Professional Documents

Culture Documents

Table 1 Foundation Type Identifier

Uploaded by

DoreenOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Table 1 Foundation Type Identifier

Uploaded by

DoreenCopyright:

Available Formats

3.

5 Foundation Requirement for Different Building Types

The designs given in this Manual are limited to where the system supports Building Types as described in Table 1.

The classification of wall and roof weights are as detailed in Clause 3.4 of this Section. Single and two storey shall be as

defined in NZS 3604:2011.

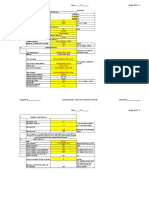

Table 1 Foundation

GROUND SECOND 1.5KPA LIVE 3KPA LIVE

Type Identifier NUMBER

FLOOR STOREY LOAD & UP TO LOAD & /OR

OF ROOF

EXTERNAL EXTERNAL 1KPA SNOW 2KPA SNOW

STORIES

WALLS WALLS LOAD LOAD

Light Light A A

SINGLE Heavy Light A B

STOREY Light Heavy B B

Heavy Heavy C C

Light Light Light C D

DOUBLE Heavy Light Light D E

STOREY Light Heavy Light D E

Heavy Heavy Light E G

3.6 Foundation Soils

The system may be used when the supporting ground Where the ultimate bearing capacity required of the

meets the definitions of “good ground” given in supporting ground is verified by Scala Penetrometer

Section 3 of NZS 3604:2011 (as modified by B1 of the testing in accordance with Clause 3.3 of NZS3604:2011

Building Compliance Documents). In addition, the or for cohesive soils using a calibrated shear vane in

system shall not be used for damp sites i.e. where it accordance with the NZGS Guideline for Hand Held

can be reasonably expected that the ground water Shear Vane Test, the bearing capacity shall exceed the

level could come within 600mm of the underside of the values in Table 2 for the proposed building type. For

system. The acceptability of the ground shall be verified scala penetrometer testing, the bearing capacity shall

in accordance with Clause 3.1.3 of NZS 3604:2011. be considered adequate when the number of blows per

300mm depth of penetration below the underside of

Solutions for soils prone to liquefaction or expansive the system at each test site exceeds the values given in

soils are available using the Firth RibRaft® technology, Table 2 below.

however these are outside the scope of this Manual and

require specific engineering design. For RibRaft® foundations compliance with Table 2

allows ultimate bearing capacities of less than 300kPa.

However, with the exception of bearing capacity all

other requirements in NZS3604:2011 for “good ground”

shall be complied with.

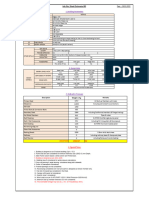

Table 2 Scala

Penetrometer FOUNDATION TYPE ULTIMATE BEARING CAPACITY MIN. BLOWS PER 300MM

Blows Required (KPA) DEPTH FOR SCALA TESTING

and Ultimate

Bearing Capacity

A 140 4

B 175 5

C 210 6

D 240 7

E 275 8

G Good ground 9

3.7 Flow Diagrams

The flow diagrams on the following pages (adapted from NZS3604:2011) will help in determining whether the

non-specific details for the system can be used for the purposes of the concrete floor slab construction. There are

two checks in the process. The first is to determine whether the proposed building complies with the requirements

set out in this Manual (Building Check), and the second is to determine whether the site complies with the

requirements set out in this Manual (Site Check).

(Note: NZS3604:2011 provides for parts of buildings to be considered as individual buildings. These flow diagrams apply to those parts of

the building where slab-on-ground is being considered and where the part of the building can be considered as an individual building under

NZS3604:2011).

S1: DESIGN INFORMATION 6

4.6 Mesh Reinforcement

The entire floor slab shall be reinforced with 665 or SE62 mesh supported on 40mm mesh chairs sitting on the

polystyrene pods.

4.7 Re-entrant Corners

In order to limit the width of cracking at the re-entrant, or internal corners, extra steel shall be placed on top

of the mesh. These shall be 2-HD12 bars (Grade 500E), 1200mm long tied to the top of the mesh at

200mm centres, with 50mm cover from the internal corner – refer Figure 3.

Figure 5

Standard RibRaft®

Construction Details

50-150 mm

85

S1: DESIGN INFORMATION 11

5.2 Wind Resistance

The building’s bracing demand from

BUILDING ROOF GROUND SECOND BU’s FOR

wind loading shall be assessed from

Section 5 of NZS 3604:2011 for both TYPE TYPE FLOOR STOREY PROVIDED LIVE

directions (i.e. along and across the EXTERNAL EXTERNAL PER 100M2 LOADING

building). The bracing capacity of the WALLS WALLS 1.5KPA OF: 3.0KPA

system must exceed the greater of the Single Storey Light Light 1630 1746

bracing demands determined.

Single Storey Heavy Light 1737 1857

The bracing capacity of the system

Single Storey Light Heavy 1802 1922

shall be determined as the sum of the

bracing capacity provided by frictional Single Storey Heavy Heavy 1909 2029

resistance (i.e. friction between the

system and the ground) and the Double Storey Light Light Light 2163 2403

bracing capacity provided by the Double Storey Heavy Light Light 2270 2510

shear keys (if any) necessary to meet

the requirements of Clause 5.2. Double Storey Light Heavy Light 2335 2575

Double Storey Heavy Heavy Light 2442 2682

The bracing capacity provided

by frictional resistance shall be

determined from Table 4 depending

on the building type, roof weight, Table 4 Bracing Capacity Provided By Frictional

and floor live loading. The bracing Resistance Per 100m2 Of Ground Floor Area

capacity provided by the shear

keys shall be the sum of the bracing

capacity of the individual shear keys

determined as follows. If the shear

key is in clay, each shear key shall be

considered to contribute 170 BU’s. If

the shear key is in sand, each shear

key shall be considered to contribute

200 BU’s. If the bracing capacity of

the system, determined from the

frictional resistance and the shear

keys as described above, is less than

the bracing demand further shear

keys shall be added until the bracing

demand is met.

Figure 7 RibRaft® Shear Key

5.3 Shear Keys

Shear key piles required by Clause 5.2

must be uniformly distributed around

the perimeter of the building, and be

located at the edge beam/internal

rib junction. Where a shear key is

required, the minimum number of

shear keys shall be two per floor plan.

Where two shear keys are used they

shall be placed at diagonally opposite

ends of the floor plan.

Construction details of the shear keys

shall be as shown on Figure 7. Shear

keys shall be a minimum of 900mm

long. The holes shall be over-drilled

at least 100mm and a polystyrene

Firth RaftMix

RibRaft® Shear Key Support placed Concrete - 20Mpa

into the bottom of each hole. This

will support only the plastic (wet)

concrete and then allow movement

of the shear key if settlement of

the supporting ground occurs. The

effective end bearing of the shear keys

is therefore eliminated.

S1: DESIGN INFORMATION 13

You might also like

- Bearing Capacity of Soils - BudhuDocument12 pagesBearing Capacity of Soils - BudhuIgnacio FloresNo ratings yet

- 180-038 - Foundation Pile Design Report - Issue 1 PDFDocument45 pages180-038 - Foundation Pile Design Report - Issue 1 PDFHiranya BarmaNo ratings yet

- The Process, Church of The Final Judgment - ScripturesDocument132 pagesThe Process, Church of The Final Judgment - Scripturescirclesphere100% (2)

- Future Visualized in The Movie BrazilDocument16 pagesFuture Visualized in The Movie BrazilsloutfyNo ratings yet

- MarlinDocument28 pagesMarlincumpio425428No ratings yet

- RoB@132+365 - Test Pile Designs & GT ReportDocument221 pagesRoB@132+365 - Test Pile Designs & GT ReportHegdeVenugopalNo ratings yet

- DC Motor CatalogueDocument12 pagesDC Motor CatalogueAbhishek KumarNo ratings yet

- Ames Perception ExperimentsDocument108 pagesAmes Perception ExperimentsMichael RoseNo ratings yet

- 7203-6311-MDC-030KL TankDocument34 pages7203-6311-MDC-030KL TankDarshJhaNo ratings yet

- Abut Pier Raft CommomDocument103 pagesAbut Pier Raft CommomAmit Singh100% (1)

- Without Weep Hole - 1Document104 pagesWithout Weep Hole - 1Amit SinghNo ratings yet

- Sec03 PDFDocument85 pagesSec03 PDFaliNo ratings yet

- API 620 DesignDocument27 pagesAPI 620 Designrsubramani100% (2)

- Relative Density and Load Capacity of SandsDocument14 pagesRelative Density and Load Capacity of SandsgatotNo ratings yet

- Condensate Storage Tank Design OverviewDocument44 pagesCondensate Storage Tank Design OverviewkpsahuNo ratings yet

- II PUC PHYSICS - Previously Appeared Questions and Answers For 2021 Exam by MANJUNATH BDocument52 pagesII PUC PHYSICS - Previously Appeared Questions and Answers For 2021 Exam by MANJUNATH BVishal Ramesh100% (1)

- L1 Finding Nemo Teacher Notes American EnglishDocument9 pagesL1 Finding Nemo Teacher Notes American Englishcris_simescuNo ratings yet

- IKM - Sample Size Calculation in Epid Study PDFDocument7 pagesIKM - Sample Size Calculation in Epid Study PDFcindyNo ratings yet

- DAR-J-109-PEB Shed-Estimate-R0Document1 pageDAR-J-109-PEB Shed-Estimate-R0Sunil RahangdaleNo ratings yet

- ACME-J-228-Unit-2 Shed-Estimate-R0Document1 pageACME-J-228-Unit-2 Shed-Estimate-R0Sunil RahangdaleNo ratings yet

- Comment - Draft - Comp Girder-26.34-R6Document61 pagesComment - Draft - Comp Girder-26.34-R6Nilay GandhiNo ratings yet

- Esr 2907Document4 pagesEsr 2907محمد الدعجةNo ratings yet

- Shed With Mezzanine-Estimate-R0Document1 pageShed With Mezzanine-Estimate-R0Sunil RahangdaleNo ratings yet

- Load pile marking layoutDocument1 pageLoad pile marking layoutPriyanka GuleriaNo ratings yet

- DropinsubmittalsDocument2 pagesDropinsubmittalsRenzo CarmenNo ratings yet

- Long Side Failure: Ultimate Bearing Capacity, Q Net Bearing Capacity, Q Computed Factor of Safety, FS N Value N ValuesDocument24 pagesLong Side Failure: Ultimate Bearing Capacity, Q Net Bearing Capacity, Q Computed Factor of Safety, FS N Value N ValuesPervy SageNo ratings yet

- Jack Up Rig DescriptionDocument2 pagesJack Up Rig DescriptionShiju Paul.MNo ratings yet

- Dokumen - Tips - York Fan Coil Unit PDFDocument16 pagesDokumen - Tips - York Fan Coil Unit PDFLaurensius ArdiNo ratings yet

- Technical Bulletin For HIT RE 500 V3 With Large Annular Gap Technical Information ASSET DOC LOC 7502228Document4 pagesTechnical Bulletin For HIT RE 500 V3 With Large Annular Gap Technical Information ASSET DOC LOC 7502228Saiful IslamNo ratings yet

- Break-Up: Weight Break Up and Summery Sheet Sr. No. WeightDocument4 pagesBreak-Up: Weight Break Up and Summery Sheet Sr. No. WeightSudhanshu PalNo ratings yet

- ICC-ES Evaluation Report ESR-2966Document7 pagesICC-ES Evaluation Report ESR-2966MD MDDNo ratings yet

- Specification GeotextileDocument10 pagesSpecification GeotextileRCBacayNo ratings yet

- CE Board Nov 2020 - RCD - Set 8 and 9Document6 pagesCE Board Nov 2020 - RCD - Set 8 and 9Dale MalazzabNo ratings yet

- Notes:: Construction of Foul Sewer Network For Inner Doha PACKAGE 3B (C816/3B)Document1 pageNotes:: Construction of Foul Sewer Network For Inner Doha PACKAGE 3B (C816/3B)Orchie DavidsonNo ratings yet

- Guying StandardDocument36 pagesGuying Standarddwas1314No ratings yet

- Landing Nipple 2,31 XNDocument1 pageLanding Nipple 2,31 XNEdwin AbelloNo ratings yet

- Offer Legrand SandwichBBT BMTC EV 02.04.2022Document1 pageOffer Legrand SandwichBBT BMTC EV 02.04.2022Darshit VyasNo ratings yet

- Notes:: Construction of Foul Sewer Network For Inner Doha PACKAGE 3B (C816/3B)Document1 pageNotes:: Construction of Foul Sewer Network For Inner Doha PACKAGE 3B (C816/3B)Orchie DavidsonNo ratings yet

- R. S. Engineering Company Latur Rate of Shuttering With Labour ChargesDocument5 pagesR. S. Engineering Company Latur Rate of Shuttering With Labour ChargesMaipalsingh ThakurNo ratings yet

- Data AL Series Threaded Insert DataDocument3 pagesData AL Series Threaded Insert DataJuan RamirezNo ratings yet

- UTC-Z3-Phase 01 - B02 (Block 7&8) - IFC Rev00Document128 pagesUTC-Z3-Phase 01 - B02 (Block 7&8) - IFC Rev00Mahmoud HamdyNo ratings yet

- SGC 233 Coupling Data SheetDocument1 pageSGC 233 Coupling Data SheetMohammad yasinNo ratings yet

- Hydac Acoplamientos CampanaDocument4 pagesHydac Acoplamientos CampanaDavid MejidoNo ratings yet

- Six KipsDocument10 pagesSix Kipsyoshdog@gmail.comNo ratings yet

- Khurmala Field Field Department Drilling Deve. Oil Wells Project TU LocationDocument9 pagesKhurmala Field Field Department Drilling Deve. Oil Wells Project TU LocationAhmedNo ratings yet

- Khurmala Field Field Department Drilling Deve. Oil Wells Project TU LocationDocument9 pagesKhurmala Field Field Department Drilling Deve. Oil Wells Project TU LocationAhmedNo ratings yet

- Building estimate for JK Cement shed in SuratDocument1 pageBuilding estimate for JK Cement shed in SuratAbhinay SoniNo ratings yet

- Blast Furnace Slag Aggregates for Base and Subbase ConstructionDocument2 pagesBlast Furnace Slag Aggregates for Base and Subbase ConstructionGreissy ReynagaNo ratings yet

- G225iexm08-Srp-M-Dwg-0003 - Rev A4Document55 pagesG225iexm08-Srp-M-Dwg-0003 - Rev A4BALASUBRAMANIAM MEGHANADHNo ratings yet

- Landing Nipples PDFDocument7 pagesLanding Nipples PDFYoucef Benferdi0% (1)

- Inverter Drive and Vector Drive Motors: Made in The U.S.ADocument24 pagesInverter Drive and Vector Drive Motors: Made in The U.S.APedroNo ratings yet

- ElectricalDocument3 pagesElectricalsid8ismNo ratings yet

- Katalog Groud Mounting 1Document5 pagesKatalog Groud Mounting 1Марко ЈелићNo ratings yet

- Valaris DS 17Document2 pagesValaris DS 17Jason EbingNo ratings yet

- All Pumps stock full range access coversDocument2 pagesAll Pumps stock full range access covers_Asylum_No ratings yet

- FAG Rolling Bearings Current InsulatedDocument6 pagesFAG Rolling Bearings Current InsulatedMekanisasi SubangNo ratings yet

- UAA10Document17 pagesUAA10abhishek_modemNo ratings yet

- C 506 Â " 00 QZUWNI1SRUQDocument8 pagesC 506 Â " 00 QZUWNI1SRUQjorge napa magallanesNo ratings yet

- AS1684 SPLIT LEVEL C2 House Tie-DownDocument34 pagesAS1684 SPLIT LEVEL C2 House Tie-DownNhư Lê0% (1)

- Seminar on What's New in BNBC 2020 for Structural EngineersDocument38 pagesSeminar on What's New in BNBC 2020 for Structural EngineersRaquib AhsanNo ratings yet

- Albian SectionsDocument36 pagesAlbian SectionsdamindaNo ratings yet

- Des UdesDocument18 pagesDes UdesskumarsrNo ratings yet

- Timber Engineering PDFDocument8 pagesTimber Engineering PDFKesavan DhuraiNo ratings yet

- Manta Ray Marine Installation ProceduresDocument5 pagesManta Ray Marine Installation ProceduresrajendrasgadviNo ratings yet

- BBB SCHDocument11 pagesBBB SCHthe_citizen89No ratings yet

- Technical Data Sheet Yukon SBDocument1 pageTechnical Data Sheet Yukon SBZdep OniuqaNo ratings yet

- Mitek - Internal Load Bearing 10 - 2011Document4 pagesMitek - Internal Load Bearing 10 - 2011Yanina MashkinaNo ratings yet

- StarLAN Technology ReportFrom EverandStarLAN Technology ReportRating: 3 out of 5 stars3/5 (1)

- 8 Wescombe Spec Home Spec - Appendix ADocument14 pages8 Wescombe Spec Home Spec - Appendix ADoreenNo ratings yet

- F D M - T B: Loor Iaphragms in Ulti Storey Imber UildingsDocument420 pagesF D M - T B: Loor Iaphragms in Ulti Storey Imber UildingsDoreenNo ratings yet

- F D M - T B: Loor Iaphragms in Ulti Storey Imber UildingsDocument420 pagesF D M - T B: Loor Iaphragms in Ulti Storey Imber UildingsDoreenNo ratings yet

- Floor Diaphragms - Seismic Bulwark or Achilles' Heel: J.M. ScarryDocument33 pagesFloor Diaphragms - Seismic Bulwark or Achilles' Heel: J.M. ScarryascivilNo ratings yet

- Deflection and DisplacementDocument1 pageDeflection and DisplacementDoreenNo ratings yet

- Deflection and Displacement BothDocument2 pagesDeflection and Displacement BothDoreenNo ratings yet

- Properties of built-up section designDocument2 pagesProperties of built-up section designDoreenNo ratings yet

- FIR0667 RibRaft Technical Manual 2020Document34 pagesFIR0667 RibRaft Technical Manual 2020DoreenNo ratings yet

- Statics: Vector Mechanics For EngineersDocument32 pagesStatics: Vector Mechanics For EngineersArdaNo ratings yet

- 8-Input Multiplexer Selects One of Eight InputsDocument3 pages8-Input Multiplexer Selects One of Eight InputsKang RoyNo ratings yet

- Architecture in The AnthropoceneDocument265 pagesArchitecture in The Anthropoceneziyad fauziNo ratings yet

- Nireesh Kumar Paidi - Updated ResumeDocument5 pagesNireesh Kumar Paidi - Updated ResumeNikhil Reddy NamreddyNo ratings yet

- Accounting For AC Winding Losses in The Electric Machine Design ProcessDocument4 pagesAccounting For AC Winding Losses in The Electric Machine Design Processjianfeng wangNo ratings yet

- Unit 1.Pptx Autosaved 5bf659481837fDocument39 pagesUnit 1.Pptx Autosaved 5bf659481837fBernadith Manaday BabaloNo ratings yet

- Rectal FluidtherapyDocument7 pagesRectal FluidtherapyIan SabogalNo ratings yet

- In Re Winslow 1966 - Scope & Content of Prior ArtDocument5 pagesIn Re Winslow 1966 - Scope & Content of Prior ArtJorel Andrew FlautaNo ratings yet

- Attachment No 2 PDFDocument10 pagesAttachment No 2 PDFTusharRoyNo ratings yet

- Towards Sustainable Water Management in SoharDocument48 pagesTowards Sustainable Water Management in SoharMiss Preyashi kumarNo ratings yet

- Seismic Design Coefficients and Factors TableDocument3 pagesSeismic Design Coefficients and Factors TableJonathan ColeNo ratings yet

- Model146C DynamicGasCal 156file - 18125Document150 pagesModel146C DynamicGasCal 156file - 18125api-26966403100% (1)

- Animals Adaptation LessonDocument6 pagesAnimals Adaptation LessonPascal Bou NajemNo ratings yet

- 016 Muscoril COPPDocument3 pages016 Muscoril COPPTheRoom23No ratings yet

- Cast Steel y Strainer Ansi Class 150Document2 pagesCast Steel y Strainer Ansi Class 150aurinkokelloNo ratings yet

- Chapter 1 - Quiz 2 Form A: A. B. C. D. E. F. G. H. I. J. K. L. M. N. O. P. 1. 2. 3. 4. 5. 6. 7. 8Document2 pagesChapter 1 - Quiz 2 Form A: A. B. C. D. E. F. G. H. I. J. K. L. M. N. O. P. 1. 2. 3. 4. 5. 6. 7. 8Olalekan Oyekunle0% (1)

- Nexon Genuine AccessoriesDocument15 pagesNexon Genuine AccessoriesjagaaniNo ratings yet

- NCE - Lesson 61 (A)Document8 pagesNCE - Lesson 61 (A)Zahir Pacasum-OmarNo ratings yet

- Week 05 - Mechanical Properties Part 1Document48 pagesWeek 05 - Mechanical Properties Part 1Dharshica MohanNo ratings yet

- The Efficient Way To Prevent Water Carryover and Keep Your Indoor Air HealthierDocument1 pageThe Efficient Way To Prevent Water Carryover and Keep Your Indoor Air HealthierAzrinshah Abu BakarNo ratings yet

- WB City GateDocument7 pagesWB City GateDiegoNo ratings yet

- PWR Bi2Document11 pagesPWR Bi2GOMTINo ratings yet