Professional Documents

Culture Documents

Removal of Mill Reject

Uploaded by

ravi singhOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Removal of Mill Reject

Uploaded by

ravi singhCopyright:

Available Formats

1.

Purpose

The purpose of the SOP “REMOVAL OF REJECTION OF COAL MILL” Operation is to train and guide operating

personnel for safe, right & correct procedures & optimum performance of the system.

2. Scope

This SOP defines the procedure of taking rejection of running coal mill.

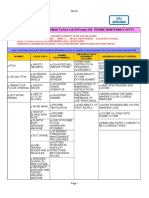

3. Roles & responsibility matrix

Sl

Desired output /

n Jobs Responsibility Competency

efficiency

o

1 Distribution Head –CPP, Head- To normalize the

Operation mill by taking

2 Compliance Station in charge/ Shift IC To decide the need of manual mill rejection manual rejection

Desk engineers Knowledge mill reject manual operation and take decisive

Field operators Field knowledge manual mill rejection. action.

4. Environment health & safety matrix

Sl Hazards Environmental Safety Precautions PPEs required

no considerations

1 Burn due to exposure Take rejection only for Clear the area before

to hot air required time to avoid taking rejection and

dust and smoke. standing position to be

safe. Use PPE.

2 Eyes and nose may get Take rejection only for Clear the area before

affected due to dust. required time to avoid taking rejection and

dust and smoke. standing position to be

safe. Use PPE

5. Legal & regulatory requirements: Not applicable

6. O & M parameters

Quantity of mill reject - <5 kg for 1 Hr duration.

7. Checks before manual rejection

7.1 Physical Checks

1. Check for mill abnormality. Example- abnormal sound, clinker formation, smoke, red hot spot in hopper.

2. Check with CCR for planned manual rejection for mill reject quantity checking. Mill start, mill stop.

3. Check with CCR for mill MRS manual condition due seal pressure low , false hopper level , Silo not available ,

silo level high , silo fire , service air compressor not available etc.

7.2 Procedure for manual rejection

Taking of mill reject shall be prohibited till following all condition are satisfied:-

1. Confirmation/Information from CCR for manual rejection requirement.

2. Mill should be in running condition.

3. PV1 to be closed before manual rejection.

4. Check if surrounding area is clean and no person is standing without PPEs.

5. Move extra manpower to safe area before taking manual rejection.

7.3 Interlocks & Protections

N/A

8. Startup sequence

For taking Mill rejection:

1. Open PV3 & PV 4 if required.

2. Take manual rejection.

9. Shutdown Procedure

For stopping of manual mill rejection:

1. Close PV3 & PV4.

2. Open PV1.

3. Ensure from CCR whether mill MRS has come in auto.

4. If MRS not in AUTO decide the frequency of manual rejection.

10. Exception / Emergency handling:

a. In case of red hot spot/ clinker formation take precaution. Inform CCR

b. In case of hopper fire or smoke take caution. Inform CCR.

13. Dos & Don’ts

DO’s DON’Ts

1. Ensure local condition. 1. Do not engage manpower without PPEs.

2. Ensure removal of extra manpower.

3. If situation is highly abnormal inform CCR

for mill shutdown.

14. Performance KPI’s

KPI ACTION

15. Abbreviation

Sr. No Abbreviation used Stands for

1 CPP Captive power plant

2 PTW Permit to work

4 LOTOTO Lock out tag out try out

5 PV Plate Valve

You might also like

- Business Plan Concept Design StudioDocument26 pagesBusiness Plan Concept Design StudioMichael Kagube100% (2)

- Baker 2010 PDFDocument111 pagesBaker 2010 PDFRizqi PriatnaNo ratings yet

- Enmas India Private Limited: (SMC Power Generation LTD Unit 2)Document3 pagesEnmas India Private Limited: (SMC Power Generation LTD Unit 2)Sachin nandgayeNo ratings yet

- Standard Operating Procedure - Electro Static PrecipitatorDocument3 pagesStandard Operating Procedure - Electro Static PrecipitatorJCSNo ratings yet

- Flowchart IDocument1 pageFlowchart Ircsrm123No ratings yet

- JSA - Main Turbine Lub Oil Pumps - OHDocument2 pagesJSA - Main Turbine Lub Oil Pumps - OHShubham Gupta0% (1)

- JPL 4X600 MW SOP for LDO ChargingDocument4 pagesJPL 4X600 MW SOP for LDO Chargingjp mishraNo ratings yet

- Sop Ldo SystemDocument8 pagesSop Ldo Systemjp mishraNo ratings yet

- 2 X 115 TPH CFBC Boiler: Ultratech Cement Limited - Apcw TadipatriDocument51 pages2 X 115 TPH CFBC Boiler: Ultratech Cement Limited - Apcw TadipatriChanna BasavaNo ratings yet

- Zincanode 620 Voc v1 Jan 2018Document2 pagesZincanode 620 Voc v1 Jan 2018Moin AltafNo ratings yet

- Valve Inspection ChecklistDocument1 pageValve Inspection ChecklistTengku Mohd ImranNo ratings yet

- Final KSK Sop Instrument CompressorDocument10 pagesFinal KSK Sop Instrument CompressorSonratNo ratings yet

- Sootblower Checklist Template GuidelinesDocument5 pagesSootblower Checklist Template GuidelinesAsnawi Sulong100% (1)

- Final AOH Report - TMD 060818Document15 pagesFinal AOH Report - TMD 060818sanmukhaNo ratings yet

- Condenser Flood Test 8 of 11Document14 pagesCondenser Flood Test 8 of 11Sara LopezNo ratings yet

- Boiler Feed Pump (BFP) : Opgs Power Gujarat PVT LTD 2X150 MW Thermal Power PlantDocument11 pagesBoiler Feed Pump (BFP) : Opgs Power Gujarat PVT LTD 2X150 MW Thermal Power PlantSaravanan SundararajNo ratings yet

- Sop For Total Power Failure.Document4 pagesSop For Total Power Failure.anon_251342212No ratings yet

- Boiler Startup Procedure PDFDocument56 pagesBoiler Startup Procedure PDFசர்வமும் சிவமயம்No ratings yet

- SOP TG Rolling and SynchronisationDocument13 pagesSOP TG Rolling and Synchronisationmoovendan pNo ratings yet

- Sop For Flushing Water PumpDocument6 pagesSop For Flushing Water PumpSonratNo ratings yet

- Sop For HTmotor PDFDocument4 pagesSop For HTmotor PDFSunny Biswal100% (1)

- Cep ChangeoverDocument1 pageCep ChangeoverSUBHASISH MUKHERJEENo ratings yet

- Boiler Emergency Control ProcedureDocument34 pagesBoiler Emergency Control ProcedureAshish LanjewarNo ratings yet

- Trip Analysis Recommendation For The FY 2020-21 (660 MW Units)Document45 pagesTrip Analysis Recommendation For The FY 2020-21 (660 MW Units)sudhakarautomatic9940No ratings yet

- NK - 008 Approved Procedure For STEAM BLOWING of North KaranpuraDocument28 pagesNK - 008 Approved Procedure For STEAM BLOWING of North KaranpuraHimanshu ChaturvediNo ratings yet

- Lubrication and Maintenance Systems for TurbinesDocument26 pagesLubrication and Maintenance Systems for TurbinesAshwani Dogra100% (1)

- Work Permit Safety Standard Training PackDocument24 pagesWork Permit Safety Standard Training PackAtma Prakash Sinha100% (1)

- SOP of Automatic Water Sprinkler SystemDocument1 pageSOP of Automatic Water Sprinkler SystemShahnawaz KazmiNo ratings yet

- POWER PLANT MAINTENANCE EQUIPMENT CLEANINGDocument25 pagesPOWER PLANT MAINTENANCE EQUIPMENT CLEANINGMariusDragoescuNo ratings yet

- Unit Station ChangeoverDocument6 pagesUnit Station ChangeoversambhuNo ratings yet

- Sop For Esp ChargingDocument3 pagesSop For Esp ChargingrubanprabuNo ratings yet

- Interlocks & ProtectionsDocument7 pagesInterlocks & ProtectionsPRAVEEN KUMAR SINGHNo ratings yet

- ESP Charging ProcedureDocument3 pagesESP Charging ProcedurevikramshounNo ratings yet

- Descaling SOPDocument2 pagesDescaling SOPTauqir Shaukat100% (1)

- 11 - SOP For Earthing Pit and EarthingDocument15 pages11 - SOP For Earthing Pit and Earthingtryu frtgeuwNo ratings yet

- SOP For BFPDocument2 pagesSOP For BFPsambhuNo ratings yet

- Safety Questions Based On Yellow BookDocument102 pagesSafety Questions Based On Yellow BookSwadhin Kumar Das0% (1)

- P90 P91 P92 P510 P515 P520: Manual of - Installation - Operating - Maintenance Gas Burners TypeDocument34 pagesP90 P91 P92 P510 P515 P520: Manual of - Installation - Operating - Maintenance Gas Burners TypeLucian CiudinNo ratings yet

- SOP For Compressor (Instrumentation & Service)Document2 pagesSOP For Compressor (Instrumentation & Service)santosh jsNo ratings yet

- FD FanDocument5 pagesFD FanPrudhvi RajNo ratings yet

- Maintenance BFPDocument28 pagesMaintenance BFPYulianto Kartono100% (1)

- Membrane CleanerDocument2 pagesMembrane CleanerJoselito Cortes100% (1)

- Template-Post Shutdown ReportDocument3 pagesTemplate-Post Shutdown Reportarief bayuNo ratings yet

- Damage To Bottom Ash Handling SysDocument6 pagesDamage To Bottom Ash Handling SyssanjeevchhabraNo ratings yet

- APHDocument3 pagesAPHMallinatha PNNo ratings yet

- Power Cable Jointing: Novatex Limited SOP / E&I / 17Document3 pagesPower Cable Jointing: Novatex Limited SOP / E&I / 17OSAMANo ratings yet

- Protection & Interlock Systems for Boilers & TurbinesDocument36 pagesProtection & Interlock Systems for Boilers & Turbinesarunrajmech09100% (2)

- LOTO ProcedureDocument2 pagesLOTO ProcedureRitesh Dev MaityNo ratings yet

- DI Pipe Handling and Storage ProcedureDocument8 pagesDI Pipe Handling and Storage ProcedureFrancis DhanarajNo ratings yet

- TSPL-OPN-SOP-Aux BoilerDocument9 pagesTSPL-OPN-SOP-Aux Boilersourav mahapatraNo ratings yet

- SOP of Pump Changing JobDocument11 pagesSOP of Pump Changing JobDwitikrushna Rout100% (1)

- Station ACW Pump Operation SOPDocument3 pagesStation ACW Pump Operation SOPSiddhant Satpathy100% (1)

- INSPECTION AND TEST PLAN FOR AIR PREHEATERDocument27 pagesINSPECTION AND TEST PLAN FOR AIR PREHEATERBui van DiepNo ratings yet

- Itc Limited Paperboards & Speciality Papers Division: Unit: Bhadrachalam, ApDocument7 pagesItc Limited Paperboards & Speciality Papers Division: Unit: Bhadrachalam, ApMohan RajNo ratings yet

- Elecon Scoop Coupling Installation Maintenance ManualDocument21 pagesElecon Scoop Coupling Installation Maintenance ManualVignesh VenkatasubramanianNo ratings yet

- Iphone 6 Silver InvoiceDocument1 pageIphone 6 Silver InvoiceMihir KumarNo ratings yet

- Total power failure restoration and cold start up proceduresDocument8 pagesTotal power failure restoration and cold start up proceduresrpshvjuNo ratings yet

- 067-SOP of ESP Line Up & ChargingDocument10 pages067-SOP of ESP Line Up & ChargingsambhuNo ratings yet

- Manual of - Installation - Operation - Maintenance Dual Fuel Burners L.P.G. - Light Oil HS5 HS10 HS18Document32 pagesManual of - Installation - Operation - Maintenance Dual Fuel Burners L.P.G. - Light Oil HS5 HS10 HS18AlvaroValdebenitoValenzuelaNo ratings yet

- Steam Turbine StartupDocument17 pagesSteam Turbine StartupRahul ChoubeyNo ratings yet

- 630-Lubrication of CSR#3Document7 pages630-Lubrication of CSR#3Buddy HartNo ratings yet

- E39 Ahsop 03Document3 pagesE39 Ahsop 03Sanjit SinghNo ratings yet

- Feeder ReadingDocument2 pagesFeeder Readingravi singhNo ratings yet

- How to register for Bank of Baroda mobile bankingDocument5 pagesHow to register for Bank of Baroda mobile bankingShyam KumarNo ratings yet

- Compendium Delhi PDFDocument223 pagesCompendium Delhi PDFsrinivasgillalaNo ratings yet

- MONTHLY ATTENDANCE REPORT FOR JANUARY 2019Document36 pagesMONTHLY ATTENDANCE REPORT FOR JANUARY 2019ravi singhNo ratings yet

- CPP Kaizen Record-Dec.-18 SL No. Kaizen Description QtyDocument8 pagesCPP Kaizen Record-Dec.-18 SL No. Kaizen Description Qtyravi singhNo ratings yet

- Effects of Air Ingress on Thermal Power Plant EfficiencyDocument3 pagesEffects of Air Ingress on Thermal Power Plant EfficiencyRajaiah JagariNo ratings yet

- Maintenance Guest ManpowerDocument4 pagesMaintenance Guest Manpowerravi singhNo ratings yet

- Search PropertyDocument1 pageSearch Propertyravi singhNo ratings yet

- APHDocument17 pagesAPHsanjeevchhabraNo ratings yet

- Alarm SystemDocument2 pagesAlarm Systemravi singhNo ratings yet

- Maintenance Guest ManpowerDocument4 pagesMaintenance Guest Manpowerravi singhNo ratings yet

- 4 - Silica in BoilerDocument3 pages4 - Silica in BoilerKrishnan ManiNo ratings yet

- REPRISM 2021 - ACTUAL VS PREDICTED PARAMETER LastDocument11 pagesREPRISM 2021 - ACTUAL VS PREDICTED PARAMETER Lastravi singhNo ratings yet

- Chart in Microsoft Office PowerPoint - WSBDocument1 pageChart in Microsoft Office PowerPoint - WSBravi singhNo ratings yet

- Case StudyDocument2 pagesCase Studyravi singhNo ratings yet

- MOC - Oil Gun TimerDocument2 pagesMOC - Oil Gun Timerravi singhNo ratings yet

- Removal of Mill RejectDocument3 pagesRemoval of Mill Rejectravi singh100% (1)

- Suggestion Fair: Mahan CPP-OperationDocument2 pagesSuggestion Fair: Mahan CPP-Operationravi singhNo ratings yet

- LDO MOC Update Ravi SinghDocument1 pageLDO MOC Update Ravi Singhravi singhNo ratings yet

- Format EnglishDocument1 pageFormat Englishravi singhNo ratings yet

- Improve Alarm System Reliability MAX DNA SIEMENSDocument4 pagesImprove Alarm System Reliability MAX DNA SIEMENSravi singhNo ratings yet

- Paper 4 Case Studies On Cycle ChemistryDocument54 pagesPaper 4 Case Studies On Cycle Chemistryravi singhNo ratings yet

- REPRISM 2021 - UNIT START UP TIME REDUCTION FinalDocument12 pagesREPRISM 2021 - UNIT START UP TIME REDUCTION Finalravi singhNo ratings yet

- Hindalco Industries LTD, Mahan Aluminium Facility / Process Change ManagementDocument2 pagesHindalco Industries LTD, Mahan Aluminium Facility / Process Change Managementravi singhNo ratings yet

- LDO MOC Update Ravi SinghDocument1 pageLDO MOC Update Ravi Singhravi singhNo ratings yet

- Managing Exfoliation in Super Critical BoilersDocument11 pagesManaging Exfoliation in Super Critical BoilersDebabrata GhoshNo ratings yet

- Ravi Shankar Singh development planDocument1 pageRavi Shankar Singh development planravi singhNo ratings yet

- Insulation Status UpdateDocument10 pagesInsulation Status Updateravi singhNo ratings yet

- NPD ReportDocument14 pagesNPD ReportHidayah AzizanNo ratings yet

- Dinda Putri Novanti - Summary Budgeting and Financial Performance TargetDocument5 pagesDinda Putri Novanti - Summary Budgeting and Financial Performance TargetDinda Putri NovantiNo ratings yet

- Business Implications of Sustainability Practices in Supply ChainsDocument25 pagesBusiness Implications of Sustainability Practices in Supply ChainsBizNo ratings yet

- PLDT Inc - 17a 2019Document381 pagesPLDT Inc - 17a 2019Kylie Luigi Leynes BagonNo ratings yet

- Accounting InformationDocument3 pagesAccounting Informationnenette cruzNo ratings yet

- Marcial Apostol: Group 5 LeaderDocument4 pagesMarcial Apostol: Group 5 LeaderRaylyn Heart RoyNo ratings yet

- Selling Groceries Through The Cloud in A Tier II City in IndiaDocument12 pagesSelling Groceries Through The Cloud in A Tier II City in IndiaFathima HeeraNo ratings yet

- Building International Brand Architecture: Integrating Branding Strategy Across MarketsDocument19 pagesBuilding International Brand Architecture: Integrating Branding Strategy Across MarketsDiana GuceaNo ratings yet

- Child Nutrition Procurement 2022Document91 pagesChild Nutrition Procurement 2022Jesse VillarrealNo ratings yet

- NPTEL Assign 3 Jan23 Behavioral and Personal FinanceDocument5 pagesNPTEL Assign 3 Jan23 Behavioral and Personal FinanceNitin Mehta - 18-BEC-030No ratings yet

- Shrimp Farming in Pakistan Urdu GuideDocument17 pagesShrimp Farming in Pakistan Urdu GuidesohailauhNo ratings yet

- GOPRO Written Case DraftDocument3 pagesGOPRO Written Case DraftBritney BissambharNo ratings yet

- 1.10 International Organization NewDocument14 pages1.10 International Organization NewArbind YadavNo ratings yet

- The BRICS Bank: An Acronym With CapitalDocument2 pagesThe BRICS Bank: An Acronym With Capitalfransheska GallegosNo ratings yet

- Faculty of Business and Management: Assignment/ Project Declaration FormDocument16 pagesFaculty of Business and Management: Assignment/ Project Declaration FormBukhari SuhaidinNo ratings yet

- Purchase ReceiptDocument5 pagesPurchase ReceiptJessica LawrenceNo ratings yet

- Tosun Lang 2017 - Policy IntegrationDocument19 pagesTosun Lang 2017 - Policy IntegrationEdward T MaiaNo ratings yet

- Economics of The AirlinesDocument40 pagesEconomics of The AirlinesAdriel M.No ratings yet

- Module 2: Assignment: PROBLEM 9 - Treasury SharesDocument8 pagesModule 2: Assignment: PROBLEM 9 - Treasury SharesYvonne DuyaoNo ratings yet

- TOI Ahmadabad PDFDocument18 pagesTOI Ahmadabad PDFJugarNo ratings yet

- IDMC EST Practice Paper For AY2223Document6 pagesIDMC EST Practice Paper For AY2223zy hoongNo ratings yet

- Intermodal Transportation System in An Evolving Economy: Research PaperDocument7 pagesIntermodal Transportation System in An Evolving Economy: Research PaperUsiwo FranklinNo ratings yet

- ELSS Investment ReceiptDocument6 pagesELSS Investment ReceiptKaran MitrooNo ratings yet

- Milk Tea Industry: An Exploratory Study: February 2020Document9 pagesMilk Tea Industry: An Exploratory Study: February 2020NING ANGELNo ratings yet

- Jayesh Gogri 170618 Records Payment PDFDocument72 pagesJayesh Gogri 170618 Records Payment PDFMadhur BihaniNo ratings yet

- UntitledDocument2 pagesUntitledRoshanNo ratings yet

- Tcs Hitech Brochure Product-Training 110509ADocument2 pagesTcs Hitech Brochure Product-Training 110509AYogesh YogiNo ratings yet

- GST Filing in IndiaDocument13 pagesGST Filing in IndiaKriti vardhanNo ratings yet

- Food Truck Financial Model Excel Template v1.8Document77 pagesFood Truck Financial Model Excel Template v1.8hanswuytsNo ratings yet