Professional Documents

Culture Documents

ASME PCC-1 Appendix-O (Assembly of Bolt Stress Determination)

Uploaded by

Mr IncognitoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ASME PCC-1 Appendix-O (Assembly of Bolt Stress Determination)

Uploaded by

Mr IncognitoCopyright:

Available Formats

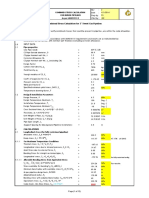

UNIVERSAL SOLUTION PTE LTD ROC/GST.

No: 201107371E Page No: 312

28 Jalan Buroh, Singapore 619484

Tel: +65 6265 9573 | Fax: +65 6265 9576

Email: sales@universalsolution.com.sg | www.universalsolution.com.sg

ASME PCC-1 Appendix-O (Assembly of Bolt Stress Determination) References

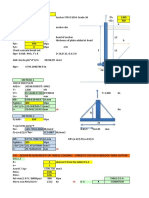

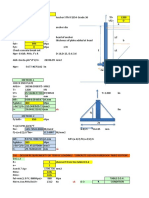

Ab = 0.302 in2, Bolt root area - O-1.3 / TEMA Section-9 Table D-5

nb = 84 Number of bolts - O-1.3 / As per Design

Ab x nb = 25.37 in2, Bolt root area x Number of bolts

Ag = 83.01 in2, Gasket Area

Øb = 0.79 in, Bolt Diameter - O-1.3 / As per Design / TEMA Section-9 Table D-5

Pmax = 72.8 Psig, Maximum Design Pressure - O-1.3 / API 660 (Clause 7.8.7)

Øg = 0.7 Fraction of Gasket Load remaining after relaxation - O-4.1 (i)

GI.D = 51.1 in, Gasket Sealing element inner diameter - O-1.3 / As per Design

GO.D = 52.2 in, Gasket Sealing element Outer diameter - O-1.3 / As per Design

Bolt yield stress = 30008.3 Psig, Bolt Yield stress at Ambient condition. - As per ASME Sec.II Part -A

SgT =(0.75 x Sg.max) = 30000 Psig, Target assembly gasket stress - O-4.1 (b)

Sbmax= (0.7 x Bolt Yield Stress) = 21006 Psig, Maximum permissible bolt stress - O-4.1 (b) (Typically 40% to 70% of Yield at Ambient)

Sbmin=(0.4xBolt Yield Stress) = 12003.32 Psig, Minimum permissible bolt stress - O-4.1 (c) (Typically 20% to 40% of Yield at Ambient)

Sg min-S = 20000 Psig, Minimum gasket Seating stress - O-4.1 (g) / API 660 (Table-3) - Kammprofile Gasket

Sg min-O = 14000 Psig, Minimum gasket Operating stress - O-4.1 (h) / API 660 (Table-3) - Kammprofile Gasket

Sgmax = 40000 Psig, Minimum permissible gasket stress - O-4.1 (f) / API 660 (Table-3) - Kammprofile Gasket

Øfmax = 0.489 Deg, Single Flange Rotation ≤ 1 , API 660 (Clause 7.8.6) - O-4.1 (d) / As per Appendix-2 (Refer channel flange calculation)

Øgmax = 1 Deg, Maximum permissible single flange rotation for gasket at the - O-4.1 (a) / Gasket manufacturer mentioned to follow ASME PCC-1 Appendix-O

maximum operating temperature.

K= 0.2 Nut Factor - O-3.1

Determination of Bolt Stress

Equation [0-1] SbSel = SgT *(Ag / (nb*Ab)) = 98169 Psi 677 Mpa

Equation [0-4] SbSel = Min(Sbsel, Sbmax) = 21006 Psi 145 Mpa

Equation [0-5] SbSel = Max(Sbsel, Sbmin) = 21006 Psi 145 Mpa

Table O-4.1-2 Maximum permissible bolt Stress prior to bolt damage, Sfmax = 74999 Psi 517 Mpa ASME Sec.2 Part 'D' / (Tensile Stress)

Equation [0-6] SbSel = Min (Sbsel, Sbmax) = 74999 Psi 517 Mpa

Additional Checks

Equation [0-7] Sbsel ≥ Sgmin-S [Ag / (Ab*nb)] = 74999 ≥ 65446 Psi 1

Equation [0-8] Sbsel ≥ [Sgmin-O * Ag +(3.14/4)*Pmax* GI.D^2] / [ Øg *Ag*nb] = 74999 ≥ 73863 Psi 1

Equation [0-9] Sbsel ≤ Sgmax [Ag / Ab*nb] = 74999 ≤ 130892 Psi 1

Table O-4.1-4 Øfmax = 0.489 Deg.

Equation [0-10] SbSel ≤ Sfmax (Øgmax / Øfmax) = 74999 ≤ 153372 Psi 1

Equation [0-2] Tb = Sbsel *K*Ab*Øb/12 297 Ft-Lb

Rounded of Assembly Bolt Torque, Tb = 300 Ft-Lb

Assembly Bolt Torque, Tb = 407 N-m 41 Kg-m

You might also like

- The Stress Analysis of Pressure Vessels and Pressure Vessel Components: International Series of Monographs in Mechanical EngineeringFrom EverandThe Stress Analysis of Pressure Vessels and Pressure Vessel Components: International Series of Monographs in Mechanical EngineeringS. S. GillRating: 3.5 out of 5 stars3.5/5 (3)

- Assembly Bolt Stress As Per Asme Pcc-1 2013Document12 pagesAssembly Bolt Stress As Per Asme Pcc-1 2013Anonymous RytT6uvX1No ratings yet

- Bolt Torque Calculations 1 PDFDocument1 pageBolt Torque Calculations 1 PDFshazanNo ratings yet

- Asme Pcc-1 App O - 411-E-103 - Ch. Cover FLGDocument12 pagesAsme Pcc-1 App O - 411-E-103 - Ch. Cover FLGVilas AndhaleNo ratings yet

- PCC1 - Addendum - 31210130 (Feb 2013) - GM1-001-G0000-MS-7880-00003Document2 pagesPCC1 - Addendum - 31210130 (Feb 2013) - GM1-001-G0000-MS-7880-00003Abhay UpadhyayNo ratings yet

- Bolt Torque Appendix-ODocument1 pageBolt Torque Appendix-OSachin5586100% (1)

- Appendix 41Document5 pagesAppendix 41Rafael_YevgenyNo ratings yet

- Pipe cap thickness and coupling rating calculationsDocument2 pagesPipe cap thickness and coupling rating calculationsmasaminathanNo ratings yet

- WRC-107 (WRC-537) and WRC-297. (WELDING RESEARCH COUNCIL)Document1 pageWRC-107 (WRC-537) and WRC-297. (WELDING RESEARCH COUNCIL)miteshpatel191No ratings yet

- ASME PCC-1 Appendix-O-CalculationDocument23 pagesASME PCC-1 Appendix-O-Calculationvpjagannaath50% (2)

- ASME PCC-1 Bolt Stress and Torque CalculationDocument11 pagesASME PCC-1 Bolt Stress and Torque Calculationndrarly100% (1)

- Skirt To Dish Joint PDFDocument64 pagesSkirt To Dish Joint PDFPrajwal ShettyNo ratings yet

- 123Document8 pages123Dalberto Ramirez50% (2)

- EJMA Calculation Report For Cryostat DNB 7HL9UC v1 3Document25 pagesEJMA Calculation Report For Cryostat DNB 7HL9UC v1 3zstNo ratings yet

- WRC Data-ModifiedDocument40 pagesWRC Data-ModifiedGovindan KrishnamoorthybashyamNo ratings yet

- Nozzle Calcs Rev ADocument6 pagesNozzle Calcs Rev AbolivarNo ratings yet

- AD 2000 Shell Under External PressureDocument3 pagesAD 2000 Shell Under External Pressuremechengg01100% (1)

- Agitator Nozzle Load Data SheetDocument1 pageAgitator Nozzle Load Data SheetAnonymous MB5YbaLrBENo ratings yet

- PV Elite 2015 Sp1 Licensee: SPLM Licensed User Filename: Untitled Nozzle Calcs.: N1 Nozl: 3 9:36am Dec 7,2018Document32 pagesPV Elite 2015 Sp1 Licensee: SPLM Licensed User Filename: Untitled Nozzle Calcs.: N1 Nozl: 3 9:36am Dec 7,2018Priyo Jati WahyonoNo ratings yet

- Impact Test Exemptions PEDDocument7 pagesImpact Test Exemptions PEDoberaiNo ratings yet

- International Codes and Standards for High-Pressure Vessel DesignDocument6 pagesInternational Codes and Standards for High-Pressure Vessel DesignkylenilsenNo ratings yet

- Allowable Nozzle LoadingsDocument3 pagesAllowable Nozzle Loadingskemo10No ratings yet

- Design of Leg & Skirt Per EN 13445-3 - 2009 PDFDocument17 pagesDesign of Leg & Skirt Per EN 13445-3 - 2009 PDFtranhonghakd5533100% (1)

- Pd5500 Flange CalculationDocument6 pagesPd5500 Flange CalculationMakrand SakpalNo ratings yet

- Loose Without Hub Type Body Flange CalculationDocument11 pagesLoose Without Hub Type Body Flange Calculation9913489806No ratings yet

- Swing Bolt CalculationDocument2 pagesSwing Bolt CalculationNicolaSavili100% (2)

- Allowable Nozzle LoadsDocument6 pagesAllowable Nozzle LoadsAlan Crocher100% (2)

- Skirt & Anchor Bolt BROWNELL & YOUNG Process Equip. DesignDocument15 pagesSkirt & Anchor Bolt BROWNELL & YOUNG Process Equip. DesignImthiyaz HNo ratings yet

- MESC SPE 85 103 - 2017 - Spiral Wound Gaskets (Amendments Supplements To Asme B16.20)Document9 pagesMESC SPE 85 103 - 2017 - Spiral Wound Gaskets (Amendments Supplements To Asme B16.20)GordonNo ratings yet

- Establishing Nozzle Allowable LoadsDocument9 pagesEstablishing Nozzle Allowable LoadsMechanical100% (1)

- Bednar - Pressure Vessel Design HandbookDocument230 pagesBednar - Pressure Vessel Design HandbookceballosingNo ratings yet

- Using The ASME VIII-1 Nozzle F Factor (UG-37)Document8 pagesUsing The ASME VIII-1 Nozzle F Factor (UG-37)Liu YangtzeNo ratings yet

- Diaphragm Elimination Using Taper-Lok - NPRADocument11 pagesDiaphragm Elimination Using Taper-Lok - NPRAN. S. PanditNo ratings yet

- FlangeCalculationASMEVIII Version5Document13 pagesFlangeCalculationASMEVIII Version5madodandembe100% (3)

- WRC 297Document9 pagesWRC 297akisdassas100% (1)

- Nozzle Loads WRC 107 Ver 1.1 PDFDocument1 pageNozzle Loads WRC 107 Ver 1.1 PDFpsaayoNo ratings yet

- WRC 107, WRC 297 Co MP PDFDocument11 pagesWRC 107, WRC 297 Co MP PDFkarthickmectr100% (2)

- EJMAStandards - 10th EditionDocument1 pageEJMAStandards - 10th EditionManish Verma100% (1)

- Rectangular Tank CalculationDocument6 pagesRectangular Tank Calculationprince kumarNo ratings yet

- FatigueLife FEA PDFDocument43 pagesFatigueLife FEA PDFAbigail SommersetNo ratings yet

- UG-39 - Flat Head ReinforcementDocument3 pagesUG-39 - Flat Head ReinforcementAshish DhokNo ratings yet

- 6.5.3 Calculation of The Reaction ForceDocument3 pages6.5.3 Calculation of The Reaction Forcesammar_10No ratings yet

- NozzlePRO PDFDocument185 pagesNozzlePRO PDFIan CarrNo ratings yet

- Work Instruction - Nozzle Load TransferDocument3 pagesWork Instruction - Nozzle Load Transfervpjagannaath100% (1)

- Stiffness Coefficients and Allowable Nozzles in API 650 TanksDocument11 pagesStiffness Coefficients and Allowable Nozzles in API 650 TanksUjwal Khandokar0% (1)

- ASME PCC-1 APP O - 411-E-103 - TS FLGDocument56 pagesASME PCC-1 APP O - 411-E-103 - TS FLGmohamed.eldesouky9120No ratings yet

- Combined Stress Calc Rev. 2Document12 pagesCombined Stress Calc Rev. 2babu75% (4)

- TM-CP1-PMT-0070 Att.4 - Strength Calculation For Bellows (Sample)Document13 pagesTM-CP1-PMT-0070 Att.4 - Strength Calculation For Bellows (Sample)jhunkujha11No ratings yet

- Nozzle TempDocument2 pagesNozzle TempRakeshNo ratings yet

- Line Sizing of The Main Production Header (A Gas / Liquid Two Phase Line)Document12 pagesLine Sizing of The Main Production Header (A Gas / Liquid Two Phase Line)Engr TheyjiNo ratings yet

- Asme Demo 125lDocument10 pagesAsme Demo 125lUdoy Hossen KhanNo ratings yet

- Input EchoDocument6 pagesInput EchohgagNo ratings yet

- REPORT (3) - MergedDocument29 pagesREPORT (3) - MergedMoustafaNo ratings yet

- Mathcad - PART II Ceiling (ICU) 20200602 (Update) - 2Document418 pagesMathcad - PART II Ceiling (ICU) 20200602 (Update) - 2BQ HeNo ratings yet

- RCC DesignDocument41 pagesRCC Designmarkedstrengthconstruction2023No ratings yet

- Shell & Dish End CalculationDocument46 pagesShell & Dish End CalculationparveshNo ratings yet

- SUPPL REINF Ver40Document9 pagesSUPPL REINF Ver40mehrdad khoeiNo ratings yet

- UntitledDocument8 pagesUntitledmehrdad khoeiNo ratings yet

- Suppl Reinf 2018 11Document9 pagesSuppl Reinf 2018 11mehrdad khoeiNo ratings yet

- Base PLate Calculation SeparatorDocument15 pagesBase PLate Calculation Separatorrudi 01No ratings yet

- Calculation of Zincalume TankDocument20 pagesCalculation of Zincalume TankMr IncognitoNo ratings yet

- Internal Coil CalculationDocument19 pagesInternal Coil CalculationMr Incognito100% (3)

- Specification For Structural Steel Buildings ANSI/AISC 360-16 CHAPTER J - Design of ConnectionsDocument9 pagesSpecification For Structural Steel Buildings ANSI/AISC 360-16 CHAPTER J - Design of ConnectionsMr Incognito100% (1)

- Flanged Header CalcnDocument13 pagesFlanged Header CalcnMr IncognitoNo ratings yet

- Mset Engineering Corporation SDN BHD: (Ref:Pressure Vessel Design Manual 3rd Edition by Dennis R. Moss Page 291 295)Document20 pagesMset Engineering Corporation SDN BHD: (Ref:Pressure Vessel Design Manual 3rd Edition by Dennis R. Moss Page 291 295)Mr IncognitoNo ratings yet

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- 3D-LABS Zincalume Water Storage Tank DesignDocument6 pages3D-LABS Zincalume Water Storage Tank DesignMr IncognitoNo ratings yet

- Lifting/Tailing Lug Calculation: Design DataDocument3 pagesLifting/Tailing Lug Calculation: Design DataMr IncognitoNo ratings yet

- Specification For Structural Steel Buildings ANSI/AISC 360-16 CHAPTER J - Design of ConnectionsDocument9 pagesSpecification For Structural Steel Buildings ANSI/AISC 360-16 CHAPTER J - Design of ConnectionsMr Incognito100% (1)

- GLS Tank - Awwa D103Document16 pagesGLS Tank - Awwa D103Mr Incognito100% (1)

- Anchors - Cross SectionDocument13 pagesAnchors - Cross SectionthreedlabsNo ratings yet

- PARTITION PLATE CALCULATIONDocument4 pagesPARTITION PLATE CALCULATIONMr IncognitoNo ratings yet

- Heating Coil Sizing For Fuel Oil TankDocument4 pagesHeating Coil Sizing For Fuel Oil TankInggitNo ratings yet

- Unit 5: Structural Modelling: Block II: From Analysis To DesignDocument76 pagesUnit 5: Structural Modelling: Block II: From Analysis To DesignPatrick FarahNo ratings yet

- MMC Fiori Cheat Sheet PDFDocument2 pagesMMC Fiori Cheat Sheet PDFAleksandar KNo ratings yet

- Bomba de Vacio Part ListDocument2 pagesBomba de Vacio Part ListNayeli Zarate MNo ratings yet

- Living Together TestDocument2 pagesLiving Together TestProfu' de biologieNo ratings yet

- Feasibility in Ergonomics AutosavedDocument63 pagesFeasibility in Ergonomics AutosavedMichael AsinguaNo ratings yet

- Managerial Economics L4 Consumer BehaviourDocument50 pagesManagerial Economics L4 Consumer BehaviourRifat al haque DhruboNo ratings yet

- The Korean MiracleDocument20 pagesThe Korean MiracleDivya GirishNo ratings yet

- Bachelor of Arts (Psychology HR Management) Y3 V2Document1 pageBachelor of Arts (Psychology HR Management) Y3 V2Kenny sylvainNo ratings yet

- Sharp Sharp Cash Register Xe A207 Users Manual 284068Document1 pageSharp Sharp Cash Register Xe A207 Users Manual 284068Zeila CordeiroNo ratings yet

- Families of Carbon Compounds: Functional Groups, Intermolecular Forces, & Infrared (IR) SpectrosDocument79 pagesFamilies of Carbon Compounds: Functional Groups, Intermolecular Forces, & Infrared (IR) SpectrosRuryKharismaMuzaqieNo ratings yet

- String inverter comparisonDocument4 pagesString inverter comparisonRakesh HateyNo ratings yet

- T2-1 MS PDFDocument27 pagesT2-1 MS PDFManav NairNo ratings yet

- Value YourselfDocument7 pagesValue YourselfTalha KhalidNo ratings yet

- OlayDocument36 pagesOlayrachit.chaudharyNo ratings yet

- Art for Ages 1-3 Focuses on DevelopmentDocument3 pagesArt for Ages 1-3 Focuses on DevelopmentPresley AbrauNo ratings yet

- Accounting For Non Specialists Australian 7th Edition Atrill Test BankDocument26 pagesAccounting For Non Specialists Australian 7th Edition Atrill Test BankJessicaMitchelleokj100% (49)

- ĐỀ THI HSGDocument13 pagesĐỀ THI HSGahmad amdaNo ratings yet

- Pediatrics Study ScheduleDocument2 pagesPediatrics Study ScheduleNatnaelNo ratings yet

- 6.1.2 The Solar SystemDocument4 pages6.1.2 The Solar System205 NursyazliyanaNo ratings yet

- What ATF - CVTF To Use For ToyotaDocument7 pagesWhat ATF - CVTF To Use For ToyotaSydneyKasongoNo ratings yet

- Mercer Role and Job Analysis InfoDocument3 pagesMercer Role and Job Analysis InfojehaniaNo ratings yet

- Confined Space: Hole Watch TrainingDocument36 pagesConfined Space: Hole Watch TrainingMalik JunaidNo ratings yet

- MsdsDocument6 pagesMsdsGis GeorgeNo ratings yet

- Islamic Center Design With Islamic ArchiDocument11 pagesIslamic Center Design With Islamic ArchiMuhammad Sufiyan SharafudeenNo ratings yet

- Haloalkanes and Haloarenes Notes GoodDocument21 pagesHaloalkanes and Haloarenes Notes GoodAnitesh DharamNo ratings yet

- Allison WallaceDocument3 pagesAllison WallaceOskar KarvajalNo ratings yet

- IruvarDocument5 pagesIruvarKarthikeya KaredlaNo ratings yet

- What Is Mean?: Extrapolation InterpolationDocument2 pagesWhat Is Mean?: Extrapolation InterpolationVinod SharmaNo ratings yet

- My CV - Rose ChebetDocument5 pagesMy CV - Rose ChebetSammy WatimaNo ratings yet

- Pruebas de Certificación Lingüística in - B1 - Ce - Sol - J - 2015 Answer Key - JUNE 2015 Task 1Document2 pagesPruebas de Certificación Lingüística in - B1 - Ce - Sol - J - 2015 Answer Key - JUNE 2015 Task 1Jeru SierraNo ratings yet