Professional Documents

Culture Documents

EGP3-01.08 Weight Control Requirements From Vendors

Uploaded by

Mathias OnosemuodeOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

EGP3-01.08 Weight Control Requirements From Vendors

Uploaded by

Mathias OnosemuodeCopyright:

Available Formats

PARSONS Document Number: EGP3-00-SP-011-100-003

CHEVRON NIGERIA LIMITED

ESCRAVOS GAS PROJECT – PHASE 3 DEVELOPMENT - ONSHORE

SPECIFICATION NUMBER EGP3–01.08

WEIGHT CONTROL REQUIREMENTS FROM VENDORS

Rev No. Date Description By CL/APPR

0 August 14, 2002 Issued for ITB BL

1 January 16, 2004 Revised for ITB3 RBM DAP

January, 2004 Specification No. EGP3-01.08 Page 1 of 8

REVISION RECORD SHEET

Notes

i.) Revisions numbers shall be A, B, C, etc. up through the issue for Invitation to Bid.

ii.) The issue for Invitation to Bid shall be Revision 0.

iii.) Revisions after the issue for Invitation to Bid shall be 1, 2, 3, etc. Any revisions made after

Revision 0 shall be denoted by a vertical line in the left hand margin against the revised

text.

iv.) A brief description of the key changes made in each revision shall be included on this

page.

REVISION DESCRIPTION OF REVISION

A Based on EGP1-01.08

B Parsons comments – Squad Check

C Issued for Chevron Nigeria Review

D Issued for FEED RFQ

0 Issued for ITB

1 Revised for ITB3 – no changes

January, 2004 Specification No. EGP3-01.08 Page 2 of 8

TABLE OF CONTENTS

PAGE

1.0 SCOPE 4

1.1 Definitions 4

2.0 REFERENCES 4

2.1 Industry Codes 4

2.2 Project Specifications 4

2.3 Standard Drawings 4

3.0 BID STAGE 5

4.0 PURCHASE ORDER 5

5.0 BULK MATERIALS 7

6.0 WEIGHT DATA SHEETS 7

ATTACHMENT 1 8

January, 2004 Specification No. EGP3-01.08 Page 3 of 8

1.0 SCOPE

This Specification describes CONTRACTOR’S weight and centre of gravity control, monitoring,

reporting and weighing requirements for equipment, packages, prefabricated module assemblies,

skids, vessels etc and bulk materials.

CONTRACTOR shall notify COMPANY of any conflicts between this specification and other

project documents or referenced industry standards.

1.1 Definitions

Definitions used in this specification are as follows:

"COMPANY" is defined as CNL

"CONTRACTOR" is defined as EPC Contractor

"SUPPLIER or SUB-CONTRACTOR" is defined as companies supplying material,

equipment or services to the CONTRACTOR.

"FEED CONTRACTOR" is defined as Parsons

"PROJECT" is defined as the EGP3 Onshore Project

2.0 REFERENCES

The following documents are hereby referenced and are considered part of this specification:

2.1 Industry Codes

Not Applicable

2.2 Project Specifications

Not Applicable

2.3 Standard Drawings

Not Applicable

January, 2004 Specification No. EGP3-01.08 Page 4 of 8

3.0 BID STAGE

The CONTRACTOR bid shall include the following information:

The dry weight - the basic weight of the item without operating fluids or temporary

attachments.

The operating weight - the weight of the item charged with operating fluids to its designed

maximum operating level.

The test weight - the weight of an item charged with water (or other test fluid) to its design test

capacity.

The lift weight - the weight of the item at the time of lifting including temporary aids such as

slings, shackles, lifting beams and attachment such as insulation, davits, ladders and

platforms etc (where applicable) but excluding operating fluids if not present.

The location of the centre of gravity in the X, Y and Z planes for each designated weight

condition.

The controls and procedures to be adopted to ensure conformity with this weight control

procedure.

The final weight of the item shall be within 20% of the weight reported at the Bid Stage. The

weight specified shall be taken into account in the Bid Evaluation.

The CONTRACTOR shall also include at the Bid Stage details of any packaging, shipping, lifting

or any other temporary weight associated with the supply of an item.

4.0 PURCHASE ORDER

4.1 The CONTRACTOR shall review the weight estimate provided in his bid and advise of any

variation in weight or centroid location necessary to comply with the purchase order

specifications. The revised weight shall include a specified positive tolerance which shall

not exceed 10% of the item's estimated final weight.

The weight thus determined is the Upper Bound Weight and shall not be exceeded in later

updates without the permission in writing of the COMPANY. This information, together

with a detailed sketch (see Attachment 1 - Weight Control Data Sheet) clearly showing the

coordinate reference location point for the centroid, shall be provided to COMPANY.

January, 2004 Specification No. EGP3-01.08 Page 5 of 8

4.2 Where detailed design drawings are stipulated to be submitted to COMPANY in the

purchase order requirements, they shall be accompanied by an update to the item weights

and the centroid given at the initial submission and at any subsequent amendment

submission.

A detailed sketch clearly showing the coordinate reference location point for the centroid

shall accompany each submission. The revised weight shall include a specified tolerance

which shall not exceed 5% of the item's final weight, nor exceed the Upper Bound Weight

estimate without permission in writing of COMPANY.

4.3 Prior to preparation for shipment of completed items, the CONTRACTOR shall weigh the

completed assembly to obtain a final Weight and Centroid location. The final weight shall

include a specified tolerance which shall not exceed ±1% the item's final weight. The

weighing method used shall be capable of accurately determining the centroid location of

the assembly in the two dimensions of the horizontal reference plane.

The CONTRACTOR shall also provide an estimate as to the centroid location in the

vertical reference plane. The CONTRACTOR shall submit a weighing procedure for

COMPANY review prior to weighing.

4.4 A detailed sketch clearly showing the coordinate reference location point for the centroid

shall be forwarded to COMPANY at least 7 days prior to the schedule delivery date. The

weighing shall be carried out on suitably calibrated weighing equipment which shall have a

calibration certificate less than one year old. The results of such weighings, together with

duplicate copies of the calibration certificate, shall be forwarded to the COMPANY at least

7 days prior to schedule delivery date.

4.5 The CONTRACTOR shall advise the COMPANY as to the dates of each weighing giving

at least 7 days notice. The CONTRACTOR shall provide facilities to allow the witnessing

of such weighings by COMPANY’S representative. Duplicate copies of the calibration

certificate for the weighing equipment proposed shall be forwarded with advice of weighing

dates.

4.6 The CONTRACTOR shall provide COMPANY with access to all information he may

require to carry out an independent audit of the CONTRACTOR’S weight and centroid

information.

January, 2004 Specification No. EGP3-01.08 Page 6 of 8

5.0 BULK MATERIALS

Where a quantity of identical items are purchased and accurate catalogue weights are not

available, a representative sample shall be test weighed. The number of items to be test weighed

shall be in accordance with the following table.

No. of Identical Items Representative Sample

1 1

2 2

3-10 3

11-100 4

100 Plus 5

Where unit weight materials are purchased and accurate catalogue weights are not available, a

representative sample shall be test weighed to confirm the unit weight. The minimum number of

samples to be test weighed shall be three, selected at random from the production process, for

each delivery of material from the CONTRACTOR.

6.0 WEIGHT DATA SHEETS

CONTRACTOR shall use the Weight Control Data Sheet and CONTRACTOR weighing

Certificate for reporting of weight control and certification information respectively.

January, 2004 Specification No. EGP3-01.08 Page 7 of 8

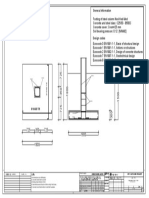

ATTACHMENT 1

PARSONS JOB NO. _________________ ITEM NO.

PARSONS ENERGY & CHEMICALS GROUP, INC.

PARSONS INQUIRY/PO. NO.

HOUSTON, TEXAS

SPECIFICATION NO.

REVISION NO. DATE

PAGE BY

WEIGHT / C.G. CONTROL

DATA SHEET

SI UNITS

APPLICABLE TO: INQUIRY PURCHASE AS BUILT

PROJECT

CLIENT

LOCATION

SERVICE

WEIGHT TYPE ESTIMATED % CONTINGENCY

WEIGHT STATUS

WEIGHT ALLOWANCE

DATA

DRY ESTIMATE

(kgs) LIFT VENDOR INFORMATION

OPERATING WEIGHED INFORMATION

TEST

“A” “A” (mm)

“B” (mm)

“X” “C” (mm)

“X” (mm)

“Y” (mm)

“Z” (mm)

C OF G

“B”

“Y”

PLAN

C OF G

“C”

“Z”

SUPPORT STEEL

ELEVATION

NOTE:

1). ALL DIMENSIONS IN SI UNITS

WEIGHT CHECKLIST

2). SKETCH IN SOME IDENTIFYING TEAM ABOVE TO HELP ORIENT THE “X” & “Y” DIMENSIONS”

INCLUDED IF NOT INCLUDED AND

ITEM APPLICABLE IN WEIGHT APPLICABLE - ESTIMATED

DATA WEIGHT

THERMAL INSULATION YES NO YES NO

FIRE PROOFING YES NO YES NO

FACTORY SKID / STEEL WORK YES NO YES NO

FCTORY SKID / INSTRUMENT YES NO YES NO

FACTORY SKID / ELECTRIC YES NO YES NO

FACTORY SKID / PIPE WORK YES NO YES NO

January, 2004 Specification No. EGP3-01.08 Page 8 of 8

You might also like

- Technical Specification of ValvesDocument28 pagesTechnical Specification of ValvesDhananjay BhaldandNo ratings yet

- YS-EWO-BEC-0102 Detail Engineering For Sanitary System Connection From Berth 71, 72 To Berth 69 Pit (Sump)Document23 pagesYS-EWO-BEC-0102 Detail Engineering For Sanitary System Connection From Berth 71, 72 To Berth 69 Pit (Sump)AdnanNo ratings yet

- Technical Specifications Section-I 1. General Information 1.1Document12 pagesTechnical Specifications Section-I 1. General Information 1.1binodeNo ratings yet

- Vol II InsulatorDocument63 pagesVol II InsulatorBarnabás KissNo ratings yet

- Administration of Ut of Daman & Diu Electicity Deaprtment,: Technical SpecificationsDocument102 pagesAdministration of Ut of Daman & Diu Electicity Deaprtment,: Technical Specificationsmanoj semwalNo ratings yet

- C4 Scope of WorkDocument10 pagesC4 Scope of WorkFaiz HussainNo ratings yet

- Solar Power Plant Bhel NTPC Part-3Document66 pagesSolar Power Plant Bhel NTPC Part-3amulya00428No ratings yet

- Specification 419 Rev 4 Storage TanksDocument10 pagesSpecification 419 Rev 4 Storage TanksABDELKADER BENABDALLAHNo ratings yet

- LNG-Requisition - Grounding - REV-0 - 27.09Document9 pagesLNG-Requisition - Grounding - REV-0 - 27.09Rince OktavianaNo ratings yet

- General Purchasing Requirements For API Storage TanksDocument5 pagesGeneral Purchasing Requirements For API Storage TanksAleem QureshiNo ratings yet

- 10 400 KV PANTO Isolator R2 Jan12Document39 pages10 400 KV PANTO Isolator R2 Jan12binodeNo ratings yet

- Volume VDocument312 pagesVolume VTengku Azaha Tengku IsmailNo ratings yet

- 02 - 220 - KV - PENTOGRAPH - ISOLATOR - R0 - Jul - 07 PDFDocument34 pages02 - 220 - KV - PENTOGRAPH - ISOLATOR - R0 - Jul - 07 PDFSwarup NayakNo ratings yet

- Technical Specs. (Vol-2) PDFDocument60 pagesTechnical Specs. (Vol-2) PDFsonuNo ratings yet

- Section-I - General & Scope of WorksDocument6 pagesSection-I - General & Scope of WorksSridhar VedulaNo ratings yet

- Specification 401 Rev 1129803527. 2 Unfired Pressure VesselDocument8 pagesSpecification 401 Rev 1129803527. 2 Unfired Pressure VesselariessuperNo ratings yet

- Technical Specifications Section-I 1. General Information 1.1Document12 pagesTechnical Specifications Section-I 1. General Information 1.1Jayant KambleNo ratings yet

- Technical Specification For PipesDocument13 pagesTechnical Specification For PipesRahul GangulyNo ratings yet

- ANSI - Ahri 400 2001 Heat ExchangerDocument18 pagesANSI - Ahri 400 2001 Heat Exchangerkgsatish1979No ratings yet

- Cofmow Specification SWL With AmcDocument78 pagesCofmow Specification SWL With Amcsanjib palNo ratings yet

- P3B-CONS-RFQ-001 - RFQ - FOR - POWER - CONSTRUCTION - R0ADocument73 pagesP3B-CONS-RFQ-001 - RFQ - FOR - POWER - CONSTRUCTION - R0ABondet CutaxNo ratings yet

- BSR Western ProvinceDocument47 pagesBSR Western ProvinceManaram Madusanka67% (3)

- Iqcs410 CsDocument19 pagesIqcs410 CsUtku BayramNo ratings yet

- Chapter 2-General Technical RequirementDocument41 pagesChapter 2-General Technical Requirementchintan pandyaNo ratings yet

- Technical Specification of STAY WIREDocument25 pagesTechnical Specification of STAY WIRESantosh GairheNo ratings yet

- General Specification: General Prescription For Required Technical DocumentationDocument16 pagesGeneral Specification: General Prescription For Required Technical DocumentationGlad BlazNo ratings yet

- National Oil Corporation: Rev Date Description Checked ApprovedDocument12 pagesNational Oil Corporation: Rev Date Description Checked ApprovedYousab JacobNo ratings yet

- Tech Spec Elevator Panki 1588046040Document29 pagesTech Spec Elevator Panki 1588046040Khushi191No ratings yet

- B - 4.5 - 44LK-5100-00-V.02-0102-A4-General Spec For Heat ExchangersDocument22 pagesB - 4.5 - 44LK-5100-00-V.02-0102-A4-General Spec For Heat ExchangersAnitNo ratings yet

- Technical Specification For FlangesDocument13 pagesTechnical Specification For FlangesRahul GangulyNo ratings yet

- Battery Charger TS Rev-0-31.12.22Document29 pagesBattery Charger TS Rev-0-31.12.22DEVI PRASAD GREENSECURENo ratings yet

- Duct SpecDocument23 pagesDuct Specqwerty_qwerty_2009100% (5)

- 4 Volume-5Document332 pages4 Volume-5Mala Seth DuttaNo ratings yet

- TR39 Volume VDocument221 pagesTR39 Volume VRamphani NunnaNo ratings yet

- Construction Standard Specification SECTION 01330 Submittal ProceduresDocument12 pagesConstruction Standard Specification SECTION 01330 Submittal Proceduresalex_blagoev2589No ratings yet

- GPH Proc Asst 00bop02 Ele 0001Document103 pagesGPH Proc Asst 00bop02 Ele 0001Shuhan Mohammad Ariful HoqueNo ratings yet

- RFQ Miscellaneous PumpDocument6 pagesRFQ Miscellaneous PumpGunturMudaAliAkbarNo ratings yet

- Method Statement For Painting System KAFD-RY-RIA2-CP04-SAB-ARF-MES-05001 Rev.01Document13 pagesMethod Statement For Painting System KAFD-RY-RIA2-CP04-SAB-ARF-MES-05001 Rev.01khalid khanNo ratings yet

- SOW2021BUILDUPCANOPYFORPARKINGMOTORCYCLEANDFABRICATEHOTBARRIER NfrefDocument26 pagesSOW2021BUILDUPCANOPYFORPARKINGMOTORCYCLEANDFABRICATEHOTBARRIER NfrefXII-2 MOH FAWAIDNo ratings yet

- Draft Spec No. Ti SPC Psi Cable 0091Document19 pagesDraft Spec No. Ti SPC Psi Cable 0091Soltani AliNo ratings yet

- SP-2202 Specification For Electric Overhead Traveling CranesDocument15 pagesSP-2202 Specification For Electric Overhead Traveling CranesHaitham Mohammad100% (1)

- GS114-8 HVAC - Terminal Units For Offshore UseDocument14 pagesGS114-8 HVAC - Terminal Units For Offshore UseDH BNo ratings yet

- GPO-EN-SPE-01004 - Weight ControlDocument15 pagesGPO-EN-SPE-01004 - Weight ControlAlina Ioana PrahoveanuNo ratings yet

- Projects & Development India LTD: EM238-TC-5201 0 Document No REV Sheet 1 of 9Document10 pagesProjects & Development India LTD: EM238-TC-5201 0 Document No REV Sheet 1 of 960606060No ratings yet

- Vol V KFW TR 107 16112017 PDFDocument376 pagesVol V KFW TR 107 16112017 PDFramesh seerviNo ratings yet

- Tender Package Electrical SystemsDocument221 pagesTender Package Electrical SystemsMohan BabuNo ratings yet

- Fiberglass Density Current Baffles - MSTDocument10 pagesFiberglass Density Current Baffles - MSTwafikmh4No ratings yet

- PHR PP QC GG 005 Non Destructive TestDocument8 pagesPHR PP QC GG 005 Non Destructive Testmashari budiNo ratings yet

- Construction Transmittal Form TemplateDocument2 pagesConstruction Transmittal Form TemplatearthurNo ratings yet

- Ano-010-Awrg-3.1 - Approval of Suppliers Stockists and Distributors of Aircraft ComponentsDocument8 pagesAno-010-Awrg-3.1 - Approval of Suppliers Stockists and Distributors of Aircraft Componentsafa.maintNo ratings yet

- Specification 103 Rev. 8 - Supplier Document RequirementsDocument16 pagesSpecification 103 Rev. 8 - Supplier Document RequirementsTadaya KasaharaNo ratings yet

- Enquiry ValveDocument4 pagesEnquiry ValvePradnyesh DivekarNo ratings yet

- Vol II of II - Technical VolDocument21 pagesVol II of II - Technical VolGururaj P KundapurNo ratings yet

- EGP3-03.31 Pipe Support Spring DesignDocument8 pagesEGP3-03.31 Pipe Support Spring DesignMathias OnosemuodeNo ratings yet

- 4-7ts - General Welding Requierments - KBRDocument11 pages4-7ts - General Welding Requierments - KBRKunal SrivastavaNo ratings yet

- PAKEJ 4 - Batteries-HighlightDocument37 pagesPAKEJ 4 - Batteries-HighlightammirulazmanNo ratings yet

- Gas-Liquid And Liquid-Liquid SeparatorsFrom EverandGas-Liquid And Liquid-Liquid SeparatorsRating: 3.5 out of 5 stars3.5/5 (3)

- Process System Value and Exergoeconomic Performance of Captive Power PlantsFrom EverandProcess System Value and Exergoeconomic Performance of Captive Power PlantsNo ratings yet

- J08937A-A-RG-00012 Rev A1 Value Engineering RegisterDocument4 pagesJ08937A-A-RG-00012 Rev A1 Value Engineering RegisterMathias OnosemuodeNo ratings yet

- Start Date ReportDocument1 pageStart Date ReportMathias OnosemuodeNo ratings yet

- J08937A-A-RG-00046 Rev A1 Interface RegisterDocument3 pagesJ08937A-A-RG-00046 Rev A1 Interface RegisterMathias OnosemuodeNo ratings yet

- Vedra Trade Services (VTS) ProfileDocument94 pagesVedra Trade Services (VTS) ProfileMathias OnosemuodeNo ratings yet

- Vedra Trade Services (VTS) ProfileDocument94 pagesVedra Trade Services (VTS) ProfileMathias OnosemuodeNo ratings yet

- J08937A-A-RG-00018 Rev D1 Risk RegisterDocument3 pagesJ08937A-A-RG-00018 Rev D1 Risk RegisterMathias OnosemuodeNo ratings yet

- Confident Level For Base Line Schedule Targeting Q4 2023-Using PRA SoftwareDocument1 pageConfident Level For Base Line Schedule Targeting Q4 2023-Using PRA SoftwareMathias OnosemuodeNo ratings yet

- Duration REPORTDocument1 pageDuration REPORTMathias OnosemuodeNo ratings yet

- AG GAS PLANT, 50MMscfd & 16, 25.5 KM Export Pipline - L1Document1 pageAG GAS PLANT, 50MMscfd & 16, 25.5 KM Export Pipline - L1Mathias OnosemuodeNo ratings yet

- Schedule Model in PRA For The AG Plant & 16inch 25.5 KM Export Line To Amena EkponoDocument1 pageSchedule Model in PRA For The AG Plant & 16inch 25.5 KM Export Line To Amena EkponoMathias OnosemuodeNo ratings yet

- Fop KC-2 - B102Document5 pagesFop KC-2 - B102Mathias OnosemuodeNo ratings yet

- Vol. II FinalDocument525 pagesVol. II FinalmishtinilNo ratings yet

- 149AKQDocument1 page149AKQMathias OnosemuodeNo ratings yet

- DPR 18-05-2021Document18 pagesDPR 18-05-2021Mathias OnosemuodeNo ratings yet

- WR Design and Fabrication of Anodes Rev 0Document10 pagesWR Design and Fabrication of Anodes Rev 0Mathias OnosemuodeNo ratings yet

- Book 1Document2 pagesBook 1Mathias OnosemuodeNo ratings yet

- Activity Duration Estimates TemplateDocument1 pageActivity Duration Estimates TemplateMathias OnosemuodeNo ratings yet

- dESIGN FOR REBAR IN A CONCRETE SLABDocument1 pagedESIGN FOR REBAR IN A CONCRETE SLABMathias OnosemuodeNo ratings yet

- 10'' Pipeline Activity Base CostingDocument2 pages10'' Pipeline Activity Base CostingMathias OnosemuodeNo ratings yet

- CIGA-NG180100021-CGSA1-CX4019-000049-Steel Connection DetailsDocument1 pageCIGA-NG180100021-CGSA1-CX4019-000049-Steel Connection DetailsMathias OnosemuodeNo ratings yet

- In-Place Strength Evaluation of Existing Fixed Offshore PlatformDocument8 pagesIn-Place Strength Evaluation of Existing Fixed Offshore PlatformMathias OnosemuodeNo ratings yet

- 11 029 - Project ScheduleDocument102 pages11 029 - Project ScheduleGoh Boon TiongNo ratings yet

- City Gate Aba Project: Gredor Nigeria LimitedDocument1 pageCity Gate Aba Project: Gredor Nigeria LimitedMathias OnosemuodeNo ratings yet

- CIGA-NG180100021-CGSA1-CX4019-000046-Elevated Water Tank Steel Structural Stand and Foundation Design ReportDocument37 pagesCIGA-NG180100021-CGSA1-CX4019-000046-Elevated Water Tank Steel Structural Stand and Foundation Design ReportMathias OnosemuodeNo ratings yet

- City Gate Aba Project: Gredor Nigeria LimitedDocument1 pageCity Gate Aba Project: Gredor Nigeria LimitedMathias OnosemuodeNo ratings yet

- City Gate Aba Project: Gredor Nigeria LimitedDocument1 pageCity Gate Aba Project: Gredor Nigeria LimitedMathias OnosemuodeNo ratings yet

- CIGA-NG180100021-CGSA1-CX4019-000046-Elevated Water Tank Steel Structural Stand Design ReportDocument13 pagesCIGA-NG180100021-CGSA1-CX4019-000046-Elevated Water Tank Steel Structural Stand Design ReportMathias OnosemuodeNo ratings yet

- Tank DesignDocument6 pagesTank DesignMathias OnosemuodeNo ratings yet

- CIGA-NG180100021-CGSA1-CX4019-000047-C01 - Elevated Water Tank Steel Structural Stand Design DrawingDocument1 pageCIGA-NG180100021-CGSA1-CX4019-000047-C01 - Elevated Water Tank Steel Structural Stand Design DrawingMathias OnosemuodeNo ratings yet

- City Gate Aba Project: Gredor Nigeria LimitedDocument1 pageCity Gate Aba Project: Gredor Nigeria LimitedMathias OnosemuodeNo ratings yet

- Planning and Scheduling of SubstructureDocument81 pagesPlanning and Scheduling of SubstructureHnin Wai Mar Aung100% (3)

- 01 Practice Management - Brightwood Study GuideDocument181 pages01 Practice Management - Brightwood Study GuideKevin DavisNo ratings yet

- Civil Engineering Question and AnswersDocument20 pagesCivil Engineering Question and AnswersUnique BoyNo ratings yet

- Fds Series: Fiber Dosing-Feeding SystemDocument15 pagesFds Series: Fiber Dosing-Feeding SystemPaul Ticla PuenteNo ratings yet

- Cost Planning and Pre-Contract Cost ControlDocument92 pagesCost Planning and Pre-Contract Cost ControlHaneefa ChNo ratings yet

- LECTURE 7 - Building PermitDocument35 pagesLECTURE 7 - Building PermitKhyverAndreiAmadorNo ratings yet

- 03 Revised TOR (EDS)Document24 pages03 Revised TOR (EDS)Jnb CreativeNo ratings yet

- Since 1999: Terracotta Roof FabricationDocument16 pagesSince 1999: Terracotta Roof FabricationSaran T SNo ratings yet

- LatestEffective Specs HIIDocument390 pagesLatestEffective Specs HIIGeorge0% (1)

- Comparative Analysis of Modular Construction Practices in Mainland China, HongDocument51 pagesComparative Analysis of Modular Construction Practices in Mainland China, Hongren renNo ratings yet

- Code Generator V2.0Document11 pagesCode Generator V2.0JobJobNo ratings yet

- Astm A750Document4 pagesAstm A750Cristian OtivoNo ratings yet

- List of Tallest Buildings in The Philippines - Wikipedia, The Free EncyclopediaDocument12 pagesList of Tallest Buildings in The Philippines - Wikipedia, The Free EncyclopediaJay Jay AranillaNo ratings yet

- Topic 1 Introduction To Site Planning - TPR151 - WEEK 2Document8 pagesTopic 1 Introduction To Site Planning - TPR151 - WEEK 2bot13335555No ratings yet

- IPE 401 - Chapter 3 - Case Study of Milling MachineDocument37 pagesIPE 401 - Chapter 3 - Case Study of Milling MachineMasrur SakibNo ratings yet

- Assets - Brochure - Course Information Qty SurveyingDocument1 pageAssets - Brochure - Course Information Qty SurveyingBVS NAGABABUNo ratings yet

- Introduction of Construction Technology For Tall Building ProjectDocument54 pagesIntroduction of Construction Technology For Tall Building ProjectHussain AliNo ratings yet

- Press Release - NHAI To Carry Out Periodic Quality Audit and Independent Inspection of Its ProjectsDocument2 pagesPress Release - NHAI To Carry Out Periodic Quality Audit and Independent Inspection of Its ProjectsHarshit DubeyNo ratings yet

- SS11 Heavy Duty Speed Sensor Drawing 21184200Document1 pageSS11 Heavy Duty Speed Sensor Drawing 21184200Arturo NarvaezNo ratings yet

- Fabrication Materials: Saudi Arabian Oil CompanyDocument31 pagesFabrication Materials: Saudi Arabian Oil CompanyD7mey XNo ratings yet

- CSHP Comprehensive SampleDocument15 pagesCSHP Comprehensive SampleDave 1998No ratings yet

- Building EstimateDocument7 pagesBuilding EstimateRamesh rammiNo ratings yet

- Custom Knife Selection Guide: Handmade Custom Knives by Brandant RobinsonDocument33 pagesCustom Knife Selection Guide: Handmade Custom Knives by Brandant RobinsonEdson GordianoNo ratings yet

- Transteel Elite GetDocument20 pagesTransteel Elite GetCharlNo ratings yet

- METHOD STATEMENT - Load, Unload, Moving, Shifting MaterialDocument1 pageMETHOD STATEMENT - Load, Unload, Moving, Shifting MaterialNazNazirah100% (4)

- Project TheoryDocument15 pagesProject TheoryUmarNo ratings yet

- Cut Sheet Rev.05Document196 pagesCut Sheet Rev.05Zeeshan YasinNo ratings yet

- Response To Gcr's N 03 High Risk Surveillance Report - 11 October 2023 (NSCR GCR n03 CRKSTN LTR Hs 000024) (NSCR Itd n03 ZWD RPT Hs 000519)Document14 pagesResponse To Gcr's N 03 High Risk Surveillance Report - 11 October 2023 (NSCR GCR n03 CRKSTN LTR Hs 000024) (NSCR Itd n03 ZWD RPT Hs 000519)Gian Carlo MiguelNo ratings yet

- World Famous Parabolic ArchesDocument4 pagesWorld Famous Parabolic ArchesKlare Montefalco100% (2)

- Produce Water Tank S.PCMDocument3 pagesProduce Water Tank S.PCMsudeesh kumarNo ratings yet