Professional Documents

Culture Documents

Process Flow Diagram: Area: Valve Jamming & Tube Splicing Process - 06

Uploaded by

aslamOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Process Flow Diagram: Area: Valve Jamming & Tube Splicing Process - 06

Uploaded by

aslamCopyright:

Available Formats

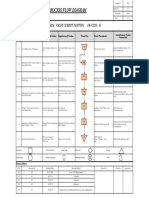

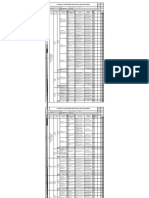

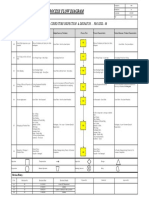

Document No.

NPD

PROCESS FLOW DIAGRAM

Revision No. 05

Revision Date 13.01.2021

Page 1 of 1

AREA : VALVE JAMMING & TUBE SPLICING … PROCESS - 06

Sub-process Desired Outcome / Product

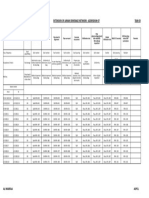

S. No. Input Sourse of Variation Output Source of Variation Process Flow Process Characteristics

Description Characteristics

Valve Offset (mm) ,

Valve Offset (mm) , Valve Jamming Time( Sec) ,

Valve Jamming Time( Sec) ,

Valve Jamming on Valve Jamming Pressure (PSI) - Out of Spec , Weak & Non-uniform Valve Adhesion 6.1 Strong & Uniform Adhesion of Valve

6.1 Valve Jamming Pressure (PSI) - As per Spec ,

Green Tube. Valve Condition for Jamming - Not OK, on Green Tube .

Valve Condition for Jamming - OK .

on Green Tube .

Design of Dye-pad erratic

Modified Dye pad to prevent cuts

Knife Low Heat , Knife Low Heat ,

Knife High Heat , Knife High Heat ,

Clamping Pressure , Clamping Pressure ,

Butting Pressure , Butting Pressure ,

Butting Time , Butting Time ,

Clamp Gap , Clamp Gap ,

6.2 Splicing of GreenTube. Knife Gap - Out of Spec Weak Joining of Green Tube Ends . 6.2 Knife Gap - As per Spec Strong Joining of Green Tube Ends .

Knife Edges - Damaged , Knife Edges - Smooth ,

Clamp Hardness - Over aged , Clamp Hardness - Not Aged ,

Clamp-End Block- Out of smooth Alignment , Clamp-End Block- In smooth Alignment ,

Taper Cutting by Knife , No Taper Cutting by Knife ,

Collapsing of Knife - Inadequate . Collapsing of Knife - Adequate .

Flash on Tube Ends ,

Solder Knife Temp - Out of Spec Solder Knife Temp - As per Spec , Spliced Green Tube with Lubricated

Soldering & Lubrication Tube Ends not Lubricated , 6.3

6.3 on Spliced Green Tube .

Composition of VL- Out of Spec,

Valve area not Lubricated,

Composition of VL- As per Spec . Ends & Valve area , free of Flash &

Trollies not covered to prevent FM Trollies fitted with cannopies to prevent FM Contamination

contaminated with FM/Tailings

Operation Transportation Inspection Storage

Preparation Manual Operation Summing Junction Delay

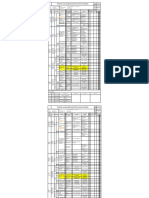

Revision History :

S No. Revision No Revision Date Revision Details Prepared By Checked by Approved By

01 00 01.01.2018 As per IATF Requirement.

02 01 10.06.2018 Design of Jamming Pad Dye modified to prevent cut marks on the Valve-edge

03 02 12.06.2019 Updation for Lubrication of Valve area .

04 03 11.11.2019 Updation for Trollies fitted with Canopy to prevent FM

05 04 18.08.2020 Updated for the smooth alignment of end-blocks to prevent Weak-splice

06 05 13.01.2021 Updated for adequate soldering-flash removal to prevent crack-splice

You might also like

- 12T1600 Mud Pump Clearance Check FormDocument1 page12T1600 Mud Pump Clearance Check FormMoataz Nazeem100% (1)

- Roadmap For ActivitiesDocument1 pageRoadmap For ActivitiesaslamNo ratings yet

- Potential Failure Mode and Effects Analysis (Pfmea)Document1 pagePotential Failure Mode and Effects Analysis (Pfmea)aslamNo ratings yet

- Procedure: Measurement System Analysis ExecutionDocument1 pageProcedure: Measurement System Analysis Executionaslam100% (1)

- Pump Head CalculationsDocument6 pagesPump Head Calculationsviral videosNo ratings yet

- Enquiry No: Part Name: Customer: Part No.:: S.No. Feasibility Conceren Yes No Remark'sDocument2 pagesEnquiry No: Part Name: Customer: Part No.:: S.No. Feasibility Conceren Yes No Remark'saslamNo ratings yet

- Process Flow DiagramDocument1 pageProcess Flow DiagramBasavaraj BkNo ratings yet

- Parts PDFDocument96 pagesParts PDFviraj arjun ghadage100% (1)

- Body Mounting Manual: KK-GH214Document264 pagesBody Mounting Manual: KK-GH214locario1No ratings yet

- MSA Training RevAFDocument134 pagesMSA Training RevAFVikram Billal100% (2)

- CT120 6986522 enUS Om 04-10Document214 pagesCT120 6986522 enUS Om 04-10Henry HuayhuaNo ratings yet

- Cat 312c Diagr ElecDocument4 pagesCat 312c Diagr ElecDaniel Galvis75% (12)

- GEA32129A Heavy Duty Gas Turbine Monitoring Protection R1Document48 pagesGEA32129A Heavy Duty Gas Turbine Monitoring Protection R1Manuel L LombarderoNo ratings yet

- Ho (V) - 4-1 Side ThrustersDocument125 pagesHo (V) - 4-1 Side ThrustershamzehNo ratings yet

- CBLMMMMMMMMDocument40 pagesCBLMMMMMMMMEra Tandaan100% (1)

- Ip060-45!20!02 Orifice Plate Assembly (Buyer's Scope)Document5 pagesIp060-45!20!02 Orifice Plate Assembly (Buyer's Scope)Rahul DevaNo ratings yet

- BOSS Flamco Pipe Support SystemDocument64 pagesBOSS Flamco Pipe Support Systempaulo100% (1)

- Process Flow Diagram: Area: Green Tube Curing Process - 07Document1 pageProcess Flow Diagram: Area: Green Tube Curing Process - 07aslamNo ratings yet

- 3 PFDDocument1 page3 PFDaslamNo ratings yet

- Minor Loss Coefficients in Pipes and Tubes ComponentsDocument1 pageMinor Loss Coefficients in Pipes and Tubes ComponentsHimanshu1712No ratings yet

- Calipers: NomenclatureDocument1 pageCalipers: NomenclatureozanNo ratings yet

- Well AssessmentDocument1 pageWell Assessmentcool cooperyNo ratings yet

- 110 01 Glass Trac Specification Guide Rev 1Document14 pages110 01 Glass Trac Specification Guide Rev 1vilegual1No ratings yet

- Sewer Check List Task-3Document1 pageSewer Check List Task-3csacas sacscNo ratings yet

- GM Gen. 1 6T70/75 GM Gen. 2 6T70/75/80Document10 pagesGM Gen. 1 6T70/75 GM Gen. 2 6T70/75/80fabricio0svs0liraNo ratings yet

- Glass Trac Specification GuideDocument14 pagesGlass Trac Specification Guidemehdi HKNo ratings yet

- HCC Tricone Technology ForSLB 6ppDocument8 pagesHCC Tricone Technology ForSLB 6ppamin peyvandNo ratings yet

- Rock Breaker Service Report 28-Jun-2019Document2 pagesRock Breaker Service Report 28-Jun-2019Kadir Koray BozyelNo ratings yet

- 545 7489 (EAG349) - Process FlowDocument1 page545 7489 (EAG349) - Process FlowDurai NaiduNo ratings yet

- Pressure Gauges: Armaturenbau GMBH Manotherm Beierfeld GMBHDocument8 pagesPressure Gauges: Armaturenbau GMBH Manotherm Beierfeld GMBHVladimirNo ratings yet

- 280 - Parametor Input ProcedureDocument3 pages280 - Parametor Input ProcedureFajriRamadhanNo ratings yet

- Pipebook Work Package 1Document39 pagesPipebook Work Package 1Renaldo akbarNo ratings yet

- Preparation 1zr-Fe Engine Mechanical Equipment PDFDocument1 pagePreparation 1zr-Fe Engine Mechanical Equipment PDFAlbert BriceñoNo ratings yet

- Road ConcretingDocument58 pagesRoad ConcretingHerbee ZevlagNo ratings yet

- Autoclave Full CatalogDocument481 pagesAutoclave Full CatalogGabriel Jamariqueli BueresNo ratings yet

- DWG CP18 20754 01 REV01 Ga Drawing PDFDocument1 pageDWG CP18 20754 01 REV01 Ga Drawing PDFEnriquinoNo ratings yet

- 12282A - Expansion Joints DatasheetDocument1 page12282A - Expansion Joints DatasheetGaurav TripathiNo ratings yet

- BHH BH13: Rubber Hoses Steel Wire SpiralDocument1 pageBHH BH13: Rubber Hoses Steel Wire SpiralАндрей КулешовNo ratings yet

- GSB-Form-255 Visual Inspection ReportDocument1 pageGSB-Form-255 Visual Inspection ReportMade GileeNo ratings yet

- Wheatly TDV-N TSV-NDocument2 pagesWheatly TDV-N TSV-NWilvir MurilloNo ratings yet

- Dimensional Inspection Report: Status: Surface: Units: AS Received Final Radial Axial Millimeters InchesDocument9 pagesDimensional Inspection Report: Status: Surface: Units: AS Received Final Radial Axial Millimeters InchesAditya PrajasNo ratings yet

- Ache Manufacturing Process - Pembangunan Mini LPG Plant 2.2 MMSCFDDocument1 pageAche Manufacturing Process - Pembangunan Mini LPG Plant 2.2 MMSCFDbayu kusumaNo ratings yet

- LL9DJUU Mechanical SealDocument2 pagesLL9DJUU Mechanical SealMayur PattanshettiNo ratings yet

- GIP2 IPFSIL-EXE-RTSB (TASB) - 000-INC-TDS-0002 - RevB (Datasheet) (1) - 4Document1 pageGIP2 IPFSIL-EXE-RTSB (TASB) - 000-INC-TDS-0002 - RevB (Datasheet) (1) - 4Kacip BolaNo ratings yet

- GeoborDocument13 pagesGeoborLuis Edgardo Fuentes MartinezNo ratings yet

- PL FormsDocument38 pagesPL FormsValueNo ratings yet

- PST4CSDocument4 pagesPST4CSNilo Villamarin CastroNo ratings yet

- Fracture Formation PressureDocument7 pagesFracture Formation Pressuredekra abdoNo ratings yet

- Design E100 PMB AND GN KEMALA 15 MMSCFD Page 96Document1 pageDesign E100 PMB AND GN KEMALA 15 MMSCFD Page 96wahyu hidayatNo ratings yet

- APN BroucherDocument8 pagesAPN BroucherpixieNo ratings yet

- Section3 - Pipeline StoppersDocument22 pagesSection3 - Pipeline StoppersMelele MuNo ratings yet

- Mini-: Precise Turning, Grooving, Threading & Face GroovingDocument24 pagesMini-: Precise Turning, Grooving, Threading & Face GroovingMiguelNo ratings yet

- 2GR-FSE - Engine Mechanical - Equipment NeededDocument2 pages2GR-FSE - Engine Mechanical - Equipment NeededJohn LockeNo ratings yet

- TOF-036 Formato de Pipe Repair Inspeciton ReportDocument2 pagesTOF-036 Formato de Pipe Repair Inspeciton ReportRodrigoNo ratings yet

- Process Flow Diagram: Area: Valve Cement Painting Process - 05Document1 pageProcess Flow Diagram: Area: Valve Cement Painting Process - 05aslamNo ratings yet

- AaaDocument9 pagesAaawretchNo ratings yet

- Inspection Report For Pipeline Route Survey Sign Copy and Blank FormatDocument1 pageInspection Report For Pipeline Route Survey Sign Copy and Blank FormatVishvjeet Prakash TiwariNo ratings yet

- Pump TemplateDocument2 pagesPump TemplateamitkrayNo ratings yet

- Pinza de Presion BB GimaticDocument2 pagesPinza de Presion BB GimaticHIDRAFLUIDNo ratings yet

- 6.7.7. Instrument Valve List (Safety Valve)Document1 page6.7.7. Instrument Valve List (Safety Valve)hungNo ratings yet

- Tyamsa - Ft-Tor - Hex - GR8 - Saej429Document2 pagesTyamsa - Ft-Tor - Hex - GR8 - Saej429Arturo VillalobosNo ratings yet

- NPT Sop Pde 006 f04 DQ BoilerDocument1 pageNPT Sop Pde 006 f04 DQ BoilerMohamed SelimNo ratings yet

- Key Features Designed For Limited Access Boiler Tube BevelingDocument1 pageKey Features Designed For Limited Access Boiler Tube Bevelingabdulgafoor54No ratings yet

- General Spec Sheets of All InstrumentsDocument32 pagesGeneral Spec Sheets of All InstrumentsArslan NisarNo ratings yet

- Sizing V Ball Fail To OpenDocument1 pageSizing V Ball Fail To Openfathan fathullahNo ratings yet

- Oil Filter Body0Document1 pageOil Filter Body0Chiller PartyNo ratings yet

- Char-Lynn: Steering Control UnitsDocument4 pagesChar-Lynn: Steering Control UnitsIslam ShoukryNo ratings yet

- Rubber Hoses Steel Wire SpiralDocument2 pagesRubber Hoses Steel Wire SpiralАндрей КулешовNo ratings yet

- Technical Specification - Pressure GaugeDocument4 pagesTechnical Specification - Pressure GaugeManodipPatilNo ratings yet

- 8 PDFDocument10 pages8 PDFjazNo ratings yet

- Curing PM Daily Check List FT-MNT-03Document2 pagesCuring PM Daily Check List FT-MNT-03aslamNo ratings yet

- Defect Details and AnalysisDocument1 pageDefect Details and AnalysisaslamNo ratings yet

- Detection: Evaluation Criteria: Ref:As Per AIAG PFMEA Standards Ril/Pfmea/Annex-C Likelihood of DetectionDocument1 pageDetection: Evaluation Criteria: Ref:As Per AIAG PFMEA Standards Ril/Pfmea/Annex-C Likelihood of DetectionaslamNo ratings yet

- Process Control Analysis - New Plant... 15.11.21Document30 pagesProcess Control Analysis - New Plant... 15.11.21aslamNo ratings yet

- Crop DataDocument1 pageCrop DataaslamNo ratings yet

- Potential Failure Mode and Effects Analysis (Pfmea)Document3 pagesPotential Failure Mode and Effects Analysis (Pfmea)aslamNo ratings yet

- Potential Failure Mode and Effects Analysis (Pfmea)Document3 pagesPotential Failure Mode and Effects Analysis (Pfmea)aslamNo ratings yet

- Critical Analysis of The Acceptance Criteria UsedDocument9 pagesCritical Analysis of The Acceptance Criteria UsedaslamNo ratings yet

- Critical Analysis of The Acceptance Criteria UsedDocument9 pagesCritical Analysis of The Acceptance Criteria UsedaslamNo ratings yet

- Green Tube Extrusion SpecificationDocument4 pagesGreen Tube Extrusion SpecificationaslamNo ratings yet

- Tube Scrap AnalysisDocument2 pagesTube Scrap AnalysisaslamNo ratings yet

- Tube Scrap AnalysisDocument2 pagesTube Scrap AnalysisaslamNo ratings yet

- Non Confirmity Closer FourDocument1 pageNon Confirmity Closer FouraslamNo ratings yet

- Defect Details and AnalysisDocument1 pageDefect Details and AnalysisaslamNo ratings yet

- Work Instructions-Testing of Physical Properties Hardness of Cured TubeDocument1 pageWork Instructions-Testing of Physical Properties Hardness of Cured TubeaslamNo ratings yet

- Tube Scrap AnalysisDocument2 pagesTube Scrap AnalysisaslamNo ratings yet

- Valve Adhesion: Work Instructions-Testing of Physical PropertiesDocument1 pageValve Adhesion: Work Instructions-Testing of Physical PropertiesaslamNo ratings yet

- Work Instructions-Testing of Physical Properties Specific GravityDocument1 pageWork Instructions-Testing of Physical Properties Specific GravityaslamNo ratings yet

- Distribution MatrixDocument1 pageDistribution MatrixaslamNo ratings yet

- Non Confirmity Closer OneDocument1 pageNon Confirmity Closer OneaslamNo ratings yet

- Non Confirmity Closer TwoDocument1 pageNon Confirmity Closer TwoaslamNo ratings yet

- Non Confirmity Closer Method-1Document1 pageNon Confirmity Closer Method-1aslamNo ratings yet

- Process Flow Diagram: Area: Cured Tube Inspection & Despatch Process - 08Document1 pageProcess Flow Diagram: Area: Cured Tube Inspection & Despatch Process - 08aslamNo ratings yet

- Process Flow Diagram: Area: Cured Tube Inspection & Despatch Process - 08Document1 pageProcess Flow Diagram: Area: Cured Tube Inspection & Despatch Process - 08aslamNo ratings yet

- Lecture Powerpoints: Physics: Principles With Applications, 7 EditionDocument45 pagesLecture Powerpoints: Physics: Principles With Applications, 7 EditionBsc CivilNo ratings yet

- Perkins Engine 1006TG2A SERIES SPARE PARTSDocument2 pagesPerkins Engine 1006TG2A SERIES SPARE PARTSIbrahim YunusNo ratings yet

- Range Rover Manual Service ToolsDocument10 pagesRange Rover Manual Service ToolsLouise RogersNo ratings yet

- Ex Motor Manual ML WebDocument156 pagesEx Motor Manual ML WebVíctor Josemaria Rivero DunoNo ratings yet

- Turcon Glyd Ring T: Double Acting Rubber Energized Plastic Faced SealDocument14 pagesTurcon Glyd Ring T: Double Acting Rubber Energized Plastic Faced SealPhong DuongNo ratings yet

- Control Chapter 1Document19 pagesControl Chapter 1Wilmar Antonio Zuluaga ArangoNo ratings yet

- Two Stage Snow Engine Service Manual: Residential ProductsDocument48 pagesTwo Stage Snow Engine Service Manual: Residential ProductsBJ DixNo ratings yet

- Prpposed Welding Procedure Specification (WPS) : Code: Asme Ix API 1104 AWS D1.1Document1 pagePrpposed Welding Procedure Specification (WPS) : Code: Asme Ix API 1104 AWS D1.1MohamedNo ratings yet

- NewpptmmsDocument28 pagesNewpptmmsVaibhav Jain0% (1)

- Automated Tugger AGV's For Factory AutomationDocument2 pagesAutomated Tugger AGV's For Factory Automationservice9046No ratings yet

- Automatic Float Switches 836 Series ABDocument37 pagesAutomatic Float Switches 836 Series ABJorge ReyesNo ratings yet

- Lpile Group ModuleDocument2 pagesLpile Group ModuleMUHAMMAD ALINo ratings yet

- Eileen IntroductionDocument43 pagesEileen IntroductionYork ZengNo ratings yet

- Compact-Line - Operating Manual 83000102.Kf PDFDocument77 pagesCompact-Line - Operating Manual 83000102.Kf PDFIsabelo RodriguezNo ratings yet

- Seleccion Chiller AguaDocument60 pagesSeleccion Chiller AguaÓscar Alfonso Gómez SepúlvedaNo ratings yet

- 2013-J C Han GT Heat Transfer ReviewDocument15 pages2013-J C Han GT Heat Transfer ReviewSsheshan PugazhendhiNo ratings yet

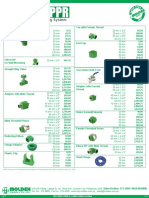

- Ecosafe PPR-Official PricelistDocument2 pagesEcosafe PPR-Official PricelistLoui Lester BarciaNo ratings yet

- T Bolt Specs PDFDocument2 pagesT Bolt Specs PDFrefaeNo ratings yet

- Problem Set 2.projectile MotionDocument9 pagesProblem Set 2.projectile MotionChristian OconNo ratings yet

- Whirlpool Awt 5067-3Document14 pagesWhirlpool Awt 5067-3Denes LazarNo ratings yet

- Training Module: Electrical Systems: Surveys On Electrical Machines - Applied BlockDocument13 pagesTraining Module: Electrical Systems: Surveys On Electrical Machines - Applied BlockmariodalNo ratings yet