Professional Documents

Culture Documents

Grow Max India Private Ltd.,Mysuru: First Piece Approval-Moulding

Grow Max India Private Ltd.,Mysuru: First Piece Approval-Moulding

Uploaded by

Kaleem Pasha Krp Kaleem0 ratings0% found this document useful (0 votes)

10 views1 pageThis document provides a first piece approval for a moulding process. It includes:

1) Visual parameters to check for defects like color variations, flashing, short fills, and other issues.

2) Dimensional parameters that specify tolerances for measurements like diameters, heights, wall thicknesses, and weights.

3) Functional parameters like handle fitment, leakage tests, and drop tests to check performance.

Original Description:

its

Original Title

FPA for moulding 1

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides a first piece approval for a moulding process. It includes:

1) Visual parameters to check for defects like color variations, flashing, short fills, and other issues.

2) Dimensional parameters that specify tolerances for measurements like diameters, heights, wall thicknesses, and weights.

3) Functional parameters like handle fitment, leakage tests, and drop tests to check performance.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

10 views1 pageGrow Max India Private Ltd.,Mysuru: First Piece Approval-Moulding

Grow Max India Private Ltd.,Mysuru: First Piece Approval-Moulding

Uploaded by

Kaleem Pasha Krp KaleemThis document provides a first piece approval for a moulding process. It includes:

1) Visual parameters to check for defects like color variations, flashing, short fills, and other issues.

2) Dimensional parameters that specify tolerances for measurements like diameters, heights, wall thicknesses, and weights.

3) Functional parameters like handle fitment, leakage tests, and drop tests to check performance.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

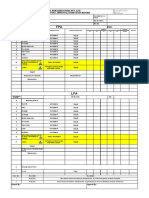

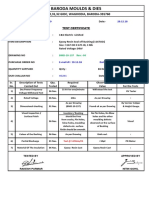

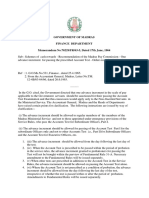

Doc. No.

GMI/QA/16-A

GROW MAX INDIA PRIVATE LTD.,MYSURU Rev.No. 00

FIRST PIECE APPROVAL-MOULDING

PURPOSE:-Mold change ( ) MATERIAL CHANGE:-( ) START UP:-( )

No of cavity :- Machine No:- Cycle Time:-

Sample Size:- Mould no:- ProductName:- Material:-

A. Visual Parameters

Sl No Parameter Checking Method Observation Sl No:- Parameter Checking Method Observation

1 Colour (As per standard shade tab) Visual 7 Flow Mark Visual

2 Flash Visual 8 Dent ,damage Visual

3 Short fill Visual 9 Dust,oil Visual

4 Gate Point,Over cut Visual 10 Burn,Water mark Visual

5 Buldging Visual 11 Shrinkage,Rib damage Visual

6 Black spot Visual 12 Pin hole,Air bubble etc. Visual

B. Dimensional Parameters

Sl No Parameter Specification Observation Checking Sl No:- Specification Observation

Parameter Checking Method

Min Max Method Min Max

1 Grosslided Capacity ( Ltr ) 14 Weight

2 Max. Dia of pail at 1st lock 15 Max. Dia of pail at 2nd lock

3 ID of pail 16 Max. OD of pail ( W/O Handle)

4 Bottom outer Dia. Of pail 17 Outer Dia. Of lid ( With rib )

5 Pail height without lid 18 Total lid height

6 Pail height with lid closed 19 POD of lid

7 ID of lid at 1st lock 20 ID of lid at 2nd lock

8 Height of 1st lock on lid / PAIL 21 Height of 2ND lock on lid / PAIL

9 Pail avg. wall thickness thick side 22 Pail avg. wall thickness bottom side

10 Lid height ( Without projection ) 23 Handle hole major diameter

11 Handle hole minor diameter 24 Handle strength

12 Max. dia of pail with handle 25 Height of in built plug

13 Thickness at edge of tinting port 26 Thickness of edge of tinting cap

C. Fuctional Parameter

Sl No Parameter Checking Method Observation

1 Handle fitment ( Pail only ) Manual

2 Fittment with mating part Lid pressing machine

For interchangability ( All matrix ) Lid pressing machine

3 Leakage Test Visual

4 Drop Test Manual

5 Line clearance Status Visual

Remarks:-

Inspected By:- Approved By:-

You might also like

- Fuse Box Diagram Toyota Camry (XV40 2007-2011)Document13 pagesFuse Box Diagram Toyota Camry (XV40 2007-2011)Zool Car زول كار0% (2)

- Check Valve DatasheetDocument4 pagesCheck Valve DatasheetSeptian FirdausNo ratings yet

- Product Audit Check SheetDocument3 pagesProduct Audit Check SheetLakshmanan Venkatesan100% (8)

- Belt Conveyor. Technical Data SheetDocument1 pageBelt Conveyor. Technical Data SheetCarmen FloresNo ratings yet

- Organization TheoryDocument110 pagesOrganization TheoryOhi OyakhireNo ratings yet

- Moot Problem 5Document26 pagesMoot Problem 5Shalini50% (2)

- Chilled Water Piping Systems (VPF Focus)Document48 pagesChilled Water Piping Systems (VPF Focus)albrgmail100% (1)

- PVRV Data Sheet PDFDocument1 pagePVRV Data Sheet PDFharshkumar patelNo ratings yet

- Multinational Corporations DevelopmentDocument10 pagesMultinational Corporations DevelopmentfysallNo ratings yet

- Centrifugal Pump API 610 10TH EDITION / ISO 13709 Process Data Sheet Si UnitsDocument15 pagesCentrifugal Pump API 610 10TH EDITION / ISO 13709 Process Data Sheet Si Unitsf09aiNo ratings yet

- Encyclopedia of Ship TechnologyDocument663 pagesEncyclopedia of Ship TechnologyNAUTASNo ratings yet

- Datasheet For RTD and ThermowellDocument1 pageDatasheet For RTD and ThermowellJeshinNo ratings yet

- 02 - Triplex PumpsDocument83 pages02 - Triplex PumpsJitendra GautamNo ratings yet

- Hague Haguevisby and HamburgDocument13 pagesHague Haguevisby and HamburgAgar Sail100% (1)

- Product Audit Check SheetDocument3 pagesProduct Audit Check SheetLakshmanan Venkatesan100% (1)

- Isa S20 Forms S21Document2 pagesIsa S20 Forms S21Joahan Anderson Estela NuñezNo ratings yet

- Pipe Conveyor SystemDocument6 pagesPipe Conveyor Systemsurajit81100% (2)

- Po-0918-Stand Post Monitor-Frozen FireDocument1 pagePo-0918-Stand Post Monitor-Frozen FireRiyu RathodNo ratings yet

- Datasheet Vacuum Gauge: Project Project Number Purchase Order RequisitionDocument5 pagesDatasheet Vacuum Gauge: Project Project Number Purchase Order RequisitionManodipPatilNo ratings yet

- Po 1678 Alu Roll Up Shutter MCDDocument1 pagePo 1678 Alu Roll Up Shutter MCDRiyu RathodNo ratings yet

- Snap Head RivetDocument1 pageSnap Head RivetVilasNo ratings yet

- Po 1678 Alu Roll Up Shutter MCD 1Document1 pagePo 1678 Alu Roll Up Shutter MCD 1Riyu RathodNo ratings yet

- Attaquant Enterprises Pvt. LTD.: Questionnaire For STORAGE TANKDocument2 pagesAttaquant Enterprises Pvt. LTD.: Questionnaire For STORAGE TANKPravin KaleNo ratings yet

- CVCalculation For Swage Sludge Tank 11-9-14Document10 pagesCVCalculation For Swage Sludge Tank 11-9-14Henry VungtauNo ratings yet

- 16 SF96RHDocument1 page16 SF96RHnappyNo ratings yet

- Jrchqdeylis 20210916-1 Ruby200Document2 pagesJrchqdeylis 20210916-1 Ruby200Ritmos Korg pa seriesNo ratings yet

- Dimensional Inspection Report: Status: Surface: Units: AS Received Final Radial Axial Millimeters InchesDocument9 pagesDimensional Inspection Report: Status: Surface: Units: AS Received Final Radial Axial Millimeters InchesAditya PrajasNo ratings yet

- Cover and Content of PackageDocument2 pagesCover and Content of Packageคุณพ่อน้อง บิ๊กบอสNo ratings yet

- Boot Basket 17485Document1 pageBoot Basket 17485khalilNo ratings yet

- CVCalculation For Swage Holding Tank 11-9-14Document10 pagesCVCalculation For Swage Holding Tank 11-9-14Henry VungtauNo ratings yet

- Form-I-005 Compressor, Gen-Set, Water Jet FormDocument1 pageForm-I-005 Compressor, Gen-Set, Water Jet FormHSSE PTCADNo ratings yet

- Final Inspectio Report 2259 Wt109Document1 pageFinal Inspectio Report 2259 Wt109Prem KumarNo ratings yet

- Product Audit Check Sheet Cum ReportDocument3 pagesProduct Audit Check Sheet Cum ReportQGFNo ratings yet

- Incoming Inspection reportDocument1 pageIncoming Inspection reportrc2834338No ratings yet

- Documents For Approval Rev-1 - ApprovedDocument42 pagesDocuments For Approval Rev-1 - ApprovedAbhijeet WayaseNo ratings yet

- 20F1001 Flow Device Operating ParametersDocument4 pages20F1001 Flow Device Operating ParametersDiego SotoNo ratings yet

- 2KVADocument20 pages2KVASandeep MauryaNo ratings yet

- CR PipaDocument7 pagesCR Pipadwi sutiknoNo ratings yet

- PG 04Document1 pagePG 04trilok corporationNo ratings yet

- LQC STDDocument2 pagesLQC STDAstronNo ratings yet

- Sample Report For Amazon FBA Jeans - RedactedDocument37 pagesSample Report For Amazon FBA Jeans - RedactedChulaka PitigalaNo ratings yet

- QAR-QD405-800 Rod As-Hoist CylinderDocument6 pagesQAR-QD405-800 Rod As-Hoist CylinderIrwanto ManafNo ratings yet

- Check Sheet Inspection: Customer Part No. Inspection by DWG No. Inspection ReportDocument1 pageCheck Sheet Inspection: Customer Part No. Inspection by DWG No. Inspection ReportJovianto PrisilaNo ratings yet

- Os SPM CVX19001 1245 042Document5 pagesOs SPM CVX19001 1245 042DarshAwadNo ratings yet

- Tool ListDocument1 pageTool Listtechontrack6No ratings yet

- Tanque de FRP - 36 PulgDocument1 pageTanque de FRP - 36 Pulgjoel floresNo ratings yet

- Check Sheet: Inspected by Checked by Aknowledged by Skill Worker HPSI Supervisor HasindDocument1 pageCheck Sheet: Inspected by Checked by Aknowledged by Skill Worker HPSI Supervisor HasindMuhammadRizaldiAfriliansyahNo ratings yet

- Schwing stetter Inspection reportsDocument21 pagesSchwing stetter Inspection reportsSridhar SriNo ratings yet

- Form I 002 Grinding FormDocument1 pageForm I 002 Grinding FormHSSE PTCADNo ratings yet

- AE-QA-02 - First Piece Inspection ReportDocument1 pageAE-QA-02 - First Piece Inspection ReportKarthi ThiyagarajanNo ratings yet

- Final Report - 1721-V-0905 BDocument5 pagesFinal Report - 1721-V-0905 BvivekNo ratings yet

- Tmu-1105 Job Card Ta-2019Document20 pagesTmu-1105 Job Card Ta-2019Anonymous YRyGcKPNo ratings yet

- PAINTING INSPECTION FORMDocument1 pagePAINTING INSPECTION FORMMarhendraNo ratings yet

- Die Dynamic Buyoff Check Sheet For Air Cushion DiesDocument3 pagesDie Dynamic Buyoff Check Sheet For Air Cushion DiesTarang ShandilyaNo ratings yet

- SAMPLE Defect SheetDocument2 pagesSAMPLE Defect SheetshafanyNo ratings yet

- Bearing LSS CoverDocument2 pagesBearing LSS CoverRagul0042No ratings yet

- PT 001 PDFDocument1 pagePT 001 PDFDang sonNo ratings yet

- QA10 PI HD 785-7 (Front & Upper Area)Document1 pageQA10 PI HD 785-7 (Front & Upper Area)ahlan robianorNo ratings yet

- Vimal Moulders India Pvt. Ltd. First/Last Part Approval Inspection ReportDocument1 pageVimal Moulders India Pvt. Ltd. First/Last Part Approval Inspection ReportartiNo ratings yet

- Challan No. H3241Document1 pageChallan No. H3241SANJAY PRAKASHNo ratings yet

- Bot 1L IBMO (Lot 3)Document2 pagesBot 1L IBMO (Lot 3)Thảo Ngọc VũNo ratings yet

- 8 PDFDocument10 pages8 PDFjazNo ratings yet

- 4-Lembar Pengesahan PengujiDocument163 pages4-Lembar Pengesahan PengujiNico Achmad ZulviansyahNo ratings yet

- QAQC Daily Inspection Report Sir JabarDocument4 pagesQAQC Daily Inspection Report Sir JabarEngr Saeed AnwarNo ratings yet

- Assessing The Opportunities Available To Banks in Financing Horticulture Sub-Sector in EthiopiaDocument11 pagesAssessing The Opportunities Available To Banks in Financing Horticulture Sub-Sector in Ethiopiamoroda keneaNo ratings yet

- Risk of Social Media For Teens in An Urban SettingDocument4 pagesRisk of Social Media For Teens in An Urban Settingdiana nistoranNo ratings yet

- CF - MM - Lead COBOL Mainframe - C# Developer - MidseniorDocument2 pagesCF - MM - Lead COBOL Mainframe - C# Developer - Midseniorpatricia isabelNo ratings yet

- (Ebook - PDF) Oracle SQL-Plus Quick ReferenceDocument20 pages(Ebook - PDF) Oracle SQL-Plus Quick Referenceparn158No ratings yet

- Inventment in Security and Portfolio TheoryDocument10 pagesInventment in Security and Portfolio Theorytmpvd6gw8fNo ratings yet

- Modi MethodDocument19 pagesModi Methodsimargrewal11No ratings yet

- A Study On Technological Implication On Human Resource Practices in Private OrganizationDocument6 pagesA Study On Technological Implication On Human Resource Practices in Private OrganizationarcherselevatorsNo ratings yet

- 116222942-Data Mining-On-Forest-Cover-PredictionDocument21 pages116222942-Data Mining-On-Forest-Cover-Predictionankit rathiNo ratings yet

- Borjal v. CA - CaseDocument19 pagesBorjal v. CA - CaseRobeh AtudNo ratings yet

- Trademark NotesDocument15 pagesTrademark NotesPhenyl EtheneNo ratings yet

- Funnel Slides V4 Powerpoint TemplateDocument7 pagesFunnel Slides V4 Powerpoint TemplatekaushikbachanNo ratings yet

- Sri Krishna College of Engineering & Technology (Autonomous)Document1 pageSri Krishna College of Engineering & Technology (Autonomous)woodksdNo ratings yet

- c15368hc PDFDocument118 pagesc15368hc PDFLuis ArayaNo ratings yet

- Account Test IncrementDocument2 pagesAccount Test IncrementVenkatesanSelvarajNo ratings yet

- From Huawei Cli Upgrade Rollback E280a6Document2 pagesFrom Huawei Cli Upgrade Rollback E280a6Hussein DhafanNo ratings yet

- Ohio State University DissertationsDocument5 pagesOhio State University DissertationsPaperWritersOnlineSingapore100% (1)

- pFMS2 PDFDocument64 pagespFMS2 PDFFaizanTariqFTNo ratings yet

- Global: Product CatalogDocument310 pagesGlobal: Product CatalogJose CarlosNo ratings yet

- Glass and Mirrors On: Section 9LDocument13 pagesGlass and Mirrors On: Section 9LmacarsalNo ratings yet

- Dell CatalogDocument28 pagesDell CatalogHarry DravenNo ratings yet

- United States v. Brandon Turner, 4th Cir. (2014)Document4 pagesUnited States v. Brandon Turner, 4th Cir. (2014)Scribd Government DocsNo ratings yet