Professional Documents

Culture Documents

Beam Design Detail Report: Material and Design Data

Beam Design Detail Report: Material and Design Data

Uploaded by

azwanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Beam Design Detail Report: Material and Design Data

Beam Design Detail Report: Material and Design Data

Uploaded by

azwanCopyright:

Available Formats

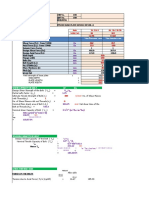

MATERIAL AND DESIGN DATA

Code of Practice fcu (N/mm²) Ec, (N/mm²) fy (N/mm²) fyv (N/mm²) γc γs

BS8110 : 1997 30 24597 460 460 1.5 1.05

Cover (mm) Side Cover (mm) Conc. Unit Weight (kN/m³) Steel Unit Weight (kg/m³)

25 25 24 7860

Beam Design Detail Report

DETAIL CALCULATION FOR BEAM GB10(150x450)

Beam Located along grid 1C/D1-B1B

Number of Span within beam = 3

Number of Section defined by user = 4

Number of Supports = 3

Beam Cantilever End = Left

Section Dimension Data

Length Width Begin Depth End Depth

Span Section

(mm) (mm) (mm) (mm)

1 1 1075 150 450 450

2 3100 150 450 450

2

3 2000 150 450 450

3 4 3500 150 450 450

MATERIAL PROPERTIES

Maximum Concrete Strain, Ecc = 0.0035

Average Concrete Stress above Neutral Axis, k1 = 12.12 N/mm²

Concrete Lever Arm Factor, k2 = 0.4518

Limiting Effective Depth Factor, cb = 0.50

k2 / k1 Factor, kkk = 0.0373

Limiting Concrete Moment Capacity Factor, kk1 = cb × k1 × (1 - cb * k2) = 0.50 × 12.12 × (1 - 0.50 × 0.4518) = 4.6911 N/mm²

BEAM GB10(150x450) SPAN NO. 1

FLEXURAL DESIGN CALCULATION

LOCATION : RIGHT SUPPORT

Design Bending Moment = 7.6 kNm Width, b = 150.0 mm Effective Depth, d = 409.0 mm

Mu / bd² = 7.6 × 1000000 / (150.0 × 409.0²) = 0.301 N/mm²

Singly Reinforced Design, limit Mu / bd² < kk1

Mu / bd² = 0.301 <= 4.691

Design as Singly Reinforced Rectangular Beam

Concrete Neutral Axis, x = 10.280 mm

Concrete Compression Force, Fc = k1 × b × x / 1000 = 12.12 × 150 × 10.280 / 1000 = 18.69 kN

Steel Area Required, AsReq = Fc × 1000 / (fy / γs) = 18.69 × 1000 / (460 / 1.05) = 43 mm²

Moment Capacity = Fc × (d - k2 × x) / 1000 = 18.69 × (409.0 - 0.4518 × 10.280) / 1000 = 7.6 kNm

Maximum Depth of Section = 450.0 mm

Minimum Tension Steel Area Required = 0.13% × 150.0 × 450.0 = 88 mm²

Top Tension Steel Area Required = 88 mm²

Bottom Compression Steel Area Required = 88 mm²

Top Reinforcement Provided = 2T12 (226 mm²)

Bottom Reinforcement Provided = 2T12 (226 mm²)

LOCATION : 1/4 SPAN

Design Bending Moment = 3.9 kNm Width, b = 150.0 mm Effective Depth, d = 409.0 mm

Mu / bd² = 3.9 × 1000000 / (150.0 × 409.0²) = 0.157 N/mm²

Singly Reinforced Design, limit Mu / bd² < kk1

Mu / bd² = 0.157 <= 4.691

Design as Singly Reinforced Rectangular Beam

Concrete Neutral Axis, x = 5.339 mm

Concrete Compression Force, Fc = k1 × b × x / 1000 = 12.12 × 150 × 5.339 / 1000 = 9.71 kN

Steel Area Required, AsReq = Fc × 1000 / (fy / γs) = 9.71 × 1000 / (460 / 1.05) = 23 mm²

Moment Capacity = Fc × (d - k2 × x) / 1000 = 9.71 × (409.0 - 0.4518 × 5.339) / 1000 = 3.9 kNm

Maximum Depth of Section = 450.0 mm

Minimum Tension Steel Area Required = 0.13% × 150.0 × 450.0 = 88 mm²

Top Tension Steel Area Required = 88 mm²

Bottom Compression Steel Area Required = 88 mm²

Top Reinforcement Provided = 2T12 (226 mm²)

Bottom Reinforcement Provided = 2T12 (226 mm²)

SHEAR & TORSION DESIGN CALCULATION

LOCATION : SECTION 1 (B:-75 mm E:1000 mm from left grid of span)

Maximum Torsion within Zone, T = 0.0 kNm

Shear at Location of Maximum Torsion, V = 9.6 kN

Link Horizontal Dimension, h1 = b - 2 × Side Cover - DiaLink = 150 - 2 × 25 - 10 = 90 mm

Link Vertical Dimension, v1 = h - 2 × Cover - DiaLink = 450 - 2 × 25 - 10 = 390 mm

Dimension x1 = Min (h1, v1) = 90 mm, y1 = Max (h1, v1) = 390 mm

Section Dimension: Dmin = 150.0 mm, Dmax = 450.0 mm

Torsion Stress, νst = 2 × T × 106 / (Dmin² × (Dmax - Dmin / 3)) = 0.00 N/mm²

Effective depth, d = 409.0 mm

Shear Stress, νss = V × 1000 / (b × d) = 9.6 × 1000 / (150.0 × 409.0) = 0.16 N/mm²

Part 2 : Clause 2.4.6 and Table 2.3

Maximum Combined Stress Allowed, νtu = Min (0.8 × √fcu, 5) = 4.38 N/mm²

Total Stress, νTot = νss + νst = 0.16 + 0.00 = 0.16 N/mm² ≤ νtu (4.38 N/mm²)

Checking for Combined Stress Allowed Pass

Part 2: Clause 2.4.5

Additional Checking While Small Cross Section (y1 < 550 mm)

Larger Link Dimension, y1 = 390.0 mm < 550 mm

νtu × y1 / 550 = 4.38 × 390.0 / 550 = 3.11 N/mm²

νst = 0.00 N/mm² ≤ 3.11 N/mm²

Checking for Torsion Stress Allowed Pass

Part 2 : Clause 2.4.6 Table 2.3

Torsion Strength contributed by concrete, νt,min = Min (0.067 × √fcu, 0.4) = 0.37 N/mm²

Torsion Stress, νst = 0.00 N/mm² < νt,min = 0.37 N/mm² -> No Torsion Reinforcement is needed

Maximum Shear within Zone, V = 9.4 kN

Maximum Shear Stress Allowed, νMax = Min (0.8 × √30, 5) = 4.38 N/mm² - Clause 3.4.5.2

Shear Stress, νss = V × 1000 / (b × d) = 9.4 × 1000 / (150.0 × 409.0) = 0.15 N/mm² ≤ νMax (4.38 N/mm²)

Checking for Maximum Shear Stress Allowed Pass

Tension Steel Area Provided, Ast = 226 mm²

- Table 3.8: Values of νc, design concrete shear stress

Steel Percentage, 100 × As / (bv × d) = 0.37 % ≤ 3.0 %

Effective Depth Ratio, edr = 400 / d = 400 / 409.0 = 0.978

(400 / d)^ ¼ = 0.994 < 1, (400 / d)^ ¼ taken as 1

Minimum fcu, fcuMin = 25 N/mm², Concrete Grade Ratio, Min(fcu, 40) / fcuMin = 30 / 25 = 1.200

Concrete Shear Capacity, νc = 0.79 {100 As / (bv d)}⅓ (400 / d)¼ (fcu / 25)⅓ / γm

= 0.79 × {0.37}⅓ × 1.000 × (1.200)⅓ / 1.25 = 0.48 N/mm²

Minimum Design Shear Stress, νMin = 0.40 N/mm²

νss = 0.153 < νc + 0.4, Provides only minimum link

Design for minimum Shear Stress, νd = νmin = 0.40 N/mm²

Shear Link Area / Spacing Ratio, SAsv_Sv = (vd × b) / (fyy × fy) = (0.40 × 150) / (0.95 × 460) = 0.137 mm²/mm

Shear Reinforcement Provided : T10-250 (Link spacing is governed by user setting)

Shear Link Area / Spacing Ratio Provided = 0.628 mm²/mm > 0.137 mm²/mm

DEFLECTION CHECKING FOR SPAN

Basic Span / Effective Depth Ratio, Br = 7.0

Span Length, l = 1075.0 mm, Effective Depth, d = 409.0 mm

Actual Span / Effective Depth Ratio, Ar = 2.6

Ultimate Design Moment, Mu = 7.6 kNm

Design Steel Strength, fy = 460.0 N/mm²

Tension Steel Area Required, AsReq = 88 mm²

Tension Steel Area Provided, AsProv = 226 mm²

Compression Steel Area Provided, AsProv (Comp.) = 226 mm²

- Checking for deflection is based on BS8110: 1997

- Table 3.9: Basic span / effective depth ratio for rectangular or flange beams

- Table 3.10: Modification factor for tension reinforcement

- Table 3.11: Modification factor for compression reinforcement

Design Service Stress in Tension Reinforcement, Equation 8

fs = {(2 × fy × AsReq) / (3 × AsProv)} × (1 / ßb)

= {(2 × 460.0 × 88) / (3 × 226)} × (1 / 1.00) = 119.0 N/mm²

Modification Factor for Tension Reinforcement, Equation 7

MFt = 0.55 + {(477 - fs) / (120 × (0.9 + (M/bd²)))}

= 0.55 + {(477 - 119.0) / (120 × (0.9 + (7.6 × 1000000 / (150 × 409.0²)))}

= 3.03 > 2.0

MFt taken as 2.0

New Modification Factor for Compression Reinforcement, Equation 9

MFc = 1 + {(100 × AsProv / (b × d)) / (3 + (100 × AsProv / (b × d)))}

= 1 + {(100 × 226 / (150.0 × 409.0)) / (3 + (100 × 226 / (150.0 × 409.0)))}

= 1.11 <= 1.5

New Deflection Ratio = (Br × MFt × MFc) / Ar = (7.0 × 2.00 × 1.11) / 2.6 = 5.91

Ratio >= 1.0 : Deflection Checked PASSED

BEAM GB10(150x450) SPAN NO. 2

FLEXURAL DESIGN CALCULATION

LOCATION : SPAN

Design Bending Moment = 4.7 kNm Width, b = 150.0 mm Effective Depth, d = 409.0 mm

Mu / bd² = 4.7 × 1000000 / (150.0 × 409.0²) = 0.188 N/mm²

Singly Reinforced Design, limit Mu / bd² < kk1

Mu / bd² = 0.188 <= 4.691

Design as Singly Reinforced Rectangular Beam

Concrete Neutral Axis, x = 6.394 mm

Concrete Compression Force, Fc = k1 × b × x / 1000 = 12.12 × 150 × 6.394 / 1000 = 11.62 kN

Steel Area Required, AsReq = Fc × 1000 / (fy / γs) = 11.62 × 1000 / (460 / 1.05) = 27 mm²

Moment Capacity = Fc × (d - k2 × x) / 1000 = 11.62 × (409.0 - 0.4518 × 6.394) / 1000 = 4.7 kNm

Maximum Depth of Section = 450.0 mm

Minimum Tension Steel Area Required = 0.13% × 150.0 × 450.0 = 88 mm²

Top Compression Steel Area Required = 88 mm²

Bottom Tension Steel Area Required = 88 mm²

Top Reinforcement Provided = 2T12 (226 mm²)

Bottom Reinforcement Provided = 2T12 (226 mm²)

LOCATION : LEFT SUPPORT

Design Bending Moment = 7.6 kNm Width, b = 150.0 mm Effective Depth, d = 409.0 mm

Mu / bd² = 7.6 × 1000000 / (150.0 × 409.0²) = 0.302 N/mm²

Singly Reinforced Design, limit Mu / bd² < kk1

Mu / bd² = 0.302 <= 4.691

Design as Singly Reinforced Rectangular Beam

Concrete Neutral Axis, x = 10.309 mm

Concrete Compression Force, Fc = k1 × b × x / 1000 = 12.12 × 150 × 10.309 / 1000 = 18.74 kN

Steel Area Required, AsReq = Fc × 1000 / (fy / γs) = 18.74 × 1000 / (460 / 1.05) = 43 mm²

Moment Capacity = Fc × (d - k2 × x) / 1000 = 18.74 × (409.0 - 0.4518 × 10.309) / 1000 = 7.6 kNm

Maximum Depth of Section = 450.0 mm

Minimum Tension Steel Area Required = 0.13% × 150.0 × 450.0 = 88 mm²

Top Tension Steel Area Required = 88 mm²

Bottom Compression Steel Area Required = 88 mm²

Top Reinforcement Provided = 2T12 (226 mm²)

Bottom Reinforcement Provided = 2T12 (226 mm²)

LOCATION : RIGHT SUPPORT

Design Bending Moment = 13.7 kNm Width, b = 150.0 mm Effective Depth, d = 409.0 mm

Mu / bd² = 13.7 × 1000000 / (150.0 × 409.0²) = 0.544 N/mm²

Singly Reinforced Design, limit Mu / bd² < kk1

Mu / bd² = 0.544 <= 4.691

Design as Singly Reinforced Rectangular Beam

Concrete Neutral Axis, x = 18.748 mm

Concrete Compression Force, Fc = k1 × b × x / 1000 = 12.12 × 150 × 18.748 / 1000 = 34.08 kN

Steel Area Required, AsReq = Fc × 1000 / (fy / γs) = 34.08 × 1000 / (460 / 1.05) = 78 mm²

Moment Capacity = Fc × (d - k2 × x) / 1000 = 34.08 × (409.0 - 0.4518 × 18.748) / 1000 = 13.7 kNm

Maximum Depth of Section = 450.0 mm

Minimum Tension Steel Area Required = 0.13% × 150.0 × 450.0 = 88 mm²

Top Tension Steel Area Required = 88 mm²

Bottom Compression Steel Area Required = 88 mm²

Top Reinforcement Provided = 2T12 (226 mm²)

Bottom Reinforcement Provided = 2T12 (226 mm²)

LOCATION : SECTION 2 - BOTTOM TENSION

Use Mid Span Design Calculation Above

LOCATION : SECTION 2 - TOP TENSION

Use Left Support Design Calculation Above

LOCATION : SECTION 3 - BOTTOM TENSION

Design Bending Moment = 4.7 kNm Width, b = 150.0 mm Effective Depth, d = 409.0 mm

Mu / bd² = 4.7 × 1000000 / (150.0 × 409.0²) = 0.188 N/mm²

Singly Reinforced Design, limit Mu / bd² < kk1

Mu / bd² = 0.188 <= 4.691

Design as Singly Reinforced Rectangular Beam

Concrete Neutral Axis, x = 6.394 mm

Concrete Compression Force, Fc = k1 × b × x / 1000 = 12.12 × 150 × 6.394 / 1000 = 11.62 kN

Steel Area Required, AsReq = Fc × 1000 / (fy / γs) = 11.62 × 1000 / (460 / 1.05) = 27 mm²

Moment Capacity = Fc × (d - k2 × x) / 1000 = 11.62 × (409.0 - 0.4518 × 6.394) / 1000 = 4.7 kNm

Maximum Depth of Section = 450.0 mm

Minimum Tension Steel Area Required = 0.13% × 150.0 × 450.0 = 88 mm²

Top Compression Steel Area Required = 88 mm²

Bottom Tension Steel Area Required = 88 mm²

LOCATION : SECTION 3 - TOP TENSION

Use Right Support Design Calculation Above

SHEAR & TORSION DESIGN CALCULATION

LOCATION : SECTION 1 LEFT SUPPORT

(B:0 mm E:1275 mm from left grid of span)

Maximum Torsion within Zone, T = 0.0 kNm

Shear at Location of Maximum Torsion, V = 7.6 kN

Link Horizontal Dimension, h1 = b - 2 × Side Cover - DiaLink = 150 - 2 × 25 - 10 = 90 mm

Link Vertical Dimension, v1 = h - 2 × Cover - DiaLink = 450 - 2 × 25 - 10 = 390 mm

Dimension x1 = Min (h1, v1) = 90 mm, y1 = Max (h1, v1) = 390 mm

Section Dimension: Dmin = 150.0 mm, Dmax = 450.0 mm

Torsion Stress, νst = 2 × T × 106 / (Dmin² × (Dmax - Dmin / 3)) = 0.00 N/mm²

Effective depth, d = 409.0 mm

Shear Stress, νss = V × 1000 / (b × d) = 7.6 × 1000 / (150.0 × 409.0) = 0.12 N/mm²

Part 2 : Clause 2.4.6 and Table 2.3

Maximum Combined Stress Allowed, νtu = Min (0.8 × √fcu, 5) = 4.38 N/mm²

Total Stress, νTot = νss + νst = 0.12 + 0.00 = 0.12 N/mm² ≤ νtu (4.38 N/mm²)

Checking for Combined Stress Allowed Pass

Part 2: Clause 2.4.5

Additional Checking While Small Cross Section (y1 < 550 mm)

Larger Link Dimension, y1 = 390.0 mm < 550 mm

νtu × y1 / 550 = 4.38 × 390.0 / 550 = 3.11 N/mm²

νst = 0.00 N/mm² ≤ 3.11 N/mm²

Checking for Torsion Stress Allowed Pass

Part 2 : Clause 2.4.6 Table 2.3

Torsion Strength contributed by concrete, νt,min = Min (0.067 × √fcu, 0.4) = 0.37 N/mm²

Torsion Stress, νst = 0.00 N/mm² < νt,min = 0.37 N/mm² -> No Torsion Reinforcement is needed

Maximum Shear within Zone, V = 7.4 kN

Maximum Shear Stress Allowed, νMax = Min (0.8 × √30, 5) = 4.38 N/mm² - Clause 3.4.5.2

Shear Stress, νss = V × 1000 / (b × d) = 7.4 × 1000 / (150.0 × 409.0) = 0.12 N/mm² ≤ νMax (4.38 N/mm²)

Checking for Maximum Shear Stress Allowed Pass

Tension Steel Area Provided, Ast = 226 mm²

- Table 3.8: Values of νc, design concrete shear stress

Steel Percentage, 100 × As / (bv × d) = 0.37 % ≤ 3.0 %

Effective Depth Ratio, edr = 400 / d = 400 / 409.0 = 0.978

(400 / d)^ ¼ = 0.994 < 1, (400 / d)^ ¼ taken as 1

Minimum fcu, fcuMin = 25 N/mm², Concrete Grade Ratio, Min(fcu, 40) / fcuMin = 30 / 25 = 1.200

Concrete Shear Capacity, νc = 0.79 {100 As / (bv d)}⅓ (400 / d)¼ (fcu / 25)⅓ / γm

= 0.79 × {0.37}⅓ × 1.000 × (1.200)⅓ / 1.25 = 0.48 N/mm²

Minimum Design Shear Stress, νMin = 0.40 N/mm²

νss = 0.120 < νc + 0.4, Provides only minimum link

Design for minimum Shear Stress, νd = νmin = 0.40 N/mm²

Shear Link Area / Spacing Ratio, SAsv_Sv = (vd × b) / (fyy × fy) = (0.40 × 150) / (0.95 × 460) = 0.137 mm²/mm

Shear Reinforcement Provided : T10-250 (Link spacing is governed by user setting)

Shear Link Area / Spacing Ratio Provided = 0.628 mm²/mm > 0.137 mm²/mm

LOCATION : SECTION 1 RIGHT ZONE

(B:1275 mm E:3100 mm from left grid of span)

Maximum Torsion within Zone, T = 0.0 kNm

Shear at Location of Maximum Torsion, V = 4.1 kN

Link Horizontal Dimension, h1 = b - 2 × Side Cover - DiaLink = 150 - 2 × 25 - 10 = 90 mm

Link Vertical Dimension, v1 = h - 2 × Cover - DiaLink = 450 - 2 × 25 - 10 = 390 mm

Dimension x1 = Min (h1, v1) = 90 mm, y1 = Max (h1, v1) = 390 mm

Section Dimension: Dmin = 150.0 mm, Dmax = 450.0 mm

Torsion Stress, νst = 2 × T × 106 / (Dmin² × (Dmax - Dmin / 3)) = 0.00 N/mm²

Effective depth, d = 409.0 mm

Shear Stress, νss = V × 1000 / (b × d) = 4.1 × 1000 / (150.0 × 409.0) = 0.07 N/mm²

Part 2 : Clause 2.4.6 and Table 2.3

Maximum Combined Stress Allowed, νtu = Min (0.8 × √fcu, 5) = 4.38 N/mm²

Total Stress, νTot = νss + νst = 0.07 + 0.00 = 0.07 N/mm² ≤ νtu (4.38 N/mm²)

Checking for Combined Stress Allowed Pass

Part 2: Clause 2.4.5

Additional Checking While Small Cross Section (y1 < 550 mm)

Larger Link Dimension, y1 = 390.0 mm < 550 mm

νtu × y1 / 550 = 4.38 × 390.0 / 550 = 3.11 N/mm²

νst = 0.00 N/mm² ≤ 3.11 N/mm²

Checking for Torsion Stress Allowed Pass

Part 2 : Clause 2.4.6 Table 2.3

Torsion Strength contributed by concrete, νt,min = Min (0.067 × √fcu, 0.4) = 0.37 N/mm²

Torsion Stress, νst = 0.00 N/mm² < νt,min = 0.37 N/mm² -> No Torsion Reinforcement is needed

Maximum Shear within Zone, V = 4.1 kN

Maximum Shear Stress Allowed, νMax = Min (0.8 × √30, 5) = 4.38 N/mm² - Clause 3.4.5.2

Shear Stress, νss = V × 1000 / (b × d) = 4.1 × 1000 / (150.0 × 409.0) = 0.07 N/mm² ≤ νMax (4.38 N/mm²)

Checking for Maximum Shear Stress Allowed Pass

Tension Steel Area Provided, Ast = 226 mm²

- Table 3.8: Values of νc, design concrete shear stress

Steel Percentage, 100 × As / (bv × d) = 0.37 % ≤ 3.0 %

Effective Depth Ratio, edr = 400 / d = 400 / 409.0 = 0.978

(400 / d)^ ¼ = 0.994 < 1, (400 / d)^ ¼ taken as 1

Minimum fcu, fcuMin = 25 N/mm², Concrete Grade Ratio, Min(fcu, 40) / fcuMin = 30 / 25 = 1.200

Concrete Shear Capacity, νc = 0.79 {100 As / (bv d)}⅓ (400 / d)¼ (fcu / 25)⅓ / γm

= 0.79 × {0.37}⅓ × 1.000 × (1.200)⅓ / 1.25 = 0.48 N/mm²

Minimum Design Shear Stress, νMin = 0.40 N/mm²

νss = 0.067 < νc + 0.4, Provides only minimum link

Design for minimum Shear Stress, νd = νmin = 0.40 N/mm²

Shear Link Area / Spacing Ratio, SAsv_Sv = (vd × b) / (fyy × fy) = (0.40 × 150) / (0.95 × 460) = 0.137 mm²/mm

Shear Reinforcement Provided : T10-250 (Link spacing is governed by user setting)

Shear Link Area / Spacing Ratio Provided = 0.628 mm²/mm > 0.137 mm²/mm

LOCATION : SECTION 2 LEFT ZONE

(B:3100 mm E:3825 mm from left grid of span)

Maximum Torsion within Zone, T = 0.0 kNm

Shear at Location of Maximum Torsion, V = 7.5 kN

Link Horizontal Dimension, h1 = b - 2 × Side Cover - DiaLink = 150 - 2 × 25 - 10 = 90 mm

Link Vertical Dimension, v1 = h - 2 × Cover - DiaLink = 450 - 2 × 25 - 10 = 390 mm

Dimension x1 = Min (h1, v1) = 90 mm, y1 = Max (h1, v1) = 390 mm

Section Dimension: Dmin = 150.0 mm, Dmax = 450.0 mm

Torsion Stress, νst = 2 × T × 106 / (Dmin² × (Dmax - Dmin / 3)) = 0.00 N/mm²

Effective depth, d = 409.0 mm

Shear Stress, νss = V × 1000 / (b × d) = 7.5 × 1000 / (150.0 × 409.0) = 0.12 N/mm²

Part 2 : Clause 2.4.6 and Table 2.3

Maximum Combined Stress Allowed, νtu = Min (0.8 × √fcu, 5) = 4.38 N/mm²

Total Stress, νTot = νss + νst = 0.12 + 0.00 = 0.12 N/mm² ≤ νtu (4.38 N/mm²)

Checking for Combined Stress Allowed Pass

Part 2: Clause 2.4.5

Additional Checking While Small Cross Section (y1 < 550 mm)

Larger Link Dimension, y1 = 390.0 mm < 550 mm

νtu × y1 / 550 = 4.38 × 390.0 / 550 = 3.11 N/mm²

νst = 0.00 N/mm² ≤ 3.11 N/mm²

Checking for Torsion Stress Allowed Pass

Part 2 : Clause 2.4.6 Table 2.3

Torsion Strength contributed by concrete, νt,min = Min (0.067 × √fcu, 0.4) = 0.37 N/mm²

Torsion Stress, νst = 0.00 N/mm² < νt,min = 0.37 N/mm² -> No Torsion Reinforcement is needed

Maximum Shear within Zone, V = 8.3 kN

Maximum Shear Stress Allowed, νMax = Min (0.8 × √30, 5) = 4.38 N/mm² - Clause 3.4.5.2

Shear Stress, νss = V × 1000 / (b × d) = 8.3 × 1000 / (150.0 × 409.0) = 0.14 N/mm² ≤ νMax (4.38 N/mm²)

Checking for Maximum Shear Stress Allowed Pass

Tension Steel Area Provided, Ast = 226 mm²

- Table 3.8: Values of νc, design concrete shear stress

Steel Percentage, 100 × As / (bv × d) = 0.37 % ≤ 3.0 %

Effective Depth Ratio, edr = 400 / d = 400 / 409.0 = 0.978

(400 / d)^ ¼ = 0.994 < 1, (400 / d)^ ¼ taken as 1

Minimum fcu, fcuMin = 25 N/mm², Concrete Grade Ratio, Min(fcu, 40) / fcuMin = 30 / 25 = 1.200

Concrete Shear Capacity, νc = 0.79 {100 As / (bv d)}⅓ (400 / d)¼ (fcu / 25)⅓ / γm

= 0.79 × {0.37}⅓ × 1.000 × (1.200)⅓ / 1.25 = 0.48 N/mm²

Minimum Design Shear Stress, νMin = 0.40 N/mm²

νss = 0.135 < νc + 0.4, Provides only minimum link

Design for minimum Shear Stress, νd = νmin = 0.40 N/mm²

Shear Link Area / Spacing Ratio, SAsv_Sv = (vd × b) / (fyy × fy) = (0.40 × 150) / (0.95 × 460) = 0.137 mm²/mm

Shear Reinforcement Provided : T10-250 (Link spacing is governed by user setting)

Shear Link Area / Spacing Ratio Provided = 0.628 mm²/mm > 0.137 mm²/mm

LOCATION : SECTION 2 RIGHT SUPPORT

(B:3825 mm E:5100 mm from left grid of span)

Maximum Torsion within Zone, T = 0.0 kNm

Shear at Location of Maximum Torsion, V = 11.7 kN

Link Horizontal Dimension, h1 = b - 2 × Side Cover - DiaLink = 150 - 2 × 25 - 10 = 90 mm

Link Vertical Dimension, v1 = h - 2 × Cover - DiaLink = 450 - 2 × 25 - 10 = 390 mm

Dimension x1 = Min (h1, v1) = 90 mm, y1 = Max (h1, v1) = 390 mm

Section Dimension: Dmin = 150.0 mm, Dmax = 450.0 mm

Torsion Stress, νst = 2 × T × 106 / (Dmin² × (Dmax - Dmin / 3)) = 0.00 N/mm²

Effective depth, d = 409.0 mm

Shear Stress, νss = V × 1000 / (b × d) = 11.7 × 1000 / (150.0 × 409.0) = 0.19 N/mm²

Part 2 : Clause 2.4.6 and Table 2.3

Maximum Combined Stress Allowed, νtu = Min (0.8 × √fcu, 5) = 4.38 N/mm²

Total Stress, νTot = νss + νst = 0.19 + 0.00 = 0.19 N/mm² ≤ νtu (4.38 N/mm²)

Checking for Combined Stress Allowed Pass

Part 2: Clause 2.4.5

Additional Checking While Small Cross Section (y1 < 550 mm)

Larger Link Dimension, y1 = 390.0 mm < 550 mm

νtu × y1 / 550 = 4.38 × 390.0 / 550 = 3.11 N/mm²

νst = 0.00 N/mm² ≤ 3.11 N/mm²

Checking for Torsion Stress Allowed Pass

Part 2 : Clause 2.4.6 Table 2.3

Torsion Strength contributed by concrete, νt,min = Min (0.067 × √fcu, 0.4) = 0.37 N/mm²

Torsion Stress, νst = 0.00 N/mm² < νt,min = 0.37 N/mm² -> No Torsion Reinforcement is needed

Maximum Shear within Zone, V = 11.4 kN

Maximum Shear Stress Allowed, νMax = Min (0.8 × √30, 5) = 4.38 N/mm² - Clause 3.4.5.2

Shear Stress, νss = V × 1000 / (b × d) = 11.4 × 1000 / (150.0 × 409.0) = 0.19 N/mm² ≤ νMax (4.38 N/mm²)

Checking for Maximum Shear Stress Allowed Pass

Tension Steel Area Provided, Ast = 226 mm²

- Table 3.8: Values of νc, design concrete shear stress

Steel Percentage, 100 × As / (bv × d) = 0.37 % ≤ 3.0 %

Effective Depth Ratio, edr = 400 / d = 400 / 409.0 = 0.978

(400 / d)^ ¼ = 0.994 < 1, (400 / d)^ ¼ taken as 1

Minimum fcu, fcuMin = 25 N/mm², Concrete Grade Ratio, Min(fcu, 40) / fcuMin = 30 / 25 = 1.200

Concrete Shear Capacity, νc = 0.79 {100 As / (bv d)}⅓ (400 / d)¼ (fcu / 25)⅓ / γm

= 0.79 × {0.37}⅓ × 1.000 × (1.200)⅓ / 1.25 = 0.48 N/mm²

Minimum Design Shear Stress, νMin = 0.40 N/mm²

νss = 0.186 < νc + 0.4, Provides only minimum link

Design for minimum Shear Stress, νd = νmin = 0.40 N/mm²

Shear Link Area / Spacing Ratio, SAsv_Sv = (vd × b) / (fyy × fy) = (0.40 × 150) / (0.95 × 460) = 0.137 mm²/mm

Shear Reinforcement Provided : T10-250 (Link spacing is governed by user setting)

Shear Link Area / Spacing Ratio Provided = 0.628 mm²/mm > 0.137 mm²/mm

DEFLECTION CHECKING FOR SPAN

Basic Span / Effective Depth Ratio, Br = 26.0

Span Length, l = 5100.0 mm, Effective Depth, d = 409.0 mm

Actual Span / Effective Depth Ratio, Ar = 12.5

Ultimate Design Moment, Mu = 4.7 kNm

Design Steel Strength, fy = 460.0 N/mm²

Tension Steel Area Required, AsReq = 88 mm²

Tension Steel Area Provided, AsProv = 226 mm²

Compression Steel Area Provided, AsProv (Comp.) = 226 mm²

- Checking for deflection is based on BS8110: 1997

- Table 3.9: Basic span / effective depth ratio for rectangular or flange beams

- Table 3.10: Modification factor for tension reinforcement

- Table 3.11: Modification factor for compression reinforcement

Design Service Stress in Tension Reinforcement, Equation 8

fs = {(2 × fy × AsReq) / (3 × AsProv)} × (1 / ßb)

= {(2 × 460.0 × 88) / (3 × 226)} × (1 / 1.00) = 119.0 N/mm²

Modification Factor for Tension Reinforcement, Equation 7

MFt = 0.55 + {(477 - fs) / (120 × (0.9 + (M/bd²)))}

= 0.55 + {(477 - 119.0) / (120 × (0.9 + (4.7 × 1000000 / (150 × 409.0²)))}

= 3.29 > 2.0

MFt taken as 2.0

New Modification Factor for Compression Reinforcement, Equation 9

MFc = 1 + {(100 × AsProv / (b × d)) / (3 + (100 × AsProv / (b × d)))}

= 1 + {(100 × 226 / (150.0 × 409.0)) / (3 + (100 × 226 / (150.0 × 409.0)))}

= 1.11 <= 1.5

New Deflection Ratio = (Br × MFt × MFc) / Ar = (26.0 × 2.00 × 1.11) / 12.5 = 4.63

Ratio >= 1.0 : Deflection Checked PASSED

BEAM GB10(150x450) SPAN NO. 3

FLEXURAL DESIGN CALCULATION

LOCATION : SPAN

Design Bending Moment = 15.2 kNm Width, b = 150.0 mm Effective Depth, d = 409.0 mm

Mu / bd² = 15.2 × 1000000 / (150.0 × 409.0²) = 0.607 N/mm²

Singly Reinforced Design, limit Mu / bd² < kk1

Mu / bd² = 0.607 <= 4.691

Design as Singly Reinforced Rectangular Beam

Concrete Neutral Axis, x = 20.986 mm

Concrete Compression Force, Fc = k1 × b × x / 1000 = 12.12 × 150 × 20.986 / 1000 = 38.15 kN

Steel Area Required, AsReq = Fc × 1000 / (fy / γs) = 38.15 × 1000 / (460 / 1.05) = 88 mm²

Moment Capacity = Fc × (d - k2 × x) / 1000 = 38.15 × (409.0 - 0.4518 × 20.986) / 1000 = 15.2 kNm

Maximum Depth of Section = 450.0 mm

Minimum Tension Steel Area Required = 0.13% × 150.0 × 450.0 = 88 mm²

Top Compression Steel Area Required = 88 mm²

Bottom Tension Steel Area Required = 88 mm²

Top Reinforcement Provided = 2T12 (226 mm²)

Bottom Reinforcement Provided = 2T12 (226 mm²)

LOCATION : LEFT SUPPORT

Design Bending Moment = 13.2 kNm Width, b = 150.0 mm Effective Depth, d = 409.0 mm

Mu / bd² = 13.2 × 1000000 / (150.0 × 409.0²) = 0.527 N/mm²

Singly Reinforced Design, limit Mu / bd² < kk1

Mu / bd² = 0.527 <= 4.691

Design as Singly Reinforced Rectangular Beam

Concrete Neutral Axis, x = 18.148 mm

Concrete Compression Force, Fc = k1 × b × x / 1000 = 12.12 × 150 × 18.148 / 1000 = 32.99 kN

Steel Area Required, AsReq = Fc × 1000 / (fy / γs) = 32.99 × 1000 / (460 / 1.05) = 76 mm²

Moment Capacity = Fc × (d - k2 × x) / 1000 = 32.99 × (409.0 - 0.4518 × 18.148) / 1000 = 13.2 kNm

Maximum Depth of Section = 450.0 mm

Minimum Tension Steel Area Required = 0.13% × 150.0 × 450.0 = 88 mm²

Top Tension Steel Area Required = 88 mm²

Bottom Compression Steel Area Required = 88 mm²

Top Reinforcement Provided = 2T12 (226 mm²)

Bottom Reinforcement Provided = 2T12 (226 mm²)

LOCATION : RIGHT SUPPORT

Design Bending Moment = 0.0 kNm Width, b = 150.0 mm Effective Depth, d = 409.0 mm

Mu / bd² = 0.0 × 1000000 / (150.0 × 409.0²) = 0.000 N/mm²

Design to minimum steel percentage specified by code,

Maximum Depth of Section = 450.0 mm

Minimum Tension Steel Area Required = 0.13% × 150.0 × 450.0 = 88 mm²

Top Tension Steel Area Required = 88 mm²

Top Reinforcement Provided = 2T12 (226 mm²)

Bottom Reinforcement Provided = 2T12 (226 mm²)

LOCATION : 1/4 SPAN

Design Bending Moment = 0.0 kNm Width, b = 150.0 mm Effective Depth, d = 409.0 mm

Mu / bd² = 0.0 × 1000000 / (150.0 × 409.0²) = 0.000 N/mm²

Design to minimum steel percentage specified by code,

Maximum Depth of Section = 450.0 mm

Minimum Tension Steel Area Required = 0.13% × 150.0 × 450.0 = 88 mm²

Top Tension Steel Area Required = 88 mm²

Top Reinforcement Provided = 2T12 (226 mm²)

Bottom Reinforcement Provided = 2T12 (226 mm²)

SHEAR & TORSION DESIGN CALCULATION

LOCATION : SECTION 1 LEFT SUPPORT

(B:0 mm E:875 mm from left grid of span)

Maximum Torsion within Zone, T = 0.0 kNm

Shear at Location of Maximum Torsion, V = 20.5 kN

Link Horizontal Dimension, h1 = b - 2 × Side Cover - DiaLink = 150 - 2 × 25 - 10 = 90 mm

Link Vertical Dimension, v1 = h - 2 × Cover - DiaLink = 450 - 2 × 25 - 10 = 390 mm

Dimension x1 = Min (h1, v1) = 90 mm, y1 = Max (h1, v1) = 390 mm

Section Dimension: Dmin = 150.0 mm, Dmax = 450.0 mm

Torsion Stress, νst = 2 × T × 106 / (Dmin² × (Dmax - Dmin / 3)) = 0.00 N/mm²

Effective depth, d = 409.0 mm

Shear Stress, νss = V × 1000 / (b × d) = 20.5 × 1000 / (150.0 × 409.0) = 0.33 N/mm²

Part 2 : Clause 2.4.6 and Table 2.3

Maximum Combined Stress Allowed, νtu = Min (0.8 × √fcu, 5) = 4.38 N/mm²

Total Stress, νTot = νss + νst = 0.33 + 0.00 = 0.33 N/mm² ≤ νtu (4.38 N/mm²)

Checking for Combined Stress Allowed Pass

Part 2: Clause 2.4.5

Additional Checking While Small Cross Section (y1 < 550 mm)

Larger Link Dimension, y1 = 390.0 mm < 550 mm

νtu × y1 / 550 = 4.38 × 390.0 / 550 = 3.11 N/mm²

νst = 0.00 N/mm² ≤ 3.11 N/mm²

Checking for Torsion Stress Allowed Pass

Part 2 : Clause 2.4.6 Table 2.3

Torsion Strength contributed by concrete, νt,min = Min (0.067 × √fcu, 0.4) = 0.37 N/mm²

Torsion Stress, νst = 0.00 N/mm² < νt,min = 0.37 N/mm² -> No Torsion Reinforcement is needed

Maximum Shear within Zone, V = 20.2 kN

Maximum Shear Stress Allowed, νMax = Min (0.8 × √30, 5) = 4.38 N/mm² - Clause 3.4.5.2

Shear Stress, νss = V × 1000 / (b × d) = 20.2 × 1000 / (150.0 × 409.0) = 0.33 N/mm² ≤ νMax (4.38 N/mm²)

Checking for Maximum Shear Stress Allowed Pass

Tension Steel Area Provided, Ast = 226 mm²

- Table 3.8: Values of νc, design concrete shear stress

Steel Percentage, 100 × As / (bv × d) = 0.37 % ≤ 3.0 %

Effective Depth Ratio, edr = 400 / d = 400 / 409.0 = 0.978

(400 / d)^ ¼ = 0.994 < 1, (400 / d)^ ¼ taken as 1

Minimum fcu, fcuMin = 25 N/mm², Concrete Grade Ratio, Min(fcu, 40) / fcuMin = 30 / 25 = 1.200

Concrete Shear Capacity, νc = 0.79 {100 As / (bv d)}⅓ (400 / d)¼ (fcu / 25)⅓ / γm

= 0.79 × {0.37}⅓ × 1.000 × (1.200)⅓ / 1.25 = 0.48 N/mm²

Minimum Design Shear Stress, νMin = 0.40 N/mm²

νss = 0.330 < νc + 0.4, Provides only minimum link

Design for minimum Shear Stress, νd = νmin = 0.40 N/mm²

Shear Link Area / Spacing Ratio, SAsv_Sv = (vd × b) / (fyy × fy) = (0.40 × 150) / (0.95 × 460) = 0.137 mm²/mm

Shear Reinforcement Provided : T10-250 (Link spacing is governed by user setting)

Shear Link Area / Spacing Ratio Provided = 0.628 mm²/mm > 0.137 mm²/mm

LOCATION : SECTION 1 MIDDLE ZONE

(B:875 mm E:2625 mm from left grid of span)

Maximum Torsion within Zone, T = 0.0 kNm

Shear at Location of Maximum Torsion, V = 18.5 kN

Link Horizontal Dimension, h1 = b - 2 × Side Cover - DiaLink = 150 - 2 × 25 - 10 = 90 mm

Link Vertical Dimension, v1 = h - 2 × Cover - DiaLink = 450 - 2 × 25 - 10 = 390 mm

Dimension x1 = Min (h1, v1) = 90 mm, y1 = Max (h1, v1) = 390 mm

Section Dimension: Dmin = 150.0 mm, Dmax = 450.0 mm

Torsion Stress, νst = 2 × T × 106 / (Dmin² × (Dmax - Dmin / 3)) = 0.00 N/mm²

Effective depth, d = 409.0 mm

Shear Stress, νss = V × 1000 / (b × d) = 18.5 × 1000 / (150.0 × 409.0) = 0.30 N/mm²

Part 2 : Clause 2.4.6 and Table 2.3

Maximum Combined Stress Allowed, νtu = Min (0.8 × √fcu, 5) = 4.38 N/mm²

Total Stress, νTot = νss + νst = 0.30 + 0.00 = 0.30 N/mm² ≤ νtu (4.38 N/mm²)

Checking for Combined Stress Allowed Pass

Part 2: Clause 2.4.5

Additional Checking While Small Cross Section (y1 < 550 mm)

Larger Link Dimension, y1 = 390.0 mm < 550 mm

νtu × y1 / 550 = 4.38 × 390.0 / 550 = 3.11 N/mm²

νst = 0.00 N/mm² ≤ 3.11 N/mm²

Checking for Torsion Stress Allowed Pass

Part 2 : Clause 2.4.6 Table 2.3

Torsion Strength contributed by concrete, νt,min = Min (0.067 × √fcu, 0.4) = 0.37 N/mm²

Torsion Stress, νst = 0.00 N/mm² < νt,min = 0.37 N/mm² -> No Torsion Reinforcement is needed

Maximum Shear within Zone, V = 18.5 kN

Maximum Shear Stress Allowed, νMax = Min (0.8 × √30, 5) = 4.38 N/mm² - Clause 3.4.5.2

Shear Stress, νss = V × 1000 / (b × d) = 18.5 × 1000 / (150.0 × 409.0) = 0.30 N/mm² ≤ νMax (4.38 N/mm²)

Checking for Maximum Shear Stress Allowed Pass

Tension Steel Area Provided, Ast = 226 mm²

- Table 3.8: Values of νc, design concrete shear stress

Steel Percentage, 100 × As / (bv × d) = 0.37 % ≤ 3.0 %

Effective Depth Ratio, edr = 400 / d = 400 / 409.0 = 0.978

(400 / d)^ ¼ = 0.994 < 1, (400 / d)^ ¼ taken as 1

Minimum fcu, fcuMin = 25 N/mm², Concrete Grade Ratio, Min(fcu, 40) / fcuMin = 30 / 25 = 1.200

Concrete Shear Capacity, νc = 0.79 {100 As / (bv d)}⅓ (400 / d)¼ (fcu / 25)⅓ / γm

= 0.79 × {0.37}⅓ × 1.000 × (1.200)⅓ / 1.25 = 0.48 N/mm²

Minimum Design Shear Stress, νMin = 0.40 N/mm²

νss = 0.301 < νc + 0.4, Provides only minimum link

Design for minimum Shear Stress, νd = νmin = 0.40 N/mm²

Shear Link Area / Spacing Ratio, SAsv_Sv = (vd × b) / (fyy × fy) = (0.40 × 150) / (0.95 × 460) = 0.137 mm²/mm

Shear Reinforcement Provided : T10-250 (Link spacing is governed by user setting)

Shear Link Area / Spacing Ratio Provided = 0.628 mm²/mm > 0.137 mm²/mm

LOCATION : SECTION 1 RIGHT SUPPORT

(B:2625 mm E:3500 mm from left grid of span)

Maximum Torsion within Zone, T = 0.0 kNm

Shear at Location of Maximum Torsion, V = 21.5 kN

Link Horizontal Dimension, h1 = b - 2 × Side Cover - DiaLink = 150 - 2 × 25 - 10 = 90 mm

Link Vertical Dimension, v1 = h - 2 × Cover - DiaLink = 450 - 2 × 25 - 10 = 390 mm

Dimension x1 = Min (h1, v1) = 90 mm, y1 = Max (h1, v1) = 390 mm

Section Dimension: Dmin = 150.0 mm, Dmax = 450.0 mm

Torsion Stress, νst = 2 × T × 106 / (Dmin² × (Dmax - Dmin / 3)) = 0.00 N/mm²

Effective depth, d = 409.0 mm

Shear Stress, νss = V × 1000 / (b × d) = 21.5 × 1000 / (150.0 × 409.0) = 0.35 N/mm²

Part 2 : Clause 2.4.6 and Table 2.3

Maximum Combined Stress Allowed, νtu = Min (0.8 × √fcu, 5) = 4.38 N/mm²

Total Stress, νTot = νss + νst = 0.35 + 0.00 = 0.35 N/mm² ≤ νtu (4.38 N/mm²)

Checking for Combined Stress Allowed Pass

Part 2: Clause 2.4.5

Additional Checking While Small Cross Section (y1 < 550 mm)

Larger Link Dimension, y1 = 390.0 mm < 550 mm

νtu × y1 / 550 = 4.38 × 390.0 / 550 = 3.11 N/mm²

νst = 0.00 N/mm² ≤ 3.11 N/mm²

Checking for Torsion Stress Allowed Pass

Part 2 : Clause 2.4.6 Table 2.3

Torsion Strength contributed by concrete, νt,min = Min (0.067 × √fcu, 0.4) = 0.37 N/mm²

Torsion Stress, νst = 0.00 N/mm² < νt,min = 0.37 N/mm² -> No Torsion Reinforcement is needed

Maximum Shear within Zone, V = 20.0 kN

Maximum Shear Stress Allowed, νMax = Min (0.8 × √30, 5) = 4.38 N/mm² - Clause 3.4.5.2

Shear Stress, νss = V × 1000 / (b × d) = 20.0 × 1000 / (150.0 × 409.0) = 0.33 N/mm² ≤ νMax (4.38 N/mm²)

Checking for Maximum Shear Stress Allowed Pass

Tension Steel Area Provided, Ast = 226 mm²

- Table 3.8: Values of νc, design concrete shear stress

Steel Percentage, 100 × As / (bv × d) = 0.37 % ≤ 3.0 %

Effective Depth Ratio, edr = 400 / d = 400 / 409.0 = 0.978

(400 / d)^ ¼ = 0.994 < 1, (400 / d)^ ¼ taken as 1

Minimum fcu, fcuMin = 25 N/mm², Concrete Grade Ratio, Min(fcu, 40) / fcuMin = 30 / 25 = 1.200

Concrete Shear Capacity, νc = 0.79 {100 As / (bv d)}⅓ (400 / d)¼ (fcu / 25)⅓ / γm

= 0.79 × {0.37}⅓ × 1.000 × (1.200)⅓ / 1.25 = 0.48 N/mm²

Minimum Design Shear Stress, νMin = 0.40 N/mm²

νss = 0.326 < νc + 0.4, Provides only minimum link

Design for minimum Shear Stress, νd = νmin = 0.40 N/mm²

Shear Link Area / Spacing Ratio, SAsv_Sv = (vd × b) / (fyy × fy) = (0.40 × 150) / (0.95 × 460) = 0.137 mm²/mm

Shear Reinforcement Provided : T10-250 (Link spacing is governed by user setting)

Shear Link Area / Spacing Ratio Provided = 0.628 mm²/mm > 0.137 mm²/mm

DEFLECTION CHECKING FOR SPAN

Basic Span / Effective Depth Ratio, Br = 26.0

Span Length, l = 3500.0 mm, Effective Depth, d = 409.0 mm

Actual Span / Effective Depth Ratio, Ar = 8.6

Ultimate Design Moment, Mu = 15.2 kNm

Design Steel Strength, fy = 460.0 N/mm²

Tension Steel Area Required, AsReq = 88 mm²

Tension Steel Area Provided, AsProv = 226 mm²

Compression Steel Area Provided, AsProv (Comp.) = 226 mm²

- Checking for deflection is based on BS8110: 1997

- Table 3.9: Basic span / effective depth ratio for rectangular or flange beams

- Table 3.10: Modification factor for tension reinforcement

- Table 3.11: Modification factor for compression reinforcement

Design Service Stress in Tension Reinforcement, Equation 8

fs = {(2 × fy × AsReq) / (3 × AsProv)} × (1 / ßb)

= {(2 × 460.0 × 88) / (3 × 226)} × (1 / 1.00) = 119.0 N/mm²

Modification Factor for Tension Reinforcement, Equation 7

MFt = 0.55 + {(477 - fs) / (120 × (0.9 + (M/bd²)))}

= 0.55 + {(477 - 119.0) / (120 × (0.9 + (15.2 × 1000000 / (150 × 409.0²)))}

= 2.53 > 2.0

MFt taken as 2.0

New Modification Factor for Compression Reinforcement, Equation 9

MFc = 1 + {(100 × AsProv / (b × d)) / (3 + (100 × AsProv / (b × d)))}

= 1 + {(100 × 226 / (150.0 × 409.0)) / (3 + (100 × 226 / (150.0 × 409.0)))}

= 1.11 <= 1.5

New Deflection Ratio = (Br × MFt × MFc) / Ar = (26.0 × 2.00 × 1.11) / 8.6 = 6.74

Ratio >= 1.0 : Deflection Checked PASSED

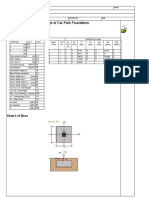

BEAM SUPPORT REACTION TABLE

Current Beam Grid Mark: 1C/D1-B1B

Beam Support Reactions

Support Reaction, kN

Support No. Grid Mark Support Type

Dead Load Live Load

1 C1B Column 10.8 0.0

2 C1 Column 21.7 0.0

3 B1B Column 14.9 0.0

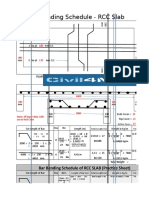

You might also like

- Water Retaining Structures To Bs 8007 and Bs 8110: Calculations OutputDocument93 pagesWater Retaining Structures To Bs 8007 and Bs 8110: Calculations Outputazwan100% (3)

- Sample Calulation BeamDocument9 pagesSample Calulation Beamche azimNo ratings yet

- Basement Shear Wall PDFDocument3 pagesBasement Shear Wall PDFYogen SthaNo ratings yet

- Bar Bending Schedule For Office BuildingDocument26 pagesBar Bending Schedule For Office BuildingSurendra MaharjanNo ratings yet

- From RCC Col To Steel ColDocument9 pagesFrom RCC Col To Steel ColJanya AssociatesNo ratings yet

- Structural Design (Type B) : GeneralDocument4 pagesStructural Design (Type B) : GeneralRakesh ShresthaNo ratings yet

- Design of BeamsDocument14 pagesDesign of BeamsNoor MohdNo ratings yet

- Boq For RCC BuildingDocument35 pagesBoq For RCC Buildingjatin kalraNo ratings yet

- Quantity & BOQ of PWDDocument11 pagesQuantity & BOQ of PWDMuhammad HamzaNo ratings yet

- The Hydraulic GradientDocument11 pagesThe Hydraulic GradientMamta SinghNo ratings yet

- Final Project - Analyze and Design A Multi-Storied BuildingDocument40 pagesFinal Project - Analyze and Design A Multi-Storied Buildingyash vermaNo ratings yet

- Combined FootingDocument2 pagesCombined FootingakhilNo ratings yet

- Footing DesignDocument7 pagesFooting Designmsiddiq1No ratings yet

- Column Base PlateDocument3 pagesColumn Base PlatePurnima ArkalgudNo ratings yet

- Calculation of Wind LoadDocument7 pagesCalculation of Wind LoadBipul PoudelNo ratings yet

- 20220902-Structural Drawing For 40'x30', EAST KYISU, DAGONSEIKKANDocument29 pages20220902-Structural Drawing For 40'x30', EAST KYISU, DAGONSEIKKANhein htet zawNo ratings yet

- Civil Enginneering: University Year 2018/2019Document21 pagesCivil Enginneering: University Year 2018/2019Mourad MouradNo ratings yet

- SlabDocument18 pagesSlabRajesh PatelNo ratings yet

- Footing Steel Quantity of Morarka CollegeDocument21 pagesFooting Steel Quantity of Morarka CollegeHANISHNo ratings yet

- Design of Stair Waist Slab: Concrete Slab Deflection CheckDocument2 pagesDesign of Stair Waist Slab: Concrete Slab Deflection CheckRathinavel VenkateshwaranNo ratings yet

- Plinth Beam DesignDocument3 pagesPlinth Beam DesignAbinash MandalNo ratings yet

- Stair CaseDocument5 pagesStair CaseMahitha ReddyNo ratings yet

- Formula For Steel QuantityDocument19 pagesFormula For Steel QuantityMukesh JangidNo ratings yet

- Built - Up Column Design ("Effectiveness of Various Built-Up Columns") Section PropertiesDocument2 pagesBuilt - Up Column Design ("Effectiveness of Various Built-Up Columns") Section PropertiesAnandNo ratings yet

- Design of Purlins Design Data: XX XX Yy IyyDocument6 pagesDesign of Purlins Design Data: XX XX Yy IyyCorey CookNo ratings yet

- QS - BasicsDocument20 pagesQS - BasicsPanyam Babu ShivanandNo ratings yet

- Two Way Slab Design in MM FormatDocument5 pagesTwo Way Slab Design in MM Formathardik_er29No ratings yet

- Two Storey Residential Project 1Document1 pageTwo Storey Residential Project 1shawwenfeytNo ratings yet

- Isolated FootingDocument3 pagesIsolated Footingvenkatesh19701No ratings yet

- DEEP BEAM DesignDocument2 pagesDEEP BEAM DesignmangeshNo ratings yet

- Column Design of 300x400Document24 pagesColumn Design of 300x400karthik100% (1)

- What Is STAAD?: Analytical ModelingDocument3 pagesWhat Is STAAD?: Analytical ModelingGodfrey EmilioNo ratings yet

- Steel DesignDocument6 pagesSteel DesignDad MeNo ratings yet

- A Project Report On Cost Ion For Various Truss ConfigurationsDocument110 pagesA Project Report On Cost Ion For Various Truss ConfigurationsNikhil100% (1)

- Slab Design Excel FileDocument4 pagesSlab Design Excel FileSuman Resolved NeupaneNo ratings yet

- Design of Isolated Rectangular FootingDocument3 pagesDesign of Isolated Rectangular FootingdsanandaNo ratings yet

- Over Head Water Tank FinalDocument4 pagesOver Head Water Tank FinalkafiNo ratings yet

- Bar Bending Schedule RCC SlabDocument6 pagesBar Bending Schedule RCC SlabAnupam SahuNo ratings yet

- Combined Footing DesignDocument4 pagesCombined Footing Designrukesh104No ratings yet

- Beam Design With Deflection CheckDocument6 pagesBeam Design With Deflection CheckKeshav RimalNo ratings yet

- Slendernesss, PEB StructureDocument1 pageSlendernesss, PEB StructurejamilNo ratings yet

- Staad-Seismic Coefficient 1 MethodDocument9 pagesStaad-Seismic Coefficient 1 MethodV.m. RajanNo ratings yet

- Concrete Mix Design As Per IS Code - 10262: 2019Document11 pagesConcrete Mix Design As Per IS Code - 10262: 2019Ravikant YadavNo ratings yet

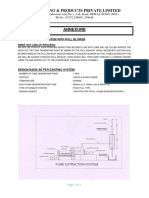

- PTPL Tubing & Products Private LimitedDocument3 pagesPTPL Tubing & Products Private LimitedANIMESH JAINNo ratings yet

- Flyover QuantityDocument29 pagesFlyover QuantityHemant GaikwadNo ratings yet

- Staad Mezzanine DesignDocument15 pagesStaad Mezzanine Designmbhanusagar.keynesNo ratings yet

- One Way Simply Supported Slab: #Value!Document25 pagesOne Way Simply Supported Slab: #Value!Kanaiyalal N. ShethNo ratings yet

- Footing DesignDocument4 pagesFooting DesignpnbastolaNo ratings yet

- Eccentric Combined FootingDocument3 pagesEccentric Combined Footingbishwaram gosainNo ratings yet

- FootingDocument14 pagesFootingJaganraj SesurajNo ratings yet

- Check For Crack Width:-: As Per IS 3370 - 2009 (Part 2), ANNEX - A, Page - 6Document2 pagesCheck For Crack Width:-: As Per IS 3370 - 2009 (Part 2), ANNEX - A, Page - 6mvap2856No ratings yet

- SCPL Phe BoqDocument120 pagesSCPL Phe BoqSajeshKumarNo ratings yet

- Beam Design Detail Report: Material and Design DataDocument10 pagesBeam Design Detail Report: Material and Design DataazwanNo ratings yet

- Beam Design Detail Report: Material and Design DataDocument10 pagesBeam Design Detail Report: Material and Design DataazwanNo ratings yet

- Slab Full Report (Span) - GBDocument182 pagesSlab Full Report (Span) - GBbce20090001No ratings yet

- Flexural Design Calculation: BEAM GB10 (300X300) SPAN NO. 1Document7 pagesFlexural Design Calculation: BEAM GB10 (300X300) SPAN NO. 1aniemzaimNo ratings yet

- Slab Design Full Report: Material and Design DataDocument22 pagesSlab Design Full Report: Material and Design DataazwanNo ratings yet

- BEAM Idp ProjectDocument14 pagesBEAM Idp ProjectSiti Nurulsyazni RusliNo ratings yet

- Beam Design Detail Report: Material and Design DataDocument20 pagesBeam Design Detail Report: Material and Design DataazwanNo ratings yet

- Beam Design Detail Report: Material and Design DataDocument33 pagesBeam Design Detail Report: Material and Design DataazwanNo ratings yet

- Application For Top-Up Switching Valuation Oct2021Document6 pagesApplication For Top-Up Switching Valuation Oct2021azwanNo ratings yet

- GEE - SW PE Calculation (Rev01)Document7 pagesGEE - SW PE Calculation (Rev01)azwanNo ratings yet

- Gee - SW PeDocument7 pagesGee - SW PeazwanNo ratings yet

- Gee - SW Pe Calculation (Old)Document16 pagesGee - SW Pe Calculation (Old)azwan100% (1)

- Beam Design Detail Report: Material and Design DataDocument33 pagesBeam Design Detail Report: Material and Design DataazwanNo ratings yet

- GEE - SW Hyraulic CalculationDocument2 pagesGEE - SW Hyraulic CalculationazwanNo ratings yet

- Beam Key Plan Report - FBDocument20 pagesBeam Key Plan Report - FBazwanNo ratings yet

- Slab Design - OkDocument35 pagesSlab Design - OkazwanNo ratings yet

- Pilecap Design by Bending Theory To B.S 8110 & B.S 8004Document59 pagesPilecap Design by Bending Theory To B.S 8110 & B.S 8004azwanNo ratings yet

- Beam Design Detail Report: Material and Design DataDocument32 pagesBeam Design Detail Report: Material and Design DataazwanNo ratings yet

- Beam Design Detail Report: Material and Design DataDocument20 pagesBeam Design Detail Report: Material and Design DataazwanNo ratings yet

- Beam Design Detail Report: Material and Design DataDocument10 pagesBeam Design Detail Report: Material and Design DataazwanNo ratings yet

- Kikuchietal Uganda Rice Retail Market TAD2015Document14 pagesKikuchietal Uganda Rice Retail Market TAD2015Oh ok SodryNo ratings yet

- Varian Cary 50 UV - VIS BrochureDocument2 pagesVarian Cary 50 UV - VIS BrochuremarcoNo ratings yet

- Prediction of Academic Performance Associated With Internet Usage Behaviors Using Machine Learning AlgorithmsDocument8 pagesPrediction of Academic Performance Associated With Internet Usage Behaviors Using Machine Learning Algorithmsmarriyam nadeemNo ratings yet

- Cs 224S / Linguist 281 Speech Recognition, Synthesis, and DialogueDocument59 pagesCs 224S / Linguist 281 Speech Recognition, Synthesis, and DialogueBurime GrajqevciNo ratings yet

- Acoples Falk Elastomer (Wrapflex) Catalogo (16 Pág.)Document16 pagesAcoples Falk Elastomer (Wrapflex) Catalogo (16 Pág.)marcelo castilloNo ratings yet

- H Series Natural Gas and Biogas Genset PricelistDocument3 pagesH Series Natural Gas and Biogas Genset Pricelist2326839No ratings yet

- DB VA V 92 Viscosity Sensor Electric For Heavy Fuel OilDocument8 pagesDB VA V 92 Viscosity Sensor Electric For Heavy Fuel Oilsike_99100% (1)

- Arjuno WelirangDocument6 pagesArjuno WelirangalvaruoNo ratings yet

- Truss Fact Book 2010Document28 pagesTruss Fact Book 2010eusufiqbalNo ratings yet

- Planet in Our Solar System - Project OutlineDocument2 pagesPlanet in Our Solar System - Project Outlineapi-613157389No ratings yet

- IT1552 Python Programming Course Handout 2020Document6 pagesIT1552 Python Programming Course Handout 2020Kashish GoelNo ratings yet

- Model Validation Test TR4 German Method With DIgSILENT GridCode PDFDocument25 pagesModel Validation Test TR4 German Method With DIgSILENT GridCode PDFbubo28No ratings yet

- Sanitary Diaphragm Valve: DescriptionDocument7 pagesSanitary Diaphragm Valve: DescriptionHilux PabloNo ratings yet

- EHVAC Objective Question Bank - Electrify Students1Document3 pagesEHVAC Objective Question Bank - Electrify Students1RitNo ratings yet

- Maximally-Flat Filters in Waveguide PDFDocument30 pagesMaximally-Flat Filters in Waveguide PDFagmnm1962No ratings yet

- Lab Manual PartDocument29 pagesLab Manual PartVikash AgrawalNo ratings yet

- PP-11-Introduction To Data Interpretation (P11) Rev 0.5Document89 pagesPP-11-Introduction To Data Interpretation (P11) Rev 0.5Asish desaiNo ratings yet

- Optimized Rat-Race Coupler With Different Shapes of Defected Ground StructureDocument4 pagesOptimized Rat-Race Coupler With Different Shapes of Defected Ground Structureravi010582No ratings yet

- Catalogue Backshells PDFDocument24 pagesCatalogue Backshells PDFGIUSEPPENo ratings yet

- Probability & Statistics Syllabus GTU 3rd Sem CEDocument2 pagesProbability & Statistics Syllabus GTU 3rd Sem CEPinak Vadher100% (1)

- Hyd 246C KENR5117KENR5117-03 - SISDocument4 pagesHyd 246C KENR5117KENR5117-03 - SISmizaelNo ratings yet

- Statistics and Set TheoryDocument7 pagesStatistics and Set TheorychillewadNo ratings yet

- Using EDEM With EnSightDocument11 pagesUsing EDEM With EnSightPeter MwangiNo ratings yet

- Unit 6 - General Account and Classification of Eubacteria, Archaebacteria and Cyanobacteria by Dr. Kirtika PadaliaDocument48 pagesUnit 6 - General Account and Classification of Eubacteria, Archaebacteria and Cyanobacteria by Dr. Kirtika PadaliaAbhishek Singh ChandelNo ratings yet

- Project Presentation - 01 To 47Document41 pagesProject Presentation - 01 To 47Shivang AhirNo ratings yet

- The Dilemma Between Dimensionality Reduction and Adversarial RobustnessDocument15 pagesThe Dilemma Between Dimensionality Reduction and Adversarial RobustnessBadiul AlamNo ratings yet

- BTS Fileformat 1.17Document31 pagesBTS Fileformat 1.17Asad MadniNo ratings yet

- Lotud ConversationsDocument109 pagesLotud Conversationsanon_553338622100% (2)

- H15B Plus-2 PCDocument92 pagesH15B Plus-2 PCЕвгений ИвановNo ratings yet

- All About EthanolaminesDocument7 pagesAll About EthanolaminesVineeth Nair100% (1)