Professional Documents

Culture Documents

RA For Hollow Metal Doors Instalation

Uploaded by

yahiya100%(1)100% found this document useful (1 vote)

51 views3 pagesRA for Hollow Metal Doors Instalation

Original Title

RA for Hollow Metal Doors Instalation

Copyright

© © All Rights Reserved

Available Formats

XLS, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentRA for Hollow Metal Doors Instalation

Copyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

100%(1)100% found this document useful (1 vote)

51 views3 pagesRA For Hollow Metal Doors Instalation

Uploaded by

yahiyaRA for Hollow Metal Doors Instalation

Copyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

You are on page 1of 3

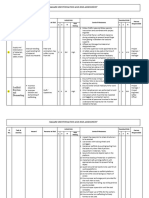

THE CONTRACTOR THE OWNER THE ENGINEER

Al Arrab Contracting Co. Custodian of Two Holy Mosques the King Abdullah Bin Abdulaziz's Project - KAP2 B2

Contract No.: 119/35/53/1 Doc. No.: ACC-KAP2B-HSSE-RA-018 Rev: 00

RISK ASSESSMENT FOR

HOLLOW METAL DOORS INSTALATION WORKS

Risk Risk Responsible

Hazard Consequence Risk Level Prevention Residual RISK

Level Person

No

RR RR

S OP S OP

(SxOP) (SxOP)

1.Ensure availability of a competent supervisor prior to

mobilize workers on site them on site and for entire the

operation

2. Ensure proper communication is established between

entire workforce

3. Mechanical fitness of the equipment must be verified prior to

mobilize them on site

4.Ensure use of same language personals in each group as

reasonably as practicable

5. Ensure adequate number of safety promotional signs and

warning signs (like "DO not enter, over head hazard etc..) in

and around the work area

Mobilization : 6. Ensure all personals are attended project safety induction Site engineer,

personal injury, property

Language barrier between work 7. Ensure adequate welfare facilities are available supervisor,

1 damage, argument between 3 4 12 M 2 2 4 T

force, unfit equipment and non 8.Ensure all workers are aware about emergency procedure Foreman,

workers

competent operator 9.Ensure all workers are complied with mandatory PPEs operator

requirements

10. Ensure workers are trained for proper manual handling

techniques wherever applicable

11. ensure workers are not going very close to the excavated

area and not crossing barricading

12. Ensure safety devices of all vehicles and

equipment like Reverse alarm, side indicators, horns Speedo

meter etc.. prior to mobilize them on site

13. Ensure adequate illumination is available prior

to start any activity

14. Ensure noise level of all equipment used for

the task is within 85Decibel

1.Ensure all vehicle & drivers are complied with legal

requirements especially valid driving license registration

certificates and insurance .

2.Designate pedestrians

3. Machines must keep away from edge of trench.

4. Ensure audible and visual warning signs are operational

5. Water pouring on access roads and other strategic areas

need to be done on regular basis to prevent dust agnation

* Death, 6.Roads need be secured from excavation and other hazards Site engineer,

Transportation :Hit with other

* Serious injury, by installing barricading and traffic signs , supervisor,

2 vehicles, people, dust generation 4 4 16 H 2 2 4 T

* property damage 7. Unauthorized personnel are not allowed to work area Foreman,

* Delays in specific works 9.Workers should be properly trained and supervised, operator

10. Only certified equipment to be used.

11. Proper maintenance of machines must be done regularly.

12. Ensure trucks

are loaded within the capacity of the truck

13. Ensure vehicle are not crossing

"danger zone" marked area which must be visible at all times

14. Fire extinguisher must be available

in site vehicles

Page 1 of 3 Revision No.00

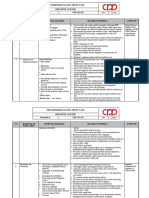

RISK ASSESSMENT FOR

HOLLOW METAL DOORS INSTALATION WORKS

Risk Risk Responsible

Hazard Consequence Risk Level Prevention Residual RISK

Level Person

No

RR RR

S OP S OP

(SxOP) (SxOP)

1. Ensure all electrical works are carried out by a competent

electrician 2.

Meticulous attention must be taken by employees while

hammering

3. Ensure workers must use eye protection respiratory aid

while using cutting machine 4.

must use electrical rubber gloves while working in live line

Small cut wounds, trip slip falls 5.

Use of Hand tools and cleaning

3 and crushing injuries, Eye 3 4 12 M Eye protection must be worn while doing hammering 6. 2 1 2 T Supervisor

surfaces

injuries Ensure all electrical cables are free from defects 7. All

rotating equipment and hand tolls must have safety guard

8. All

tolls and equipment must be as per manufacturers

recommendations 9.

Use compatible hand gloves and other means of skin

protection

1. use mechanical aids as reasonably as practicable 2.

All ways follow team handling of loads

3. Training need to be given workers for

kinetic method of manual handling

Manual Handling: Tools and Back Injuries, crushing injuries 4.Ensure work area is free from slippery Supervisor/

4 3 4 12 M 2 2 4 T

other materials etc… materials and other debris Safety

5.Use compatible pep especially hand gloves and

safety shoes

6.ensure work area is stable and not uneven

7. Use proper hand gloves

1. Use mechanical aids as reasonably as practicable

2. Proper eye protection must be used by all workers for the

process

3. Compatible PPE which must include but not limited to

Chemical gloves( rubber glove) wellington Boots and

hardwearing leather gloves for formwork

4. Access to work area must be restricted to authorized

* Skins cut/burns personals only especially while using scaffold

* Adverse impact on eyes 5.Ensure hanger wires are safe and properly attached

5 Installation Of Hollow metal doors * Slip and falls 4 3 12 M 6. workers must use respiratory aid(dust mask) while dealing 2 2 4 T S, operator

with cement

7.Ensure work area must be free from all slippery materials

8. Use proper

hand gloves in order to make a good grip on boards

9. Use mechanical aid as

reasonably as practicable 10. Ensure work area is free

from all slippery materials 11. Ensure all workers are using

proper hand gloves 12. Identify and

secure all protruding steel

Hazard : The potential unsafe incidents to be occurred while the initiating event is happening.

Consequence : The possible consequence when any hazards are occurring.

Risk Level : Categorizing the risks

: The activity to prevent possible or

Prevention expected incident.

: Responsible person to prevent the

Responsible person hazard.

Page 2 of 3 Revision No.00

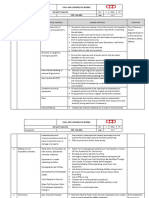

RISK ASSESSMENT FOR

HOLLOW METAL DOORS INSTALATION WORKS

Risk Risk Responsible

Hazard Consequence Risk Level Prevention Residual RISK

Level Person

No

RR RR

S OP S OP

(SxOP) (SxOP)

Risk Assessment Definitions : S : Severity

OP : Occurrence Possibility

RR : Risk Rating

Severity Rating ; 1 – 5 (1 = least severe; 5 = most severe) Occurrence Possibility: 1 – 5 (1 = least possible; 5 = most possible)

1 - Very minor (first aid treatment)

2- Minor (first aid treatment, absent from work- one shift ) 2- Low ( once in three months

3- Middle (treatment needed in hospital) 3- Middle ( once a month)

4- Serious (treatment needed in hospital, absent from work for lengthy 4- High ( once a week)

5- Very serious (death) 5- Very high (once a day)

Risk Rating Classification = Severity X Occurrence

T: Tolerable Risk; 0 – 5 = Tolerable, no action necessary.

L: Low Risk; 6 – 10 = no urgent action needed, Training at site, inductions

M: Medium Risk; 11 – 15 = action needed, Training at site, inductions, warning signs, documentation.

H: High Risk; 16 – 20 = stop work, urgent action needed, Severe precautions, work schedule change, training, emergency planning drills

VH: Very High Risk 21 – 25 = immediately stop work, urgent action needed, have to reevaluate site hazards, design and schedule change

Page 3 of 3 Revision No.00

You might also like

- PMP Cheat SheetDocument2 pagesPMP Cheat Sheetyogesh sharma89% (9)

- Working at Height - SH&E Risk AssessmentDocument2 pagesWorking at Height - SH&E Risk AssessmentyahiyaNo ratings yet

- NPCL Project Chennai Risk Assessment Record: Activity: Installation of Fire Fighting SystemDocument15 pagesNPCL Project Chennai Risk Assessment Record: Activity: Installation of Fire Fighting SystemabbasNo ratings yet

- Edgar Payne - Composition of Outdoor Painting PDFDocument187 pagesEdgar Payne - Composition of Outdoor Painting PDFihavenoimagination92% (90)

- JSA For Diesel Filling at Del CampDocument6 pagesJSA For Diesel Filling at Del CampMohammed Minhaj60% (5)

- Jsa For Blowing of Air in Underground PipesDocument4 pagesJsa For Blowing of Air in Underground PipesMohammed MinhajNo ratings yet

- Confined Space Entry - SH&E Risk Assessment: Middle EastDocument5 pagesConfined Space Entry - SH&E Risk Assessment: Middle EastyahiyaNo ratings yet

- Jsa For Road WorksDocument11 pagesJsa For Road Worksyc safety75% (12)

- JSA For Road BarrierDocument3 pagesJSA For Road BarrierMohammed MinhajNo ratings yet

- Risk Assessment of Block Works and Plastering WorksDocument7 pagesRisk Assessment of Block Works and Plastering Worksfaizan khanNo ratings yet

- JSA For Installation of Precast SlabDocument4 pagesJSA For Installation of Precast Slabyc safety100% (3)

- Risk Assessment For Installation of Ventilation FansDocument5 pagesRisk Assessment For Installation of Ventilation Fansfaizan khanNo ratings yet

- 145 Manual ChecklistDocument4 pages145 Manual ChecklistElLoko MartinesNo ratings yet

- Hira - Back FillingDocument5 pagesHira - Back FillingSatya NaiduNo ratings yet

- HIRA FOR Equipment Instalation.Document8 pagesHIRA FOR Equipment Instalation.Deepak G100% (1)

- JSA Hot Work and ModificationDocument19 pagesJSA Hot Work and ModificationBrings MotoVlogNo ratings yet

- Usage of Hand ToolsDocument4 pagesUsage of Hand ToolsJeffersonDeGuiaNo ratings yet

- Risk Assessment of Testing and Commissioning of Fire Alarm SystemDocument4 pagesRisk Assessment of Testing and Commissioning of Fire Alarm Systemfidgety67% (3)

- JSA For Scaffolding Erection and Dismentling Inside The Building Room at Accommodation Block CDocument5 pagesJSA For Scaffolding Erection and Dismentling Inside The Building Room at Accommodation Block Cnoahlungu96No ratings yet

- JSA - Fire Proofing WorksDocument5 pagesJSA - Fire Proofing WorksAnis Uddin100% (3)

- JSA For Screeding With MeshDocument4 pagesJSA For Screeding With MeshMohammed Minhaj100% (1)

- Risk Assessment For Testing and Commissioning of Water Supply Pipes Including ChlorinationDocument3 pagesRisk Assessment For Testing and Commissioning of Water Supply Pipes Including Chlorinationfidgety100% (4)

- RA For Stone Work Rev1Document5 pagesRA For Stone Work Rev1Muhammed yahiyaNo ratings yet

- JSA For Diesel Filling at Del CampDocument6 pagesJSA For Diesel Filling at Del CampMohammed Ali QaziNo ratings yet

- JSA For Grouting and Air Blowing1Document3 pagesJSA For Grouting and Air Blowing1Mohammed MinhajNo ratings yet

- Project: Field Erection of 15000 Bbls Tank (Ik-2545) : Job Safety Analysis / Safe Work Method Statement-SWMSDocument7 pagesProject: Field Erection of 15000 Bbls Tank (Ik-2545) : Job Safety Analysis / Safe Work Method Statement-SWMSJohnNo ratings yet

- RA - For Precast ChambersDocument5 pagesRA - For Precast ChambersKallem RajashekarNo ratings yet

- Band Saw Machine HIRADocument4 pagesBand Saw Machine HIRAChethanNo ratings yet

- HIRA - Carpentry Work-018Document8 pagesHIRA - Carpentry Work-018Satya Naidu100% (1)

- JSA For Lifting of RebarsDocument5 pagesJSA For Lifting of RebarsNiraNo ratings yet

- Risk Assessment (MAN HOLE)Document3 pagesRisk Assessment (MAN HOLE)yahiyaNo ratings yet

- Copy of JSA For Cathodic Protection For Oily Water LineDocument6 pagesCopy of JSA For Cathodic Protection For Oily Water LineMohammed Minhaj80% (5)

- Risk Assessment For Installation of Drainage Pipes and FittingsDocument8 pagesRisk Assessment For Installation of Drainage Pipes and Fittingsfaizan khan100% (2)

- Risk Assessment - Installation of Cable Trays & DCAC CablesDocument5 pagesRisk Assessment - Installation of Cable Trays & DCAC CablesIbrahim Esmat100% (1)

- Risk Assessment For Installation of Water Supply SystemDocument2 pagesRisk Assessment For Installation of Water Supply Systemمقاول تكييف كهرباء وصحيNo ratings yet

- JSA For Scaffolding Erection and Dismentling at Process AreaDocument5 pagesJSA For Scaffolding Erection and Dismentling at Process Areanoahlungu96No ratings yet

- Risk Assessment For .Testing and Commissioning of Fire DamperDocument9 pagesRisk Assessment For .Testing and Commissioning of Fire Damperarun kurlanNo ratings yet

- JSA 03 Gate Entrance Traffic ProposalDocument10 pagesJSA 03 Gate Entrance Traffic Proposalrahul tkNo ratings yet

- AT&T Case StudyDocument9 pagesAT&T Case StudyAdrian DsouzaNo ratings yet

- Manual HandlingDocument4 pagesManual HandlingJeffersonDeGuiaNo ratings yet

- XX - PTW 609066 Doc1Document17 pagesXX - PTW 609066 Doc1JeffersonDeGuiaNo ratings yet

- Risk Assessment For Excavation Works Prior To Installation of Signage Gantry at Road A3Document6 pagesRisk Assessment For Excavation Works Prior To Installation of Signage Gantry at Road A3Muideen OyedeleNo ratings yet

- Welfare Facilities - ChecklistDocument2 pagesWelfare Facilities - Checklistyahiya100% (4)

- Usage of Power ToolsDocument5 pagesUsage of Power ToolsJeffersonDeGuiaNo ratings yet

- Hse-027 - Environmental Site Inspection - ChecklistDocument4 pagesHse-027 - Environmental Site Inspection - ChecklistyahiyaNo ratings yet

- Austria vs. NLRCDocument2 pagesAustria vs. NLRCJenilyn EntongNo ratings yet

- ACI Policies and Recommended Practices Seventh Edition FINAL v2Document129 pagesACI Policies and Recommended Practices Seventh Edition FINAL v2Valmir AndradeNo ratings yet

- Pte Essays With AnswersDocument19 pagesPte Essays With AnswersMani Shankar100% (3)

- Risk Assessment of Fire Hose Reel InstallationDocument9 pagesRisk Assessment of Fire Hose Reel Installationfidgety100% (2)

- BCPC 2nd QTR Meeting Minutes 2017Document2 pagesBCPC 2nd QTR Meeting Minutes 2017Anne Abellanosa100% (2)

- RA For Stone Work Rev0Document5 pagesRA For Stone Work Rev0yahiya0% (1)

- Risk Assessment For Stone WorkDocument17 pagesRisk Assessment For Stone WorkKhuda BukshNo ratings yet

- Arc WeldingDocument4 pagesArc WeldingJeffersonDeGuiaNo ratings yet

- Risk Assessment and ControlDocument8 pagesRisk Assessment and Controlanand.v4491No ratings yet

- JSA of 33KV Bay - Rev001 - 15072020Document3 pagesJSA of 33KV Bay - Rev001 - 15072020Aradhya SinghNo ratings yet

- JSA For Childrens RoomDocument3 pagesJSA For Childrens Roomkalai selvanNo ratings yet

- Hazard Identification & Risk AssessmentDocument8 pagesHazard Identification & Risk Assessmentanand.v4491No ratings yet

- Jsa For Drilling WellDocument5 pagesJsa For Drilling WellAnna JisabaNo ratings yet

- Gunitting Operation JSA HSE ProfessionalsDocument1 pageGunitting Operation JSA HSE ProfessionalsSamadov 13No ratings yet

- JSA For New EmployeesDocument20 pagesJSA For New EmployeesNilayNo ratings yet

- JHSA For Temporary Plastic Septic TankDocument4 pagesJHSA For Temporary Plastic Septic TankAnna JisabaNo ratings yet

- JSA - Area Hard BarricationDocument1 pageJSA - Area Hard BarricationNFRN0% (1)

- Jsa For Plaster WorkDocument4 pagesJsa For Plaster Workumar KhitabNo ratings yet

- SWP 03 - Hacking WorksDocument3 pagesSWP 03 - Hacking WorksGerald Wong NttNo ratings yet

- Job Safety AnalysisDocument3 pagesJob Safety AnalysisMuhammad KaleemNo ratings yet

- Risk Assessment For Installation of DX Split UnitDocument8 pagesRisk Assessment For Installation of DX Split Unitfaizan khanNo ratings yet

- Jsa For Concreate and CivilworksDocument7 pagesJsa For Concreate and CivilworksAnna JisabaNo ratings yet

- Ra For Fire Protection Piping Installation WorksDocument7 pagesRa For Fire Protection Piping Installation WorksprinceNo ratings yet

- Blank JSA For Building WorksDocument5 pagesBlank JSA For Building Worksiftikhar ahmadNo ratings yet

- JHSA Water Supply and Sewer InstallationDocument4 pagesJHSA Water Supply and Sewer InstallationAnna JisabaNo ratings yet

- Risk Assessment - Installation of Back Painted GlassDocument7 pagesRisk Assessment - Installation of Back Painted GlassMuhammad NadeemNo ratings yet

- Office or Workplace SH&E Inspection: Office/ Location Floor Room AreaDocument4 pagesOffice or Workplace SH&E Inspection: Office/ Location Floor Room AreayahiyaNo ratings yet

- Checklist For Belt SlingsDocument1 pageChecklist For Belt SlingsyahiyaNo ratings yet

- Work Fatigue: 1.0 Purpose and ScopeDocument2 pagesWork Fatigue: 1.0 Purpose and ScopeyahiyaNo ratings yet

- Demolition Safety - Check List: Date: REV.: Form NoDocument2 pagesDemolition Safety - Check List: Date: REV.: Form NoyahiyaNo ratings yet

- Work at Height: 1.0 Purpose and ScopeDocument12 pagesWork at Height: 1.0 Purpose and ScopeyahiyaNo ratings yet

- Project: Date of Issue Report #:: Form #Document1 pageProject: Date of Issue Report #:: Form #yahiyaNo ratings yet

- Welding, Cutting and Hot WorkDocument6 pagesWelding, Cutting and Hot WorkyahiyaNo ratings yet

- Violence in The Workplace: 1.0 Purpose and ScopeDocument3 pagesViolence in The Workplace: 1.0 Purpose and ScopeyahiyaNo ratings yet

- Heat Stress Prevention: 1.0 Purpose and ScopeDocument10 pagesHeat Stress Prevention: 1.0 Purpose and ScopeyahiyaNo ratings yet

- Lifting Operations and Lifting EquipmentDocument4 pagesLifting Operations and Lifting EquipmentyahiyaNo ratings yet

- Driver and Vehicle SafetyDocument7 pagesDriver and Vehicle SafetyyahiyaNo ratings yet

- Chemical Spill Control: 1.0 Purpose and ScopeDocument2 pagesChemical Spill Control: 1.0 Purpose and ScopeyahiyaNo ratings yet

- Traffic Management: 1.0 Purpose and ScopeDocument3 pagesTraffic Management: 1.0 Purpose and ScopeyahiyaNo ratings yet

- Waste Management: 1.0 Purpose and ScopeDocument3 pagesWaste Management: 1.0 Purpose and ScopeyahiyaNo ratings yet

- Community Assets Mapping and SurveysDocument4 pagesCommunity Assets Mapping and SurveysabdullahNo ratings yet

- Melissa Fellman ResumeDocument1 pageMelissa Fellman Resumeapi-300877369No ratings yet

- Whitehead and BiosemioticsDocument22 pagesWhitehead and BiosemioticsJ PNo ratings yet

- U2 - Keith Haring Comprehension QuestionsDocument3 pagesU2 - Keith Haring Comprehension QuestionsSteve GOopNo ratings yet

- Political Law NotesDocument186 pagesPolitical Law NotesDaneva AnticamaraNo ratings yet

- Name: Tuhin Uddin Roni ID: 193-10-2136 Batch: 48-B Course Title: Art of Living Course Code: AOL 101Document2 pagesName: Tuhin Uddin Roni ID: 193-10-2136 Batch: 48-B Course Title: Art of Living Course Code: AOL 101Mr. RoniNo ratings yet

- Entrepreneurship Development Institute of IndiaDocument7 pagesEntrepreneurship Development Institute of IndiaAnisha MarwahNo ratings yet

- Muhammad Mustafa Shakil Shadman Ameen Reshma Reaz KhanDocument1 pageMuhammad Mustafa Shakil Shadman Ameen Reshma Reaz Khansajal sazzadNo ratings yet

- Pereka Online Registration ManualDocument7 pagesPereka Online Registration ManualaxnoobxisNo ratings yet

- Chapter 5 Customer SatisfactionDocument23 pagesChapter 5 Customer SatisfactionChristian BallespinNo ratings yet

- First Division (G.R. No. 163504, August 05, 2015)Document12 pagesFirst Division (G.R. No. 163504, August 05, 2015)JB AndesNo ratings yet

- EXTAC - 1010 - Rev - NONCOMBATANT EVACUATION OPERATIONSDocument96 pagesEXTAC - 1010 - Rev - NONCOMBATANT EVACUATION OPERATIONSAbrarNo ratings yet

- RP Male at Home Training Program FAQ 1Document2 pagesRP Male at Home Training Program FAQ 1Lawrence HeughNo ratings yet

- Grattitude Lesson Nov 28 - ps1Document2 pagesGrattitude Lesson Nov 28 - ps1api-491037759No ratings yet

- Operations Strategy and Competitiveness: What Is Operation?Document6 pagesOperations Strategy and Competitiveness: What Is Operation?Mejidana, Rica Mae N.No ratings yet

- WDA WorldofPay A04Document6 pagesWDA WorldofPay A04AVNo ratings yet

- Colorful Modern Chemistry Science Post Laboratory Experiment PresentationDocument17 pagesColorful Modern Chemistry Science Post Laboratory Experiment PresentationMatthew QuiazonNo ratings yet

- Maximizing Your InfluenceDocument1 pageMaximizing Your InfluenceHosamKusbaNo ratings yet

- Gender Inequality in The Philippine Labor MarketDocument41 pagesGender Inequality in The Philippine Labor MarketADBGADNo ratings yet

- Corrective and Preventive Action - WikipediaDocument20 pagesCorrective and Preventive Action - WikipediaFkNo ratings yet

- Ust GN 2011 Taxation Law PreliminariesDocument6 pagesUst GN 2011 Taxation Law PreliminariesGrachelle SerranoNo ratings yet

- ACORD v. ZamoraDocument31 pagesACORD v. ZamoraPrincess Samantha SarcedaNo ratings yet