Professional Documents

Culture Documents

1-3 Drilling Fundamentals: 1-3.1 Equipment

Uploaded by

Mohamed Abozeima0 ratings0% found this document useful (0 votes)

53 views1 pageOriginal Title

PWC01F04

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

53 views1 page1-3 Drilling Fundamentals: 1-3.1 Equipment

Uploaded by

Mohamed AbozeimaCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

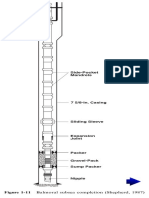

6 INTRODUCTION TO DRILLING AND WELL COMPLETIONS

1-3 DRILLING FUNDAMENTALS supposed to support 10,000 ft and, in some cases, as

much as 30,000 ft of drillpipe and additional equipment.

The basic principles and technology of drilling an oil or

A drill bit (Figure 1-4) is attached to the bottom of the

gas well are established and are described in texts

drillpipe by one or more drill collars. The entire assembly

(Bourgoyne et al., 1991; Mitchell, 1993; Gatlin, 1960).

ends at the floor of a drilling rig and is connected to a

The following is a brief overview of drilling fundamen-

rotary table. This table, along with a special joint called

tals.

the kelly, provides rotational motion to the drilling

assembly.

While rotary drilling has dominated the petroleum

1-3.1 Equipment

industry in the last 50 years, cable-tool drilling preceded

Drilling a petroleum well is a complex process that it and was the mainstay of early drilling. In some rare

requires large, heavy-duty equipment. A conventional cases, it is still used today. For cable-tool drilling, the

drilling rig consists first of a structure that can support drilling assembly is suspended from a wire rope. The

several hundred tons. A ‘‘million-pound’’ rig is routinely assembly is then reciprocated, striking blows to the for-

Crown Block

Derrick

Engines

Traveling Block

Mud Mud Pits

Pumps

Kelly

Rotary

Table

Drillpipe

Drill Bit

Figure 1-4 Rotary drilling rig with the important components

You might also like

- How to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheFrom EverandHow to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheRating: 4.5 out of 5 stars4.5/5 (2)

- Basic Knowledge of Blasthole Drill (Guide Book)Document44 pagesBasic Knowledge of Blasthole Drill (Guide Book)Hakim Ammor100% (1)

- Introduction of Drilling Rig in Oil & Gas Indutry - WikipediaDocument12 pagesIntroduction of Drilling Rig in Oil & Gas Indutry - WikipediaFaiz AhmadNo ratings yet

- Coiled TubingDocument26 pagesCoiled TubingSuleiman BaruniNo ratings yet

- Hole Cleaning-Total Best PracticesDocument13 pagesHole Cleaning-Total Best PracticesMohamed AbozeimaNo ratings yet

- Lec 2 Intro To Drilling EngineeringDocument28 pagesLec 2 Intro To Drilling EngineeringRanaBarzamArshad100% (1)

- BJ Coiled Tubing Equipment Manual Version 1Document90 pagesBJ Coiled Tubing Equipment Manual Version 1Franklyn Frank95% (39)

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!From EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Rating: 5 out of 5 stars5/5 (2)

- Steam Turbines A Book of Instruction for the Adjustment and Operation of the Principal Types of this Class of Prime MoversFrom EverandSteam Turbines A Book of Instruction for the Adjustment and Operation of the Principal Types of this Class of Prime MoversRating: 5 out of 5 stars5/5 (2)

- Basic Drilling EngineeringDocument26 pagesBasic Drilling Engineeringgfaux03No ratings yet

- Mechanical (Turbines and Auxiliary Equipment): Second Revised and Enlarged EditionFrom EverandMechanical (Turbines and Auxiliary Equipment): Second Revised and Enlarged EditionA. SherryRating: 4 out of 5 stars4/5 (5)

- Concrete For Water StructureDocument22 pagesConcrete For Water StructureIntan MadiaaNo ratings yet

- Well Completion CourseDocument70 pagesWell Completion Courseazze bouz100% (1)

- Drilling and Technology4Document11 pagesDrilling and Technology4Aryan el-BerwarîNo ratings yet

- Chapter (4) Drilling Methods and Type of RigsDocument26 pagesChapter (4) Drilling Methods and Type of RigsFarhat Mirza100% (1)

- IS-2800 - 1 Construction of TubewellDocument14 pagesIS-2800 - 1 Construction of TubewellRam Balak Roy100% (2)

- Lecture 3 - Drilling Methods and Process-1Document34 pagesLecture 3 - Drilling Methods and Process-1hasan sabah100% (2)

- Moor 1994 Cane ShreddingDocument4 pagesMoor 1994 Cane Shreddingamarnath jagirdar100% (1)

- Drilling and Technology3Document12 pagesDrilling and Technology3Aryan el-BerwarîNo ratings yet

- Basic Drilling EngineeringDocument26 pagesBasic Drilling EngineeringbhuvanchaudhariNo ratings yet

- Kinetic Energy Storage: Theory and Practice of Advanced Flywheel SystemsFrom EverandKinetic Energy Storage: Theory and Practice of Advanced Flywheel SystemsRating: 3 out of 5 stars3/5 (1)

- Drilling PreliminariesDocument141 pagesDrilling PreliminariesMohammed Safuvan Kazhungil100% (1)

- Soft Torque System (Paper) - OME Paper 112Document18 pagesSoft Torque System (Paper) - OME Paper 112Odion Ikhajiagbe100% (1)

- Basic Drilling EngineeringDocument26 pagesBasic Drilling EngineeringAhmedsharifMohammedNo ratings yet

- QuizDocument11 pagesQuizDanica RamosNo ratings yet

- Drilling Rig: From Wikipedia, The Free EncyclopediaDocument13 pagesDrilling Rig: From Wikipedia, The Free EncyclopediaSoham DeNo ratings yet

- Study Material of Fe &WLDocument103 pagesStudy Material of Fe &WLSoundar SamuelNo ratings yet

- Drilling and Technology2Document12 pagesDrilling and Technology2Aryan el-BerwarîNo ratings yet

- Surface Components: Above Rig FloorDocument26 pagesSurface Components: Above Rig FloorInternational Certification100% (1)

- Pile Driving OperationsDocument33 pagesPile Driving OperationsSid Khan100% (1)

- Drilling and Technology10Document12 pagesDrilling and Technology10Aryan el-BerwarîNo ratings yet

- Lec 2 Intro To Drilling EngineeringDocument28 pagesLec 2 Intro To Drilling EngineeringNoumanIhsanNo ratings yet

- Pile InstallationDocument18 pagesPile InstallationAmal AmranNo ratings yet

- Drilling and Technology1Document12 pagesDrilling and Technology1Aryan el-BerwarîNo ratings yet

- CBIP - Tunnel Manual PDFDocument124 pagesCBIP - Tunnel Manual PDFRanjithkumar SNo ratings yet

- Drilling and Technology9Document12 pagesDrilling and Technology9Aryan el-BerwarîNo ratings yet

- Rehabilitation and Retrofitting of Structurs Question PapersDocument4 pagesRehabilitation and Retrofitting of Structurs Question PapersYaswanthGorantlaNo ratings yet

- Chapter 7 Pulverisers PlantDocument11 pagesChapter 7 Pulverisers PlantBineet Kumar VarmaNo ratings yet

- The Design of Piled Foundations: Structures and Solid Body MechanicsFrom EverandThe Design of Piled Foundations: Structures and Solid Body MechanicsRating: 4 out of 5 stars4/5 (8)

- Petrostrategies, Inc.: 1. 2. 3. 4. 5. 6. Classes 7. ReferencesDocument3 pagesPetrostrategies, Inc.: 1. 2. 3. 4. 5. 6. Classes 7. ReferencespanthaloorNo ratings yet

- Drilling RotDocument5 pagesDrilling RotHELPPPPPNo ratings yet

- Boreholes Water Wells Natural GasDocument17 pagesBoreholes Water Wells Natural Gasjk.epro2762No ratings yet

- Rotary SystemDocument9 pagesRotary SystemHomam MohammadNo ratings yet

- Subject: ScientificDocument5 pagesSubject: ScientificHomam MohammadNo ratings yet

- 03 PDFDocument45 pages03 PDFBrijesh MishraNo ratings yet

- Halco A Z of Drilling ReducedDocument41 pagesHalco A Z of Drilling ReducedDiego Ignacio VelizNo ratings yet

- DRLG 6035pDocument24 pagesDRLG 6035pJorge Jiménez100% (2)

- An Overview On The Modeling of Oilwell Drilling VibrationsDocument6 pagesAn Overview On The Modeling of Oilwell Drilling Vibrationssobhan mohammadiNo ratings yet

- Introduction To DrillingDocument68 pagesIntroduction To DrillingJugurta GoudjilNo ratings yet

- Unit Operations in MiningDocument10 pagesUnit Operations in MiningNaveenNo ratings yet

- Reliance Drilling PDFDocument55 pagesReliance Drilling PDFsambhajiNo ratings yet

- Power and RotaryDocument15 pagesPower and RotaryMU TENo ratings yet

- Chapter 2Document44 pagesChapter 2Yash GandhiNo ratings yet

- Drilling and Technology5Document11 pagesDrilling and Technology5Aryan el-BerwarîNo ratings yet

- Tunnelling Induced Ground Movements and Their EffectsDocument62 pagesTunnelling Induced Ground Movements and Their Effectskksamy2007No ratings yet

- 1.underground Mining Methods and EquipmentDocument18 pages1.underground Mining Methods and EquipmentMihaelaCeciliaNo ratings yet

- Oil Field Familiarization: Rig Types & Their ComponentsDocument15 pagesOil Field Familiarization: Rig Types & Their ComponentsObakoma JosiahNo ratings yet

- Oil Field EquipementDocument55 pagesOil Field Equipementعبدالحميد العرفيNo ratings yet

- Chapter-1 Introduction To Well PlanningDocument33 pagesChapter-1 Introduction To Well Planningsparda94No ratings yet

- Assignment SubsurfaceDocument10 pagesAssignment SubsurfaceLeo NgoulouNo ratings yet

- Appendix F - Construction of Pile Foundation - BNBC 2020 CommentaryDocument12 pagesAppendix F - Construction of Pile Foundation - BNBC 2020 CommentaryTarif Aziz MarufNo ratings yet

- Unit Operation of MiningDocument29 pagesUnit Operation of MiningKevin Casanova MartínezNo ratings yet

- Petroleum Well Construction PWC02F01Document1 pagePetroleum Well Construction PWC02F01Mohamed AbozeimaNo ratings yet

- Petroleum Well Construction WC01F11Document1 pagePetroleum Well Construction WC01F11Mohamed AbozeimaNo ratings yet

- Petroleum Well Construction PWC02F03Document1 pagePetroleum Well Construction PWC02F03Mohamed AbozeimaNo ratings yet

- PWC01F05Document1 pagePWC01F05Mohamed AbozeimaNo ratings yet

- PWC01F06Document1 pagePWC01F06Mohamed AbozeimaNo ratings yet

- PrefaceDocument1 pagePrefaceMohamed AbozeimaNo ratings yet

- PWC01F07Document1 pagePWC01F07Mohamed AbozeimaNo ratings yet

- RMS 3000 Rotary-Mounted Slips and Elevator: ApplicationsDocument1 pageRMS 3000 Rotary-Mounted Slips and Elevator: ApplicationsMohamed AbozeimaNo ratings yet

- Flush-Joint Elevator: Runs Flush-Joint Pipe Without The Need To Use Threaded Lift NubbinsDocument1 pageFlush-Joint Elevator: Runs Flush-Joint Pipe Without The Need To Use Threaded Lift NubbinsMohamed AbozeimaNo ratings yet

- Petroleum Well Construction - ContribDocument1 pagePetroleum Well Construction - ContribMohamed AbozeimaNo ratings yet

- Low Profile Spider Elevator 400 PDFDocument2 pagesLow Profile Spider Elevator 400 PDFMohamed AbozeimaNo ratings yet

- Cleaning and Dressing PBR PDFDocument5 pagesCleaning and Dressing PBR PDFMohamed AbozeimaNo ratings yet

- Drilling 12 1.4 in HoleDocument1 pageDrilling 12 1.4 in HoleMohamed AbozeimaNo ratings yet

- General Hints / Tips Emergency Action Recipes .. Blowout - Barite PlugDocument2 pagesGeneral Hints / Tips Emergency Action Recipes .. Blowout - Barite PlugMohamed AbozeimaNo ratings yet

- NBR-575 Operation Game Plan HRDH-1201 Running 4 '' Completion Nov 18, 2014 To: RM/NTP, DR, Ad, Me, Baker Eng, Franks. Al-Mansori S/LDocument2 pagesNBR-575 Operation Game Plan HRDH-1201 Running 4 '' Completion Nov 18, 2014 To: RM/NTP, DR, Ad, Me, Baker Eng, Franks. Al-Mansori S/LMohamed Abozeima100% (1)

- GAME PLAN Retrieve Whipstock Mill BPDocument1 pageGAME PLAN Retrieve Whipstock Mill BPMohamed AbozeimaNo ratings yet

- GAME PLAN RTTS RBP Wellhead WorkDocument1 pageGAME PLAN RTTS RBP Wellhead WorkMohamed AbozeimaNo ratings yet

- Decision Tree For EWL FishingDocument1 pageDecision Tree For EWL FishingMohamed AbozeimaNo ratings yet

- Cleaning Plan: Any Question Ask Mud Engineers (24hours) Mohamed Attwa&ahmedDocument1 pageCleaning Plan: Any Question Ask Mud Engineers (24hours) Mohamed Attwa&ahmedMohamed AbozeimaNo ratings yet

- Prevalence of Peptic Ulcer in Patients Attending Kampala International University Teaching Hospital in Ishaka Bushenyi Municipality, UgandaDocument10 pagesPrevalence of Peptic Ulcer in Patients Attending Kampala International University Teaching Hospital in Ishaka Bushenyi Municipality, UgandaKIU PUBLICATION AND EXTENSIONNo ratings yet

- Validation of AnalyticalDocument307 pagesValidation of AnalyticalJagdish ChanderNo ratings yet

- Fracture and FatigueDocument15 pagesFracture and FatigueZou JiaweiNo ratings yet

- Supreme Court of The United StatesDocument296 pagesSupreme Court of The United StatesABC News PoliticsNo ratings yet

- The Finley ReportDocument46 pagesThe Finley ReportToronto StarNo ratings yet

- Circuitos Digitales III: #IncludeDocument2 pagesCircuitos Digitales III: #IncludeCristiamNo ratings yet

- Switch CondenserDocument14 pagesSwitch CondenserKader GüngörNo ratings yet

- Allplan 2006 Engineering Tutorial PDFDocument374 pagesAllplan 2006 Engineering Tutorial PDFEvelin EsthefaniaNo ratings yet

- La Salle Lipa Integrated School Senior High School Community 1 Quarter Summative Assessment Earth Science AY 2021-2022 Household Conservation PlanDocument4 pagesLa Salle Lipa Integrated School Senior High School Community 1 Quarter Summative Assessment Earth Science AY 2021-2022 Household Conservation PlanKarlle ObviarNo ratings yet

- Epenisa 2Document9 pagesEpenisa 2api-316852165100% (1)

- Czech Republic GAAPDocument25 pagesCzech Republic GAAPFin Cassie Lazy100% (1)

- Ver Notewin 10Document5 pagesVer Notewin 10Aditya SinghNo ratings yet

- Historical DocumentsDocument82 pagesHistorical Documentsmanavjha29No ratings yet

- PanasonicDocument35 pagesPanasonicAsif Shaikh0% (1)

- Unit 13 - Business Hotels and Sales ConferencesDocument24 pagesUnit 13 - Business Hotels and Sales ConferencesMiguel Angel Escoto CanoNo ratings yet

- Sealant Solutions: Nitoseal Thioflex FlamexDocument16 pagesSealant Solutions: Nitoseal Thioflex FlamexBhagwat PatilNo ratings yet

- Lenskart SheetDocument1 pageLenskart SheetThink School libraryNo ratings yet

- Automatic Stair Climbing Wheelchair: Professional Trends in Industrial and Systems Engineering (PTISE)Document7 pagesAutomatic Stair Climbing Wheelchair: Professional Trends in Industrial and Systems Engineering (PTISE)Abdelrahman MahmoudNo ratings yet

- Sworn Statement of Assets, Liabilities and Net WorthDocument3 pagesSworn Statement of Assets, Liabilities and Net WorthShelby AntonioNo ratings yet

- Kicks: This Brochure Reflects The Product Information For The 2020 Kicks. 2021 Kicks Brochure Coming SoonDocument8 pagesKicks: This Brochure Reflects The Product Information For The 2020 Kicks. 2021 Kicks Brochure Coming SoonYudyChenNo ratings yet

- AutoCAD Dinamicki Blokovi Tutorijal PDFDocument18 pagesAutoCAD Dinamicki Blokovi Tutorijal PDFMilan JovicicNo ratings yet

- Chat Application (Collg Report)Document31 pagesChat Application (Collg Report)Kartik WadehraNo ratings yet

- BMT6138 Advanced Selling and Negotiation Skills: Digital Assignment-1Document9 pagesBMT6138 Advanced Selling and Negotiation Skills: Digital Assignment-1Siva MohanNo ratings yet

- Icom IC F5021 F6021 ManualDocument24 pagesIcom IC F5021 F6021 ManualAyam ZebossNo ratings yet

- A Religious LeadershipDocument232 pagesA Religious LeadershipBonganiNo ratings yet

- PovidoneDocument2 pagesPovidoneElizabeth WalshNo ratings yet

- Aman 5Document1 pageAman 5HamidNo ratings yet