Professional Documents

Culture Documents

Magnetic Examination Report: Sketch

Uploaded by

Seret BroOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Magnetic Examination Report: Sketch

Uploaded by

Seret BroCopyright:

Available Formats

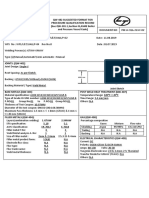

MAGNETIC EXAMINATION REPORT

Customer : PT.PETRODRILL Drawing No. :- Report No :001/MT/PETRODRILL/21

Project Name : Procedure No. :

Unit No : None Applicable CODE : AWS D.1.1 - 2015

Material Spec. : A 36 W P S No. :

MT Equipment Yoke Other Lifting Force : 10 lb

Particle : Visible Fluorescent Wet Dry

Temperature : Ambient Particle application : Spray Other

Brand’s Name/Types : Magnaflux Particle : 7HF White Contrast :WCP2 Cleaner :SKC-S

Batch no. of : Particle :01352 White Contrast :01252 Cleaner :01125

Examination Method : Continuous Field strength check Minimum twice in each area, right angle each other

Surface Prep : As welded As machined As ground Solvent Wipe

Stage of Examination : As welded After Heat treated Other

Scope of Examinat: Base Metal Edge Prep Back Chipping

Weld New Weld Repair Other

Types of Result ( mm )

Part Name No.Joint Thickness ( mm ) Length(mm) Qty

Discontinuities

Accepted Rejected

H 298X149X6X8X6000 1 TW=6 mm;TF=8 mm - - Accepted - 6

PN. FLANGE 20Q3SK6K61665 2 TW=6 mm;TF=8 mm - - Accepted -

PN.WEB 20Q1101902201-4 3 TW=6 mm;TF=8 mm - - Accepted -

4 TW=6 mm;TF=8 mm - - Accepted -

sketch :

Examined by : Reviewed / witnessed by : Reviewed / witnessed by : Reviewed / witnessed by

NDE LEVEL :

DATE : DATE : DATE : DATE :

MT AREA

MAGNETIC EXAMINATION REPORT

Customer : PT.PETRODRILL Drawing No. :- Report No :002/MT/PETRODRILL/21

Project Name : Procedure No. :

Unit No : None Applicable CODE : AWS D.1.1 - 2015

Material Spec. : A 36 W P S No. :

MT Equipment Yoke Other Lifting Force : 10 lb

Particle : Visible Fluorescent Wet Dry

Temperature : Ambient Particle application : Spray Other

Brand’s Name/Types : Magnaflux Particle : 7HF White Contrast :WCP2 Cleaner :SKC-S

Batch no. of : Particle :01352 White Contrast :01252 Cleaner :01125

Examination Method : Continuous Field strength check Minimum twice in each area, right angle each other

Surface Prep : As welded As machined As ground Solvent Wipe

Stage of Examination : As welded After Heat treated Other

Scope of Examinat: Base Metal Edge Prep Back Chipping

Weld New Weld Repair Other

Types of Result ( mm )

Part Name No.Joint Thickness ( mm ) Length(mm) Qty

Discontinuities

Accepted Rejected

H 298X149X6X8X6000 1 TW=6 mm;TF=8 mm - - Accepted - 6

PN. FLANGE 20Q3SK6K61665 2 TW=6 mm;TF=8 mm - - Accepted -

PN.WEB 20Q1101902201-4 3 TW=6 mm;TF=8 mm - - Accepted -

4 TW=6 mm;TF=8 mm - - Accepted -

sketch :

Examined by : Reviewed / witnessed by : Reviewed / witnessed by : Reviewed / witnessed by

NDE LEVEL :

DATE : DATE : DATE : DATE :

MT AREA

MAGNETIC EXAMINATION REPORT

Customer : PT.PETRODRILL Drawing No. :- Report No :003/MT/PETRODRILL/21

Project Name : Procedure No. :

Unit No : None Applicable CODE : AWS D.1.1 - 2015

Material Spec. : A 36 W P S No. :

MT Equipment Yoke Other Lifting Force : 10 lb

Particle : Visible Fluorescent Wet Dry

Temperature : Ambient Particle application : Spray Other

Brand’s Name/Types : Magnaflux Particle : 7HF White Contrast :WCP2 Cleaner :SKC-S

Batch no. of : Particle :01352 White Contrast :01252 Cleaner :01125

Examination Method : Continuous Field strength check Minimum twice in each area, right angle each other

Surface Prep : As welded As machined As ground Solvent Wipe

Stage of Examination : As welded After Heat treated Other

Scope of Examinat: Base Metal Edge Prep Back Chipping

Weld New Weld Repair Other

Types of Result ( mm )

Part Name No.Joint Thickness ( mm ) Length(mm) Qty

Discontinuities

Accepted Rejected

H 298X149X6X8X6000 1 TW=6 mm;TF=8 mm - - Accepted - 5

PN. FLANGE 20Q3SK6K61665 2 TW=6 mm;TF=8 mm - - Accepted -

PN.WEB 20Q1101902201-4 3 TW=6 mm;TF=8 mm - - Accepted -

4 TW=6 mm;TF=8 mm - - Accepted -

sketch :

Examined by : Reviewed / witnessed by : Reviewed / witnessed by : Reviewed / witnessed by

NDE LEVEL :

DATE : DATE : DATE : DATE :

MT AREA

MAGNETIC EXAMINATION REPORT

Customer : PT.PETRODRILL Drawing No. :- Report No :004/MT/PETRODRILL/21

Project Name : RIG PDSI#20.2/EMSCO Procedure No. : PM-QC-01-02

Unit No : None Applicable CODE : AWS D.1.1 - 2020

Material Spec. : A 36 W P S No. :

MT Equipment Yoke Other Lifting Force : 10 lb

Particle : Visible Fluorescent Wet Dry

Temperature : Ambient Particle application : Spray Other

Brand’s Name/Types : Magnaflux Particle : 7HF White Contrast :WCP2 Cleaner :SKC-S

Batch no. of : Particle :01352 White Contrast :01252 Cleaner :01125

Examination Method : Continuous Field strength check Minimum twice in each area, right angle each other

Surface Prep : As welded As machined As ground Solvent Wipe

Stage of Examination : As welded After Heat treated Other

Scope of Examinat: Base Metal Edge Prep Back Chipping

Weld New Weld Repair Other

Types of Result ( mm )

Part Name No.Joint Thickness ( mm ) Length(mm) Qty

Discontinuities

Accepted Rejected

H 298X149X6X8X6000 1 TW=6 mm;TF=8 mm - - Accepted - 3

PN. FLANGE 20Q3SK6K61665 2 TW=6 mm;TF=8 mm - - Accepted -

PN.WEB 20Q11019022011F4-3 3 TW=6 mm;TF=8 mm - - Accepted -

4 TW=6 mm;TF=8 mm - - Accepted -

sketch :

MT AREA MT AREA

Examined by : Reviewed / witnessed by : Reviewed / witnessed by : Reviewed / witnessed by

NDE LEVEL :

DATE : DATE : DATE : DATE :

MT AREA

MAGNETIC EXAMINATION REPORT

Customer : PT.PETRODRILL Drawing No. :- Report No :005/MT/PETRODRILL/21

Project Name : RIG PDSI#20.2/EMSCO Procedure No. : PM-QC-01-02

Unit No : None Applicable CODE : AWS D.1.1 - 2020

Material Spec. : A 36 W P S No. :

MT Equipment Yoke Other Lifting Force : 10 lb

Particle : Visible Fluorescent Wet Dry

Temperature : Ambient Particle application : Spray Other

Brand’s Name/Types : Magnaflux Particle : 7HF White Contrast :WCP2 Cleaner :SKC-S

Batch no. of : Particle :01352 White Contrast :01252 Cleaner :01125

Examination Method : Continuous Field strength check Minimum twice in each area, right angle each other

Surface Prep : As welded As machined As ground Solvent Wipe

Stage of Examination : As welded After Heat treated Other

Scope of Examinat: Base Metal Edge Prep Back Chipping

Weld New Weld Repair Other

Types of Result ( mm )

Part Name No.Joint Thickness ( mm ) Length(mm) Qty

Discontinuities

Accepted Rejected

H 298X149X6X8X6000 1 TW=6 mm;TF=8 mm - - Accepted - 5

PN. FLANGE 20Q3SK6K61665 2 TW=6 mm;TF=8 mm - - Accepted -

PN.WEB 20Q1101902201-4 3 TW=6 mm;TF=8 mm - - Accepted -

4 TW=6 mm;TF=8 mm - - Accepted -

sketch :

MT AREA MT AREA

Examined by : Reviewed / witnessed by : Reviewed / witnessed by : Reviewed / witnessed by

NDE LEVEL :

DATE : DATE : DATE : DATE :

MT AREA

MAGNETIC EXAMINATION REPORT

Customer : PT.PETRODRILL Drawing No. :- Report No :006/MT/PETRODRILL/21

Project Name : RIG PDSI#20.2/EMSCO Procedure No. : PM-QC-01-02

Unit No : None Applicable CODE : AWS D.1.1 - 2020

Material Spec. : A 36 W P S No. :

MT Equipment Yoke Other Lifting Force : 10 lb

Particle : Visible Fluorescent Wet Dry

Temperature : Ambient Particle application : Spray Other

Brand’s Name/Types : Magnaflux Particle : 7HF White Contrast :WCP2 Cleaner :SKC-S

Batch no. of : Particle :01352 White Contrast :01252 Cleaner :01125

Examination Method : Continuous Field strength check Minimum twice in each area, right angle each other

Surface Prep : As welded As machined As ground Solvent Wipe

Stage of Examination : As welded After Heat treated Other

Scope of Examinat: Base Metal Edge Prep Back Chipping

Weld New Weld Repair Other

Types of Result ( mm )

Part Name No.Joint Thickness ( mm ) Length(mm) Qty

Discontinuities

Accepted Rejected

H 298X149X6X8X6000 1 TW=6 mm;TF=8 mm - - Accepted - 5

PN. FLANGE 20Q3SK6K61665 2 TW=6 mm;TF=8 mm - - Accepted -

PN.WEB 20Q1101902201-4 3 TW=6 mm;TF=8 mm - - Accepted -

4 TW=6 mm;TF=8 mm - - Accepted -

sketch :

MT AREA MT AREA

Examined by : Reviewed / witnessed by : Reviewed / witnessed by : Reviewed / witnessed by

NDE LEVEL :

DATE : DATE : DATE : DATE :

MT AREA

MAGNETIC EXAMINATION REPORT

Customer : PT.PETRODRILL Drawing No. :- Report No :007/MT/PETRODRILL/21

Project Name : RIG PDSI#20.2/EMSCO Procedure No. : PM-QC-01-02

Unit No : None Applicable CODE : AWS D.1.1 - 2020

Material Spec. : A 36 W P S No. :

MT Equipment Yoke Other Lifting Force : 10 lb

Particle : Visible Fluorescent Wet Dry

Temperature : Ambient Particle application : Spray Other

Brand’s Name/Types : Magnaflux Particle : 7HF White Contrast :WCP2 Cleaner :SKC-S

Batch no. of : Particle :01352 White Contrast :01252 Cleaner :01125

Examination Method : Continuous Field strength check Minimum twice in each area, right angle each other

Surface Prep : As welded As machined As ground Solvent Wipe

Stage of Examination : As welded After Heat treated Other

Scope of Examinat: Base Metal Edge Prep Back Chipping

Weld New Weld Repair Other

Types of Result ( mm )

Part Name No.Joint Thickness ( mm ) Length(mm) Qty

Discontinuities

Accepted Rejected

H 298X149X6X8X6000 1 TW=6 mm;TF=8 mm - - Accepted - 3

PN. FLANGE 20Q3SK6K61665 2 TW=6 mm;TF=8 mm - - Accepted -

PN.WEB 20Q1101902201-4 3 TW=6 mm;TF=8 mm - - Accepted -

4 TW=6 mm;TF=8 mm - - 5 -

sketch :

MT AREA MT AREA

Examined by : Reviewed / witnessed by : Reviewed / witnessed by : Reviewed / witnessed by

NDE LEVEL :

DATE : DATE : DATE : DATE :

MT AREA

MAGNETIC EXAMINATION REPORT

Customer : PT.PETRODRILL Drawing No. :- Report No :008/MT/PETRODRILL/21

Project Name : RIG PDSI#20.2/EMSCO Procedure No. : PM-QC-01-02

Unit No : None Applicable CODE : AWS D.1.1 - 2020

Material Spec. : A 572 GR.50 W P S No. :

MT Equipment Yoke Other Lifting Force : 10 lb

Particle : Visible Fluorescent Wet Dry

Temperature : Ambient Particle application : Spray Other

Brand’s Name/Types : Magnaflux Particle : 7HF White Contrast :WCP2 Cleaner :SKC-S

Batch no. of : Particle :01352 White Contrast :01252 Cleaner :01125

Examination Method : Continuous Field strength check Minimum twice in each area, right angle each other

Surface Prep : As welded As machined As ground Solvent Wipe

Stage of Examination : As welded After Heat treated Other

Scope of Examinat: Base Metal Edge Prep Back Chipping

Weld New Weld Repair Other

Types of Result ( mm )

Part Name No.Joint Thickness ( mm ) Length(mm) Qty

Discontinuities

Accepted Rejected

H 390X200X8X12X6000 1 TW=8mm;TF=12mm - - Accepted - 2

PN. FLANGE PN.804857-01 2 TW=8mm;TF=12mm - - Accepted -

PN.WEB PN.80741606 3 TW=8mm;TF=12mm - - Accepted -

4 TW=8mm;TF=12mm - - Accepted -

sketch :

MT AREA MT AREA

Examined by : Reviewed / witnessed by : Reviewed / witnessed by : Reviewed / witnessed by

NDE LEVEL :

DATE : DATE : DATE : DATE :

MT AREA

MAGNETIC EXAMINATION REPORT

Customer : PT.PETRODRILL Drawing No. :- Report No :009/MT/PETRODRILL/21

Project Name : RIG PDSI#20.2/EMSCO Procedure No. : PM-QC-01-02

Unit No : None Applicable CODE : AWS D.1.1 - 2020

Material Spec. : A 572 GR.50 W P S No. :

MT Equipment Yoke Other Lifting Force : 10 lb

Particle : Visible Fluorescent Wet Dry

Temperature : Ambient Particle application : Spray Other

Brand’s Name/Types : Magnaflux Particle : 7HF White Contrast :WCP2 Cleaner :SKC-S

Batch no. of : Particle :01352 White Contrast :01252 Cleaner :01125

Examination Method : Continuous Field strength check Minimum twice in each area, right angle each other

Surface Prep : As welded As machined As ground Solvent Wipe

Stage of Examination : As welded After Heat treated Other

Scope of Examinat: Base Metal Edge Prep Back Chipping

Weld New Weld Repair Other

Types of Result ( mm )

Part Name No.Joint Thickness ( mm ) Length(mm) Qty

Discontinuities

Accepted Rejected

H 390X200X8X12X6000 1 TW=8mm;TF=12mm - - Accepted - 2

PN. FLANGE PN.803367-02 2 TW=8mm;TF=12mm - - Accepted -

PN.804857-01 3 TW=8mm;TF=12mm - - Accepted -

PN.WEB PN.80741606 4 TW=8mm;TF=12mm - - Accepted -

sketch :

MT AREA MT AREA

Examined by : Reviewed / witnessed by : Reviewed / witnessed by : Reviewed / witnessed by

NDE LEVEL :

DATE : DATE : DATE : DATE :

MT AREA

MAGNETIC EXAMINATION REPORT

Customer : PT.PETRODRILL Drawing No. :- Report No :010/MT/PETRODRILL/21

Project Name : RIG PDSI#20.2/EMSCO Procedure No. : PM-QC-01-02

Unit No : None Applicable CODE : AWS D.1.1 - 2020

Material Spec. : A 572 GR.50 W P S No. :

MT Equipment Yoke Other Lifting Force : 10 lb

Particle : Visible Fluorescent Wet Dry

Temperature : Ambient Particle application : Spray Other

Brand’s Name/Types : Magnaflux Particle : 7HF White Contrast :WCP2 Cleaner :SKC-S

Batch no. of : Particle :01352 White Contrast :01252 Cleaner :01125

Examination Method : Continuous Field strength check Minimum twice in each area, right angle each other

Surface Prep : As welded As machined As ground Solvent Wipe

Stage of Examination : As welded After Heat treated Other

Scope of Examinat: Base Metal Edge Prep Back Chipping

Weld New Weld Repair Other

Types of Result ( mm )

Part Name No.Joint Thickness ( mm ) Length(mm) Qty

Discontinuities

Accepted Rejected

H 390X200X8X12X6000 1 TW=8mm;TF=12mm - - Accepted - 2

PN. FLANGE PN.803367-02 2 TW=8mm;TF=12mm - - Accepted -

PN.WEB PN.80741605 3 TW=8mm;TF=12mm - - Accepted -

4 TW=8mm;TF=12mm - - Accepted -

sketch :

MT AREA MT AREA

Examined by : Reviewed / witnessed by : Reviewed / witnessed by : Reviewed / witnessed by

NDE LEVEL :

DATE : DATE : DATE : DATE :

MT AREA

MAGNETIC EXAMINATION REPORT

Customer : PT.PETRODRILL Drawing No. :- Report No :011/MT/PETRODRILL/21

Project Name : RIG PDSI#20.2/EMSCO Procedure No. : PM-QC-01-02

Unit No : None Applicable CODE : AWS D.1.1 - 2020

Material Spec. : A 572 GR.50 W P S No. :

MT Equipment Yoke Other Lifting Force : 10 lb

Particle : Visible Fluorescent Wet Dry

Temperature : Ambient Particle application : Spray Other

Brand’s Name/Types : Magnaflux Particle : 7HF White Contrast :WCP2 Cleaner :SKC-S

Batch no. of : Particle :01352 White Contrast :01252 Cleaner :01125

Examination Method : Continuous Field strength check Minimum twice in each area, right angle each other

Surface Prep : As welded As machined As ground Solvent Wipe

Stage of Examination : As welded After Heat treated Other

Scope of Examinat: Base Metal Edge Prep Back Chipping

Weld New Weld Repair Other

Types of Result ( mm )

Part Name No.Joint Thickness ( mm ) Length(mm) Qty

Discontinuities

Accepted Rejected

H 390X200X8X12X6000 1 TW=8mm;TF=12mm - - Accepted - 1

PN. FLANGE PN.803367-02 2 TW=8mm;TF=12mm - - Accepted -

PN.804857-01 3 TW=8mm;TF=12mm - - Accepted -

PN.WEB PN.80741604 4 TW=8mm;TF=12mm - - Accepted -

sketch :

MT AREA MT AREA

Examined by : Reviewed / witnessed by : Reviewed / witnessed by : Reviewed / witnessed by

NDE LEVEL :

DATE : DATE : DATE : DATE :

MT AREA

MAGNETIC EXAMINATION REPORT

Customer : PT.PETRODRILL Drawing No. :- Report No :012/MT/PETRODRILL/21

Project Name : RIG PDSI#20.2/EMSCO Procedure No. : PM-QC-01-02

Unit No : None Applicable CODE : AWS D.1.1 - 2020

Material Spec. : A 572 GR.50 W P S No. :

MT Equipment Yoke Other Lifting Force : 10 lb

Particle : Visible Fluorescent Wet Dry

Temperature : Ambient Particle application : Spray Other

Brand’s Name/Types : Magnaflux Particle : 7HF White Contrast :WCP2 Cleaner :SKC-S

Batch no. of : Particle :01352 White Contrast :01252 Cleaner :01125

Examination Method : Continuous Field strength check Minimum twice in each area, right angle each other

Surface Prep : As welded As machined As ground Solvent Wipe

Stage of Examination : As welded After Heat treated Other

Scope of Examinat: Base Metal Edge Prep Back Chipping

Weld New Weld Repair Other

Types of Result ( mm )

Part Name No.Joint Thickness ( mm ) Length(mm) Qty

Discontinuities

Accepted Rejected

H496X200X10X14 1 TW=10 mm;TF=14mm - - Accepted - 3

PN. FLANGE PK803368-08 2 TW=10 mm;TF=14mm - - Accepted -

3 TW=10 mm;TF=14mm - - Accepted -

PN.WEB PK804392-07 4 TW=10 mm;TF=14mm - - Accepted -

sketch :

MT AREA MT AREA

Examined by : Reviewed / witnessed by : Reviewed / witnessed by : Reviewed / witnessed by

NDE LEVEL :

DATE : DATE : DATE : DATE :

MT AREA

MAGNETIC EXAMINATION REPORT

Customer : PT.PETRODRILL Drawing No. :- Report No :013/MT/PETRODRILL/21

Project Name : RIG PDSI#20.2/EMSCO Procedure No. : PM-QC-01-02

Unit No : None Applicable CODE : AWS D.1.1 - 2020

Material Spec. : A 572 GR.50 W P S No. :

MT Equipment Yoke Other Lifting Force : 10 lb

Particle : Visible Fluorescent Wet Dry

Temperature : Ambient Particle application : Spray Other

Brand’s Name/Types : Magnaflux Particle : 7HF White Contrast :WCP2 Cleaner :SKC-S

Batch no. of : Particle :01352 White Contrast :01252 Cleaner :01125

Examination Method : Continuous Field strength check Minimum twice in each area, right angle each other

Surface Prep : As welded As machined As ground Solvent Wipe

Stage of Examination : As welded After Heat treated Other

Scope of Examinat: Base Metal Edge Prep Back Chipping

Weld New Weld Repair Other

Types of Result ( mm )

Part Name No.Joint Thickness ( mm ) Length(mm) Qty

Discontinuities

Accepted Rejected

H496X200X10X14 1 TW=10 mm;TF=14mm - - Accepted - 3

PN. FLANGE PK803368-08 2 TW=10 mm;TF=14mm - - Accepted -

3 TW=10 mm;TF=14mm - - Accepted -

PN.WEB PK804392-07 4 TW=10 mm;TF=14mm - - Accepted -

sketch :

MT AREA MT AREA

Examined by : Reviewed / witnessed by : Reviewed / witnessed by : Reviewed / witnessed by

NDE LEVEL :

DATE : DATE : DATE : DATE :

MAGNETIC EXAMINATION REPORT

Customer : PT.PETRODRILL Drawing No. :- Report No :014/MT/PETRODRILL/21

Project Name : RIG PDSI#20.2/EMSCO Procedure No. : PM-QC-01-02

Unit No : None Applicable CODE : AWS D.1.1 - 2020

Material Spec. : A 572 GR.50 W P S No. :

MT Equipment Yoke Other Lifting Force : 10 lb

Particle : Visible Fluorescent Wet Dry

Temperature : Ambient Particle application : Spray Other

Brand’s Name/Types : Magnaflux Particle : 7HF White Contrast :WCP2 Cleaner :SKC-S

Batch no. of : Particle :01352 White Contrast :01252 Cleaner :01125

Examination Method : Continuous Field strength check Minimum twice in each area, right angle each other

Surface Prep : As welded As machined As ground Solvent Wipe

Stage of Examination : As welded After Heat treated Other

Scope of Examinat: Base Metal Edge Prep Back Chipping

Weld New Weld Repair Other

Types of Result ( mm )

Part Name No.Joint Thickness ( mm ) Length(mm) Qty

Discontinuities

Accepted Rejected

H496X200X12X14 1 TW=10 mm;TF=14mm - - Accepted - 1

PN. FLANGE R87544 2 TW=10 mm;TF=14mm - - Accepted -

3 TW=10 mm;TF=14mm - - Accepted -

PN.WEB PK804587-5 4 TW=10 mm;TF=14mm - - Accepted -

sketch :

MT AREA MT AREA

Examined by : Reviewed / witnessed by : Reviewed / witnessed by : Reviewed / witnessed by

NDE LEVEL :

DATE : DATE : DATE : DATE :

MAGNETIC EXAMINATION REPORT

Customer : PT.PETRODRILL Drawing No. :- Report No :015/MT/PETRODRILL/21

Project Name : RIG PDSI#20.2/EMSCO Procedure No. : PM-QC-01-02

Unit No : None Applicable CODE : AWS D.1.1 - 2020

Material Spec. : A 572 GR.50 W P S No. :

MT Equipment Yoke Other Lifting Force : 10 lb

Particle : Visible Fluorescent Wet Dry

Temperature : Ambient Particle application : Spray Other

Brand’s Name/Types : Magnaflux Particle : 7HF White Contrast :WCP2 Cleaner :SKC-S

Batch no. of : Particle :01352 White Contrast :01252 Cleaner :01125

Examination Method : Continuous Field strength check Minimum twice in each area, right angle each other

Surface Prep : As welded As machined As ground Solvent Wipe

Stage of Examination : As welded After Heat treated Other

Scope of Examinat: Base Metal Edge Prep Back Chipping

Weld New Weld Repair Other

Types of Result ( mm )

Part Name No.Joint Thickness ( mm ) Length(mm) Qty

Discontinuities

Accepted Rejected

H496X200X12X14 1 TW=10 mm;TF=14mm - - Accepted - 1

PN. FLANGE PK803368-06 2 TW=10 mm;TF=14mm - - Accepted -

PK803369-08 3 TW=10 mm;TF=14mm - - Accepted -

PN.WEB PK804587-7 4 TW=10 mm;TF=14mm - - Accepted -

sketch :

MT AREA MT AREA

Examined by : Reviewed / witnessed by : Reviewed / witnessed by : Reviewed / witnessed by

NDE LEVEL :

DATE : DATE : DATE : DATE :

MAGNETIC EXAMINATION REPORT

Customer : PT.PETRODRILL Drawing No. :- Report No :016/MT/PETRODRILL/21

Project Name : RIG PDSI#20.2/EMSCO Procedure No. : PM-QC-01-02

Unit No : None Applicable CODE : AWS D.1.1 - 2020

Material Spec. : A 572 GR.50 W P S No. :

MT Equipment Yoke Other Lifting Force : 10 lb

Particle : Visible Fluorescent Wet Dry

Temperature : Ambient Particle application : Spray Other

Brand’s Name/Types : Magnaflux Particle : 7HF White Contrast :WCP2 Cleaner :SKC-S

Batch no. of : Particle :01352 White Contrast :01252 Cleaner :01125

Examination Method : Continuous Field strength check Minimum twice in each area, right angle each other

Surface Prep : As welded As machined As ground Solvent Wipe

Stage of Examination : As welded After Heat treated Other

Scope of Examinat: Base Metal Edge Prep Back Chipping

Weld New Weld Repair Other

Types of Result ( mm )

Part Name No.Joint Thickness ( mm ) Length(mm) Qty

Discontinuities

Accepted Rejected

H244X175X8X12 1 TW=8mm;TF=12mm - - Accepted - 1

PN.FLANGE 2 TW=8mm;TF=12mm - - Accepted -

PN. PK854857-06/PK804857-03 3 TW=8mm;TF=12mm - - Accepted -

PN.WEB 4 TW=8mm;TF=12mm - - Accepted -

: PN. PK80741603

sketch :

MT AREA MT AREA

Examined by : Reviewed / witnessed by : Reviewed / witnessed by : Reviewed / witnessed by

NDE LEVEL :

DATE : DATE : DATE : DATE :

MAGNETIC EXAMINATION REPORT

Customer : PT.PETRODRILL Drawing No. :- Report No :017/MT/PETRODRILL/21

Project Name : RIG PDSI#20.2/EMSCO Procedure No. : PM-QC-01-02

Unit No : None Applicable CODE : AWS D.1.1 - 2020

Material Spec. : A 572 GR.50 W P S No. :

MT Equipment Yoke Other Lifting Force : 10 lb

Particle : Visible Fluorescent Wet Dry

Temperature : Ambient Particle application : Spray Other

Brand’s Name/Types : Magnaflux Particle : 7HF White Contrast :WCP2 Cleaner :SKC-S

Batch no. of : Particle :01352 White Contrast :01252 Cleaner :01125

Examination Method : Continuous Field strength check Minimum twice in each area, right angle each other

Surface Prep : As welded As machined As ground Solvent Wipe

Stage of Examination : As welded After Heat treated Other

Scope of Examinat: Base Metal Edge Prep Back Chipping

Weld New Weld Repair Other

Types of Result ( mm )

Part Name No.Joint Thickness ( mm ) Length(mm) Qty

Discontinuities

Accepted Rejected

H244X175X8X12 1 TW=8mm;TF=12mm - - Accepted - 1

PN.FLANGE 2 TW=8mm;TF=12mm - - Accepted -

PN. 804857-03 3 TW=8mm;TF=12mm - - Accepted -

PN.WEB 4 TW=8mm;TF=12mm - - Accepted -

PN. PK80741605

sketch :

MT AREA MT AREA

Examined by : Reviewed / witnessed by : Reviewed / witnessed by : Reviewed / witnessed by

NDE LEVEL :

DATE : DATE : DATE : DATE :

MAGNETIC EXAMINATION REPORT

Customer : PT.PETRODRILL Drawing No. :- Report No :018/MT/PETRODRILL/21

Project Name : RIG PDSI#20.2/EMSCO Procedure No. : PM-QC-01-02

Unit No : None Applicable CODE : AWS D.1.1 - 2020

Material Spec. : A 572 GR.50 W P S No. :

MT Equipment Yoke Other Lifting Force : 10 lb

Particle : Visible Fluorescent Wet Dry

Temperature : Ambient Particle application : Spray Other

Brand’s Name/Types : Magnaflux Particle : 7HF White Contrast :WCP2 Cleaner :SKC-S

Batch no. of : Particle :01352 White Contrast :01252 Cleaner :01125

Examination Method : Continuous Field strength check Minimum twice in each area, right angle each other

Surface Prep : As welded As machined As ground Solvent Wipe

Stage of Examination : As welded After Heat treated Other

Scope of Examinat: Base Metal Edge Prep Back Chipping

Weld New Weld Repair Other

Types of Result ( mm )

Part Name No.Joint Thickness ( mm ) Length(mm) Qty

Discontinuities

Accepted Rejected

H244X175X8X12 1 TW=8mm;TF=12mm - - Accepted - 1

PN.FLANGE 2 TW=8mm;TF=12mm - - Accepted -

PN. 804857-03 3 TW=8mm;TF=12mm - - Accepted -

PN.WEB 4 TW=8mm;TF=12mm - - Accepted -

PN. PK80741606

sketch :

MT AREA MT AREA

Examined by : Reviewed / witnessed by : Reviewed / witnessed by : Reviewed / witnessed by

NDE LEVEL :

DATE : DATE : DATE : DATE :

MAGNETIC EXAMINATION REPORT

Customer : PT.PETRODRILL Drawing No. :- Report No :019/MT/PETRODRILL/21

Project Name : RIG PDSI#20.2/EMSCO Procedure No. : PM-QC-01-02

Unit No : None Applicable CODE : AWS D.1.1 - 2020

Material Spec. : A 572 GR.50 W P S No. :

MT Equipment Yoke Other Lifting Force : 10 lb

Particle : Visible Fluorescent Wet Dry

Temperature : Ambient Particle application : Spray Other

Brand’s Name/Types : Magnaflux Particle : 7HF White Contrast :WCP2 Cleaner :SKC-S

Batch no. of : Particle :01352 White Contrast :01252 Cleaner :01125

Examination Method : Continuous Field strength check Minimum twice in each area, right angle each other

Surface Prep : As welded As machined As ground Solvent Wipe

Stage of Examination : As welded After Heat treated Other

Scope of Examinat: Base Metal Edge Prep Back Chipping

Weld New Weld Repair Other

Types of Result ( mm )

Part Name No.Joint Thickness ( mm ) Length(mm) Qty

Discontinuities

Accepted Rejected

H244X175X8X12 1 TW=8mm;TF=12mm - - Accepted - 1

PN.FLANGE 2 TW=8mm;TF=12mm - - Accepted -

PN. 804857-04 3 TW=8mm;TF=12mm - - Accepted -

PN.WEB 4 TW=8mm;TF=12mm - - Accepted -

PN. PK80376907

sketch :

MT AREA MT AREA

Examined by : Reviewed / witnessed by : Reviewed / witnessed by : Reviewed / witnessed by

NDE LEVEL :

DATE : DATE : DATE : DATE :

MAGNETIC EXAMINATION REPORT

Customer : PT.PETRODRILL Drawing No. :- Report No :020/MT/PETRODRILL/21

Project Name : RIG PDSI#20.2/EMSCO Procedure No. : PM-QC-01-02

Unit No : None Applicable CODE : AWS D.1.1 - 2020

Material Spec. : A 572 GR.50 W P S No. :

MT Equipment Yoke Other Lifting Force : 10 lb

Particle : Visible Fluorescent Wet Dry

Temperature : Ambient Particle application : Spray Other

Brand’s Name/Types : Magnaflux Particle : 7HF White Contrast :WCP2 Cleaner :SKC-S

Batch no. of : Particle :01352 White Contrast :01252 Cleaner :01125

Examination Method : Continuous Field strength check Minimum twice in each area, right angle each other

Surface Prep : As welded As machined As ground Solvent Wipe

Stage of Examination : As welded After Heat treated Other

Scope of Examinat: Base Metal Edge Prep Back Chipping

Weld New Weld Repair Other

Types of Result ( mm )

Part Name No.Joint Thickness ( mm ) Length(mm) Qty

Discontinuities

Accepted Rejected

H300X200X8X12 1 TW=8mm;TF=12mm - - Accepted - 6

PN.FLANGE 2 TW=8mm;TF=12mm - - Accepted -

PK803367-01/PK803367-04 3 TW=8mm;TF=12mm - - Accepted -

PN.WEB 4 TW=8mm;TF=12mm - - Accepted -

PK.80375908/PK80375906

sketch :

MT AREA MT AREA

Examined by : Reviewed / witnessed by : Reviewed / witnessed by : Reviewed / witnessed by

NDE LEVEL :

DATE : DATE : DATE : DATE :

MAGNETIC EXAMINATION REPORT

Customer : PT.PETRODRILL Drawing No. :- Report No :021/MT/PETRODRILL/21

Project Name : RIG PDSI#20.2/EMSCO Procedure No. : PM-QC-01-02

Unit No : None Applicable CODE : AWS D.1.1 - 2020

Material Spec. : A 572 GR.50 W P S No. :

MT Equipment Yoke Other Lifting Force : 10 lb

Particle : Visible Fluorescent Wet Dry

Temperature : Ambient Particle application : Spray Other

Brand’s Name/Types : Magnaflux Particle : 7HF White Contrast :WCP2 Cleaner :SKC-S

Batch no. of : Particle :01352 White Contrast :01252 Cleaner :01125

Examination Method : Continuous Field strength check Minimum twice in each area, right angle each other

Surface Prep : As welded As machined As ground Solvent Wipe

Stage of Examination : As welded After Heat treated Other

Scope of Examinat: Base Metal Edge Prep Back Chipping

Weld New Weld Repair Other

Types of Result ( mm )

Part Name No.Joint Thickness ( mm ) Length(mm) Qty

Discontinuities

Accepted Rejected

H300X200X8X12 1 TW=8mm;TF=12mm - - Accepted - 6

PN.FLANGE 2 TW=8mm;TF=12mm - - Accepted -

PK 804857-02/PK804857-05/PK804857-07 3 TW=8mm;TF=12mm - - Accepted -

PK804857-08 4 TW=8mm;TF=12mm - - Accepted -

PN.WEB

PK80741605/PK80376907

sketch :

MT AREA MT AREA

Examined by : Reviewed / witnessed by : Reviewed / witnessed by : Reviewed / witnessed by

NDE LEVEL :

DATE : DATE : DATE : DATE :

MAGNETIC EXAMINATION REPORT

Customer : PT.PETRODRILL Drawing No. :- Report No :022/MT/PETRODRILL/21

Project Name : RIG PDSI#20.2/EMSCO Procedure No. : PM-QC-01-02

Unit No : None Applicable CODE : AWS D.1.1 - 2020

Material Spec. : A 572 GR.50 W P S No. :

MT Equipment Yoke Other Lifting Force : 10 lb

Particle : Visible Fluorescent Wet Dry

Temperature : Ambient Particle application : Spray Other

Brand’s Name/Types : Magnaflux Particle : 7HF White Contrast :WCP2 Cleaner :SKC-S

Batch no. of : Particle :01352 White Contrast :01252 Cleaner :01125

Examination Method : Continuous Field strength check Minimum twice in each area, right angle each other

Surface Prep : As welded As machined As ground Solvent Wipe

Stage of Examination : As welded After Heat treated Other

Scope of Examinat: Base Metal Edge Prep Back Chipping

Weld New Weld Repair Other

Types of Result ( mm )

Part Name No.Joint Thickness ( mm ) Length(mm) Qty

Discontinuities

Accepted Rejected

H300X200X8X12 1 TW=8mm;TF=12mm - - Accepted - 4

PN.FLANGE 2 TW=8mm;TF=12mm - - Accepted -

PK803367-06/PK803367-03 3 TW=8mm;TF=12mm - - Accepted -

4 TW=8mm;TF=12mm - - Accepted -

PN.WEB

PK80741604

sketch :

MT AREA MT AREA

Examined by : Reviewed / witnessed by : Reviewed / witnessed by : Reviewed / witnessed by

NDE LEVEL :

DATE : DATE : DATE : DATE :

MAGNETIC EXAMINATION REPORT

Customer : PT.PETRODRILL Drawing No. :- Report No :023/MT/PETRODRILL/21

Project Name : RIG PDSI#20.2/EMSCO Procedure No. : PM-QC-01-02

Unit No : None Applicable CODE : AWS D.1.1 - 2020

Material Spec. : A 572 GR.50 W P S No. :

MT Equipment Yoke Other Lifting Force : 10 lb

Particle : Visible Fluorescent Wet Dry

Temperature : Ambient Particle application : Spray Other

Brand’s Name/Types : Magnaflux Particle : 7HF White Contrast :WCP2 Cleaner :SKC-S

Batch no. of : Particle :01352 White Contrast :01252 Cleaner :01125

Examination Method : Continuous Field strength check Minimum twice in each area, right angle each other

Surface Prep : As welded As machined As ground Solvent Wipe

Stage of Examination : As welded After Heat treated Other

Scope of Examinat: Base Metal Edge Prep Back Chipping

Weld New Weld Repair Other

Types of Result ( mm )

Part Name No.Joint Thickness ( mm ) Length(mm) Qty

Discontinuities

Accepted Rejected

H600X200X12X18 1 TW=12 mm;TF=18 mm - - Accepted - 2

PN.FLANGE 2 TW=12 mm;TF=18 mm - - Accepted -

PK803375-01 3 TW=12 mm;TF=18 mm - - Accepted -

PN.WEB 4 TW=12 mm;TF=18 mm - - Accepted -

PK804857-04

sketch :

MT AREA MT AREA

Examined by : Reviewed / witnessed by : Reviewed / witnessed by : Reviewed / witnessed by

NDE LEVEL :

DATE : DATE : DATE : DATE :

MAGNETIC EXAMINATION REPORT

Customer : PT.PETRODRILL Drawing No. :- Report No :024/MT/PETRODRILL/21

Project Name : RIG PDSI#20.2/EMSCO Procedure No. : PM-QC-01-02

Unit No : None Applicable CODE : AWS D.1.1 - 2020

Material Spec. : A 572 GR.50 W P S No. :

MT Equipment Yoke Other Lifting Force : 10 lb

Particle : Visible Fluorescent Wet Dry

Temperature : Ambient Particle application : Spray Other

Brand’s Name/Types : Magnaflux Particle : 7HF White Contrast :WCP2 Cleaner :SKC-S

Batch no. of : Particle :01352 White Contrast :01252 Cleaner :01125

Examination Method : Continuous Field strength check Minimum twice in each area, right angle each other

Surface Prep : As welded As machined As ground Solvent Wipe

Stage of Examination : As welded After Heat treated Other

Scope of Examinat: Base Metal Edge Prep Back Chipping

Weld New Weld Repair Other

Types of Result ( mm )

Part Name No.Joint Thickness ( mm ) Length(mm) Qty

Discontinuities

Accepted Rejected

H200X200X8X12 1 TW=8 mm;TF=12 mm - - Accepted - 3

PN.FLANGE 2 TW=8 mm;TF=12 mm - - Accepted -

PK803367-06/PK803367-03 3 TW=8 mm;TF=12 mm - - Accepted -

PN.WEB 4 TW=8 mm;TF=12 mm - - Accepted -

PK80741606

sketch :

MT AREA MT AREA

Examined by : Reviewed / witnessed by : Reviewed / witnessed by : Reviewed / witnessed by

NDE LEVEL :

DATE : DATE : DATE : DATE :

MAGNETIC EXAMINATION REPORT

Customer : PT.PETRODRILL Drawing No. :- Report No :025/MT/PETRODRILL/21

Project Name : RIG PDSI#20.2/EMSCO Procedure No. : PM-QC-01-02

Unit No : None Applicable CODE : AWS D.1.1 - 2020

Material Spec. : A 572 GR.50 W P S No. :

MT Equipment Yoke Other Lifting Force : 10 lb

Particle : Visible Fluorescent Wet Dry

Temperature : Ambient Particle application : Spray Other

Brand’s Name/Types : Magnaflux Particle : 7HF White Contrast :WCP2 Cleaner :SKC-S

Batch no. of : Particle :01352 White Contrast :01252 Cleaner :01125

Examination Method : Continuous Field strength check Minimum twice in each area, right angle each other

Surface Prep : As welded As machined As ground Solvent Wipe

Stage of Examination : As welded After Heat treated Other

Scope of Examinat: Base Metal Edge Prep Back Chipping

Weld New Weld Repair Other

Types of Result ( mm )

Part Name No.Joint Thickness ( mm ) Length(mm) Qty

Discontinuities

Accepted Rejected

H200X200X8X12 1 TW=8 mm;TF=12 mm - - Accepted - 3

PN.FLANGE 2 TW=8 mm;TF=12 mm - - Accepted -

. PK803367-05 3 TW=8 mm;TF=12 mm - - Accepted -

PN.WEB 4 TW=8 mm;TF=12 mm - - Accepted -

PK80741603

sketch :

MT AREA MT AREA

Examined by : Reviewed / witnessed by : Reviewed / witnessed by : Reviewed / witnessed by

NDE LEVEL :

DATE : DATE : DATE : DATE :

MAGNETIC EXAMINATION REPORT

Customer : PT.PETRODRILL Drawing No. :- Report No :026/MT/PETRODRILL/21

Project Name : RIG PDSI#20.2/EMSCO Procedure No. : PM-QC-01-02

Unit No : None Applicable CODE : AWS D.1.1 - 2020

Material Spec. : A 572 GR.50 W P S No. :

MT Equipment Yoke Other Lifting Force : 10 lb

Particle : Visible Fluorescent Wet Dry

Temperature : Ambient Particle application : Spray Other

Brand’s Name/Types : Magnaflux Particle : 7HF White Contrast :WCP2 Cleaner :SKC-S

Batch no. of : Particle :01352 White Contrast :01252 Cleaner :01125

Examination Method : Continuous Field strength check Minimum twice in each area, right angle each other

Surface Prep : As welded As machined As ground Solvent Wipe

Stage of Examination : As welded After Heat treated Other

Scope of Examinat: Base Metal Edge Prep Back Chipping

Weld New Weld Repair Other

Types of Result ( mm )

Part Name No.Joint Thickness ( mm ) Length(mm) Qty

Discontinuities

Accepted Rejected

H200X200X8X12 1 TW=8 mm;TF=12 mm - - Accepted - 4

PN.FLANGE 2 TW=8 mm;TF=12 mm - - Accepted -

PK803367-05/PK854857-06 3 TW=8 mm;TF=12 mm - - Accepted -

PN.WEB 4 TW=8 mm;TF=12 mm - - Accepted -

PK80741605/PK80375905

sketch :

MT AREA MT AREA

Examined by : Reviewed / witnessed by : Reviewed / witnessed by : Reviewed / witnessed by

NDE LEVEL :

DATE : DATE : DATE : DATE :

MAGNETIC EXAMINATION REPORT

Customer : PT.PETRODRILL Drawing No. :- Report No :027/MT/PETRODRILL/21

Project Name : RIG PDSI#20.2/EMSCO Procedure No. : PM-QC-01-02

Unit No : None Applicable CODE : AWS D.1.1 - 2020

Material Spec. : A 572 GR.50 W P S No. :

MT Equipment Yoke Other Lifting Force : 10 lb

Particle : Visible Fluorescent Wet Dry

Temperature : Ambient Particle application : Spray Other

Brand’s Name/Types : Magnaflux Particle : 7HF White Contrast :WCP2 Cleaner :SKC-S

Batch no. of : Particle :01352 White Contrast :01252 Cleaner :01125

Examination Method : Continuous Field strength check Minimum twice in each area, right angle each other

Surface Prep : As welded As machined As ground Solvent Wipe

Stage of Examination : As welded After Heat treated Other

Scope of Examinat: Base Metal Edge Prep Back Chipping

Weld New Weld Repair Other

Types of Result ( mm )

Part Name No.Joint Thickness ( mm ) Length(mm) Qty

Discontinuities

Accepted Rejected

H200X200X8X12 1 TW=8 mm;TF=12 mm - - Accepted - 2

PN.FLANGE 2 TW=8 mm;TF=12 mm - - Accepted -

PK804857-05/PK804857-07 3 TW=8 mm;TF=12 mm - - Accepted -

PN.WEB 4 TW=8 mm;TF=12 mm - - Accepted -

PK80375905

sketch :

MT AREA MT AREA

Examined by : Reviewed / witnessed by : Reviewed / witnessed by : Reviewed / witnessed by

NDE LEVEL :

DATE : DATE : DATE : DATE :

MAGNETIC EXAMINATION REPORT

Customer : PT.PETRODRILL Drawing No. :- Report No :028/MT/PETRODRILL/21

Project Name : RIG PDSI#20.2/EMSCO Procedure No. : PM-QC-01-02

Unit No : None Applicable CODE : AWS D.1.1 - 2020

Material Spec. : A 572 GR.50 W P S No. :

MT Equipment Yoke Other Lifting Force : 10 lb

Particle : Visible Fluorescent Wet Dry

Temperature : Ambient Particle application : Spray Other

Brand’s Name/Types : Magnaflux Particle : 7HF White Contrast :WCP2 Cleaner :SKC-S

Batch no. of : Particle :01352 White Contrast :01252 Cleaner :01125

Examination Method : Continuous Field strength check Minimum twice in each area, right angle each other

Surface Prep : As welded As machined As ground Solvent Wipe

Stage of Examination : As welded After Heat treated Other

Scope of Examinat: Base Metal Edge Prep Back Chipping

Weld New Weld Repair Other

Types of Result ( mm )

Part Name No.Joint Thickness ( mm ) Length(mm) Qty

Discontinuities

Accepted Rejected

H200X200X8X12 1 TW=8 mm;TF=12 mm - - Accepted - 4

PN.FLANGE 2 TW=8 mm;TF=12 mm - - Accepted -

PK804857-03/PK803367-04 3 TW=8 mm;TF=12 mm - - Accepted -

PN.WEB 4 TW=8 mm;TF=12 mm - - Accepted -

PK80376907

sketch :

MT AREA MT AREA

Examined by : Reviewed / witnessed by : Reviewed / witnessed by : Reviewed / witnessed by

NDE LEVEL :

DATE : DATE : DATE : DATE :

You might also like

- MT PipaDocument70 pagesMT PipaDani Madrid12No ratings yet

- Penetrant Test Report: PT DegremontDocument14 pagesPenetrant Test Report: PT DegremontMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Example Report TOFD 2 INT-GP1186-09-70 PDFDocument1 pageExample Report TOFD 2 INT-GP1186-09-70 PDFEMTC EMTCNo ratings yet

- Example Report TOFD 2 INT-GP1186!09!70Document1 pageExample Report TOFD 2 INT-GP1186!09!70EMTC EMTC100% (1)

- 1335 - EC1904Document1 page1335 - EC1904Deipak HoleNo ratings yet

- Essential welding procedure qualification recordDocument2 pagesEssential welding procedure qualification recordmainur mechanical engineer0% (1)

- Phased Array Ultrasonic Examination Report: Contractor: Report No.: Client: Exam DateDocument1 pagePhased Array Ultrasonic Examination Report: Contractor: Report No.: Client: Exam DateshervinyNo ratings yet

- He Mrut 006Document3 pagesHe Mrut 006Hao TranNo ratings yet

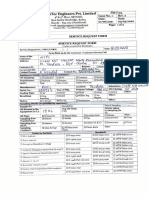

- ForenTec Engineers Pvt. Limited Service Request FormDocument2 pagesForenTec Engineers Pvt. Limited Service Request FormForenTec Engineers RanchiNo ratings yet

- BC MT 1688-0000Document84 pagesBC MT 1688-0000Tuấn ĐậuNo ratings yet

- 56STLZ 1Document223 pages56STLZ 1Dani Madrid12No ratings yet

- Flexural PPRCDocument1 pageFlexural PPRCMirza Aqeel AhmedNo ratings yet

- RecafcoDocument1 pageRecafcom.aliNo ratings yet

- 75914199-2 - Fu-10-Pad - Eyes-Mpi, 20-May-2024Document1 page75914199-2 - Fu-10-Pad - Eyes-Mpi, 20-May-2024Mohamed El-SawahNo ratings yet

- Pqr-Band Ring PDFDocument3 pagesPqr-Band Ring PDFamitNo ratings yet

- FISHERDocument3 pagesFISHERPower Booster Sdn BhdNo ratings yet

- Kelvion Plate Heat Exchanger QuotationDocument2 pagesKelvion Plate Heat Exchanger QuotationJafarNo ratings yet

- HE Header E535Document91 pagesHE Header E535rizal mubarokNo ratings yet

- Feuille Des Donnees Cables F&G: ProjetDocument6 pagesFeuille Des Donnees Cables F&G: ProjetAshraf Ammar100% (1)

- Hmmu331021 9Document5 pagesHmmu331021 9ANGEL ANTONIO GUTIERREZ CONTRERASNo ratings yet

- Dual Fuel Genset - Heat Recovery-1-2Document2 pagesDual Fuel Genset - Heat Recovery-1-2Ab Sami100% (1)

- He Mrut 005Document3 pagesHe Mrut 005Hao TranNo ratings yet

- PQR GmawDocument4 pagesPQR GmawEr Sumant Kumar Singh0% (1)

- Ultrasonic Examination Report: Discharge DamperDocument1 pageUltrasonic Examination Report: Discharge DamperSaurav RoyNo ratings yet

- Magnetic Particle Inspection Report: TEM INSPECTED: Assembly (X Over 2",pipes 2",elbows)Document2 pagesMagnetic Particle Inspection Report: TEM INSPECTED: Assembly (X Over 2",pipes 2",elbows)Khalil ChabbouhNo ratings yet

- Report PTDocument3 pagesReport PTGancie 26No ratings yet

- Kelvion Plate Heat Exchanger: Thermal Data For: NT100X CDL-10Document2 pagesKelvion Plate Heat Exchanger: Thermal Data For: NT100X CDL-10JafarNo ratings yet

- Report of Ultrasonic Flaw Detection Test of Weld JointDocument1 pageReport of Ultrasonic Flaw Detection Test of Weld Jointkevin desai100% (1)

- Ldeal Eentre: Service TrainingDocument1 pageLdeal Eentre: Service Trainingnur hasanNo ratings yet

- Test Report For Synchronous MachinesDocument60 pagesTest Report For Synchronous MachinesMaria MarcanoNo ratings yet

- Test Report PDFDocument60 pagesTest Report PDFMaria Marcano100% (2)

- MAGNETIC INSPECTIONDocument4 pagesMAGNETIC INSPECTIONiksan_adityoNo ratings yet

- Ultrasonic Thickness Measurement ReportDocument2 pagesUltrasonic Thickness Measurement ReportKaushal GandhiNo ratings yet

- L&t-Ut-Se-1678 - R1 30-03-2023Document1 pageL&t-Ut-Se-1678 - R1 30-03-2023SamirNo ratings yet

- HE-MRUT-001Document3 pagesHE-MRUT-001Hao TranNo ratings yet

- 1485 - Ec2252-HardDocument1 page1485 - Ec2252-HardDeepak HoleNo ratings yet

- Kuwait Lab Tests Zinc Coating ThicknessDocument3 pagesKuwait Lab Tests Zinc Coating Thicknessm.aliNo ratings yet

- Amir Construction & Company Ltd. Manlift UT Report-14 (06.10.22)(1)Document3 pagesAmir Construction & Company Ltd. Manlift UT Report-14 (06.10.22)(1)sumit singhNo ratings yet

- Mpi 44444286 ..Document1 pageMpi 44444286 ..Khalil ChabbouhNo ratings yet

- PQR With-PwhtDocument2 pagesPQR With-PwhtKarthikNo ratings yet

- Heat Exchanger Performance SpecDocument2 pagesHeat Exchanger Performance SpecStevan KrstojevicNo ratings yet

- Runsheet WPQT ModernDocument9 pagesRunsheet WPQT ModernYUDI IRMAWANTONo ratings yet

- Tmu-1105 Job Card Ta-2019Document20 pagesTmu-1105 Job Card Ta-2019Anonymous YRyGcKPNo ratings yet

- Inquiry/Order: Your Contact Partner at SEWDocument3 pagesInquiry/Order: Your Contact Partner at SEWAnonymous 9ZSghmNo ratings yet

- He Mrut 004Document3 pagesHe Mrut 004Hao TranNo ratings yet

- 15SV2GG4F60: Operating DataDocument4 pages15SV2GG4F60: Operating DatajtorerocNo ratings yet

- SWATHI PQR Procedure QualificationDocument10 pagesSWATHI PQR Procedure QualificationMustu AkolawalaNo ratings yet

- HE Can Warmer 3150313-173 english versionDocument2 pagesHE Can Warmer 3150313-173 english versiongrantday2000No ratings yet

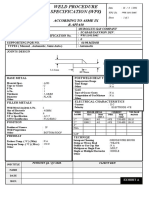

- Weld Procedure Specification (WPS) : According To Asme Ix &Document1 pageWeld Procedure Specification (WPS) : According To Asme Ix &Mina Roger SamyNo ratings yet

- He Mrut 003Document3 pagesHe Mrut 003Hao TranNo ratings yet

- MPI Inspection ProcedureDocument5 pagesMPI Inspection ProcedureDinesh GuptaNo ratings yet

- Data SheetDocument5 pagesData SheetRah KhanNo ratings yet

- Ultrasonic Exam Report Steam Drum JointsDocument3 pagesUltrasonic Exam Report Steam Drum JointsBalkishan DyavanapellyNo ratings yet

- 10-03-2020 C1 Gland Steam Superheater - MTDocument6 pages10-03-2020 C1 Gland Steam Superheater - MTDave CheungNo ratings yet

- Hyundai India Drive ShaftDocument21 pagesHyundai India Drive ShaftCROWNTECH SURFACENo ratings yet

- En Iso 9606 1 GDocument2 pagesEn Iso 9606 1 GAnonymous dziHEjc7Y100% (1)

- RTCLNT 142111 Wa 44Document1 pageRTCLNT 142111 Wa 44Mitul KapadiaNo ratings yet

- Welding Procedure Qualification Record (WPQR) (ISO 15614-1-2017)Document3 pagesWelding Procedure Qualification Record (WPQR) (ISO 15614-1-2017)ramesh rajaNo ratings yet

- Ultrasonic Examination Report: The Royal Utilisation Services Pvt. LTDDocument9 pagesUltrasonic Examination Report: The Royal Utilisation Services Pvt. LTDNazmul HasanNo ratings yet

- Pressuremeter Testing: Methods and InterpretationFrom EverandPressuremeter Testing: Methods and InterpretationRating: 5 out of 5 stars5/5 (2)

- Dimension Inspection ReportsDocument4 pagesDimension Inspection ReportsSeret BroNo ratings yet

- Dimension Inspection ReportsDocument4 pagesDimension Inspection ReportsSeret BroNo ratings yet

- Welded Beam Dimension Inspection ReportsDocument5 pagesWelded Beam Dimension Inspection ReportsSeret BroNo ratings yet

- Dimension Inspection ReportsDocument4 pagesDimension Inspection ReportsSeret BroNo ratings yet

- Speccoats AntiCorrosiveBrochureDocument36 pagesSpeccoats AntiCorrosiveBrochurereinpolyNo ratings yet

- 06 Inquirybio ch06Document42 pages06 Inquirybio ch06HabzboiiNo ratings yet

- Cosmos Alminium-Technical - Specifications PDFDocument2 pagesCosmos Alminium-Technical - Specifications PDFmindsopenNo ratings yet

- CAA Guidelines Antibiotic Free Inputs NewDocument19 pagesCAA Guidelines Antibiotic Free Inputs Newroshan asnotkarNo ratings yet

- Wiring Cable StandardDocument6 pagesWiring Cable StandardAli AhmadNo ratings yet

- Chemistry Why Do Liquids Boil at Different TemperaturesDocument3 pagesChemistry Why Do Liquids Boil at Different TemperaturesVALERY JOHANA RONCALLO BARRIOSNo ratings yet

- Practical 2Document8 pagesPractical 2Farid FazamyNo ratings yet

- Coordination TheoryDocument38 pagesCoordination TheorySLEVINPJOY100% (11)

- Laporan Praktikum Organotransitonal Metal ChemistryDocument14 pagesLaporan Praktikum Organotransitonal Metal ChemistryChristina ApriliaNo ratings yet

- Effect of Die Bonding On The Performance of High Power Semiconductor Laser DiodeDocument4 pagesEffect of Die Bonding On The Performance of High Power Semiconductor Laser DiodecjpanchalNo ratings yet

- General Chemistry 1 / Chemistry For Engineers: CH4701, CH4001Document21 pagesGeneral Chemistry 1 / Chemistry For Engineers: CH4701, CH4001Tadhg O'ShaughnessyNo ratings yet

- Group 3 - PBL 1 - PresentationDocument26 pagesGroup 3 - PBL 1 - PresentationBima SetyaputraNo ratings yet

- Prop 3lisitsin2008Document9 pagesProp 3lisitsin2008AlejandraNo ratings yet

- (Asit) Metal-Free Methods in The Synthesis of Macrocyclic Schiff BasesDocument34 pages(Asit) Metal-Free Methods in The Synthesis of Macrocyclic Schiff Baseslütfü çavdarNo ratings yet

- H2 Chem Notes 9729 PDFDocument78 pagesH2 Chem Notes 9729 PDFBobNo ratings yet

- 2015-5 - TechPresentation - Bentley ASME RTP 1Document71 pages2015-5 - TechPresentation - Bentley ASME RTP 1Christian Cobo100% (4)

- Guide To Selection: Hot Rolled Carbon Steel BarsDocument4 pagesGuide To Selection: Hot Rolled Carbon Steel BarsJess OrtonNo ratings yet

- STOICHIOMETRY REVISION QUIZDocument4 pagesSTOICHIOMETRY REVISION QUIZAshwin Balaji0% (1)

- Vitamin A CapsulesDocument2 pagesVitamin A CapsulesWeda MaharaniNo ratings yet

- Solutions FinalDocument12 pagesSolutions FinalAman DeepNo ratings yet

- Composite Materials NotesDocument7 pagesComposite Materials NotesAnanya67% (3)

- 5.1 Measuring Energy Changes Question D1 ChemistryDocument2 pages5.1 Measuring Energy Changes Question D1 ChemistryWilliam MelhadoNo ratings yet

- Metzger AlbrechtDocument289 pagesMetzger Albrechtmax capetownNo ratings yet

- 2-Nutrient ManagementDocument27 pages2-Nutrient ManagementFrance Nicole Joy MoracaNo ratings yet

- Extraction and Utilization of Rice Bran OilDocument12 pagesExtraction and Utilization of Rice Bran OilMudit ChauhanNo ratings yet

- Compressed Gas Cylinder SafetyDocument36 pagesCompressed Gas Cylinder Safetyelvis hidalgoNo ratings yet

- Ihsan Ullah Khan ThesisDocument66 pagesIhsan Ullah Khan ThesisBehramand KhanNo ratings yet

- Rate of Reaction 1 QPDocument11 pagesRate of Reaction 1 QPRobert EdwardsNo ratings yet

- Physico-Chemical Analysis of Pressmud Compost and VermicompostDocument5 pagesPhysico-Chemical Analysis of Pressmud Compost and VermicompostSonal Manik CNo ratings yet

- Solution Preparation GuideDocument3 pagesSolution Preparation GuidezannubaqotrunnadhaNo ratings yet