Professional Documents

Culture Documents

Required Audit Report

Uploaded by

pardeep kumarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Required Audit Report

Uploaded by

pardeep kumarCopyright:

Available Formats

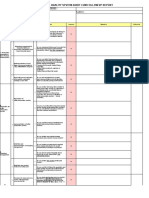

DOCUMENTS REQUIRED

SL NO. DEPARTMENT NAME DOCUMENT NAME STATUS

1)PPAP INDEX

2)PSW

3)APPROVED DRAWING

4)PFD

5)PFMEA

6)CONTROL PLAN

NEW PRODUCT

1 7)OPERATION STANDARD

DEVELOPMENT(PPAP)

8)INSPECTION STANDARD

9)PDI REPORT

10)RAW MATERIAL CERTIFICATE (RMTC+ LAB REPORT)

11)PACKING STANDARD

12)WORK INSTRUCTIONS

13)NPD PROCEDURE

1)PROCEDURE FOR APQP & ECN

2)APQP MATRIX

3)APQP MOM

4)APQP TIME PLAN.

5)TOOL DEVELOP MENT NANO PLAN

6)TOOL DEVELOPMENT MICRO PLAN

2 APQP

7)PAST TROUBAL DATA

8)PROCEDURE FOR PFMEA

9) PFMEA REVIEW PLAN

10)APPROVED PFMEA

11)MASS PRODUCTION FORMAT

12)NEW ENQUIRY REGISTER/FORM

1)PROCEDURE FOR INITIANAL SUPPLY CONTROL

INITIAL PRODUCTION CONTROL 2)INITIAL SUPPLY TERMINATION CHECK SHEET

3

(IPC) 3)PROCEDURE FOR ECN PCN

4)INITIAL SUPPLY LOG BOOK

1)4M CHANGE STANDARD

2)ECN CONTROL REGISTER

3)4M CHANGE PROCEDURE

4 CHANGE MANAGEMENT 4)4M CHANGE REPORT

5)4M SUMMARY REPORT

6)ABNORMAL SITUATION PROCEDURE

7)INTIAL PART STORAGE CONDITION

1)PROCEDURE FOR CONTROL OF DOCUMENT

2)PROCEDURE FOR RECORD RETENTION

5 SANDARD MANAGEMENT

3)MASTER LIST OF DOCUMENTS ( RECORDS)

4)APPROVED CONTROL PLAN

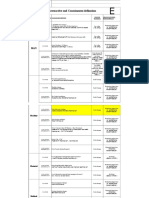

1)Operator Training Procedure

2)Staff Training Procedure

3)OPERATOR AND STAFF SKILL MATRIX

4)ANNUAL TRAINING CALENDER

DOCUMENTS REQUIRED

SL NO. DEPARTMENT NAME DOCUMENT NAME STATUS

5)TNI

6 EDUCATION AND TRAINING 6)List of New Joining

7)Operator Multi Skilling Procedure

8)Operator Observation Plan

9)Operator Observation REPORT

10)POISION CAKE TEST PLAN AND REPORT

11)Procedure for poission cake test

1)PROCEDURE FOR INTERNAL QUALITY AUDITS

2) QUALITY PROCEDURE PROCESS AUDIT

3) QUALITY PROCEDURE PRODUCT AUDIT

7 QUALITY AUDIT

4)INTERNAL AUDIT,PROCESS & PRODUCT PLAN

5)INTERNAL,PROCESS & PRODUCT AUDIT REPORT,NC REPORTS WITH C/M

6)SUMMARY REPORT OF PROCESS/PRODUCT/INTERNAL AUDIT

1) ABNORMAL SITUATION PROCUDURE

2) CUSTOMER COMPLAINT HANDLING

3)Procedure for Control of Non Conforming Product

8 QUALITY ABNORMALITY

4) Procedure for Corrective & Preventive Action

5)Customer Complaint Reg.

6)INHOUSE REJECTION(RED BIN) REPORT,CM WITH EVIDENCE REPORT

1)Procedure for Supplier Selection

2)Supplier audit chack sheet & REPORT,CM EVIDENCES

9 SUPPLIER CONTROL

3)Approved supplier list

4)SUPPLIER PERFORMANCE REPORT

1)WI FOR DEFINING STORGE INSTRUCTION

2)MONITORING SHEET OF LUX LEVAL

10 5 S MANAGEMENT 3)Procedure for Stores incoming

4)RECORD OF STOR,PACK, FINISH PRODUCT

5)REC, STORE & ISSUE OF PRODUCTS

1)PACKING STANDARD

2)BIN/TROLLEY/PALLENT MANAGEMENT

3)BIN WASHING WI

11 HANDLING MANAGEMENT

4)WI FOR PACKING

5)Procedure for Bin Trolley Management

6)Trolley Maint Checksheet

1)Procedure for Control of Non Conforming Product

2)FLOW CHART FOR TRECEBALITY OF PART

12 PRODUCT MANAGEMENT 3)SKILD MATRIX CHART REWORK INSPECTOR - OPERATOR

4)RED BIN REJECTION REPORT

5)REWORK REPORT

1) PROCEDURE FOR TOOL MAINTENANCE

2)TOOL PREVENTIVE MAINTENANCE PLAN

3)PREVENTIVE MAINTENANCE PLAN FOR MACHINE

4)CRITICAL SPARE PART & MONITORING CONSUMABLE CONSUMPTION SHEET

5)PROCEDURE FOR MACHINE MAINTENANCE

6)PROCEDURE FOR CALIBRATION IMTE

DOCUMENTS REQUIRED

SL NO. DEPARTMENT NAME DOCUMENT NAME STATUS

7)ACCEPTANCE CRITERIA

8) MASTER LIST OF MEASURING INSTRUMENT DONE

13 MAINTENANCE

9)MASTER LIST OF LIMIT SAMPLE

10)MEASURING INSTRUMENT CALIBRATION PLAN DONE

11)CALLIBRATION REPORT DONE

12)M/C B/D ANALYSIS REPORT

13)MASTER LIST OF MACHINES

14)MACHINE HISTORY CARD

15)M/C PM CHECK SHEET

16)DAILY M/C CHECK SHEET

You might also like

- The Toilet Paper Entrepreneur PDFDocument198 pagesThe Toilet Paper Entrepreneur PDFMarco Gómez Caballero83% (6)

- Management Review Programme (Insert Year) : ISO 9001:2015 QMSDocument2 pagesManagement Review Programme (Insert Year) : ISO 9001:2015 QMSFrench Sarah NeraNo ratings yet

- Department Name: Production Department Name: Production: Material ResourcesDocument21 pagesDepartment Name: Production Department Name: Production: Material ResourcesLesly LesNo ratings yet

- Turtle Diagrams - Stores + ShippingDocument1 pageTurtle Diagrams - Stores + Shippingcem electromechNo ratings yet

- Skill MatrixxDocument11 pagesSkill MatrixxNikhil SirNo ratings yet

- Skill Matrix: 1 - Basic Trg. AcquiredDocument4 pagesSkill Matrix: 1 - Basic Trg. AcquiredDinesh KumarNo ratings yet

- VSA Audit Preparation Plan: Legends Activity Planned Activity Done Activity PendingDocument1 pageVSA Audit Preparation Plan: Legends Activity Planned Activity Done Activity PendingrakeshNo ratings yet

- Master TimingDocument4 pagesMaster TimingPk NimiwalNo ratings yet

- Formato 8DDocument2 pagesFormato 8DALEJANDRONo ratings yet

- Capa - 2Document1 pageCapa - 2Quality DWINo ratings yet

- Modele PDCA Adapté en 8DDocument6 pagesModele PDCA Adapté en 8DNedra DebbechNo ratings yet

- Test Bank For Financial Management Principles and Applications 10th Edition by KeownDocument19 pagesTest Bank For Financial Management Principles and Applications 10th Edition by KeownPria Aji PamungkasNo ratings yet

- COA CIRCULAR NO. 2023-003 June 14 2023Document14 pagesCOA CIRCULAR NO. 2023-003 June 14 2023Jennifer Go100% (2)

- Lone Pine CafeDocument4 pagesLone Pine CafeRahul TiwariNo ratings yet

- 8D Report: Vasanth - Production Engineer Vijaykumar - Quality Head Prabhakaran - Final in Charge Premkumar-CNC OperatorDocument4 pages8D Report: Vasanth - Production Engineer Vijaykumar - Quality Head Prabhakaran - Final in Charge Premkumar-CNC OperatorVasanth KumarNo ratings yet

- 5.6 MRM Minutes 2020Document7 pages5.6 MRM Minutes 2020Musyoka Urbanus100% (1)

- 6 Sigma SD Shaft Dia. VariationDocument32 pages6 Sigma SD Shaft Dia. Variationsageershaikh100% (1)

- Change Management C Pillar Stacking Reduced From 1+4 To 1+2Document18 pagesChange Management C Pillar Stacking Reduced From 1+4 To 1+2shobha shelarNo ratings yet

- QM PillarDocument49 pagesQM PillarMAngesh GadeNo ratings yet

- Efwe 2 e 4 GF 1 W 3Document1 pageEfwe 2 e 4 GF 1 W 3BALACHANDAR SNo ratings yet

- Skill CriteriaDocument1 pageSkill CriteriaDinesh Kumar100% (1)

- QA & QC Organization Chart PDFDocument1 pageQA & QC Organization Chart PDFFashion MangoNo ratings yet

- Improvement KaizenDocument11 pagesImprovement KaizenAnkur DhirNo ratings yet

- Nikhil Quality 6YOEDocument3 pagesNikhil Quality 6YOENikhil DhimanNo ratings yet

- Supplier Name Auditors: Vendor Attendees:: JudgmentDocument4 pagesSupplier Name Auditors: Vendor Attendees:: Judgment3A System SolutionNo ratings yet

- Quality CricleDocument22 pagesQuality CricleQSSD ENTERPRISESNo ratings yet

- Sr. No. Metric Goal Data Source Base Line: TallbrosDocument3 pagesSr. No. Metric Goal Data Source Base Line: TallbrosVikas KashyapNo ratings yet

- Development Time LineDocument1 pageDevelopment Time LineMohitrajranikashyapNo ratings yet

- Procedure For Set Up Approval, in Process & Final InspectionDocument7 pagesProcedure For Set Up Approval, in Process & Final InspectionRavi javaliNo ratings yet

- Internal Audit Check List MRDocument3 pagesInternal Audit Check List MRGanesh Iyer100% (1)

- Point No. 6Document10 pagesPoint No. 6Rohtash fastnerNo ratings yet

- Non Conformity Report: Part Name:-Clamp Bolt Model: M4 Clamp Bolt Supplier:-Paradise Indus. Customer: PICLDocument1 pageNon Conformity Report: Part Name:-Clamp Bolt Model: M4 Clamp Bolt Supplier:-Paradise Indus. Customer: PICLAyush NarangNo ratings yet

- LHPL-FMT-09 Break Down Hrs Monitoring Chart MTTR & MTBFDocument6 pagesLHPL-FMT-09 Break Down Hrs Monitoring Chart MTTR & MTBFDevendra SinghNo ratings yet

- 4m Change & Ecn NoteDocument1 page4m Change & Ecn NoteAnurag ChaudharyNo ratings yet

- KTFL 1st PageDocument1 pageKTFL 1st PageRahul ChavanNo ratings yet

- 4 M Change LatestDocument8 pages4 M Change LatestVikas KashyapNo ratings yet

- Rejection Record.Document10 pagesRejection Record.karan shahNo ratings yet

- Process Validation Record: Format No.: - DateDocument2 pagesProcess Validation Record: Format No.: - DateRaja DuraiNo ratings yet

- Audit Programme 1Document27 pagesAudit Programme 1I am JacobNo ratings yet

- Potential Failure Mode and Effect Analysis: Doc - No.: FMEA/TL-01 A REV. NO.: 06 ORG. Date: 18.03.2021Document4 pagesPotential Failure Mode and Effect Analysis: Doc - No.: FMEA/TL-01 A REV. NO.: 06 ORG. Date: 18.03.2021Mukesh YadavNo ratings yet

- Anand Kumar ResumeDocument3 pagesAnand Kumar ResumeArun ShishodiaNo ratings yet

- Process Audit Check SheetDocument5 pagesProcess Audit Check SheetaliNo ratings yet

- Marathan Motor (I) PVT LTD.: 5S Committee-PlantDocument4 pagesMarathan Motor (I) PVT LTD.: 5S Committee-PlantRishi GautamNo ratings yet

- LP LA N: Control PlanDocument26 pagesLP LA N: Control PlanSyed ShabbirNo ratings yet

- Toaz - Info Red Bin Analysis Procedure PRDocument4 pagesToaz - Info Red Bin Analysis Procedure PRRohit QualityNo ratings yet

- Chapterwise Microlevel Action Plan - 23rd Jun '21Document20 pagesChapterwise Microlevel Action Plan - 23rd Jun '21Ankit SainiNo ratings yet

- QMS Cross Audit 18Document4 pagesQMS Cross Audit 18rajesh sharmaNo ratings yet

- F16 (SOP - hrd.01) Kaizen Implementation SheetDocument1 pageF16 (SOP - hrd.01) Kaizen Implementation SheetRAHUL YADAVNo ratings yet

- Sr. No. Date Phenomenon Requirement From RNTBCI (From ASES Report) Actions From Supplier Pilot Target DateDocument4 pagesSr. No. Date Phenomenon Requirement From RNTBCI (From ASES Report) Actions From Supplier Pilot Target DateAnkit SainiNo ratings yet

- Kaizen - Esp02 221B4 DamperDocument4 pagesKaizen - Esp02 221B4 DamperRakesh Kumar Singh (Phase 1B)No ratings yet

- NC Analysis Report 3L5Y-Blank FormatDocument160 pagesNC Analysis Report 3L5Y-Blank Formatshobha shelarNo ratings yet

- Quality Month Nov.22Document11 pagesQuality Month Nov.22Quality Sanand Jairaj GroupNo ratings yet

- MTBF - MTTRDocument11 pagesMTBF - MTTRYogesh BadheNo ratings yet

- You Exec - Process Optimization Methodologies FreeDocument7 pagesYou Exec - Process Optimization Methodologies FreeAta JaafatNo ratings yet

- FIR-garments PDFDocument4 pagesFIR-garments PDFTarun PariharNo ratings yet

- Qav Observation Closer Sheet FormatDocument1 pageQav Observation Closer Sheet FormatDEVENDERNo ratings yet

- 5A CAPA Best Practices (I) (MQ1)Document24 pages5A CAPA Best Practices (I) (MQ1)Chris GloverNo ratings yet

- Xfmea Pfmea PDFDocument8 pagesXfmea Pfmea PDFvinidesoNo ratings yet

- Cii Erode: 1S PresentationDocument19 pagesCii Erode: 1S PresentationsathyabalaramanNo ratings yet

- 4M Change Machined RodDocument4 pages4M Change Machined RodOBSC PerfectionNo ratings yet

- CAPA Rust ProblemDocument2 pagesCAPA Rust ProblemMohit SinghNo ratings yet

- 5 Why WeldingRobot ToyotaDocument1 page5 Why WeldingRobot ToyotaMickloSoberanNo ratings yet

- Equipment People: The ISO 9001:2015 Implementation Handbook": Turtle DiagramDocument3 pagesEquipment People: The ISO 9001:2015 Implementation Handbook": Turtle DiagramTatiana Rilo0% (1)

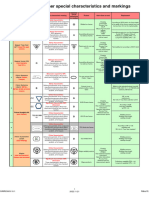

- Customer Special CharacteristicsDocument1 pageCustomer Special Characteristicspundhir12898No ratings yet

- 0IATFACTIVITYDEPT23Document1 page0IATFACTIVITYDEPT23Dilshad AliNo ratings yet

- Cash JournalDocument7 pagesCash JournalASHOKA GOWDANo ratings yet

- Rheostats OCT2010Document16 pagesRheostats OCT2010youplaiNo ratings yet

- Starbucks Confirms Rapid Growth StrategyDocument2 pagesStarbucks Confirms Rapid Growth StrategyAlexandros PetronikolosNo ratings yet

- A Study On Customer Based Brand Equity (CBBE) of Amazon Amongst Millennial's of Surat City. (ResponsesDocument5 pagesA Study On Customer Based Brand Equity (CBBE) of Amazon Amongst Millennial's of Surat City. (ResponsesMohammed GodilNo ratings yet

- Assignment Banking, Insurance and Financial Services BASEL Norms Analysis of Union BankDocument2 pagesAssignment Banking, Insurance and Financial Services BASEL Norms Analysis of Union Banksomya mathurNo ratings yet

- BKash ProfileDocument10 pagesBKash ProfileAshik Md Siam100% (1)

- CHPT 1...... The Foundations of EntrepreneurshipDocument62 pagesCHPT 1...... The Foundations of EntrepreneurshipHashim MalikNo ratings yet

- Alfred Marshall 3Document7 pagesAlfred Marshall 3agapitodimagiba021No ratings yet

- Nanjing TiO2 SDS-EU V1.0Document8 pagesNanjing TiO2 SDS-EU V1.0dipen royNo ratings yet

- ALUMNI MEET 2023-24 SampleDocument16 pagesALUMNI MEET 2023-24 SampleTamil SelvanNo ratings yet

- SL - No. Company Building Name Unit No. Floor NoDocument25 pagesSL - No. Company Building Name Unit No. Floor Novijay kumar anantNo ratings yet

- Ifrs at A Glance IAS 21 The Effects of Changes In: Foreign Exchange RatesDocument4 pagesIfrs at A Glance IAS 21 The Effects of Changes In: Foreign Exchange Ratesمعن الفاعوريNo ratings yet

- Supply Chain Management of Pharmaceuticals: "Working Together For Healthier World"Document19 pagesSupply Chain Management of Pharmaceuticals: "Working Together For Healthier World"Shahrukh Ghulam NabiNo ratings yet

- Summer Internership Project Report: Bharat Coking Coal LimitedDocument6 pagesSummer Internership Project Report: Bharat Coking Coal LimitedKoushik GuptaNo ratings yet

- Criteria For Supplier Selection: A Literature Review: ArticleDocument6 pagesCriteria For Supplier Selection: A Literature Review: ArticleMohammed ShahinNo ratings yet

- A Personal Selling Strategy: DevelopingDocument14 pagesA Personal Selling Strategy: DevelopingAdeesh KakkarNo ratings yet

- Royal Enfield Project 36 Organisation StudyDocument45 pagesRoyal Enfield Project 36 Organisation StudyVijay AravindNo ratings yet

- Service Plan For 2GO TravelDocument33 pagesService Plan For 2GO TravelPaulino OccupadoNo ratings yet

- The Rampant Case of Unemployment in The PhilippinesDocument3 pagesThe Rampant Case of Unemployment in The PhilippinesTomas DocaNo ratings yet

- Pretty in Pink Word Resume TemplateDocument2 pagesPretty in Pink Word Resume TemplateanishkadiyalaNo ratings yet

- The Indian Economy Problems and ProspectsDocument23 pagesThe Indian Economy Problems and ProspectsgeniusMAHINo ratings yet

- The Foreign Exchange MarketDocument3 pagesThe Foreign Exchange MarketDavina AzaliaNo ratings yet

- 148 - Doing Business in MALIDocument6 pages148 - Doing Business in MALIEvan ComenNo ratings yet

- Commercial Lease Jan 2022Document12 pagesCommercial Lease Jan 2022Aniella94No ratings yet

- DCE Price List 2021-11-15Document1 pageDCE Price List 2021-11-15Boanerges MalazarteNo ratings yet