Professional Documents

Culture Documents

Ione VP 14 P 102ab 001 - 1

Ione VP 14 P 102ab 001 - 1

Uploaded by

ضياء محمدOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ione VP 14 P 102ab 001 - 1

Ione VP 14 P 102ab 001 - 1

Uploaded by

ضياء محمدCopyright:

Available Formats

PROJECT : KARBALA REFINERY PROJECT

LOCATION : KARBALA, IRAQ

Babak

EMPLOYER : STATE COMPANY FOR OIL PROJECTS(SCOP)

PMC REVIEW STATUS CODE

Nicnezhad

2015.05.0

CODE 1 : REJECTED

CODE 2 : REVIEWED WITH COMMENTS

P.O. NO. : IONE-00-PO-MP-2010

CODE 3 : NO COMMENTS / APPROVED

ITEM : 14-P-102A/B

Refer to: IONE-AA00-PE-PM-0005 for code

description

5 15:43:38

Pump Data Sheet

+01'00'

IONE-VP-1

4

-P-1

02

A/B-001

DOCUMENT STATUS

□ 1 :Approved

Approved with Comments. Vendor to amend and re-

Same Comments with 13-P-102A/B □ 2 :

submit for Approval.

□ 3 :Not Approved. Vendor to re submit For Approval

□ 4 :Information Only

NOTE: Permission to proceed does not constitute acceptance of approval

of design details, calculations, analysis, test methods or materials

developed/selected by the Supplier and does not relieve the Supplier from

full compliance with contractual obligations .

REVIEW DATE: 15 . APR . 15 .

ENGINEER LEAD ENGINEER

1 3

0-M ar-1

5

FOR APPROVAL

SK.HW ANG K.H RYOO J.W KO

0 1

2

-Feb-1

5

FOR APPROVAL SK.HW ANG K.H RYOO J.W KO

REV. DATE

DESCRIPTION PRPD CHKD APPRD APPRD

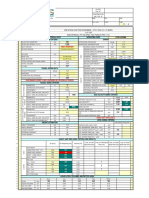

MECHANICAL DATA SHEET

LPG/C4 FEED PUMP

DOC. No. : IONE-1A14-DS-RM-14P102

KARBALA REFINERY PROJECT Rev. 1 Page 1/7

Ref. FEED No. : S-00781-4345234

MECHANICAL DATA SHEET

FOR

LPG/C4 FEED PUMP

(14-P-102 A/B)

PROJECT : KARBALA REFINERY PROJECT

LOCATION : KARBALA, IRAQ

OWNER : STATE COMPANY FOR OIL PROJECTS (SCOP)

CHKD

REVD

APPRD

CONFD

Rev. Date DESCRIPTION PRPD

(LS LE)

(LS EM)

(JV ED)

(SCOP)

Joint Venture of Hyundai Engineering & Construction Co., Ltd., and GS Engineering & Construction Co., Ltd., and SK

Engineering & Construction Co., Ltd., and Hyundai Engineering Co., Ltd.,

Note :

a) Revision bar(vertical line) shall be placed in the right hand margin to indicate where the changes has been made

b) PRPD = Prepared by, CHKD = Checked by, REVD = Reviewed by, APPRD = Approved by, CONFD = Confirmed by

MECHANICAL DATA SHEET

LPG/C4 FEED PUMP

DOC. No. : IONE-1A14-DS-RM-14P102

KARBALA REFINERY PROJECT Rev. 1 Page 2/7

Ref. FEED No. : S-00781-4345234

REVISION HISTORY

Rev. Date Description Page

0 12.MAR.15 First Issue All

1 30.MAR.15 Portion of Head information was changed.

3

1 30.MAR.15 Portion of operation condition was changed.

3

1 30.MAR.15 Portion of motor driver was changed. 3

1 30.MAR.15 Portion of pump performance was changed. 3

1 30.MAR.15 Portion of seal data was changed. 4

1 30.MAR.15 Portion of note was changed. 4

1 30.MAR.15 Portion of construction was changed. 5

1 30.MAR.15 Portion of surface preparation and paint was changed. 5

1 30.MAR.15 Portion of QA inspection and testing was changed. 6

KARBALA REFINERY PROJECT

SCOP – IRAQ (Contract n° 2171)

Rev Page

CENTRIFUGAL PUMP

DOC. No. : IONE-1A14-DS-RM-14P102

PROCESS DATA SHEET

(API 610)

Item No. : 14-P-102 A/B

1

3/7

1

SERVICE

LPG / C4 FEED PUMP

3 1

NO. REQUIRED

2 (1 operating + 1 stand-by)

PUMP SIZE 2x3-9.5

TYPE

BB5

NO. STAGES

9

4

MANUFACTURER

ITT GOULDS PUMPS

MODEL

7200CB

SERIAL NO.

4434512A/B

5

APPLICABLE TO: PROPOSALS PURCHASE AS BUILT

6

NOTES:NFORMATION BELOW TO BE COMPLETED: BY PURCHASER

BY MANUFACTURER BY MANUFACTURER OR PURCHASER

7

DATA SHEETS NOTES / REMARKS

8 ITEM NO.

ATTACHED ITEM NO. ATTACHED ITEM NO. ATTACHED

9 PUMP

14-P-102 A 14-P-102 B

10 MOTOR

14-PM-102 A 14-PM-102 B

11 GEAR

12 TURBINE

13 APPLICABLE OVERLAY STANDARD(S):

14

OPERATING CONDITIONS (5.1.3) LIQUID (5.1.3)

3 3

15 FLOW, NORMAL

20.2 (m /h) RATED 24.2

(m /h)

LIQUID TYPE OR NAME

LPG / C4 LIQUID

16

OTHER TURNDOWN : OVER 0% of NORMAL FLOW TO BE COVERED BY PUMP

HAZARDOUS FLAMMABLE

(5.1.5)

17

18 1 SUCTION PRESSURE MAX./RATED 48.2(HOLD) / 13.51

(kg/cm²g)

MIN. NORMAL MAX

19 DISCHARGE PRESSURE 47.22

(kg/cm²g)

PUMPING TEMP (°C)

38

Note 12

20 DIFFERENTIAL PRESSURE

33.71

(kg/cm²)

VAPOUR PRESS. (kg/cm²a)

9.7

21 DIFF. HEAD 679.6

(m) NPSHA 8.40 (See Remark)

(m)

RELATIVE DENSITY (SG):

0.496 0.548

22

PROCESS VARIATIONS (5.1.4)

VISCOSITY (cP)

0.108

23 STARTING CONDITIONS (5.1.4)

AUTO-START

SPECIFIC HEAT, Cp (kcal/kg°C)

24 SERVICE: CONT.

INTERMITTENT (STARTS/DAY)

CHLORIDE CONCENTRATION (6.5.2.4)

(mg/kg)

25 PARALLEL OPERATION REQ'D (5.1.13)

H 2S CONCENTRATION

(mol fraction) WET (5.12.1.12c)

26 SITE DATA (5.1.3) (NOTE 3)

CORROSIVE / EROSIVE AGENT (5.12.1.9)

27

28 LOCATION: (5.1.30)

MATERIALS (5.12.1.1)

29 INDOOR HEATED OUTDOOR UNHEATED

ANNEX H CLASS (5.12.1.1)

S-8

30 ELECTRICAL AREA CLASSIFICATION (5.1.24 / 6.1.4)

(NOTE 4)

MIN DESIGN METAL TEMP (5.12.4.1)

-29.8

(°C)

31 ZONE 2 GR IIC TEMP CLASS

T3

REDUCED HARDNESS MATERIALS REQ'D. (5.12.1.12)

32 WINTERIZATION REQ'D TROPICALIZATION REQ'D .

BARREL/CASE

LTCS

IMPELLER

316L SS

33

SITE DATA (5.1.30)

CASE/IMPELLER WEAR RINGS

316L SS Hard Faced

34 ALTITUDE

(m) BAROMETER

(bar a)

SHAFT

Nitronic 50

35 RANGE OF AMBIENT TEMPS: MIN/MAX. -8.5

/

55

(°C)

DIFFUSERS

316LSS

36 RELATIVE HUMIDITY: MIN / MAX 9

/

97

(%)

37 UNUSUAL CONDITIONS: (5.1.30)

DUST FUMES

PERFORMANCE:

38

OTHER

PROPOSAL CURVE NO.

8148-0

2980

RPM

39

IMPELLER DIA. RATED

230

MAX.

241 MIN.

216

(mm)

40

IMPELLER TYPE

Closed

41

DRIVER TYPE

RATED POWER

59.49

(kW) EFFICIENCY

41.5

(%)

42 INDUCTION MOTOR STEAM TURBINE

GEAR

MINIMUM CONTINUOUS FLOW:

3 3

43 OTHER

THERMAL

(m /h)

STABLE

10.87

(m /h)

3

44 1

PREFERRED OPER. REGION

24.4

TO

41.9

(m /h)

3

45 MOTOR DRIVER (6.1.1 / 6.1.4)

ALLOWABLE OPER. REGION

10.87

TO

43.9

(m /h)

46 MANUFACTURE R

HHI

MAX HEAD @ RATED IMPELLER

742.35

(m)

47 110

(kW)

3000

RPM

MAX POWER @ RATED IMPELLER

92.32

(kW)

48 1 FRAME

315

ENCLOSURE

Ex de

NPSHR AT RATED FLOW

2.91

(m) (5.1.10)

49 1 HORIZONTAL VERTICAL SERVICE FACTOR 1.0

MAX. SUCTION SPECIFIC SPEED:

7236 US

(5.1.11)

50 VOLTS/PHASE/HERTZ (5)3300 / 3 /

50

MAX. SOUND PRESS. LEVEL REQ'D

85 @ 1 m

(dBA) (5.1.16)

51

TYPE

EST MAX SOUND PRESS. LEVEL

Later

(dBA) (5.1.16)

52

MINIMUM STARTING VOLTAGE (6.1.5)

EST MAX SOUND POWER LEVEL

(dBA) (5.1.16)

53 INSULATION F TEMP. RISE B

UTILITY CONDITIONS (5.1.3) (NOTE 3)

54

FULL LOAD AMPS

Later

ELECTRICITY VOLTAGE PHASE HERTZ

55

LOCKED ROTOR AMPS Later

DRIVERS

3300

3

50

56

STARTING METHOD D.O.L

HEATING

57

LUBE GREASE

SYSTEM VOLTAGE DIP

80% OTHER

(6.1.5)

58

59 BEARINGS (TYPE/NUMBER):

STEAM

MAX. PRESS. MAX. TEMP.

MIN. PRESS.

MIN. TEMP.

60 RADIAL

BALL

/

LATER

DRIVERS

61 THRUST

BALL

/

LATER

HEATING

62

VERTICAL THRUST CAPACITY

COOLING WATER: (5.1.19) SOURCE

63 UP (kgf) DOWN (kgf)

SUPPLY TEMP.

32

(°C) MAX. RETURN TEMP.

43 (°C)

64

NORM. PRESS.

4

(kg/cm²g)

DESIGN PRESS.

7

(kg/cm²g)

65

MIN. RET. PRESS

2.5

(kg/cm²g)

MAX. ALLOW. D.P

1.5

(kg/cm²)

66

CHLORIDE CONCENTRATION:

(mg/kg)

67

REMARKS

68

NPSHA IS BASED ON TOP OF FOUNDATION (0.3m FROM GRADE).

69

70

71

TECHNIP ITALY S.p.A. - 00148 ROMA - Viale Castello della Magliana, 68

KARBALA REFINERY PROJECT

SCOP – IRAQ (Contract n° 2171)

Rev Page

CENTRIFUGAL PUMP

DOC. No. : IONE-1A14-DS-RM-14P102

PROCESS DATA SHEET

(API 610)

Item No. : 14-P-102 A/B 1 4/7

1 MECHANICAL SEAL (CONT.)

2 1 SEAL DATA: [Later] PIPING ASSEMBLY:

3 1 SEE ATTACHED ISO 21049/API 682 DATA SHEET THREADED UNIONS SOCKET WELDED

4 NON-API 682 SEAL FLANGED TUBE TYPE FITTINGS

5 APPENDIX H (610) SEAL CODE REMARKS

6 SEAL MANUFACTURER John Crane

7 SIZE AND TYPE /

8 MANUFACTURER CODE PACKING

9 ARRANGEMENT: (NOTE 10) PACKING DATA:

10 SINGLE DUAL UNPRESSURIZED DUAL PRESSURIZED MANUFACTURER

11 SEAL CHAMBER DATA: TYPE

12 TEMPERATURE (°C) SIZE NO. OF RINGS

13 PRESSURE (kg/cm²g) PACKING INJECTION REQUIRED

14 FLOW (m³/h) FLOW (m³/h) @ (°C)

15 SEAL FLUSH PIPING: LANTERN RING

16 1 SEAL FLUSH PIPING PLAN API Plan 02/53B STEAM AND COOLING WATER PIPING

17 TUBING CARBON STEEL COOLING WATER PIPING PLAN M (6.5.3.1)

18 1 PIPE STAINLESS STEEL COOLING WATER REQUIREMENTS

19 SEAL FLUSH FLUID TYPE SEAL JACKET/BRG HSG (m³/h) @ (kg/cm²g)

20 1 AUXILIARY FLUSH PLAN API Plan 02/53B SEAL HEAT EXCHANGER (m³/h) @ (kg/cm²g)

21 TUBING CARBON STEEL QUENCH (m³/h) @ (kg/cm²g)

22 PIPE STAINLESS STEEL TOTAL COOLING WATER (m³/h)

23 AUXILIARY FLUSH FLUID TYPE STEAM PIPING: TUBING PIPE

24

25 NOTES

26

27 1. MECHANICAL DESIGN CONDITIONS

28 - DESIGN PRESSURE: 95.0 kg/cm²g

29 - DESIGN TEMPERATURE: 80 °C

30

31 2. ONE PUMP IS RUNNING AND ONE IS STAND-BY

32

33 1 3. FOR SITE AND UTILITIES DATA REFER TO BASIC DESIGN DATA IONE-AA00-SP-PR-0001.

34

35 4. PRELIMINARY AREA CLASSIFICATION IS SAFE AREA. AREA CLASSIFICATION SHALL BE CONFIRMED LATER

36

37 1 5. REFER TO DOC. IONE-AA00-SP-EL-1001

38

39 6. CAPACITY CONTROL : THROTTLING

40

41 7. CONTROLLABLE RANGE (% OF RATED) : 0-100%

42

43 8. MINIMUM FLOW DEVICE SHALL BE SPECIFIED BY VENDOR.

44

45 1 9. MAXIMUM POSSIBLE SHUT-OFF PRESSURE : 90.5(HOLD) (kg/cm²g)

46

; TO BE VERIFIED BY VENDOR. DESIGN PRESSURE OF CONNECTED PIPING IS 95 (kg/cm²g)

47

48 10. PUMPS TO BE PROVIDED WITH DOUBLE MECHANICAL SEALS.

49

50 11. PRESSURE RATING OF THE SUCTION SIDE TO BE THE SAME AS THE DISCHARGE SIDE PRESSURE RATING.

51

52 12. PUMP SUCTION TEMPERATURE MAY BE UP TO 55°C RESULTING IN NPSHA = 8.4 m liq. (NPSHA 8.4 m liq. IS BASED ON PUMP CENTER LINE.)

53

54 13. MOTOR TO BE SIZED FOR END OF CURVE OPERATION. (AUTO START SHALL BE PROVIDED FOR BOTH PUMPS)

55

56 1 14. Will be delete. RECOMMENDED WARM-UP FLOW SHALL BE ADDED TO RATED CAPACITY, IF NECESSARY .

57

58

Added Note

59

60

- DISCHARGE VESSEL HEIGHT ABOVE PUMP CENTER : 6m liq.

61

; ELEVATION/LOCATION OF NOZZLES ON VESSELS TO BE CONFIRMED LATER.

62

63 - MAXIMUM DENSITY OF PUMPED LIQUID IS 548kg/m 3 .

64

65 - TURN DOWN : 30% OF NORMAL OPERATING FLOWRATE.

66

67

68

69

70

71

TECHNIP ITALY S.p.A. - 00148 ROMA - Viale Castello della Magliana, 68

KARBALA REFINERY PROJECT

SCOP – IRAQ (Contract n° 2171)

Rev Page

CENTRIFUGAL PUMP

DOC. No. : IONE-1A14-DS-RM-14P102

PROCESS DATA SHEET

(API 610)

Item No. : 14-P-102 A/B 1 5/7

1 CONSTRUCTION SURFACE PREPARATION AND PAINT

2 ROTATION: (VIEWED FROM COUPLING END) CW CCW MANUFACTURER'S STANDARD OTHER (SEE BELOW)

3 PUMP TYPE: (4.1) SPECIFICATION NO. IONE-AA00-SP-PR-2300-01

4 BB1 BB2 BB3 BB5 PUMP:

5 1 CASING MOUNTING: PUMP SURFACE PREPARATION

Sa 2-1/2 (SSPC-SP10)

6 1 CENTERLINE NEAR CENTERLINE PRIMER

Interzinc22

7 1 FOOT FINISH COAT

Intergard475HS(intermediate), Interthane990 (final)

8 CASING SPLIT: BASEPLATE: (6.3.17)

9 1 AXIAL RADIAL BASEPLATE SURFACE PREPARATION

Sa 2-1/2 (SSPC-SP10)

10 1 CASING TYPE: PRIMER

Interzinc22

11 1 SINGLE VOLUTE MULTIPLE VOLUTE DIFFUSER FINISH COAT

Intergard475HS(intermediate), Interthane990 (final)

12 BETWEEN BEARINGS BARREL DETAILS OF LIFTING DEVICES(6 .3.20)

13 CASE PRESSURE RATING: SHIPMENT: (7.4.1)

14 1 MAX ALLOWABLE WORKING PRESSURE 175.8 (kg/cm²g)

DOMESTIC EXPORT EXPORT BOXING REQUIRED

15 1 @ 80

(°C) (REFER TO PAGE 2) OUTDOOR STORAGE MORE THAN 6 MONTHS

16 1 HYDROTEST PRESSURE 263.7 (kg/cm²g) SPARE ROTOR ASSEMBLY PACKAGED FOR:

17 SUCTION PRESS . REGIONS MUST BE DESIGNED SHIPPING CONTAINER (8.2.8.3) VERTICAL STORAGE (8.2.8.2)

18 FOR MAWP (5.3.6) TYPE OF SHIPPING PREPARATION N2 PURGE (8.2.8.4)

19 NOZZLE CONNECTIONS: (5.4.2) HEATING AND COOLING

20 SIZE (DN) FLANGE FACING POSITION HEATING JACKET REQ'D. (5.8.9) COOLING REQ'D.

21 RATING COOLING WATER PIPING PLAN (6.5.3.1) M

22 1 SUCTION 3 ANSI 1500# RTJ Side

C.W. PIPING:

23 1 DISCHARGE 2 ANSI 1500# RTJ Top

PIPE TUBING; FITTINGS

24 1 BALANCE DRUM 1 Later

Later External C.W. PIPING MATERIALS:

25 1 PRESSURE CASING AUX. CONNECTIONS: (5.4.3) S. STEEL C. STEEL GALVANIZED

26 NO. SIZE (DN) TYPE COOLING WATER REQUIREMENTS:

3

27 1 DRAIN 1 3/4 1500#/RTJ/With Vavle BEARING HOUSING (m /h) @

(kg/cm²g)

3

28 VENT Self venting HEAT EXCHANGER Later (m /h) @ Later (kg/cm²g)

29 PRESS . GAUGE STEAM PIPING: TUBING PIPE

30 TEMP GAUGE BEARINGS AND LUBRICATION (8)

31 WARM-UP BEARING (TYPE/NUMBER) (5.10.1):

32 1 BALANCE / LEAK-OFF 1 Later Later RADIAL Ball

/

Later

33 MACHINED AND STUDDED CONNECTIONS (5.4.3.8) THRUST Ball

/

Later

34 CYLINDRICAL THREADS REQUIRED (5.4.3.3) LUBRICATION (5.11.3, 5.11.4):

35 ROTOR: RING OIL HYDRODYNAMIC PURGE OIL MIST PURE OIL MIST

36 COMPONENT BALANCE TO ISO 1940 G1.0 (5.9.4.4) CONSTANT LEVEL OILER PREFERENCE (5.10.2.2):

37 SHRINK FIT -LIMITED MOVEMENT IMPELLERS (8.2.2.3) PRESSURE LUBE SYS. ISO 10438-3 ISO 10438-2 (8.2.6.1/8.2.6.5)

38 COUPLINGS:(6 .2.2) OIL VISC. ISO GRADE VG 68

39 MANUFACTURER METASTREAM MODEL TSKS OIL PRESS . TO BE GREATER THAN COOLANT PRESSURE

40 1 RATING (kW per 100 r/min) 5.53 REVIEW AND APPROVE THRUST BEARING SIZE (8.2.5.2.4)

41 SPACER LENGTH 250 (mm) SERVICE FACT. 1.5 OIL HEATER REQUIRED: STEAM ELECTRIC

42 DRIVER HALF COUPLING MOUNTED BY: INSTRUMENTATION (6.4.2)

43 PUMP MFR. DRIVER MFR. PURCHASER SEE ATTACHED API-670 DATA SHEET

44 COUPLING WITH HYDRAULIC FIT (6.2.10) ACCELEROMETER(S) (6.4.2.1)

45 COUPLING BALANCED TO ISO 1940-1 G6.3 (6.2.3) PROVISION FOR VIBRATION PROBES (6.4.2.2)

46 COUPLING PER ISO 14691 (6.2.4) RADIAL PER BRG. AXIAL PER BRG.

47 COUPLING PER ISO 10441 (6.2.4) PROVISION FOR MOUNTING ONLY (5.10.2.11)

48 COUPLING PER API 671 (6.2.4) FLAT SURFACE REQ'D (5.10.2.12)

49 NON SPARK COUPLING GUARD (6.2.14c) RADIAL BEARING METAL TEMP. THRUST BRG METAL TEMP.

50 COUPLING GUARD STANDARD PER (6.2.14a) TEMP. GAUGES (WITH THERMOWELLS)

51 BASEPLATES: MONITORS AND CABLES SUPPLIED BY (6.4.2.4)

52 API BASEPLATE NUMBER (ANNEX D) REMARKS

53 NON-GROUT CONSTRUCTION (6.3.13)

54 OTHER

55 MECHANICAL SEAL: (5.8.1)

56 1 SEE ATTACHED ISO 21049/API 682 DATA SHEET

57 MASSES (kg)

58 PUMP Later BASEPLATE 3934

59 DRIVER Later TOTAL Later

60 GEAR Later

61

62 REMARKS

63

64 15. BEARINGS TO BE PROTECTED BY INPROSEAL VBXX

65

66

67

68

69

70

71

TECHNIP ITALY S.p.A. - 00148 ROMA - Viale Castello della Magliana, 68

KARBALA REFINERY PROJECT

SCOP – IRAQ (Contract n° 2171)

Rev Page

CENTRIFUGAL PUMP

DOC. No. : IONE-1A14-DS-RM-14P102

PROCESS DATA SHEET

(API 610)

Item No. : 14-P-102 A/B 1 6/7

1 SPARE PARTS (TABLE 18) QA INSPECTION AND TESTING (CONT.)

2 START-UP NORMAL MAINTENANCE TEST NON-WIT WIT OBSERVE

3 SPECIFY HYDROSTATIC (7.3.2)

4 PERFORMANCE (7.3.3)

5 OTHER PURCHASER REQUIREMENTS NPSH (7.3.4.2) (16)

6 COORDINATION MEETING REQUIRED (9.1.3) RETEST ON SEAL L'KGE (7.3.3.2d)

7 MAXIMUM DISCHARGE PRESSURE TO INCLUDE (5.3.2) RETEST REQUIRED AFTER FINAL

8 HEAD ADJUSTMENT (7.3.3.5b)

9 MAX RELATIVE DENSITY COMPLETE UNIT TEST (7.3.4.3)

10 MAX DIA. IMPELLERS AND/OR NO OF STAGES SOUND LEVEL TEST (7.3.4.4)

11 OPERATION TO TRIP SPEED CLEANLINESS PRIOR TO

12 CONNECTION DESIGN APPROVAL (5.12.3.4/8.2.1.4) FINAL ASSEMBLY (7.2.2.2)

13 INERT GAS INHIBITED STORAGE - SPARE CARTRIDGE (8.2.8.4) NOZZLE LOAD TEST (6.3.6)

14 TORSIONAL ANALYSIS REQUIRED (5.9.2.1) CHECK FOR CO-PLANAR

15 TORSIONAL ANALYSIS REPORT (5.9.2.6) MOUNTING PAD SURFACES (6.3.3)

16 PROGRESS REPORTS (9.3.3) MECHANICAL RUN UNTIL OIL

17 OUTLINE OF PROCEDURES FOR OPTIONAL TESTS (9.2.5) TEMP. STABLE (7.3.4.7.1)

18 ADDITIONAL DATA REQUIRING 20 YEARS RETENTION (7.2.2.1f) 4 HR. MECHANICAL RUN AFTER

19 LATERAL ANALYSIS REQUIRED (8.2.4.1 / 8.2.4.1.3) OIL TEMP. STABLE (7.3.4.7.3)

20 DYNAMIC BALANCE ROTOR (8.2.4.2) 4 HR. MECH. RUN TEST(7.3.4.7.2)

21 MANIFOLD PIPING TO SINGLE CONNECTION (6.5.1.6) TRUE PEAK VELOCITY

22 VENT DRAIN COOLING WATER DATA (7.3.3.4d)

23 MOUNT SEAL RESERVOIR OFF BASEPLATE (6.5.1.4) BRG HSG RESONANCE

24 FLANGES REQ'D IN PLACE OF SOCKET WELD UNIONS (6.5.2.8) TEST (7.3.4.6)

25 CONNECTION BOLTING REMOVE / INSPECT

26 PTFE COATING ASTM A153 GALVANIZED HYDRODYNAMIC BEARINGS

27 PAINTED SS AFTER TEST (8.2.7.5)

28 INSTALLATION LIST IN PROPOSAL (9.2.3L) AUXILIARY EQUIPMENT

29 QA INSPECTION AND TESTING TEST (7.3.4.5)

30 SHOP INSPECTION (7.1.4) IMPACT TESTING (5.12.4.3)

31 PERFORMANCE CURVE APPR. PER EN 13445

32 TEST WITH SUBSTITUTE SEAL (7.3.3.2) PER ASME VIII

33 MATERIAL CERTIFICATION REQUIRED (5.12.1.8)

34 CASING IMPELLER SHAFT VENDOR KEEP REPAIR AND HT RECORDS (7.2.1.1c)

35 OTHER VENDOR SUBMIT TEST PROCEDURES (7.3.1.2 / 9.2.5)

36 CASTING REPAIR PROCEDURE APPROVAL REQ'D (5.12.2.5) VENDOR SUBMIT TEST DATA WITHIN 24 HOURS (7.3.3.3e)

37 INSPECTION REQUIRED FOR CONNECTION WELDS (5.12.3.4e) INCLUDE PLOTTED VIBRATION SPECTRA (5.9.3.3)

38 MAG PARTICLE LIQUID PENETRANT RECORD FINAL ASSEMBLY RUNNING CLEARANCES

39 RADIOGRAPHIC ULTRASONIC COMPLETION OF INSPECTION CHECK LIST (7.1.6)

40 INSPECTION REQUIRED FOR CASTINGS (7.2.1.3)(5.12.1.5)

41 1 MAG PARTICLE LIQUID PENETRANT OA Inspection and test testing shall be conducted as per Source

42 1 RADIOGRAPHIC ULTRASONIC Inspection Procedure (IONE-AA00-PE-QA-0012)

43 HARDNESS TEST REQUIRED: (7.2.2.3)

44 ADDITIONAL SURFACE / SUBSURFACE EXAMINATION (7.2.1.3)

45 FOR

46 METHOD

47

48 REMARKS

49

50 16. NPSH TEST REQUIRED WHEN NPSH MARGIN OF AVAILABLE OVER REQUIRED IS LESS THAN 1 METER

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

TECHNIP ITALY S.p.A. - 00148 ROMA - Viale Castello della Magliana, 68

KARBALA REFINERY PROJECT

SCOP – IRAQ (Contract n° 2171)

Rev Page

CENTRIFUGAL PUMP

DOC. No. : IONE-1A14-DS-RM-14P102

PROCESS DATA SHEET

(API 610)

Item No. : 14-P-102 A/B 1 7/7

1

PRESSURE DESIGN CODES

2

WELDING REQUIREMENTS

3

PURCHASER DEFINED MATERIAL INSPECTIONS

5 APPLICABLE TO: PROPOSALS PURCHASE AS BUILT

6 1 FOR SCOP

UNIT

14

7 1 SITE KARBALA, IRAQ

SERVICE

LPG / C4 FEED PUMP

9 NOTES: INFORMATION BELOW TO BE COMPLETED: BY PURCHASER BY MANUFACTURER BY MANUFACTURER OR PURCHASER

10

11 PRESSURE VESSEL DESIGN CODE REFERENCES .

12 THESE REFERENCES MUST BE LISTED BY THE MANUFACTURER

13 CASTING FACTORS USED IN DESIGN ( 5.3.4) (TABLE 3)

14 SOURCE OF MATERIAL PROPERTIES

15

16 WELDING AND REPAIRS (5.12.3)

17 THESE REFERENCES MUST BE LISTED BY THE PURCHASER . (DEFAULT TO TABLE 10 IF NO PURCHASER PREFERENCE IS STATED)

18 ALTERNATIVE WELDING CODES AND STANDARDS (5.12.3.1)

19 Welding Requirement (Applicable Code or Standard) Purchaser defined Default per Table 10

20 Welder/operator qualification

21 Welding procedure qualification

22 Non-pressure retaining structural welding such as baseplates or supports

23 Magnetic particle or liquid penetrant examination of the plate edges

24 Postweld heat treatment

25 Postweld heat treatment of casing fabrication welds

26

27 MATERIAL INSPECTION (7.2.2.1) (7.2.1.3)

28 THESE REFERENCES MUST BE LISTED BY THE PURCHASER (DEFAULT TO TABLE 13 IF NO PURCHASER PREFERENCE IS STATED)

29 ALTERNATIVE MATERIAL INSPECTIONS AND ACCEPTANCE CRITERIA (SEE TABLE 13)

30 Type of inspection Methods For fabrications Castings

31 Radiography

32 Ultrasonic inspection

33 Magnetic particle inspection

34 Liquid penetrant inspection

35 REMARKS

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

TECHNIP ITALY S.p.A. - 00148 ROMA - Viale Castello della Magliana, 68

You might also like

- VD 1233 330 Dig 001 1Document12 pagesVD 1233 330 Dig 001 1Reza AranNo ratings yet

- Vibration-Free Rod-Baffle Design of TubeDocument5 pagesVibration-Free Rod-Baffle Design of Tubehwang2No ratings yet

- Force Feed Lubrication Sysytem ImprovementsDocument8 pagesForce Feed Lubrication Sysytem Improvementsdiego yecid millan mendozaNo ratings yet

- Solutions: Oil and Natural Gas Corporation Ltd. IndiaDocument41 pagesSolutions: Oil and Natural Gas Corporation Ltd. IndiaShubham WadavkarNo ratings yet

- 1231 de 00 DC PCJ 001 01Document33 pages1231 de 00 DC PCJ 001 01Hamid MansouriNo ratings yet

- Cause and Effect Diagram: Doc No.: IONE-VP-02-K-001-005Document9 pagesCause and Effect Diagram: Doc No.: IONE-VP-02-K-001-005ضياء محمدNo ratings yet

- Cause and Effect Diagram: Doc No.: IONE-VP-02-K-001-005Document9 pagesCause and Effect Diagram: Doc No.: IONE-VP-02-K-001-005ضياء محمدNo ratings yet

- DatasheetDocument1 pageDatasheetDeni HermawanNo ratings yet

- Boiler Tube Plugging PDFDocument3 pagesBoiler Tube Plugging PDFCarlos Anibal OrtizNo ratings yet

- General Notes: FAC1-P-611003A /B FAC1-PM-611003A/BDocument1 pageGeneral Notes: FAC1-P-611003A /B FAC1-PM-611003A/Bsecret soldierNo ratings yet

- 10083a 1X M6 Ab 00006 04Document1 page10083a 1X M6 Ab 00006 04wael zakariaNo ratings yet

- Acp Master P&id Oct 20 NewDocument65 pagesAcp Master P&id Oct 20 NewAhmedNo ratings yet

- R420-FR-2130 A/B: NotesDocument1 pageR420-FR-2130 A/B: NotesMubashir fareed100% (1)

- IPS-MBD21907-In-516B-Data Sheet of On Off Valve-Flush Bottom (Y Type) - ADocument3 pagesIPS-MBD21907-In-516B-Data Sheet of On Off Valve-Flush Bottom (Y Type) - ANikhil KarkeraNo ratings yet

- 10083a 1X M6 Ab 00007 04Document1 page10083a 1X M6 Ab 00007 04wael zakariaNo ratings yet

- D62 - 691 - 5 - C4-Specification Sheets PDFDocument26 pagesD62 - 691 - 5 - C4-Specification Sheets PDFSoumiyaNo ratings yet

- S-03710 P42118-Rev. 3-P18-Steam DrumDocument1 pageS-03710 P42118-Rev. 3-P18-Steam Drumwylie01No ratings yet

- HAazopDocument35 pagesHAazopSaravanan ElangovanNo ratings yet

- Heat Exchanger DesignDocument35 pagesHeat Exchanger Designdarkbreaker3244No ratings yet

- Liquified Gas HandbookDocument39 pagesLiquified Gas HandbookMerisaBestariFNo ratings yet

- Integrated PFD Rev.0Document138 pagesIntegrated PFD Rev.0saifi khanNo ratings yet

- Prosper CompleteDocument598 pagesProsper CompleteArturo AndresNo ratings yet

- Painampuram, Muthukurmandal, S.P.S.R. Nellore District, A.PDocument22 pagesPainampuram, Muthukurmandal, S.P.S.R. Nellore District, A.Pkkumar_717405No ratings yet

- Centrifugal CompressorsDocument68 pagesCentrifugal CompressorsVinay ChandwaniNo ratings yet

- Piping Interview Questions 1Document3 pagesPiping Interview Questions 1mithunjobs80% (5)

- Control SystemsDocument38 pagesControl Systemsضياء محمدNo ratings yet

- National Oil Corporation: Rev Date Description Checked ApprovedDocument28 pagesNational Oil Corporation: Rev Date Description Checked ApprovedYousab JacobNo ratings yet

- 05 FS GduDocument18 pages05 FS GduAnonymous O0lyGOShYGNo ratings yet

- 315020-DOC-7015 - (Instrument Datasheet - Pressure Regulator Valve) - RevADocument3 pages315020-DOC-7015 - (Instrument Datasheet - Pressure Regulator Valve) - RevAanwar sadatNo ratings yet

- KG98 2 ONT OMF in 7861 DS 151 R4 Pressure Transmitter Datasheet (Code 1)Document9 pagesKG98 2 ONT OMF in 7861 DS 151 R4 Pressure Transmitter Datasheet (Code 1)Madheswaran DharmapuriNo ratings yet

- IONE-AA00-PID-0021-001 - Code 2Document25 pagesIONE-AA00-PID-0021-001 - Code 2dhiaa mohammedNo ratings yet

- DBB (DN50 CL600)Document1 pageDBB (DN50 CL600)hameedNo ratings yet

- R2B-P3-206-02-P-HD-00220 - DATASHEETS FOR PRESSURE REGULATING VALVE, U-21000 - Rev.1Document11 pagesR2B-P3-206-02-P-HD-00220 - DATASHEETS FOR PRESSURE REGULATING VALVE, U-21000 - Rev.1Diana Paula Echartea MolinaNo ratings yet

- Unit 330Document22 pagesUnit 330mohamed ghorabNo ratings yet

- Utility Process Training - Basic: Karbala Refinery ProjectDocument36 pagesUtility Process Training - Basic: Karbala Refinery Projectdhiaa mohammedNo ratings yet

- General Notes: / B RCA-F-001-ADocument55 pagesGeneral Notes: / B RCA-F-001-Acarmela alburqueque100% (1)

- Ips-mbd18002-In-517 Rev. A - Ls Top MountedDocument8 pagesIps-mbd18002-In-517 Rev. A - Ls Top MountedNikhil KarkeraNo ratings yet

- National Oil Corporation: Rev Date Description Checked ApprovedDocument26 pagesNational Oil Corporation: Rev Date Description Checked ApprovedRochdi SahliNo ratings yet

- Proc Eng P&I DDocument60 pagesProc Eng P&I DGiang T LeNo ratings yet

- 1230 OperationDocument346 pages1230 OperationYasin Elaswad100% (1)

- Guideline For Preparing IPDS - Instrument Process Data SheetDocument3 pagesGuideline For Preparing IPDS - Instrument Process Data Sheetbalaji krishnan100% (1)

- ACFrOgALH7tI4bGAHoY RBTNzPHzMIyHy7FK3 - NLfBCnaIFG6 NJq3Ec8m HIQzGzsRrhL - EaKBKBfiHbz8J4GJN6MjbtxKXVhWqDR 2HbQRcF HAQ5 - xgrqTpvP2io PDFDocument6 pagesACFrOgALH7tI4bGAHoY RBTNzPHzMIyHy7FK3 - NLfBCnaIFG6 NJq3Ec8m HIQzGzsRrhL - EaKBKBfiHbz8J4GJN6MjbtxKXVhWqDR 2HbQRcF HAQ5 - xgrqTpvP2io PDFMurali MuthuNo ratings yet

- BFW Cooler Datasheet Rev-2Document3 pagesBFW Cooler Datasheet Rev-2Anonymous iCFJ73OMpDNo ratings yet

- Process Design Basis FOR Unit 06 - Diesel Hydrodesulphurization UnitDocument24 pagesProcess Design Basis FOR Unit 06 - Diesel Hydrodesulphurization Unitdhiaa mohammedNo ratings yet

- 8yetc DWG PR 1010 21 - Rev - B0 PDFDocument10 pages8yetc DWG PR 1010 21 - Rev - B0 PDFmohsin moinNo ratings yet

- SMP For Silica Hach 5500scDocument7 pagesSMP For Silica Hach 5500scPrince MaheshNo ratings yet

- Level Setting Diagrams: JOB No. 25635 25635-220-J6-0410-00001Document7 pagesLevel Setting Diagrams: JOB No. 25635 25635-220-J6-0410-00001Aldo QuispeNo ratings yet

- Utility Process Training - Basic: Karbala Refinery ProjectDocument32 pagesUtility Process Training - Basic: Karbala Refinery Projectdhiaa mohammedNo ratings yet

- IPS-MBD21907-In-529 - Datasheet of PH Transmitter - ADocument3 pagesIPS-MBD21907-In-529 - Datasheet of PH Transmitter - ANikhil KarkeraNo ratings yet

- SFCCL Reformer DCI R1Document38 pagesSFCCL Reformer DCI R1maheshNo ratings yet

- Line List: Bandar Abbas Gas Condensate Refinery ProjectDocument31 pagesLine List: Bandar Abbas Gas Condensate Refinery Projectmb_sirousNo ratings yet

- Ione VP 04 H 101 002 0Document299 pagesIone VP 04 H 101 002 0ضياء محمدNo ratings yet

- Unit 02 NHT Operator Training Material - 20210626 REV1Document72 pagesUnit 02 NHT Operator Training Material - 20210626 REV1ضياء محمدNo ratings yet

- National Oil Corporation: Rev Date Description Checked ApprovedDocument21 pagesNational Oil Corporation: Rev Date Description Checked ApprovedYousab JacobNo ratings yet

- RCH +D + +F+¡ (+ ) PDFDocument38 pagesRCH +D + +F+¡ (+ ) PDFSyamil DzulfidaNo ratings yet

- Instrument Process Datasheet Control Valves Section 100: Technologies TechnologiesDocument13 pagesInstrument Process Datasheet Control Valves Section 100: Technologies TechnologiesMohamedNo ratings yet

- VF006-IN-ILD-0002 - Instrument Loop Drawing - Rev.0Document197 pagesVF006-IN-ILD-0002 - Instrument Loop Drawing - Rev.0Phạm Tấn PhướcNo ratings yet

- Appendix 5 - Control and Alarm SetpointsDocument20 pagesAppendix 5 - Control and Alarm SetpointsCù Xuân HuyNo ratings yet

- DcrerweDocument1 pageDcrerwesri9987No ratings yet

- 1308-306-MEC-DTS-012 - Rev 1 - Vapour Return Blower - UpdateDocument9 pages1308-306-MEC-DTS-012 - Rev 1 - Vapour Return Blower - UpdateAyahKenzieNo ratings yet

- WPRK Pack Preparation PDFDocument42 pagesWPRK Pack Preparation PDFYusufNo ratings yet

- CompressorDocument33 pagesCompressorfvaefaNo ratings yet

- 769-E-1102 Propane Chiller - P2 PDFDocument8 pages769-E-1102 Propane Chiller - P2 PDFamit8808No ratings yet

- Orifice Plate DatasheetDocument29 pagesOrifice Plate DatasheetshayabajNo ratings yet

- Indra: Detail Pre-Commissioning Procedure For Service Test of Cooling Water For Unit 040/041/042/043Document62 pagesIndra: Detail Pre-Commissioning Procedure For Service Test of Cooling Water For Unit 040/041/042/043AnhTuấnPhanNo ratings yet

- Any Change Shall Be Submitted For Review.: Hindustan Urvarak and Rasayan Limited Barauni & SindriDocument6 pagesAny Change Shall Be Submitted For Review.: Hindustan Urvarak and Rasayan Limited Barauni & Sindrigudapati9No ratings yet

- Epcc-04 Package - Delayed Coker Unit (Dcu) With Unsaturated LPG Treating UnitDocument7 pagesEpcc-04 Package - Delayed Coker Unit (Dcu) With Unsaturated LPG Treating UnitKunalNo ratings yet

- 2093-FE-7903 Rev. CDocument34 pages2093-FE-7903 Rev. CAyush ChoudharyNo ratings yet

- 08572-Trht-Ms-Ppfm003-A06-001 - D General Arrangement Drawing Fire Water Storage TankDocument3 pages08572-Trht-Ms-Ppfm003-A06-001 - D General Arrangement Drawing Fire Water Storage TankSamer ArousNo ratings yet

- L2CM 410 58 DS 502 - RBDocument9 pagesL2CM 410 58 DS 502 - RBidilfitriNo ratings yet

- International Bechtel Co. LTDDocument6 pagesInternational Bechtel Co. LTDmostafaNo ratings yet

- Mecánica Data Sheet For Walnut Shell Filter Feed Pumps Tag P-222051 A/B - Stap - Pia LlanitoDocument5 pagesMecánica Data Sheet For Walnut Shell Filter Feed Pumps Tag P-222051 A/B - Stap - Pia LlanitoJavier Andres Barahona GarciaNo ratings yet

- Ione VP 02 H 001 069 - 1Document4 pagesIone VP 02 H 001 069 - 1ضياء محمدNo ratings yet

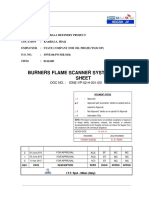

- Burners Flame Scanner System Data SheetDocument4 pagesBurners Flame Scanner System Data Sheetضياء محمدNo ratings yet

- MS Samsung Joint Multi Airconditioner PDFDocument2 pagesMS Samsung Joint Multi Airconditioner PDFMacSparesNo ratings yet

- HSVC1 PP4-QA, QC Equipment Status Report - 20190731Document21 pagesHSVC1 PP4-QA, QC Equipment Status Report - 20190731nkvonNo ratings yet

- CHAPTER 3 FINAL PAPER AirconDocument8 pagesCHAPTER 3 FINAL PAPER Airconjohanna faith israelNo ratings yet

- Gas Tightness TestDocument3 pagesGas Tightness TestRod Kenneth LubongNo ratings yet

- Calculator - Superheated Steam Table - TLVDocument2 pagesCalculator - Superheated Steam Table - TLVhej hejNo ratings yet

- QuizDocument4 pagesQuizsololexzibNo ratings yet

- Transport Phenomena 1Document20 pagesTransport Phenomena 1Kaify PeshmergaNo ratings yet

- Kerala Syllabus 9th Standard Physics Solutions Chapter 1 Forces in FluidsDocument21 pagesKerala Syllabus 9th Standard Physics Solutions Chapter 1 Forces in Fluidssajith kumar VariathNo ratings yet

- Flow Induced NoiseDocument40 pagesFlow Induced NoiseManouel Cem CebiogluNo ratings yet

- Edwards E2M28 E2M30 Maintenance Kit Parts ListDocument2 pagesEdwards E2M28 E2M30 Maintenance Kit Parts ListUmar MajeedNo ratings yet

- Biogas ProductionDocument19 pagesBiogas Productionkunal kashyapNo ratings yet

- Oxy Fuel Cut Chart Koike All 1Document12 pagesOxy Fuel Cut Chart Koike All 1Norden ConradNo ratings yet

- EEx Explosion ProofDocument4 pagesEEx Explosion ProofvbgiriNo ratings yet

- Product Catalogue: FLEXIM - Flexible Industrial MeasurementDocument24 pagesProduct Catalogue: FLEXIM - Flexible Industrial Measurementadh3ckNo ratings yet

- Cooling TowerDocument5 pagesCooling TowerfaisalnadimNo ratings yet

- Air Conditioning Fundamentals: ©2000 Caterpillar IncDocument13 pagesAir Conditioning Fundamentals: ©2000 Caterpillar IncAnonymous NtS775PYyNo ratings yet

- Advanced Separation-1Document44 pagesAdvanced Separation-1fekremariam AmbawNo ratings yet

- Steam Jet Refrigeration SystemDocument6 pagesSteam Jet Refrigeration SystembbaytlNo ratings yet

- 04BR05Document6 pages04BR05martiguada1No ratings yet

- Air Receiver TankDocument4 pagesAir Receiver TankHudaFiHayyatNo ratings yet