Professional Documents

Culture Documents

Cold Forming Procedure of Single Piece 2:1 Ellipsoidal Dish End

Uploaded by

suria qaqcOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cold Forming Procedure of Single Piece 2:1 Ellipsoidal Dish End

Uploaded by

suria qaqcCopyright:

Available Formats

QA/CFP/02

COLD FORMING PROCEDURE OF SINGLE PIECE

2:1 ELLIPSOIDAL DISH END REV.0

Page 1 of 4

COLD FORMING PROCEDURE OF SINGLE PIECE 2:1 ELLIPSOIDAL DISH END

CLIENT EPCL

PO NO.

MATERIAL A-36

JOB CN 2F Exchanger

SIZE OF DISH END 500mm x 6mm

TYPE OF DISH END ELLIPSOIDAL

DRAWING NO T07B01-100FE20-0200

ITEM NO 01 (QTY.02)

Altaf Khan Nauman Suria EPCL

01 Rev-00 18/3/2021 QA/QC Eng. Director Client

Sr. No. Rev. No. Date Prepared by Approved by Accepted by

QA/CFP/02

COLD FORMING PROCEDURE OF SINGLE PIECE

2:1 ELLIPSOIDAL DISH END REV.0

Page 2 of 4

❖ SCOPE: -

This specific procedure describes the method of pressing the seamless single piece dish

end by cold forming process

❖ REFERENCE STANDERD: -

ASME Sec VIII Div. 1 Edition 2015

ASME Sec II Part A Edition 2015

ASME Sec V Edition 2015

❖

DISH END FORMING ACTIVITIES & RESPONSIBILITIES

➢ Quality Control Engineer

1. Quality Control Engineer shall be responsible to send the Quality assurance plan i.e.

Inspection test plan, Mill test certificates, Heat treatment procedures, NDT procedures,

forming procedure send to client for approval.

2. QC Engineer shall be responsible to proceed with job only after approval of all technical

documents received

3. QC Engineer shall be responsible for to ensure that the received plates are free from scales

/rust /oil / grease. If required mechanical cleaning shall be applying to clean the plate

surface.

4. Correlate the plate’s identification with Mill Test Certificate and review/verify the mill

test certificate as per requirement of ASME Sec II-part A. Original Mill Marking shall be

recorded and included in final technical dossier.

5. Verify the Dish development marking i.e. blank diameter shall be done as per plate layout

and check that identification stamping transfer on marked blanks and on balance plate.

6. QC Engineer shall prepare the Material identification report and Identify the developed

blank.

➢ Production Supervisor

a. Production supervisor shall be responsible to check the approved drawing and to ensure

that the gas cuts / plasma cutting of Dish end blank is done as per layout.

b. Production Supervisor shall be responsible to check that cut blanks are serration free

c. Seamless blank shall be formed by the cold successive pressing method. Suitable dies and

punches of CS material shall be used for required size, shape & profile as per approved

drawing. Two dimensional templates used for checking & inter-stage inspection as per the

drawing and as per relevant code.

d. Dish End shall be cold formed by following stages

1. Crowning: - Crowning is spherical pressing from edge to center successively by

super imposing 50% of pressing as shown. Below.

Dish End Blank

Dish Blank

QA/CFP/02

COLD FORMING PROCEDURE OF SINGLE PIECE

2:1 ELLIPSOIDAL DISH END REV.0

Page 3 of 4

Crowning

2. Edge braking: - Reducing diameter by braking edges and keep diameter

approximate 100 to 150 mm more than required diameter

100 -150mm

Edge braking

3. knuckling: - Edge braked portion is pressed into knuckling die & punches. This

Die & Punch is of same knuckle radius with spring back allowance and at the

same time desired circumference is achieved so is the diameter.

Dish End Diameter

Knuckling Knuckled

4. Polishing/ Ovality Correction: - by pressing high spots on crown portion to

achieve gradual profile on crown is called polishing. Ovality correction is done by

pressing minus side diameter to the required/ desired diameter.

e. After complete forming of Dish End, Heat treatment i.e. Normalizing shall be carried out

as per cycle mentioned in approved drawing.

f. Water level shall be done along with reference line. The trimming line shall be marked on

the dish ends

g. After leveling trimming to be carried out by machining and production supervisor is

responsible to monitor this activity and check that weld edge preparation shall be as per

approved drawing and checked by bevel protractor.

h. Grinding shall be carried from entire full inside & outside full surface.

➢

SAFETY: -

a. Shop floor worker shall be aware of safety procedure.

b. During the forming of Dish end all workers/operator shall wear the protective equipment

such as helmets, safety shoes, goggles & hand gloves etc.

c. No one shall be allowed to enter in shop without helmet, safety shoe.

d. All the safety procedure shall be taken as per safety manual. Special attention/safety

precaution shall be taken while pressing the dish ends

➢

INSPECTION EXAMINATION & TESTING: -

Inspection of the formed head for the dimensional and shape requirement as per approved

drawing. The following stages are carried out & shall be witnessed by client EPCL.

a. Layout of the template profile on the floor and checking of the template with reference

dimensions of dished end.

b. Checking of template in various directions inside the formed head for the over crowning

QA/CFP/02

COLD FORMING PROCEDURE OF SINGLE PIECE

2:1 ELLIPSOIDAL DISH END REV.0

Page 4 of 4

and under crowning tolerances of the code.

c. Checking the inside circumference and inside diameter as per approved drawing.

d. Checking the minimum thickness by the calibrated thickness meter at various points to

ascertain that the minimum thickness at any point is not below the drawing requirement,

e. Checking the height, ovality (±1%) as per approved drawing.

f. 100% DP Test on Inside full surface shall be carry out after complete forming & Heat

Treatment.

g.Dimensional, visual inspection report with all other technical documents including NDT

reports will be submitted to client.

➢ HANDLING & DISPATCH: -

a.Once all inspection activities over dish end shall be ready for dispatch.

b.During the handling & Dispatch proper care shall be taken.

c. During handling the dish end always use proper protection i.e. polythene/fiber sheets to

avoid the damage on side.

d.During packing use protective films such as polythene, bubble sheets to avoid the direct

contact of surface with each other.

e. During the dispatch use the antirust oil from outside of dish end to avoid the rusting due to

atmospheric condition.

f. Do not hammer the dish ends from outside to fit in packing, always make the proper packing

to avoid the damage on dish ends

You might also like

- Shop Fabrication and Inspection Procedure for Gasoline and Engine Oil TankDocument7 pagesShop Fabrication and Inspection Procedure for Gasoline and Engine Oil TankGATOTNo ratings yet

- Floating Head Heat Exchanger Hydrotest ProcedureDocument15 pagesFloating Head Heat Exchanger Hydrotest ProcedureDoğuhan DenizgezNo ratings yet

- Procedure for Flame Straightening Structural SteelDocument3 pagesProcedure for Flame Straightening Structural SteelAvishek Gupta100% (1)

- Wps & Pqr-013 (Ss Gtaw-Smaw TGS)Document17 pagesWps & Pqr-013 (Ss Gtaw-Smaw TGS)Atuk SafizNo ratings yet

- Repair Procedure For Super Heater Coil TubesDocument2 pagesRepair Procedure For Super Heater Coil Tubesbehzad mohammadiNo ratings yet

- Lot Inspection Report For LPG New CylindersDocument3 pagesLot Inspection Report For LPG New CylindersJagannath MajhiNo ratings yet

- Baking and Drying Temperature of ElectrodesDocument1 pageBaking and Drying Temperature of ElectrodesshisNo ratings yet

- Irrigation System Materials and Installation SpecificationDocument92 pagesIrrigation System Materials and Installation Specificationsushant_moreyNo ratings yet

- STS EDAC WELD REPAIR PROCEDUREDocument51 pagesSTS EDAC WELD REPAIR PROCEDUREmohd as shahiddin jafriNo ratings yet

- PWHTDocument3 pagesPWHTharishcsharmaNo ratings yet

- Painting Report Cd3Document15 pagesPainting Report Cd3sivaNo ratings yet

- Jotun Resist 86Document5 pagesJotun Resist 86Ansar AliNo ratings yet

- 22 LNT Ni1 (ER80S-Ni1) 2.4mm 3.1 MTCDocument1 page22 LNT Ni1 (ER80S-Ni1) 2.4mm 3.1 MTCnwoforNo ratings yet

- Long Seam Inspection ProcedureDocument4 pagesLong Seam Inspection ProcedureDeepak100% (1)

- Wps PQR Spec IndexDocument1 pageWps PQR Spec IndexTridib DeyNo ratings yet

- Incoming Material Inspection Report: Date of ReceiptDocument1 pageIncoming Material Inspection Report: Date of ReceiptRaj MNo ratings yet

- Table UCS-56-2 Postweld Heat Treatment Requirements For Carbon and Low Alloy Steels - P-No. 3Document7 pagesTable UCS-56-2 Postweld Heat Treatment Requirements For Carbon and Low Alloy Steels - P-No. 3MechanicalNo ratings yet

- Ferrite Content ReportDocument2 pagesFerrite Content ReportJawad MunirNo ratings yet

- SA 387 Grade 91 Class 2Document4 pagesSA 387 Grade 91 Class 2briang-2No ratings yet

- Astm A179 PDFDocument1 pageAstm A179 PDFgaminNo ratings yet

- Zinc Plating Reports 01Document2 pagesZinc Plating Reports 01Amandeep Singh100% (1)

- High Performance Epoxy Coating SpecificationDocument12 pagesHigh Performance Epoxy Coating SpecificationDanny SeeNo ratings yet

- Header Plug Seal Weld ProcedureDocument3 pagesHeader Plug Seal Weld ProcedureMohd Shafuaaz Kassim100% (1)

- WPS NMB 001Document6 pagesWPS NMB 001mohamed nasserNo ratings yet

- MS For Fabrication of Above-Ground Storage TankDocument8 pagesMS For Fabrication of Above-Ground Storage Tankdadz mingiNo ratings yet

- Welding Report For Tank 1Document1 pageWelding Report For Tank 1Rifki HasyaNo ratings yet

- GMAWDocument12 pagesGMAWsushant47No ratings yet

- Application Form For CSWIP 10 Year Assessment (Overseas) No LogbookDocument10 pagesApplication Form For CSWIP 10 Year Assessment (Overseas) No LogbookKarthikeyanNo ratings yet

- Guidance To Prepare Wps PQR For WeldingDocument1 pageGuidance To Prepare Wps PQR For WeldingHamid MansouriNo ratings yet

- Job Procedure For Tanks Radiography Test: 10 of Ramadan City, Industrial Area A1, EgyptDocument13 pagesJob Procedure For Tanks Radiography Test: 10 of Ramadan City, Industrial Area A1, EgyptShubham ShuklaNo ratings yet

- Covalence HTLP80Document2 pagesCovalence HTLP80Jèfrì PìnémNo ratings yet

- External Pipe Wrapping - Inspection and Test Plan: Description of LocationDocument2 pagesExternal Pipe Wrapping - Inspection and Test Plan: Description of LocationDavidNo ratings yet

- ADOR Booklet F Web FDocument132 pagesADOR Booklet F Web FbadesharamkNo ratings yet

- 3LPE Repair ProcedureDocument3 pages3LPE Repair Procedurelhanx2No ratings yet

- Welding Procedure Specification (WPS) : Page: 1/1Document5 pagesWelding Procedure Specification (WPS) : Page: 1/1Walid BdeirNo ratings yet

- Low Hydrogen Electrode BakingDocument1 pageLow Hydrogen Electrode BakingnksNo ratings yet

- WPS for FCAW Welding of SteelDocument2 pagesWPS for FCAW Welding of SteelHamid MansouriNo ratings yet

- Material Information Sheet For Plates: Erndtebrücker EisenwerkDocument2 pagesMaterial Information Sheet For Plates: Erndtebrücker EisenwerkAhmad KamilNo ratings yet

- Blasting and Painting Inspection Report: Achieved Profile Date of Report No: DFT Application DateDocument3 pagesBlasting and Painting Inspection Report: Achieved Profile Date of Report No: DFT Application DateLOPA THANDARNo ratings yet

- Welder and Wps Qualification Control ProcedureDocument24 pagesWelder and Wps Qualification Control ProcedurejhuliocessarsNo ratings yet

- Asme CCase 1987-2Document2 pagesAsme CCase 1987-2ADAMJSRAONo ratings yet

- CV Mechanical Engineer with Extensive Experience in Oil & Gas ProjectsDocument3 pagesCV Mechanical Engineer with Extensive Experience in Oil & Gas Projectshamza brahmiNo ratings yet

- Job Procedure For PWHT of Storage Tanks: 10 of Ramadan City, Industrial Area A1, EgyptDocument5 pagesJob Procedure For PWHT of Storage Tanks: 10 of Ramadan City, Industrial Area A1, EgyptShubham ShuklaNo ratings yet

- Storing and Redrying Electrodes-Lincoln ElectricDocument3 pagesStoring and Redrying Electrodes-Lincoln ElectricjasminneeNo ratings yet

- Heat Treatment of Thin Wall Tanks by Internal Oil Firing MethodDocument7 pagesHeat Treatment of Thin Wall Tanks by Internal Oil Firing MethodKrishna VachaNo ratings yet

- Helium leak test procedureDocument7 pagesHelium leak test procedureChandrasekhar mishraNo ratings yet

- BS 1724 (Bronze Welding by Gas)Document24 pagesBS 1724 (Bronze Welding by Gas)nandi_scrNo ratings yet

- Base Matrial chemical Analysis, Electrode and Filler Wire for Various Welding ProcessDocument1 pageBase Matrial chemical Analysis, Electrode and Filler Wire for Various Welding ProcessMel gibsonNo ratings yet

- The NEW Company ProfileDocument26 pagesThe NEW Company ProfilewisandhaNo ratings yet

- Inspection Certificate According To EN 10204, Type 3.1.: EN ISO 17632-A: T464MM1H5Document1 pageInspection Certificate According To EN 10204, Type 3.1.: EN ISO 17632-A: T464MM1H5abdulNo ratings yet

- JNK Heaters Co - LTD: Ferrite Test ReportDocument1 pageJNK Heaters Co - LTD: Ferrite Test ReportUzorNo ratings yet

- Welding Parameters Control PipelineDocument1 pageWelding Parameters Control PipelinemusheerNo ratings yet

- Thermal Power Project Weld Inspection ReportDocument1 pageThermal Power Project Weld Inspection ReportAshwani DograNo ratings yet

- 8 JSA Holyday TestDocument3 pages8 JSA Holyday TestYosua SitumorangNo ratings yet

- 8615 Nozzle Orientation Report 01Document4 pages8615 Nozzle Orientation Report 01Bsc Aditya Singh Dinkar100% (1)

- SOW Fabrikasi C-335-01 - 19.116.1Document1 pageSOW Fabrikasi C-335-01 - 19.116.1AlfanNo ratings yet

- Cold Forming Procedure Ellipsoidal Dish EndDocument4 pagesCold Forming Procedure Ellipsoidal Dish EndKunal Ajgaonkar100% (1)

- Fabrication Procedure for Rolling Shell PlatesDocument10 pagesFabrication Procedure for Rolling Shell PlatesMuhammad Yunus NurdinNo ratings yet

- Pulley Manufacturing ProceduresDocument4 pagesPulley Manufacturing ProceduresVijayakumar SamyNo ratings yet

- TT306 Dossier.Document29 pagesTT306 Dossier.suria qaqcNo ratings yet

- Suria Engineering.: Test Pack For Tt307B PipingDocument18 pagesSuria Engineering.: Test Pack For Tt307B Pipingsuria qaqcNo ratings yet

- 10+ Years Mechanical Engineering and Project Management ExperienceDocument1 page10+ Years Mechanical Engineering and Project Management Experiencesuria qaqcNo ratings yet

- Daily Inword Gate Pass (D)Document195 pagesDaily Inword Gate Pass (D)suria qaqcNo ratings yet

- BOQ PIPING Total DetailDocument16 pagesBOQ PIPING Total Detailsuria qaqcNo ratings yet

- Suria Engineering Dossier for TT307B StructureDocument41 pagesSuria Engineering Dossier for TT307B Structuresuria qaqcNo ratings yet

- Engineering dossier for DSQ structure EDC/VCM extentionDocument62 pagesEngineering dossier for DSQ structure EDC/VCM extentionsuria qaqcNo ratings yet

- Sub Station Structure.Document33 pagesSub Station Structure.suria qaqcNo ratings yet

- Suria Engineering.: Test Pack For Tt307B PipingDocument16 pagesSuria Engineering.: Test Pack For Tt307B Pipingsuria qaqcNo ratings yet

- Suria Engineering Dossier for TLE-01 StructureDocument39 pagesSuria Engineering Dossier for TLE-01 Structuresuria qaqcNo ratings yet

- Suria Engineering Dossier for GF-304CR StructureDocument35 pagesSuria Engineering Dossier for GF-304CR Structuresuria qaqcNo ratings yet

- Tle-02 Dossier.Document40 pagesTle-02 Dossier.suria qaqcNo ratings yet

- Weekly HSE ReportDocument1 pageWeekly HSE Reportsuria qaqcNo ratings yet

- Ovr Dossier.Document93 pagesOvr Dossier.suria qaqcNo ratings yet

- JOTI RFI Log 23-11-2020Document1 pageJOTI RFI Log 23-11-2020suria qaqcNo ratings yet

- Task Instructions (Ti) : Date: Time: Dept: PTW No Location: Emergency No: What Is The Task Today?Document2 pagesTask Instructions (Ti) : Date: Time: Dept: PTW No Location: Emergency No: What Is The Task Today?suria qaqcNo ratings yet

- Observation Sheet: ObservationsDocument1 pageObservation Sheet: Observationssuria qaqcNo ratings yet

- E1461 Dossier.Document46 pagesE1461 Dossier.suria qaqcNo ratings yet

- Suria Engineering Staff List: Doc No: Rev By: DateDocument3 pagesSuria Engineering Staff List: Doc No: Rev By: Datesuria qaqcNo ratings yet

- Site Hse Rules: Doc No: Rev By: DateDocument1 pageSite Hse Rules: Doc No: Rev By: Datesuria qaqcNo ratings yet

- Suria Engineering: Tool Box Talk FormDocument1 pageSuria Engineering: Tool Box Talk Formsuria qaqcNo ratings yet

- Method StatementDocument1 pageMethod Statementsuria qaqcNo ratings yet

- Site Hse Rules: Doc No: Rev By: DateDocument1 pageSite Hse Rules: Doc No: Rev By: Datesuria qaqcNo ratings yet

- Near Miss Meeting AttendenceDocument1 pageNear Miss Meeting Attendencesuria qaqcNo ratings yet

- Name Plate Waste Water TankDocument1 pageName Plate Waste Water Tanksuria qaqcNo ratings yet

- PPEs Issue ListDocument1 pagePPEs Issue Listsuria qaqcNo ratings yet

- Suria Engineering's 7 Golden Rules for Safe Work PracticesDocument1 pageSuria Engineering's 7 Golden Rules for Safe Work Practicessuria qaqcNo ratings yet

- Method StatementDocument1 pageMethod Statementsuria qaqcNo ratings yet

- Equipment Recalibration DateDocument1 pageEquipment Recalibration Datesuria qaqcNo ratings yet

- Dish EndDocument1 pageDish Endadam150161No ratings yet

- Land Sale Dispute Interest Rate CaseDocument3 pagesLand Sale Dispute Interest Rate CaseAnne MiguelNo ratings yet

- FR-F800 Instruction Manual PDFDocument614 pagesFR-F800 Instruction Manual PDFelivandrojuniorNo ratings yet

- Personal Styling Service-Contract - No WatermarkDocument5 pagesPersonal Styling Service-Contract - No WatermarkLexine Emille100% (1)

- 3 Kinds of de Facto Government:: CharacteristicsDocument10 pages3 Kinds of de Facto Government:: CharacteristicsAbigael SeverinoNo ratings yet

- Static GK For Iift Snap and XatDocument19 pagesStatic GK For Iift Snap and XatnavinkumargNo ratings yet

- Navigating The Digital Age PDFDocument369 pagesNavigating The Digital Age PDFSteve GilsonNo ratings yet

- Educ 13C Questions For MidtermDocument9 pagesEduc 13C Questions For MidtermSannie MonoyNo ratings yet

- Toaz - Info Module in Ergonomics and Planning Facilities For The Hospitality Industry PRDocument33 pagesToaz - Info Module in Ergonomics and Planning Facilities For The Hospitality Industry PRma celine villoNo ratings yet

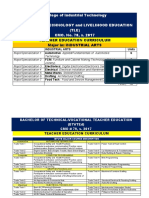

- College of Industrial Technology Bachelor of Technology and Livelihood Education (TLE) CMO. No. 78, S. 2017Document5 pagesCollege of Industrial Technology Bachelor of Technology and Livelihood Education (TLE) CMO. No. 78, S. 2017Industrial TechnologyNo ratings yet

- Global CityDocument3 pagesGlobal Citycr lamigoNo ratings yet

- Zodiac Working Boat MK6HDDocument4 pagesZodiac Working Boat MK6HDdan antonNo ratings yet

- The Stolen EaglesDocument12 pagesThe Stolen EaglesJavier Horacio FernandezNo ratings yet

- Manual Flowpet 5GDocument56 pagesManual Flowpet 5GRahkmat DanizarNo ratings yet

- Share KhanDocument17 pagesShare KhanRicha GargNo ratings yet

- Government's Role in Public HealthDocument2 pagesGovernment's Role in Public Healthmrskiller patchNo ratings yet

- What Is A Human Resources Strategy?Document8 pagesWhat Is A Human Resources Strategy?abdallah abdNo ratings yet

- Total Standards: - Total Sub-Standards: - Total ESR StandardsDocument8 pagesTotal Standards: - Total Sub-Standards: - Total ESR StandardsHCX dghhqNo ratings yet

- Un Authorised Sites Regularisation Within Sept 2009Document2 pagesUn Authorised Sites Regularisation Within Sept 2009Sridhara babu. N - ಶ್ರೀಧರ ಬಾಬು. ಎನ್No ratings yet

- Importance of Communication by ThiruvalluvarDocument7 pagesImportance of Communication by ThiruvalluvarRamavallabhanNo ratings yet

- Kalokal Barangay Highway HillsDocument35 pagesKalokal Barangay Highway HillsDixie MirandaNo ratings yet

- Accounting for Business CombinationsDocument52 pagesAccounting for Business CombinationsEliza BethNo ratings yet

- SDA HLD Template v1.3Document49 pagesSDA HLD Template v1.3Samuel TesfayeNo ratings yet

- PRACTICA (1) (1) - Páginas-2-4Document3 pagesPRACTICA (1) (1) - Páginas-2-4EDDY POLICARPIO BRAVO HUAMANINo ratings yet

- 03board of Directors Resolution For AGRONetBIZ ENGLISHDocument1 page03board of Directors Resolution For AGRONetBIZ ENGLISHyuswirdaNo ratings yet

- Jasmine Nagata Smart GoalsDocument5 pagesJasmine Nagata Smart Goalsapi-319625868No ratings yet

- NOC Hardware Management SO.P. Derricks FormattedDocument3 pagesNOC Hardware Management SO.P. Derricks Formattedapi-27532183No ratings yet

- Space Management Guidelines: Brief SummaryDocument17 pagesSpace Management Guidelines: Brief SummaryMOHD JIDINo ratings yet

- Spare Parts Catalog - Scooptram ST1030Document956 pagesSpare Parts Catalog - Scooptram ST1030Elvis RianNo ratings yet

- AarDocument2 pagesAarkomar agusNo ratings yet