Professional Documents

Culture Documents

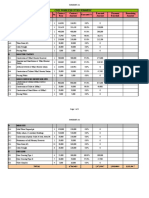

Bottom Chord

Uploaded by

ARSE0 ratings0% found this document useful (0 votes)

126 views3 pagesThis document summarizes the structural design of roof trusses according to Eurocode 3. It analyzes three load cases - dead load + imposed load, dead load + live load + wind load, and dead load + wind load. For the bottom chord, it checks the axial tensile and compressive resistance. It determines the section satisfies classification requirements and checks the buckling resistance. It also verifies the deflection is less than the allowable limit. The analysis shows UA 50 X 50 X 6 sections are adequate for the entire roof truss.

Original Description:

Original Title

bottom chord

Copyright

© © All Rights Reserved

Available Formats

XLS, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document summarizes the structural design of roof trusses according to Eurocode 3. It analyzes three load cases - dead load + imposed load, dead load + live load + wind load, and dead load + wind load. For the bottom chord, it checks the axial tensile and compressive resistance. It determines the section satisfies classification requirements and checks the buckling resistance. It also verifies the deflection is less than the allowable limit. The analysis shows UA 50 X 50 X 6 sections are adequate for the entire roof truss.

Copyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

126 views3 pagesBottom Chord

Uploaded by

ARSEThis document summarizes the structural design of roof trusses according to Eurocode 3. It analyzes three load cases - dead load + imposed load, dead load + live load + wind load, and dead load + wind load. For the bottom chord, it checks the axial tensile and compressive resistance. It determines the section satisfies classification requirements and checks the buckling resistance. It also verifies the deflection is less than the allowable limit. The analysis shows UA 50 X 50 X 6 sections are adequate for the entire roof truss.

Copyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

You are on page 1of 3

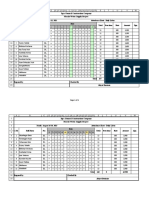

In all cases, (T) – Tensile force; (C) – Compressive force

Structural Design of Roof Trusses to Eurocode 3

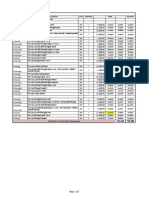

All structural steel employed in the design has the following

properties;

fy (Yield strength) 275N/mm2

fu (ultimate tensile strength 430N/mm2

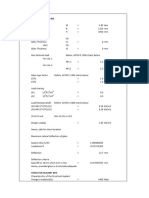

3.1 Design of the bottom chord (considering maximum effects)

LOAD CASE 1: DEAD LOAD + IMPOSED LOAD only

Fu = γGjGk + γQkQk

Ultimate design force (NEd) = 1.35Gk + 1.5Qk #REF! tensile

LOAD CASE 2: DEAD LOAD + LIVE LOAD + WIND LOAD acting

simultaneously

Partial factor for permanent actions (DK) 1.0

Partial factor for leading variable actions (Wk) 1.5

Therefore ultimate design force in the member = Fu = γGjGk +

γWkWk = Gk + 1.5Wk. #REF! Tensile

LOAD CASE 3: DEAD LOAD + WIND LOAD acting

simultaneously

Partial factor for permanent actions (DK)

Partial factor for leading variable actions (Wk)

Therefore ultimate design force in the member = Fu = γGjGk + #REF! compressive

γWkWk = Gk + 1.5Wk.

Therefore, all bottom chord members should be able to resist

an axial tensile load of107.4045 kN and a possible reversal of

stresses with a compressive load of 116.8 kN

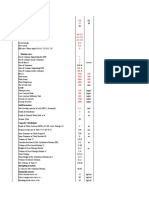

Length of longest bottom chord member 3000mm

Consider EQUAL ANGLES UA 50 X 50 X 6 50 6

Gross Area 5.69cm2

Radius of gyration (axis y-y) 1.51cm

Considering one M12 bolt (14mm diameter allowance) – 3.72cm2

Equivalent tension area

Equivalent tension area for welded connection 4.88cm2

NERd is lesser of Anet*Fy/gM0 and 0.9*Anet*Fu/gM2

Anet*Fy/gM0 156.475

0.9*Anet*Fu/gM2 176.1624

therefore NERd 156.475

Nsd/NtRd #REF! #REF!

Compression and Buckling resistance

thickness of section t= 6

Section classification

e=Ö(235/Fy) 0.9244

h/t = 50/6 8.3333

Referring to Table 5.2 (sheet 3) of Eurocode 3, Part 1-1, for

class 3 classification,

h/t <= 15e and (h + b)/2t <= 11.5e In our case,

15e= 13.866 ok

(h + b)/2t <= 11.5e 10.631 ok

Thus, the section satisfies both of the conditions.

Resistance of the member to uniform compression

NcRd=Afy/gMo 156.475

Ned/NcRd #REF! #REF!

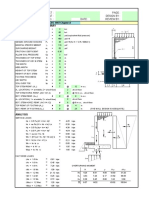

Buckling resistance of member (clause 5.5 ENV 1993-1-1:1992)

Since the member is pinned at both ends, critical buckling 3000mm

length is the same for all axis; Lcr

slenderness ratio l=Lcr/ril1

l1=93.9e 86.803

in the planar axis l–= 2.304

Buckling curve b is approperiate for all angle section

according to table 6.2 of eurocode 3

ϕ=0.5[1+a(l-0.2)+l^2] 3.512

xy=1/(ϕ+Ö(ϕ^2-l^2) 0.162

NbRd=xyAFy/gM1 25.391

Ncd/NbRd #REF! #REF!

CHECK FOR DEFLECTION

Employing UA 50 X 50 X 6 in all members of the roof truss;

the deflection due to unfactored imposed load calculated

using STAADPRO V8i software is 1.028mm

Allowable deflection for roofs (Table 4.1 ENV 1993-1-1:1992) = #REF!

L/250 =

1.028mm < 28.8mm. Therefore deflection is ok

4 Conclusion

The analysis and design for the section members have been

successfully carried as shown in the calculations above.

Whenever the wind load effect is greater than the live load

effect, one should always watch out for possible reversal of

stresses during load combinations. The design has shown that

the provision of UA 50 X 50 X 6 for the entire roof truss will

be adequate.

You might also like

- Vertical MembersDocument3 pagesVertical MembersARSENo ratings yet

- Truss Top ChordDocument3 pagesTruss Top ChordARSENo ratings yet

- Steel Beam DesignDocument26 pagesSteel Beam DesignWazini D. Izani100% (1)

- Precast Concrete Structures Second Edition PDF Compressed 300 599Document300 pagesPrecast Concrete Structures Second Edition PDF Compressed 300 599anucha 1No ratings yet

- Pratt Type Roof Truss-DesignDocument9 pagesPratt Type Roof Truss-DesignARSE0% (1)

- CONN MacauV2 - 1226R1 LugDocument1 pageCONN MacauV2 - 1226R1 Lugchirathip vasuvattakulNo ratings yet

- End Plate Design As Per-Ec3Document18 pagesEnd Plate Design As Per-Ec36j7100% (1)

- Structural Cals For UCWDocument11 pagesStructural Cals For UCWShubham SoniNo ratings yet

- Slide Share BDocument42 pagesSlide Share BShakeel WaseemNo ratings yet

- Design of Bolted Beam Splice Connections According To EC3Document11 pagesDesign of Bolted Beam Splice Connections According To EC3Franklyn Genove100% (2)

- 6.3 Design Values of Combined ActionsDocument7 pages6.3 Design Values of Combined Actionsmn4webNo ratings yet

- Extended LECTUREDocument21 pagesExtended LECTUREbaraka100% (1)

- Composite Slab For Proposed Residential House-1Document7 pagesComposite Slab For Proposed Residential House-1JosephNo ratings yet

- Summary of ECP Euations 2019-2020Document10 pagesSummary of ECP Euations 2019-2020Ahmed Mamdouh100% (1)

- Worked Example ADocument10 pagesWorked Example AsoareculNo ratings yet

- Elevated Service ReservoirDocument35 pagesElevated Service ReservoirRamachandra SahuNo ratings yet

- Steel Column DesignDocument4 pagesSteel Column Designvsnsfb100% (1)

- Slab Design To BS 8110Document11 pagesSlab Design To BS 8110Samuel Antobam100% (2)

- Torsion Validation ShayanDocument10 pagesTorsion Validation ShayanGicuNo ratings yet

- Weld 3Document1 pageWeld 3canettijNo ratings yet

- 1200x800 Column DesignDocument4 pages1200x800 Column DesignrameshkaaNo ratings yet

- 1B. - Tension Members Ce134p - Escruz - LRFDDocument43 pages1B. - Tension Members Ce134p - Escruz - LRFDJed CernechezNo ratings yet

- Week 7 Truss DesignDocument39 pagesWeek 7 Truss DesignFoo He XuanNo ratings yet

- Sci Publication p387 Steel Building Desi 2Document4 pagesSci Publication p387 Steel Building Desi 2Visuvaratnam Suseendran100% (1)

- Tension Member LRFDDocument9 pagesTension Member LRFDgullipalliNo ratings yet

- ADS Project (1 To 3)Document43 pagesADS Project (1 To 3)damanNo ratings yet

- How To Design Roof Purlins - A Solved Example - Structville...Document23 pagesHow To Design Roof Purlins - A Solved Example - Structville...Charles Vladimir SolvaskyNo ratings yet

- 6-Prof. Zahid Ahmad Siddiqi Lec-6-Flexural Analysis and Design of BeamsDocument17 pages6-Prof. Zahid Ahmad Siddiqi Lec-6-Flexural Analysis and Design of BeamsMuhammadAboubakarFarooqNo ratings yet

- Design Purlin - As 4600Document8 pagesDesign Purlin - As 4600trung1983No ratings yet

- WeldDocument43 pagesWeldAuggie AranzadoNo ratings yet

- New Example 14 Simple FrameDocument6 pagesNew Example 14 Simple FrameminnNo ratings yet

- AISC Design ChecksDocument22 pagesAISC Design ChecksYogeshUndeNo ratings yet

- Chapter 3 - Restrained BeamDocument46 pagesChapter 3 - Restrained BeamMADHURJO MEHENAZ A20EA3003No ratings yet

- KKKH3353 - Structural Steel Design - Joints 2Document26 pagesKKKH3353 - Structural Steel Design - Joints 2Zeyad Tareq Al SaroriNo ratings yet

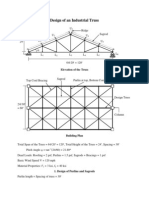

- Design of Industrial TrussDocument15 pagesDesign of Industrial TrussGurnam Singh Sodhi100% (3)

- 1 - SPLICE-WPB 700X300X204.5 - DraftDocument7 pages1 - SPLICE-WPB 700X300X204.5 - DraftAvishek DeyNo ratings yet

- 10T SWL Spreader Bar R2-Fos2.0Document8 pages10T SWL Spreader Bar R2-Fos2.0Snr Designer JayaNo ratings yet

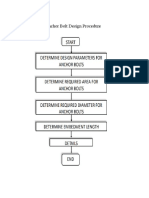

- Towerwind Analysis - Anchoragebolt - Base PlateDocument14 pagesTowerwind Analysis - Anchoragebolt - Base PlateJoy lauriaNo ratings yet

- Report 30 TonDocument10 pagesReport 30 TonMARYANo ratings yet

- Report 30 TonDocument10 pagesReport 30 TonMARYANo ratings yet

- Tubular Truss ExampleDocument12 pagesTubular Truss ExampleMock Khang Hi100% (1)

- Design of Plate Girder With Corrugated WebDocument6 pagesDesign of Plate Girder With Corrugated WebSharad SaterneNo ratings yet

- 1B. - Tension Members Ce134p-2 - EscruzDocument33 pages1B. - Tension Members Ce134p-2 - EscruzAireesha GozeNo ratings yet

- Appendix B - Design Examples: B.1 Multi-Span Precast Concrete Girder Made Continuous With Composite DeckDocument35 pagesAppendix B - Design Examples: B.1 Multi-Span Precast Concrete Girder Made Continuous With Composite DeckMICHAEL TADESSENo ratings yet

- 5.1 SS Steel BracketDocument5 pages5.1 SS Steel BracketAndrej SørensenNo ratings yet

- 22a-RSJ Runway Beam Check-Simply Supported-Hand OperatedDocument2 pages22a-RSJ Runway Beam Check-Simply Supported-Hand OperatedParthiban Arivazhagan100% (1)

- Shear Stress in BeamsDocument11 pagesShear Stress in Beamsangelica abanesNo ratings yet

- Applied Moment, Shear and Axial LoadsDocument8 pagesApplied Moment, Shear and Axial LoadsMallesh NenkatNo ratings yet

- Tension Members 2022Document44 pagesTension Members 2022ahmadlbraheem0987No ratings yet

- Monorail Beam Design 3TDocument22 pagesMonorail Beam Design 3Tdeepak_dce_me100% (3)

- Column Steel DesignDocument37 pagesColumn Steel DesignIlya Joohari100% (1)

- Steel Member Deflection CheckDocument12 pagesSteel Member Deflection CheckProlay MannaNo ratings yet

- Unrestrained Beam With End MomentsDocument9 pagesUnrestrained Beam With End MomentsNikos StathoulopoulosNo ratings yet

- Truss Design - Faculty Wing - EN1993Document13 pagesTruss Design - Faculty Wing - EN1993JonathanNo ratings yet

- Cylindrical Compression Helix Springs For Suspension SystemsFrom EverandCylindrical Compression Helix Springs For Suspension SystemsNo ratings yet

- 1000m3 ConcreteDocument3 pages1000m3 ConcreteARSENo ratings yet

- MaterialsDocument9 pagesMaterialsARSE100% (1)

- Material Request FormDocument1 pageMaterial Request FormARSENo ratings yet

- StatusDocument2 pagesStatusARSE100% (1)

- Nehase 1-15Document4 pagesNehase 1-15ARSENo ratings yet

- Item No.-1000m3Document7 pagesItem No.-1000m3ARSENo ratings yet

- Nehase 1-15Document4 pagesNehase 1-15ARSENo ratings yet

- Ug Sump DesignDocument12 pagesUg Sump DesignARSENo ratings yet

- Attendance Sheet MyaleDocument2 pagesAttendance Sheet MyaleARSENo ratings yet

- Elevated 150m3Document7 pagesElevated 150m3ARSENo ratings yet

- Design ExamplesDocument42 pagesDesign ExamplesARSENo ratings yet

- Dci Fitting: Item No Description Unit Quantity Pipes, Valves and Fittings Install Inlet PipeDocument1 pageDci Fitting: Item No Description Unit Quantity Pipes, Valves and Fittings Install Inlet PipeARSENo ratings yet

- Retainingwall Dsa OshpdDocument4 pagesRetainingwall Dsa OshpdMohamad HartadiNo ratings yet

- AugustDocument4 pagesAugustARSENo ratings yet

- Ub Template NewDocument2 pagesUb Template NewARSENo ratings yet

- If You Are Asked To Determine "Optimal" Pipe Sizes of This Network, How Would You Approach?Document2 pagesIf You Are Asked To Determine "Optimal" Pipe Sizes of This Network, How Would You Approach?ARSENo ratings yet

- Pre CalculationDocument1 pagePre CalculationARSENo ratings yet

- Pay#4 EditedDocument114 pagesPay#4 EditedARSENo ratings yet

- Payment #2 Electro MechanicalDocument21 pagesPayment #2 Electro MechanicalARSENo ratings yet

- Assignment 1 2022Document5 pagesAssignment 1 2022ARSENo ratings yet

- Other CSi SoftwDocument3 pagesOther CSi SoftwARSENo ratings yet

- Fitting PVCDocument1 pageFitting PVCARSENo ratings yet

- HDPE Artificial Well Description Unit Quantity 1 Inlet Pipe & Fittings Item NoDocument1 pageHDPE Artificial Well Description Unit Quantity 1 Inlet Pipe & Fittings Item NoARSENo ratings yet

- Design of A Looped Network Using Watercad/Watergems Individual Assignment For Jigjiga StudentsDocument2 pagesDesign of A Looped Network Using Watercad/Watergems Individual Assignment For Jigjiga StudentsARSENo ratings yet

- Pay#4 EditedDocument114 pagesPay#4 EditedARSENo ratings yet

- Abebe Sub Contract Revised 2014Document2 pagesAbebe Sub Contract Revised 2014ARSENo ratings yet

- Daniel Tian Li: Input Data & Design SummaryDocument4 pagesDaniel Tian Li: Input Data & Design SummaryARSENo ratings yet

- Material Required For Cooling TankDocument2 pagesMaterial Required For Cooling TankARSENo ratings yet

- Timesheet FormatDocument2 pagesTimesheet FormatARSENo ratings yet

- Material Required For 500m3Document2 pagesMaterial Required For 500m3ARSENo ratings yet

- Misel 2Document15 pagesMisel 2Undarma 1405No ratings yet

- Bump Grade Force On Wire Student-1Document3 pagesBump Grade Force On Wire Student-1Benjamin WatsonNo ratings yet

- Word Formation - Open Cloze Exercises Unit 1Document2 pagesWord Formation - Open Cloze Exercises Unit 1Fatima Luz RuizNo ratings yet

- Simulation LAB (CAE) M.Tech I-I Sem Mechanical Engineering Machine DesignDocument24 pagesSimulation LAB (CAE) M.Tech I-I Sem Mechanical Engineering Machine Designjeevan scplNo ratings yet

- October 2016 2Document16 pagesOctober 2016 2Tanvika AroraNo ratings yet

- EKJERP IPPF Document Eng v1.2 250819Document63 pagesEKJERP IPPF Document Eng v1.2 250819ahmad yaniNo ratings yet

- Classroom of The Elite Vol. 8Document244 pagesClassroom of The Elite Vol. 8Rahul Lakra85% (13)

- Engineering Thought Intelligence Fictional Intellectual Behave Exercise 1 ComputationDocument4 pagesEngineering Thought Intelligence Fictional Intellectual Behave Exercise 1 Computationposgas aceNo ratings yet

- Combinatorics 2 Solutions UHSMCDocument5 pagesCombinatorics 2 Solutions UHSMCWalker KroubalkianNo ratings yet

- Đề Trung Học Thực Hành Đại Học Sư Phạm 2020-2021Document8 pagesĐề Trung Học Thực Hành Đại Học Sư Phạm 2020-2021Chi Vũ LinhNo ratings yet

- A Level Pure Unit 7 Parametric Equations QPDocument2 pagesA Level Pure Unit 7 Parametric Equations QPsaNo ratings yet

- Grade 9 Module 5Document8 pagesGrade 9 Module 5alisoncielo45No ratings yet

- Answers 2Document4 pagesAnswers 2Vika BodokiaNo ratings yet

- Reduced Adjective ClausesDocument1 pageReduced Adjective Clausesmetoeflgrammar100% (1)

- Sciencedirect: Development of Battery Monitoring System in Smart Microgrid Based On Internet of Things (Iot)Document6 pagesSciencedirect: Development of Battery Monitoring System in Smart Microgrid Based On Internet of Things (Iot)KiranNo ratings yet

- Geography Worksheet 1 Rural SettlementsDocument14 pagesGeography Worksheet 1 Rural SettlementsLelethuNo ratings yet

- DLL-All Subjects - Week 7 Day 1Document5 pagesDLL-All Subjects - Week 7 Day 1Windel Beth Quimat ZafraNo ratings yet

- Arte PoveraDocument13 pagesArte PoveraSohini MaitiNo ratings yet

- Lesson From Seveso ItalyDocument48 pagesLesson From Seveso ItalyBilal ZamanNo ratings yet

- FNCPDocument3 pagesFNCPDarcey NicholeNo ratings yet

- Employee Engagement - Korn - Ferry InternationalDocument2 pagesEmployee Engagement - Korn - Ferry InternationalЯрослава ЛояничNo ratings yet

- Introduction in Linguistic HANDOUTSDocument6 pagesIntroduction in Linguistic HANDOUTSRica Mae CastroNo ratings yet

- HG - Grade 12 - Module 3 - October 14Document19 pagesHG - Grade 12 - Module 3 - October 14RhasmineKyle BeltranNo ratings yet

- AS Level Mathematics Statistics (New)Document49 pagesAS Level Mathematics Statistics (New)Alex GoldsmithNo ratings yet

- Filtergehà Use - Beutel Und - Kerzen - enDocument5 pagesFiltergehà Use - Beutel Und - Kerzen - ennabila OktavianiNo ratings yet

- Scaffold 2Document3 pagesScaffold 2Mahmoud Elsayed MohamedNo ratings yet

- Afa 7&8Document11 pagesAfa 7&8APMNo ratings yet

- Skills Development PlanDocument1 pageSkills Development PlanJES MARIES MENDEZNo ratings yet

- DCS - VI Sem SchemeDocument2 pagesDCS - VI Sem SchemePriya UpadhyayNo ratings yet

- Email Etiquettes: Click To Add TextDocument25 pagesEmail Etiquettes: Click To Add Textmanveen kaurNo ratings yet