Professional Documents

Culture Documents

Process Flow Diagram: Area: Green Tube Curing Process - 07

Uploaded by

aslamOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Process Flow Diagram: Area: Green Tube Curing Process - 07

Uploaded by

aslamCopyright:

Available Formats

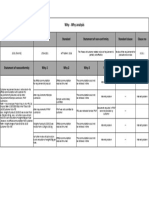

Document No.

NPD

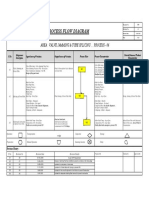

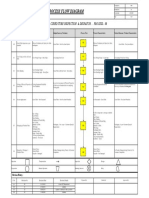

PROCESS FLOW DIAGRAM

Revision No. 03

Revision Date 30.06.20

Page 1 of 1

AREA : GREEN TUBE CURING … PROCESS - 07

Desired Outcome / Product

S. No. Sub-process Description Input Sourse of Variation Output Source of Variation Process Flow Process Characteristics

Characteristics

7.1

Chilling Time - Out of Spec , Chilling Time - As per Spec ,

7.1 Green Tube Splice Chilling Crown Area of Green Tube not Chilled Crown Area of Green Tube - Chilled

Moisture at Chilling Surface No Moisture at Chilling Surface.

7.2

7.2 Green Tube Preforming Green Tube Inflation - Out of Spec Green Tube - Not in Shape. Green Tube Inflation - As per Spec . Green Tube in Shape .

Cured Tube - Not Free from Defects & Customer Cured Tube - Free from Defects & Customer

Chilling Time , Specific Characteristics - Chilling Time , Specific Characteristics -

Peg set , Tube Size, Peg set , Tube Size,

Internal Air Pressure , Mould Number, 7.3 Internal Air Pressure , Mould Number,

Mould Temperature , Tube Appearance , Mould Temperature , Tube Appearance ,

7.3 Curing of Green Tube . Curing Time , Engraving / Venting , Curing Time , Engraving / Venting ,

Vent Time - Out of Spec , Month Code , Vent Time - As per Spec , Month Code ,

Step in Mould, ISI Mark & CML Number and Mould free of Step, ISI Mark & CML Number and

Mould-tightening bolts - Loose Valve Code - Not Confirming . Mould tightening - adequate Valve Code - Confirming .

Physical Properties-Not confirming Field Physical Properties- Confirming Field

Performance Performance

Operation Transportation Inspection Storage

Preparation Manual Operation Summing Junction Delay

Revision History :

S No. Revision No Revision Date Revision Details Prepared By Checked by Approved By

01 00 01.01.2018 As per IATF Requirement.

02 01 27.02.19 Updation

03 02 15.02.20 Updation

Updated to address for 16.9-28(TAFE) Puncture

04 03 30.06.20 problem due to Mould step

You might also like

- Process Flow Diagram: Area: Valve Jamming & Tube Splicing Process - 06Document1 pageProcess Flow Diagram: Area: Valve Jamming & Tube Splicing Process - 06aslamNo ratings yet

- 3 PFDDocument1 page3 PFDaslamNo ratings yet

- Process Flow Diagram: Area: Cured Tube Inspection & Despatch Process - 08Document1 pageProcess Flow Diagram: Area: Cured Tube Inspection & Despatch Process - 08aslamNo ratings yet

- Surface Condenser Specification Sheet: DesignDocument1 pageSurface Condenser Specification Sheet: DesignboeiniNo ratings yet

- Snap Head RivetDocument1 pageSnap Head RivetVilasNo ratings yet

- NPT Sop Pde 006 f04 DQ BoilerDocument1 pageNPT Sop Pde 006 f04 DQ BoilerMohamed SelimNo ratings yet

- Expansion Joint For EvaporateurDocument2 pagesExpansion Joint For EvaporateurLAKHTIRINo ratings yet

- Well Completions QuestionaireDocument27 pagesWell Completions QuestionaireashwaniNo ratings yet

- Inspection Standard: Daily Inprocess Inspection/Prod./Rejection ReportDocument5 pagesInspection Standard: Daily Inprocess Inspection/Prod./Rejection ReportPrakash kumarTripathiNo ratings yet

- SSV QTN 2022 2023 01277Document1 pageSSV QTN 2022 2023 01277Sachin Kumar SinghNo ratings yet

- Pipebook Work Package 1Document39 pagesPipebook Work Package 1Renaldo akbarNo ratings yet

- Jjl-Em-455-327 - en Valves and Actuators List For Exhaust Gas Bypass Stack PDFDocument2 pagesJjl-Em-455-327 - en Valves and Actuators List For Exhaust Gas Bypass Stack PDFZaki nouiNo ratings yet

- 300 Cutting Data Manual Smart Focus 300+FC-300+PerCut4000Document36 pages300 Cutting Data Manual Smart Focus 300+FC-300+PerCut4000peswanipgNo ratings yet

- Design Project HAZOP Draft 6Document6 pagesDesign Project HAZOP Draft 6Aleksei SukhovNo ratings yet

- 01 25284124-8230-26-000-0006 REV.02 Piping List EXISTING PIPE RACKDocument2 pages01 25284124-8230-26-000-0006 REV.02 Piping List EXISTING PIPE RACKRajeev KumarNo ratings yet

- Datasheet For Drum Scrubber of Line B & CDocument4 pagesDatasheet For Drum Scrubber of Line B & Clarbiaboumadi363No ratings yet

- SRI-MPS-EPC Upgrading Jetty Tuban and Its Ancillary Production and Transportaion Facilities-SBI - MFN22147R0Document5 pagesSRI-MPS-EPC Upgrading Jetty Tuban and Its Ancillary Production and Transportaion Facilities-SBI - MFN22147R0Dito NarendraNo ratings yet

- Process Flow Diagram: Area: Final Compound Mixing Process - 03Document1 pageProcess Flow Diagram: Area: Final Compound Mixing Process - 03aslamNo ratings yet

- Calculation Sheet of Main Pipes - Rev DDocument5 pagesCalculation Sheet of Main Pipes - Rev DAnonymous uXdS9Y7No ratings yet

- 01 25284124-8230-26-000-0008 REV.02 Piping List Tie-InDocument2 pages01 25284124-8230-26-000-0008 REV.02 Piping List Tie-InRajeev KumarNo ratings yet

- Heat Exchanger: Data Sheet ForDocument1 pageHeat Exchanger: Data Sheet ForAmanNo ratings yet

- Shell and Tube Heat ExchangerDocument1 pageShell and Tube Heat ExchangerNurulHiNo ratings yet

- Spherical TankDocument6 pagesSpherical Tankhgag selimNo ratings yet

- IPS-C-PM-215-Equipment Record CardDocument1 pageIPS-C-PM-215-Equipment Record Cardseguridadyambiente641No ratings yet

- Form H-3 Manufacturer'S Data Report For Watertube Boilers As Required by The Provisions of The ASME Code Rules, Section IVDocument2 pagesForm H-3 Manufacturer'S Data Report For Watertube Boilers As Required by The Provisions of The ASME Code Rules, Section IVmohdfirdausNo ratings yet

- 8 PDFDocument10 pages8 PDFjazNo ratings yet

- TSH-IP-00.0025 - 02 Bore & Counter Bore Diameter and Chamfer Diameter InspectionDocument5 pagesTSH-IP-00.0025 - 02 Bore & Counter Bore Diameter and Chamfer Diameter InspectionCong BuiNo ratings yet

- Falcon CatalogueDocument16 pagesFalcon CatalogueSayemAbusadatNo ratings yet

- 01 - 25284124-8230-26-000-0004 - REV.02 - Piping - List - O & U UndergroundDocument2 pages01 - 25284124-8230-26-000-0004 - REV.02 - Piping - List - O & U UndergroundRajeev KumarNo ratings yet

- 01 25284124-8230-26-000-0003 REV.02 Piping List EPCM6 PIPE RACKDocument1 page01 25284124-8230-26-000-0003 REV.02 Piping List EPCM6 PIPE RACKRajeev KumarNo ratings yet

- Strainer PDFDocument7 pagesStrainer PDFvinoj chandranNo ratings yet

- Mould Check List / Trial Record: FG Control Tube FG H-TopDocument8 pagesMould Check List / Trial Record: FG Control Tube FG H-ToprajeshNo ratings yet

- FM-109-17.1 - Nozzle Inspection ReportDocument1 pageFM-109-17.1 - Nozzle Inspection ReportSudeesh nNo ratings yet

- Data Sheet EjectorDocument4 pagesData Sheet EjectorGunturMudaAliAkbarNo ratings yet

- Laporan KerjaDocument1 pageLaporan Kerjagenta abadiNo ratings yet

- Certified: Continental Gold Buritica Mine Water Treatment ProjectDocument4 pagesCertified: Continental Gold Buritica Mine Water Treatment ProjectDistrisoluciones MC S.A.SNo ratings yet

- Gas Sizing PDFDocument36 pagesGas Sizing PDFChetan ChuriNo ratings yet

- Livent Corporation: Confidential Livent Document NoDocument21 pagesLivent Corporation: Confidential Livent Document NoRonald VillalongaNo ratings yet

- Mould Trial ReportDocument5 pagesMould Trial ReportSUBODHH0% (1)

- Hojas de Datos Planta de GasDocument23 pagesHojas de Datos Planta de GasCarlos RinconNo ratings yet

- Livent Corporation: Confidential Livent Document NoDocument6 pagesLivent Corporation: Confidential Livent Document NoRonald VillalongaNo ratings yet

- لقرشس) ) ~ءقشرسيDocument1 pageلقرشس) ) ~ءقشرسيMohamed SelimNo ratings yet

- Reem Takrouri PDF - Results PDFDocument5 pagesReem Takrouri PDF - Results PDFريم تكروريNo ratings yet

- Jhabua Power Limited: Document No. Issue No/Date Revision No/DateDocument2 pagesJhabua Power Limited: Document No. Issue No/Date Revision No/DatebhaskarNo ratings yet

- R-P-AP-0001 Rev00 Georg Fischer CATA SPEC Parametrization of Catalogue Elements PDFDocument5 pagesR-P-AP-0001 Rev00 Georg Fischer CATA SPEC Parametrization of Catalogue Elements PDFdesai_tejasNo ratings yet

- Sahyog Engineering Industries: Isc Inprocess/Production/Rejection & P.P.M ReportDocument3 pagesSahyog Engineering Industries: Isc Inprocess/Production/Rejection & P.P.M ReportPrakash kumarTripathiNo ratings yet

- Inspection Standard: Daily Inprocess Inspection/Prod./Rejection ReportDocument3 pagesInspection Standard: Daily Inprocess Inspection/Prod./Rejection ReportPrakash kumarTripathiNo ratings yet

- Tag-3375-301, 4 1-2 12 SPFDocument1 pageTag-3375-301, 4 1-2 12 SPFFernando CastelblancoNo ratings yet

- Pengajuan Wps ASMEDocument1 pagePengajuan Wps ASMEFerdie OSNo ratings yet

- Technical Specification - Pressure GaugeDocument4 pagesTechnical Specification - Pressure GaugeManodipPatilNo ratings yet

- Intercambiador Agua AguaDocument19 pagesIntercambiador Agua Agualimarali1705No ratings yet

- TSH Ip 53.0051 - 02Document5 pagesTSH Ip 53.0051 - 02Cong BuiNo ratings yet

- PT 001 PDFDocument1 pagePT 001 PDFDang sonNo ratings yet

- Master Data Report YES (Check One) NO: Asme Boiler and Pressure Vessel CodeDocument2 pagesMaster Data Report YES (Check One) NO: Asme Boiler and Pressure Vessel CodeMuhammad Fitransyah Syamsuar Putra0% (1)

- Eil FormatDocument1 pageEil Formatsales.aquavalvesNo ratings yet

- Pressure Reducing Station Qap Alfa LavalDocument1 pagePressure Reducing Station Qap Alfa LavalajmainNo ratings yet

- Data Sheet, GAD and QAP of Y StrainerDocument13 pagesData Sheet, GAD and QAP of Y StrainerSHABAHATNo ratings yet

- Pmi ReportDocument5 pagesPmi ReportMANIMARAN QCNo ratings yet

- Crop DataDocument1 pageCrop DataaslamNo ratings yet

- Process Control Analysis - New Plant... 15.11.21Document30 pagesProcess Control Analysis - New Plant... 15.11.21aslamNo ratings yet

- Curing PM Daily Check List FT-MNT-03Document2 pagesCuring PM Daily Check List FT-MNT-03aslamNo ratings yet

- Critical Analysis of The Acceptance Criteria UsedDocument9 pagesCritical Analysis of The Acceptance Criteria UsedaslamNo ratings yet

- Roadmap For ActivitiesDocument1 pageRoadmap For ActivitiesaslamNo ratings yet

- Potential Failure Mode and Effects Analysis (Pfmea)Document3 pagesPotential Failure Mode and Effects Analysis (Pfmea)aslamNo ratings yet

- Detection: Evaluation Criteria: Ref:As Per AIAG PFMEA Standards Ril/Pfmea/Annex-C Likelihood of DetectionDocument1 pageDetection: Evaluation Criteria: Ref:As Per AIAG PFMEA Standards Ril/Pfmea/Annex-C Likelihood of DetectionaslamNo ratings yet

- Work Instructions-Testing of Physical Properties Specific GravityDocument1 pageWork Instructions-Testing of Physical Properties Specific GravityaslamNo ratings yet

- Procedure: Measurement System Analysis ExecutionDocument1 pageProcedure: Measurement System Analysis Executionaslam100% (1)

- Valve Adhesion: Work Instructions-Testing of Physical PropertiesDocument1 pageValve Adhesion: Work Instructions-Testing of Physical PropertiesaslamNo ratings yet

- Non Confirmity Closer FourDocument1 pageNon Confirmity Closer FouraslamNo ratings yet

- Defect Details and AnalysisDocument1 pageDefect Details and AnalysisaslamNo ratings yet

- Potential Failure Mode and Effects Analysis (Pfmea)Document1 pagePotential Failure Mode and Effects Analysis (Pfmea)aslamNo ratings yet

- Non Confirmity Closer OneDocument1 pageNon Confirmity Closer OneaslamNo ratings yet

- Enquiry No: Part Name: Customer: Part No.:: S.No. Feasibility Conceren Yes No Remark'sDocument2 pagesEnquiry No: Part Name: Customer: Part No.:: S.No. Feasibility Conceren Yes No Remark'saslamNo ratings yet

- Non Confirmity Closer Method-1Document1 pageNon Confirmity Closer Method-1aslamNo ratings yet

- Flow Diagram: Area: Master Compound Mixing . Process - 02Document1 pageFlow Diagram: Area: Master Compound Mixing . Process - 02aslamNo ratings yet

- Why Why AnalysisDocument1 pageWhy Why AnalysisaslamNo ratings yet

- Process Flow Diagram: Area: Valve Cement Painting Process - 05Document1 pageProcess Flow Diagram: Area: Valve Cement Painting Process - 05aslamNo ratings yet

- Why - Why Analysis: NC Identification No Audit Date Standard Statement of Non-Confirmity Standard Clause Clause NoDocument1 pageWhy - Why Analysis: NC Identification No Audit Date Standard Statement of Non-Confirmity Standard Clause Clause NoaslamNo ratings yet

- Process Flow Diagram: Area: Final Compound Mixing Process - 03Document1 pageProcess Flow Diagram: Area: Final Compound Mixing Process - 03aslamNo ratings yet

- Food ProductionDocument106 pagesFood ProductionAna Marie100% (1)

- 6RA80 Quick Commissioning Without TachoDocument7 pages6RA80 Quick Commissioning Without TachoBaldev SinghNo ratings yet

- How To Build A GreenhouseDocument67 pagesHow To Build A GreenhouseBolarinwaNo ratings yet

- Catalog Man 1Document116 pagesCatalog Man 1Petrov AndreiNo ratings yet

- Biopsy: Assessment Diagnosis Planning Intervention Rationale EvaluationDocument5 pagesBiopsy: Assessment Diagnosis Planning Intervention Rationale EvaluationDan HizonNo ratings yet

- Chapter 13 Managerial AccountingDocument168 pagesChapter 13 Managerial AccountingChandler Schleifs100% (4)

- Module III Rural MarketingDocument30 pagesModule III Rural MarketingNikita YadavNo ratings yet

- Motion of A Simple Pendulum in A FluidDocument16 pagesMotion of A Simple Pendulum in A FluidGokul JeevaNo ratings yet

- Emerging Therapeutic Options in The Management of Diabetes Recent Trends, Challenges and Future DirectionsDocument21 pagesEmerging Therapeutic Options in The Management of Diabetes Recent Trends, Challenges and Future DirectionsGabriela PachecoNo ratings yet

- Project Report of Dhanashree Goat FarmDocument56 pagesProject Report of Dhanashree Goat FarmNandan GowdaNo ratings yet

- 2.PsychoCrash Social Psy-1Document62 pages2.PsychoCrash Social Psy-1Gopika Sureshnv0% (1)

- Anatomia Dezvoltarii PancreasuluiDocument49 pagesAnatomia Dezvoltarii Pancreasuluitarra abuNo ratings yet

- PricelistDocument4 pagesPricelistMAYMART CASABANo ratings yet

- WorldShop CatalougeDocument200 pagesWorldShop Catalougee2ashNo ratings yet

- Academic Program Required Recommended Academic Program Required RecommendedDocument1 pageAcademic Program Required Recommended Academic Program Required Recommendedonur scribdNo ratings yet

- DST Tmpm370fydfg-Tde en 21751Document498 pagesDST Tmpm370fydfg-Tde en 21751trân văn tuấnNo ratings yet

- Stock+List 6ct8.3g2 Esn#30549237 Cpl#2218 GeneradorDocument34 pagesStock+List 6ct8.3g2 Esn#30549237 Cpl#2218 GeneradorAlexis SanchezNo ratings yet

- Ruger MKIIDocument1 pageRuger MKIIMike Pape100% (1)

- DysphagiaDocument4 pagesDysphagiaMicaNo ratings yet

- Brochure ISDocument4 pagesBrochure ISJAYESH VIKRAM RastogiNo ratings yet

- Neoliberalism and Altered State Developmentalism in The Twenty First Century Extractive Regime of IndonesiaDocument26 pagesNeoliberalism and Altered State Developmentalism in The Twenty First Century Extractive Regime of IndonesiaErwin SuryanaNo ratings yet

- Chapter 4: Palm Oil and Oleochemical Industries.: Presented By: Lovelyna Eva Nur Aniqah Siti MaryamDocument15 pagesChapter 4: Palm Oil and Oleochemical Industries.: Presented By: Lovelyna Eva Nur Aniqah Siti MaryamdaabgchiNo ratings yet

- EI6704: UNIT 5 NotesDocument19 pagesEI6704: UNIT 5 NotesMadhu MithaNo ratings yet

- Salmonella - Methods and Protocols.-springer-Verlag New York (2020)Document215 pagesSalmonella - Methods and Protocols.-springer-Verlag New York (2020)Yudith ParamitadeviNo ratings yet

- Mold Maintenance StepDocument0 pagesMold Maintenance StepMonica JoynerNo ratings yet

- Department of Mechanical EnginneringDocument11 pagesDepartment of Mechanical EnginneringViraj SukaleNo ratings yet

- Origami Undergrad ThesisDocument63 pagesOrigami Undergrad ThesisEduardo MullerNo ratings yet

- Regulatory Framework For Water Dams in QuebecDocument2 pagesRegulatory Framework For Water Dams in QuebecRaveeNo ratings yet

- Manual Elspec SPG 4420Document303 pagesManual Elspec SPG 4420Bairon Alvira ManiosNo ratings yet