

- Gasket ChìDocument8 pagesGasket ChìPhượng NguyễnNo ratings yet

- Cảm Biến Nhiệt ĐộDocument2 pagesCảm Biến Nhiệt ĐộPhượng NguyễnNo ratings yet

- PH Sensor - CPS77D - Endress & HauserDocument16 pagesPH Sensor - CPS77D - Endress & HauserPhượng NguyễnNo ratings yet

- 1.02.E.DT42S Thermodynamic Steam Traps DN15-25Document2 pages1.02.E.DT42S Thermodynamic Steam Traps DN15-25Son Trinh PhuongNo ratings yet

- Processes: Analysis of Power Input of An In-Line Rotor-Stator Mixer For Viscoplastic FluidsDocument15 pagesProcesses: Analysis of Power Input of An In-Line Rotor-Stator Mixer For Viscoplastic FluidsPhượng NguyễnNo ratings yet

- DN 2K2 CurveDocument1 pageDN 2K2 CurvePhượng NguyễnNo ratings yet

- AN ISO 9001, ISO 14001, OHSAS 18001, PED 2014/68/EU, Ad 2000 Merkblatt W0 Certified CompanyDocument12 pagesAN ISO 9001, ISO 14001, OHSAS 18001, PED 2014/68/EU, Ad 2000 Merkblatt W0 Certified CompanyPhượng NguyễnNo ratings yet

- Training Course ComsolDocument3 pagesTraining Course ComsolPhượng NguyễnNo ratings yet

- High Strength Bolts - KulakDocument21 pagesHigh Strength Bolts - KulakalmeteckNo ratings yet

- ExperimentalDocument5 pagesExperimentalbabuNo ratings yet

- Self-Assessment Exercise 1 QuestionsDocument3 pagesSelf-Assessment Exercise 1 QuestionsDeniz YiğitNo ratings yet

- Sb10k97581-Un38 3Document11 pagesSb10k97581-Un38 3Juan-Luis García ZapataNo ratings yet

- June 2011 MathsDocument4 pagesJune 2011 MathsWellington BandaNo ratings yet

- BS en Iso 10893-12-2011Document16 pagesBS en Iso 10893-12-2011gokhan karakayaNo ratings yet

- Datasheet For Weigh Feeder (M-3131)Document1 pageDatasheet For Weigh Feeder (M-3131)Joe GrosirNo ratings yet

- Eee1016 Non-Destructive-testing TH 1.0 47 Eee1016Document3 pagesEee1016 Non-Destructive-testing TH 1.0 47 Eee1016Anbarasan SubramaniyanNo ratings yet

- General Physics Lab. Report1Document10 pagesGeneral Physics Lab. Report1Ba LamNo ratings yet

- SINGGAR MULIA ENGINEERING HORIZONTAL 2-PHASE SEPARATORDocument3 pagesSINGGAR MULIA ENGINEERING HORIZONTAL 2-PHASE SEPARATORElias EliasNo ratings yet

- Dwnload Full Electrical Engineering Concepts and Applications 1st Edition Reza Zekavat Solutions Manual PDFDocument36 pagesDwnload Full Electrical Engineering Concepts and Applications 1st Edition Reza Zekavat Solutions Manual PDFwonders.stufferlx27100% (10)

- Week 7-Transformers Voltage Regulation and Per Unit calculations-ELEC2300Document30 pagesWeek 7-Transformers Voltage Regulation and Per Unit calculations-ELEC2300Look AxxNo ratings yet

- Laboratory Handout Radiation Heat TransferDocument4 pagesLaboratory Handout Radiation Heat TransferYusuf Ersin ÇALIŞKANNo ratings yet

- Degetted,: Fance On A in Ficld &Document11 pagesDegetted,: Fance On A in Ficld &AnkitNo ratings yet

- Angularity Number Test Aim of The ExperimentDocument4 pagesAngularity Number Test Aim of The ExperimentakhilaNo ratings yet

- Physics SolvedDocument16 pagesPhysics SolvedAbhijeet Singh PanwarNo ratings yet

- Chapter 1 - Physical World: +1 Physics Chapterwise Previous Year Questions (2009-2020)Document95 pagesChapter 1 - Physical World: +1 Physics Chapterwise Previous Year Questions (2009-2020)കായംകുളം കൊച്ചുണ്ണി100% (1)

- Experiment 1: The Visible Spectra of Soft Drinks: A. Pre-Laboratory QuestionsDocument5 pagesExperiment 1: The Visible Spectra of Soft Drinks: A. Pre-Laboratory QuestionsMuhd Mirza HizamiNo ratings yet

- Assignment-1 Fluid Properties & Pressure Mesurement 2021Document3 pagesAssignment-1 Fluid Properties & Pressure Mesurement 2021PATEL VRAJNo ratings yet

- E Steam ProjectDocument10 pagesE Steam ProjectOmar ShahzadNo ratings yet

- BEEE304L - PSE - Module - 4 - L3 - Long Transmission LineDocument15 pagesBEEE304L - PSE - Module - 4 - L3 - Long Transmission LineRahul ganthNo ratings yet

- CapacitorsDocument10 pagesCapacitorsOnlineDownloadsNo ratings yet

- Physics Practical Report 5Document8 pagesPhysics Practical Report 5NatashaAnneNo ratings yet

- 4.2 Lucy-Electric - MPM-MV24-2Document4 pages4.2 Lucy-Electric - MPM-MV24-2Pachok KHEMPETNo ratings yet

- North South University: Lab 3: Loading Effect of Voltage Divider CircuitDocument4 pagesNorth South University: Lab 3: Loading Effect of Voltage Divider CircuitLittle WizardNo ratings yet

- Question 2Document3 pagesQuestion 2Vishak PuthoorNo ratings yet

- Fetal Growth Chart: Gestational Length, Weight, and Length by WeekDocument4 pagesFetal Growth Chart: Gestational Length, Weight, and Length by WeekDwi PutricNo ratings yet

- Understanding Microstrip LinesDocument23 pagesUnderstanding Microstrip Linescdg prqNo ratings yet

- Module 3 Evaporation Part 2Document24 pagesModule 3 Evaporation Part 2Lei LopezNo ratings yet

- The Forces Are With Us: Name - ClassDocument4 pagesThe Forces Are With Us: Name - ClassSapphire BlueNo ratings yet