Professional Documents

Culture Documents

Cable Anchors: 11.1 GENERAL

Uploaded by

அம்ரு சாந்திவேலு0 ratings0% found this document useful (0 votes)

17 views1 pageOriginal Title

71_4649_00_104_P1

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

17 views1 pageCable Anchors: 11.1 GENERAL

Uploaded by

அம்ரு சாந்திவேலுCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

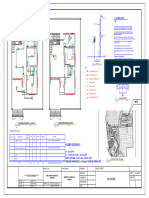

Login: Pandey, Deepak, Date: 8/31/2021 9:50:04 AM

N:\Working Drawings\4649_Pinnapuram IREP\Drawing Final\00-General\71_4649_00_104_P1.dwg

CABLE ANCHORS (4) DRILLING OF THE HOLES SHALL CONFORM TO THE LEAST OF THE FOLLOWING TOLERANCES:

(a) INITIAL ALIGNMENT WHEN SETTING UP THE DRILLING RIG SHALL NOT DEVIATE BY MORE THAN 2°

(d) THE SPACE BETWEEN THE WIRES / STRANDS AND THE PE PIPE SHALL BE FILLED WITH NEAT

CEMENT GROUT AFTER STRESSING AND RE-STRESSING HAS BEEN COMPLETED AND THE ANCHOR

(6) THE CONTRACTOR SHALL RECORD AND COMPARE, JOINTLY WITH THE ENGINEER, WITH THE

ACCEPTANCE CRITERIA ALL THE IMPORTANT CONDITIONS AND OBSERVATIONS DURING THE

HAS BEEN ACCEPTED BY THE ENGINEER.

11.1 GENERAL FROM THE SPECIFIED AXIS OF HE DRILL HOLE. STRESSING PROCEDURE, THE LOADS APPLIED AND THE ELONGATION OF THE TENDON WITH EACH

(3) PROPERTIES AND QUALITY OF THE EPOXY FORMULATION TO BE USED FOR TREATMENT OF FREE

(b) DEVIATION OF THE HOLE DURING DRILLING SHALL BE LIMITED TO 1/30 OF THE OVERALL HOLE LOAD INCREMENT. THE VALUES MEASURED DURING THE SIMPLE AND COMPREHENSIVE-STRESSING

(i) CABLE ANCHORS ARE TENSIONED REINFORCING ELEMENTS OF HIGHER CAPACITY THAN THE AND FIXED LENGTHS OF THE ANCHORS SHALL BE APPROVED BY THE ENGINEER BEFORE ITS USE.

LENGTH. TESTS SHALL BE PLOTTED AND ALL RECORDS AND GRAPHS SUBMITTED TO THE ENGINEER.

OTHER REINFORCING ELEMENTS, CONSISTING OF HIGH STRENGTH STEEL TENDON FITTED WITH A

STRESSING ANCHORAGE (FIXED LENGTH) AT THE INNER END, AND A MEANS FOR TRANSFERRING (4) THE FOLLOWING SHALL BE ADOPTED FOR PROTECTING THE ANCHOR HEAD AGAINST CORROSION:

(5) CORE DRILLING SHALL BE PERFORMED FOR EXPLORATORY PURPOSES WHERE REQUIRED BY THE

(7) THE TEST LOAD TO WHICH CABLE ANCHORS SHALL BE SUBJECTED DURING VARIOUS TESTS SHALL BE

FORCE TO THE ROCK SURFACE AT THE OUTER END. ENGINEER, AND CORES SHALL BE STORED IN SUITABLE CORE BOXES AND KEPT IN A SECURE (e) THE BEARING PLATE OF ALL CABLE ANCHORS, STRESSED ACCORDING TO THE PROCEDURE

PLACE. DESCRIBED UNDER THE HEADING “STRESSING OF CABLE ANCHORS AND ACCEPTANCE TESTS”, 80 % OF THE GUARANTEED ULTIMATE TENSILE STRENGTH (GUTS) OF THE TENDON, IF NOT

(ii) INSTALLATION OF POST TENSIONED CABLE ANCHORS INCLUDES EXCAVATION FOR CONCRETE

BASES, PLACING OF SHOTCRETE , DRILLING AND TESTING OF HOLES, FURNISHING OF CABLE SHALL BE PAINTED WITH PRIMER PAINT. THIS MATERIAL CONFORMING TO THE RELEVANT INDIAN OTHERWISE SPECIFIED BY THE ENGINEER. LOCK OFF LOAD SHALL BE 60 % OF GUTS OF THE

(6) THE SEQUENCE (METHOD STATEMENT) OF DRILLING OF HOLES SHALL BE APPROVED BY THE

ANCHORS WITH ALL ACCESSORIES, LOAD CELLS, PERMANENT CORROSION PROTECTION OF ALL STANDARDS SHALL BE APPROVED BY THE ENGINEER. TENDON, IF NOT OTHERWISE SPECIFIED BY THE ENGINEER.

ENGINEER BEFORE STARTING THE WORK.

ELEMENTS OF THE CABLE ANCHOR, ANCHORING THE SAME TO PRECAST BLOCK/PEDESTAL, (f) CORROSION PROTECTION OF THE HEADS OF CABLE ANCHORS WHICH HAVE BEEN ACCEPTED BY

PRIMARY GROUTING, STRESSING, TESTING, RE-STRESSING, SECONDARY GROUTING AND FINISHING, (7) DURING THE DRILLING OPERATIONS, ALL CHANGES IN ROCK TYPE SHOULD BE RECORDED (8) STRESSING SHALL BE MADE, BY APPLYING A SINGLE JACK TO ALL STRANDS / WIRES. JACK SHALL

THE ENGINEER SHALL BE AS FOLLOWS:

AND ALL OTHER AUXILIARY AND SUPPORTING WORKS. TOGETHER WITH NOTES ON DRILLING RATES, FLUSHING LOSSES OR GAINS, AND STOPPAGES. BE ACTUATED BY A HYDRAULIC PACK. DURING STRESSING OPERATIONS ALL WIRES/STRANDS OF A

(i) A MIN. 3mm THICK STEEL CAP CONTAINING THE UPPER GROUT VENT PIPE (STAGE I AND STAGE II)

(iii) THE ANCHOR MATERIALS AND PARTS, TENSIONING, INSTALLATION AND GROUTING PROCEDURE (8) AFTER COMPLETION OF THE DRILLING IN ROCK, THE ENTIRE LENGTH OF THE HOLE SHALL BE TENDON SHALL BE STRESSED SIMULTANEOUSLY.

AND A LOWER INJECTION PIPE SHALL BE PROVIDED TO PROTECT THE HEAD,

SHALL CONFORM TO THE APPLICABLE INDIAN STANDARDS (IS 10270), OR WHERE NOT COVERED BY WASHED OUT WITH CLEAN WATER, AS APPROVED BY THE ENGINEER.

THE STANDARDS, TO THE RELEVANT INTERNATIONAL STANDARDS AND SHALL BE APPROVED BY (ii) THE SIZE OF THE CAP SHALL BE SUCH THAT IT SHALL HAVE A MINIMUM CLEARANCE OF 50 MM (9) THE MEASURING EQUIPMENT SHALL BE ABLE TO MEASURE DISPLACEMENT OF 0.01 MM WHEN CREEP

(9) EACH DRILL HOLE IN ROCK SHALL BE CHECKED FOR WATER TIGHTNESS BY MEANS OF WATER

THE ENGINEER BEFORE INCORPORATING INTO THE WORK. FROM THE HEAD MECHANISM, IS BEING MEASURED.

PRESSURE TESTS BEFORE THE ANCHOR IS INSTALLED. AFTER DRILLING AFTER DRILL HOLE

(iv) THE ENTIRE WORK OF DRILLING AND GROUTING OF DRILL HOLES FOR CABLE ANCHORS; COMPLITION, TESTS SHALL BE CARRIED OUT ON A LENGTH EQUAL TO FIXED LENGTH PLUS 2 M (iii) THE STEEL PROTECTION CAP SHALL BE WELDED TO THE BEARING PLATE AFTER PROVIDING (10) THE MEASUREMENT OF LOADS IN CABLE ANCHORS SHALL BE BY HYDRAULIC OR ELECTRICAL LOAD

FABRICATION, INSTALLATION AND TESTING SHALL BE CARRIED OUT UNDER THE GUIDANCE AND AND IF WATER LOSS IS FOUND TO BE MORE THAN 3 LUGEON, CONSOLIDATION GROUTING SUITABLE GASKET,

MEASURING DEVICE ABLE TO MEASURE TO AN ACCURACY OF BETTER THAN 2 % OF THE MAXIMUM

SUPERVISION OF QUALIFIED PROFESSIONALS EXPERIENCED IN THIS SPECIFIC FIELD, AND UNDER THROUGH THE HOLE SHALL BE CARRIED OUT. AFTER SUCCESSFUL GROUTING WORKS THE HOLE

(iv) AFTER THE STEEL PROTECTION CAP HAS BEEN WELDED TO THE BEARING PLATE, THE CEMENT APPLIED LOAD DURING EACH TEST. ANY LOAD-MEASURING DEVICE USED FOR LOAD LOSS TESTS

STRICT QUALITY CONTROL. SHALL BE REDRILLED, WATER TEST REPEATED AND THE WHOLE PROCEDURE REPEATED TILL A

GROUT SHALL BE FILLED IN THROUGH LOWER INJECTION PIPE TO FILL COMPLETELY THE INNER

LUGEON VALUE OF LESS THAN 3 IS OBTAINED. THE CONTRACTOR SHALL MAKE A COMPLETE SHALL BE ABLE TO MEASURE LOADS TO 0.5 % OF THE MAXIMUM APPLIED LOAD.

11.2 DEFINITIONS RECORD OF THE WATER-PRESSURE TESTING. THIS PROCEDURE IS SUBJECTED TO APPROVAL BY

SIDE WITH CEMENT GROUT, CEMENT GROUT SHALL BE OF THE SAME MIX AS USED FOR GROUTING

THE FIXED AND FREE ANCHOR LENGTH, (11) ALL ACCEPTANCE TESTS SHALL BE CARRIED OUT IN THE PRESENCE OF THE ENGINEER. CABLE

THE FOLLOWING TERMS ARE USED IN THE TEXT TO CONFORM WITH THE INTERNATIONAL STANDARDS: THE ENGINEER.

(v) THE SUITABILITY CAPS APPROVED BY THE ENGINEER FOR BOTH THE INJECTION PIPE AND VENT ANCHORS WHICH DO NOT FULFILS THE ACCEPTANCE CRITERIA WILL BE REJECTED BY THE ENGINEER

LOCK-OFF LOAD IS THE LOAD TRANSFERRED TO THE HEAD IMMEDIATELY AFTER LOCK-OFF, BEFORE (10) THE DRILL HOLE SHALL ALSO BE GROUTED AND REDRILLED IF GROUNDWATER IS ENTERING THE

PIPE SHALL BE PROVIDED, AND REPLACED BY THE CONTRACTOR.

LONG-TERM LOSSES START TO OCCUR. DRILL HOLE, OR IF DURING EXECUTION OF THE WATER PRESSURE TESTS WATER ENTRY INTO

NEIGHBOURING DRILL HOLES IS OBSERVED. (vi) TWO COATS OF SUITABLE ANTI CORROSION PAINT, APPROVED BY THE ENGINEER SHALL BE

PROOF LOAD IS THE MAXIMUM TEST LOAD TO WHICH THE CABLE ANCHOR IS SUBJECTED. (12) AFTER THE CABLE ANCHOR HAS BEEN TENSIONED, THE STRESSING SHALL NOT BE RELAXED FOR

APPLIED TO ALL EXPOSED STEEL AFTER THE STEEL CAP HAS BEEN WELDED TO THE BEARING

(11) CONSOLIDATION GROUTING SHALL BE CARRIED OUT WITH NEAT CEMENT AND WATER GROUT. ANY PURPOSE, UNLESS DIRECTED BY THE ENGINEER.

DATUM LOAD IS THE LEVEL OF LOAD FROM WHICH THE CABLE ANCHOR HEAD DISPLACEMENT IS PLATE.

ADMIXTURES, IF REQUIRED, FOR IMPROVING WORKABILITY AND/OR DURABILITY, TO REDUCE

MEASURED DURING A STRESS TEST. IN GENERAL, A VALUE OF 10 % TEST LOAD IS ADOPTED.

BLEEDING OR SHRINKAGE OR INCREASING RATE OF STRENGTH DEVELOPMENT AND TO ENSURE

SUITABILITY TEST IS A LOAD TEST TO CONFIRM THAT A PARTICULAR CABLE ANCHOR DESIGN WILL BE SMOOTH FLOW PROPERTIES AND COMPACTNESS OF THE GROUT, SHALL BE TESTED AND HAVE 11.7 INSTALLATION AND CABLE ANCHOR GROUTING

ADEQUATE IN PARTICULAR GROUND CONDITIONS. TO BE APPROVED BY THE ENGINEER PRIOR TO THEIR USE.

(1) A REINFORCED CONCRETE PAD SHALL BE CONSTRUCTED ON THE PREPARED EXCAVATED

11.9 MONITORING

ACCEPTANCE TEST IS THE LOAD TEST TO CONFIRM THAT THE CABLE ANCHOR CONFORMS TO THE (12) UPON COMPLETION, THE DRILL HOLE SHALL BE TIGHTLY PLUGGED IN SUITABLE MANNER TO GROUND IN ACCORDANCE WITH PROVISION OF THE SECTION “CONCRETE”. CONCRETE SHALL BE

ACCEPTANCE CRITERIA. EACH WORKING CABLE ANCHOR WILL UNDERGO THE ACCEPTANCE TEST. PREVENT CONTAMINATION BY FOREIGN MATTER. THE HOLE SHALL BE WASHED CLEAN PRIOR TO OF CLASS M20/A40. HIGH EARLY STRENGTH CEMENT MAY BE USED. CALCIUM CHLORIDE OR

INSERTING THE CABLE ANCHOR. IN LOOSE MATERIAL CASING SHALL SUPPORT THE WALLS OF (1) ALL CABLE ANCHORS, WHICH HAVE BEEN STRESSED ACCORDING TO THE ACCEPTANCE TEST

ADMIXTURE CONTAINING IT SHALL NOT BE USED. NO STRESSING OF THE CABLE ANCHOR SHALL BE

11.3 SUITABILITY TESTS THE DRILL HOLE UNTIL THE CABLE ANCHOR HAS BEEN INSTALLED. IN EARTH OR ROCK LIABLE TO PERFORMED UNTIL THE CUBE COMPRESSIBLE STRENGTH OF THE BASE CONCRETE HAS REACHED (SIMPLE STRESSING TEST) SHALL BE LOAD CHECKED BY LIFT OFF TEST IMMEDIATELY AFTER

SWELL THE CABLE ANCHOR SHALL BE INSTALLED AND GROUTED IMMEDIATELY. 2

(1) SUITABILITY TESTS FOR CABLE ANCHORS (FOR TEST CABLE ANCHORS) WILL BE CARRIED OUT IN 20N/MM . STRESSING AND AGAIN 3-5 DAYS LATER. CABLE ANCHOR SHALL BE ACCEPTED ONLY IF THE RESIDUAL

ACCORDANCE WITH THE REQUIREMENTS OF THE RELEVANT INDIAN STANDARDS AND WHERE NOT (13) ANY HOLE THAT BECOMES CLOGGED OR OTHERWISE OBSTRUCTED BEFORE THE COMPLETION (2) THE CABLE ANCHOR / TENDON SHALL BE SLOWLY INSERTED INTO THE HOLE IN SUCH A MANNER AS CABLE ANCHOR LOAD IS MORE THAN 98 % OF THE LOCK-OFF LOAD, IF THE LOSS IS MORE THE CABLE

COVERED BY THESE STANDARDS TO THE APPLICABLE INTERNATIONAL STANDARDS OR AS OF CABLE ANCHORING OPERATION SHALL BE CLEANED OR REDRILLED. IF NOT POSSIBLE TO PREVENT DAMAGE AND TANGLING OF THE INDIVIDUAL WIRES / STRANDS. AT THE BOTTOM OF ANCHOR WILL BE RESTRESSED AND AN ADDITIONAL LOAD CHECK SHALL BE PERFORMED AGAIN

DIRECTED BY THE ENGINEER IN ORDER TO FIND OUT SUITABLE PROCEDURE FOR DRILL HOLE ANOTHER HOLE SHALL BE PROVIDED BY THE CONTRACTOR. THE TENDON SLEEVE OR NOSE CONE SHALL BE USED OF TENDON OR BOREHOLE DAMAGE

ROCK TREATMENT PRIOR TO CABLE ANCHOR INSTALLATION AND TO DETERMINE THE FOLLOWING: AFTER 3-5 DAYS.

DURING HOMING. SPECIAL CARE SHALL BE TAKEN TO ENSURE THAT CORROSION PROTECTION

(ii) TO ASCERTAIN EXTERNAL CABLE ANCHOR RESISTANCE IN THE ACTUAL GROUND CONDITIONS, IN

11.5 MATERIAL (EPOXY COATING) REMAINS UNDAMAGED DURING INSERTION INTO THE HOLE. (2) ALL CABLE ANCHORS, WHICH WILL BE TESTED ACCORDING TO THE COMPREHENSIVE STRESSING

PARTICULAR BOND BETWEEN GROUT AND ROCK. (1) THE TENDON (DESIGN LOAD REF. TO DRAWING) SHALL BE COMPOSED OF 12 TENSILE STRENGTH (3) AFTER BEING INSERTED, THE CABLE ANCHOR SHALL BE FIXED IN POSITION SO THAT NO TEST SHALL BE SHORT TERM MONITORED DURING THE TIME OF INSTALLATION OF THE WORKING

STEEL WIRE STRANDS (DIA 15.7mm) AS ALSO USED IN PRESTRESSED CONCRETE, AND DISPLACEMENT CAN OCCUR DURING THE GROUTING WORK. THE TENDON SHALL BE CENTERED IN

(iii) TO DERIVE THE OPTIMUM BOND LENGTH AND VERIFY THE ADEQUACY OF THE FIXED LENGTH OF CABLE ANCHORS BY MEANS OF MEASURING THE RESIDUAL LOAD WITH A HYDRAULIC LOAD CELL SO

CONFORMING TO IS 6003 OR IS 6006, RESPECTIVELY. WIRES / STRANDS WHICH DO NOT CONFORM THE HOLE BY SPACERS SO THAT ADEQUATE COVERING WITH THE GROUTING MATERIAL IS

CABLE ANCHORS AS SPECIFIED IN THE RELEVANT DRAWINGS IN RELATION TO THEIR WORKING AS TO ENSURE THAT THE RESIDUAL CABLE ANCHOR LOAD IS MORE THAN 98 % OF THE LOCK OFF

TO IS 6003 OR TO IS 6006 WILL BE REJECTED BY THE ENGINEER. ENSURED AS SHOWN RELEVANT DRAWINGS AND DIRECTED BY THE ENGINEER.

CAPACITIES, GROUND CONDITIONS AND LOCATIONS SO AS TO ENSURE A MINIMUM FACTOR OF

(2) THE WIRES / STRANDS SHALL BE CONTINUOUS WITHOUT SPLICES OR COUPLERS AND SHALL BE LOAD. IF THE LOSS IS MORE, THE CABLE ANCHORS SHALL BE RE-STRESSED AS DESCRIBED. THE

SAFETY EQUAL OR BIGGER THAN THAT OF THE TENDONS, AS SPECIFIED BY THE MANUFACTURER. (4) IMMEDIATELY FOLLOWING INSTALLATION OF THE CABLE ANCHOR INTO THE HOLE, THE PRIMARY

FREE OF DIRT, OIL, RUST AND WITHOUT MECHANICAL DAMAGE. STRANDS SHALL BE DELIVERED IN GROUTING OF THE ANCHORAGE ZONE AND OUTSIDE OF SHEATHING SHALL BE CARRIED OUT. THE MEASURING INTERVALS AS PER INTERNATIONAL PRACTICE SHALL BE AS FOLLOWS:

(iv) TO CHECK THE ADEQUACY OF THE FORESEEN WORKING PROCEDURES (DRILLING, CONSOLIDATION

COILS OF AT LEAST 1.50 M IN DIAMETER, PROPERLY PROTECTED AGAINST ABRASION AND GROUTING EQUIPMENT MUST PERMIT GROUT PRESSURE UP TO 20 BARS. FIRST WEEK AFTER STRESSING DAILY

GROUTING AND ROCK REINFORCING WORK) AND DESIGN DETAILS OF WORKING CABLE ANCHORS.

CORROSION BY A FACTORY APPLIED METHOD. RD

(v) TO DETERMINE THE APPARENT TENDON FREE LENGTH. (5) GROUT MIXTURE, USE OF ADMIXTURES, MIXING, GROUTING PRESSURE AND GROUTING UP TO 3 WEEK AFTER STRESSING EACH 3 DAY

(3) THE HEAD ASSEMBLY SHALL ALLOW THE TENDON TO BE STRESSED, TEST LOADED AND LOCKED EQUIPMENT SHALL BE SUBJECT TO APPROVAL BY THE ENGINEER BEFORE ANY ANCHOR UP TO 6 WEEK AFTER STRESSING WEEKLY

(vi) TO ESTABLISH ACCEPTANCE CRITERIA INCLUDING CREEP CRITERIA FOR TESTING OF WORKING OFF, AND, IF REQUIRED, RESTRESSED. IT SHALL DISTRIBUTE THE TENDON LOAD TO THE MAIN GROUTING IS CARRIED OUT. PROPORTIONING AND MIXING PROCEDURES SHALL BE DETERMINED

CABLE ANCHORS. STRUCTURE IN ACCORDANCE WITH THE OVERALL DESIGN OF THE STRUCTURE THROUGH AFTER 6 WEEKS TO SIX MONTHS OR TILL THE EACH 2ND WEEK

BY PRELIMINARY GROUT TESTS. PROPERTIES TO CHECK AND CONTROL INCLUDE STRENGTH

DESIGNED OR TESTED COMPONENTS. THE ANCHOR HEAD NEEDS TO BE SUFFICIENT TO CARRY DEVELOPMENT, FLOW CHARACTERISTICS AND BLEEDING AND SHRINKAGE. CABLE ANCHOR IS ACCEPTED BY THE ENGINEER

(Vii) TO FIND OUT SPECIFICATIONS (IF REQUIRED) TO EVENTUALLY CONSOLIDATE THE ENTIRE ROCK THE SUM OF THE ULTIMATE LOAD OF THE STEEL TENDONS. THE STRESSING MECHANISM SHALL

(6) PROPER GROUT PIPES SHALL BE USED TO ENSURE GROUTING FROM BOTTOM TO TOP AND (3) ACCEPTANCE SHALL BE SUBJECT TO THE CONDITION THAT THE LOSS IN STRESS IS LESS THAN 2%

BELOW THE HEAD BY PRE-GROUTING THE AREA BEFORE THE CABLE ANCHORS ARE PLACED IN THE BE SUCH THAT THE MEASUREMENT OF THE LOADS AND DEFORMATIONS IS GUARANTEED DURING

STRESSING TESTS. ACHIEVE COMPLETE FILLING WITH NEAT CEMENT GROUT. THIS REQUIREMENT APPLIES TO ALL OF THE LOCK-OFF LOAD.

DRILL HOLE. CABLE ANCHOR-GROUTING OPERATIONS INCLUDING END CAP FILLING.

(4) THE TENDON BOND LENGTH SHALL BE AS PER DRAWING, AND SHALL BE APPROVED BY THE

(2) TEST CABLE ANCHORS SHALL BE INSTALLED AND TESTED IN SOME TYPICAL GEOLOGICAL (7) AS SOON AS POSSIBLE, AFTER STRESSING OR RE-STRESSING HAVE BEEN COMPLETED AND CABLE

ENGINEER BEFORE THE WORK IS STARTED.

CONDITIONS EXPECTED IN EXCAVATION PRIOR TO COMMENCEMENT OF ANY INSTALLATIONS OF ANCHOR HAS BEEN ACCEPTED BY THE ENGINEER, THE SECONDARY GROUTING INSIDE AND

THE PERMANENT CABLE ANCHORS. THE SUITABILITY TEST FOR CABLE ANCHORS SHALL BE USED (5) THE TENDONS SHALL BE SHOP FABRICATED AND SHALL BE FREE FROM DIRT, DUST OR ANY OUTSIDE OF THE SHEATHING SHALL BE PERFORMED TO ENCASE COMPLETELY THE

ONLY FOR TESTING AND NOT AS A PART OF THE PERMANENT CABLE ANCHORING SYSTEM. TEST OTHER DELETERIOUS MATERIAL. THE PARTS SUCH AS SPREAD, RINGS, SHEATHS, WIRE CAPS, STRANDS/WIRES FOR THE FULL LENGTH OF THE HOLE AND TO FILL ALL VOIDS.

ANCHORS SHALL BE TESTED UP TO ULTIMATE LOAD. CLAMPING, RINGS ANCHOR BASE PLATES, HEADS, ETC., SHALL BE EITHER SHOP FABRICATED OR

FIELD FABRICATED IN ACCORDANCE WITH BY THE ENGINEER APPROVED METHOD. (8) THE RECESS LEFT IN THE CONCRETE PAD FOR ACCOMMODATING THE HEAD SHALL BE FILLED WITH

(3) AN ACCURATE DRILLING AND GROUTING RECORD SHALL BE KEPT FOR EACH TEST TO ALLOW A CONCRETE IF NOT OTHERWISE DIRECTED BY THE ENGINEER.

COMPARISON OF THE TEST CABLE ANCHORS WITH THE PERMANENT CABLE ANCHORS (WHICH HAVE (6) SHEATHING MATERIAL SHALL BE DURABLE, RUST AND CORROSION PROOF, FLEXIBLE AND WATER

NOT UNDERGONE ANY TESTS). IF TOO LARGE DEVIATIONS OCCUR DURING THE INSTALLATION OF TIGHT. GROUT TUBE SHALL BE MADE OF PVC AND RE-INJECTION TUBE SHALL BE PERFORATED 11.8 STRESSING OF CABLE ANCHOR AND ACCEPTANCE TESTS

CABLE ANCHORS, THE ENGINEER MAY ORDER A NEW SERIES OF TESTS TO BE PERFORMED IN AT REGULAR INTERVALS WITH HOLES COVERED WITH RUBBER SLEEVES.

DIFFERENT CONDITIONS.

(4) THE NUMBER OF TEST CABLE ANCHORS SHALL CORRESPOND TO 2 % OF TOTAL CABLE ANCHORS

11.6 CORROSION PROTECTION (1) STRESSING OF THE CABLE ANCHOR SHALL BE PERFORMED ONLY WHEN THE GROUT HAS

2

ACHIEVED MINIMUM CYLINDER STRENGTH OF 20 N/MM AND ONLY AFTER THE END

OR AS PER AGREED PERCENTAGE TO BE INSTALLED, BUT MINIMUM 3 PIECES SHALL BE SUPPLIED (1) CORROSION PROTECTION OF FIXED LENGTH OF TENDONS SHALL CONFORM TO CLAUSE 7.2 (A) ANCHORAGE/FIXED LENGTH HAS ACQUIRED THE REQUIRED STRENGTH. THE MINIMUM TIME

FOR TESTING PURPOSES AND NOT USED AGAIN. AND 7.2 (B) OF IS 10270 AS BELOW: BETWEEN GROUTING OF ANCHORAGE ZONE OR CONCRETING THE PAD, AND STRESSING SHALL BE

(5) THE MEASURING EQUIPMENT SHALL BE ABLE TO MEASURE DISPLACEMENT OF 0.01 MM WHEN CREEP ESTABLISHED DURING THE SUITABILITY TESTS OR AS SPECIFIED BY THE ENGINEER.

(a) THE FIXED LENGTH OF THE CABLE ANCHORS SHALL BE REPEATEDLY GROUTED USING NEAT

IS BEING MEASURED. CEMENT GROUT UNDER PRESSURE TO OBTAIN THE PERMEABILITY OF UNDER 3 LUGEONS FOR (2) THE STRESSING SHALL FOLLOW A PROGRAM SUBMITTED BY THE CONTRACTOR WHICH SHALL

(6) THE MEASUREMENT OF LOADS IN CABLE ANCHORS SHALL BE BY HYDRAULIC OR ELECTRICAL LOAD THE SURROUNDING STRATA. INCLUDE THE SEQUENCE IN WHICH THE CABLE ANCHORS ARE TO BE STRESSED UP TO THE TEST

MEASURING DEVICE ABLE TO MEASURE TO AN ACCURACY OF BETTER THAN 2% OF THE MAXIMUM LOADS, THE LOCK-OFF LOADS (LOCK-OFF LOAD = DESIGN OR WORKING LOAD + ALLOWANCE OF

(b) THE FIXED LENGTH SHALL BE TREATED WITH EPOXY FORMULATION AS FOLLOWS:

APPLIED LOAD DURING EACH TEST. ANY LOAD-MEASURING DEVICE USED FOR LOAD LOSS TESTS 10% FOR LONG TERM LOSSES), ANY EVENTUAL STRESSING MODIFICATIONS TO BE MADE

SHALL BE ABLE TO MEASURE LOADS TO 0.5 % OF THE MAXIMUM APPLIED LOAD. (i) THE HIGH TENSILE STEEL WIRES OR STRANDS ARE FIRST PRE TREATED BY SAND BLASTING OR SUBSEQUENTLY AND TESTS TO BE CARRIED OUT, AND SHALL BE APPROVED BY THE ENGINEER.

GRIT BLASTING PROCESS. THEREAFTER, THE WIRES / STRANDS ARE CLEANED THOROUGHLY BY

(7) AT LEAST 2 OF THE TEST CABLE ANCHORS SHALL CONTAIN A TENDON WITH A CAPACITY HIGHER (3) ALL CABLE ANCHORS SHALL BE CHECKED BY MEANS OF AN ACCEPTANCE TEST (OR SIMPLE

USING THE THINNER.

THAN THAT OF THE WORKING CABLE ANCHOR, SO AS TO ENABLE TESTING BOND CAPACITY STRESSING TEST) AND AT LEAST 10% OF THE TOTAL NUMBER OF CABLE ANCHORS INSTALLED

BETWEEN GROUT AND ROCK AT ULTIMATE TENDON LOAD OF A WORKING CABLE ANCHOR. (ii) THE FIRST COAT OF EPOXY FORMULATION IS APPLIED UNIFORMLY ON THE WIRES / STRANDS AND SHALL UNDERGO THE COMPREHENSIVE STRESSING TESTS STIPULATED IN THE INTERNATIONAL

BOREHOLE DIAMETER SHALL BE KEPT SAME AS FOR WORKING CABLE ANCHORS. TENDON STRESS IT IS ALLOWED TO DRY FOR A PERIOD OF 2 TO 3 HOURS. THE SECOND COAT IS APPLIED STANDARDS TO THE SATISFACTION OF THE ENGINEER.

THEREAFTER AND THE SAME IS ALLOWED TO DRY FOR 24 HOURS. THIS IS THEN ROUGHENED BY P1 GENERAL MODIFICATION BAS JIT SSE 30.03.21

SHALL BE LIMITED TO 95 % OF YIELD STRESS OF THESE CABLE ANCHORS. (4) DURING THE ACCEPTANCE TEST, BEHAVIOR OF THE CABLE ANCHOR AT THE TEST LOAD AND THE

SANDPAPER AND THE THIRD COAT IS THEN APPLIED UNIFORMLY. WHILE THE THIRD COAT IS STILL REV.No. REVISION DESCRIPTION DRAWN CH'KED APP'D DATE

(8) ALL SUITABILITY TESTS SHALL BE CARRIED OUT IN THE PRESENCE OF THE ENGINEER. DEFORMATION SHALL BE OBSERVED FOR A PERIOD OF TIME IN ACCORDANCE WITH PROCEDURES

TACKY, QUARTZ SAND IS SPRINKLED OVER IT TO INCREASE THE BOND. PREFEASIBILITY STUDY INCEPT. & BASIC DESIGN CONSTRUCTION DESIGN

ESTABLISHED BY THE SUITABILITY TESTS. AFTER REACHING THE TEST LOAD THE CABLE ANCHOR

(9) FOR FURTHER SAMPLING, TESTING AND QUALITY ASSURANCE DETAILS REFER RELEVANT CHAPTER. (2) CORROSION PROTECTION OF FREE LENGTH OF CABLE ANCHORS SHALL BE AS FOLLOWS SHALL BE DETAINED TO ZERO OR DATUM LOAD (I.E. ABOUT 10 % OF TEST LOAD) AND THEREAFTER FEASIBILITY STUDY TENDER DESIGN AS-BUILT DRAWINGS

(ESSENTIALLY IN ACCORDANCE WITH CLAUSES 7.1 (B), (C) AND (D) OF IS 10270): STRESSED TO LOCK OFF LOAD AND FURTHER BY THE AMOUNT NECESSARY TO COMPENSATE FOR

11.4 DRILLING OF HOLES AND WATER PRESSURE TESTING SEATING LOSS. SEATING LOSSES SHALL BE RESTRICTED TO 6 MM.

GREENKO ENERGY PROJECTS PRIVATE LIMITED

(a) THE TENDON COMPRISING OF SEVERAL HIGH TENSILE WIRES/STRANDS ENCLOSED IN A

(1) HOLES SHALL BE DRILLED AS SPECIFIED HEREIN AND IN ACCORDANCE WITH APPLICABLE SUITABLE DIAMETER HIGH DENSITY POLYETHYLENE (HDPE) PIPE WITH A MINIMUM THICKNESS OF (5) DURING THE COMPREHENSIVE STRESSING TEST, THE CABLE ANCHOR SHALL BE TENSIONED IN STANDALONE PUMPED STORAGE COMPONENT OF PINNAPURAM IREP

PROVISIONS OF THE SECTION “DRILLING AND GROUTING” AT THE LOCATIONS AND TO THE DEPTHS 2mm. THE DIAMETER OF THE HDPE PIPE SHALL BE GREATER THAN THE ENCLOSED WIRES / STEPS. BEHAVIOR OF THE CABLE ANCHORS SHALL BE OBSERVED DURING THE INTERMEDIATE

AND INCLINATION SHOWN ON THE DRAWINGS OR AS DIRECTED BY THE ENGINEER. THE DRILLING STRANDS. (SEE DRAWING NO. ...............) STEPS, THE UNLOADING PERIODS AND AT THE TEST LOAD. THE LOAD SHALL BE MAINTAINED AT SURFACE EXCAVATION & ROCK SUPPORT

METHOD SHALL BE SUITED TO THE TYPE OF GROUND AND THE NECESSARY DRILL HOLE DIAMETER. EACH STEP FOR A PERIOD OF TIME IN ACCORDANCE WITH PROCEDURES ESTABLISHED BY THE

(b) THE ANNULAR SPACE BETWEEN THE HDPE PIPE AND THE HOLE SHALL BE FILLED WITH NEAT

SUITABILITY TESTS. THE LOAD / DEFORMATION CURVE SHALL BE RECORDED FOR LOADING AND

GENERAL NOTES

(2) DIAMETER OF THE HOLES SHALL BE SUCH AS REQUIRED BY THE MANUFACTURER, OR AS DIRECTED CEMENT GROUT.

BY THE ENGINEER. DEPTH OF THE HOLE SHALL EXCEED THE TOTAL CABLE ANCHOR LENGTH UNLOADING. AFTER REACHING THE TEST LOAD, THE CABLE ANCHOR SHALL BE DETAINED TO ZERO

(INCLUDING THE FIXED LENGTH) BY 500 MM OR BY SUCH ADDITIONAL AMOUNT AS REQUIRED IN (c) THE WIRES / STRANDS SHALL BE PAINTED WITH EPOXY BASED PAINT AS FOLLOWS: OR DATUM LOAD (I.E. ABOUT 10 % OF TEST LOAD). THEREAFTER, THE CABLE ANCHOR SHALL BE

RESTRESSED TO LOCK OFF LOAD AND STRESSED FURTHER BY THE AMOUNT NECESSARY TO SHEET 4 OF 4

CASE DRILL CUTTINGS CANNOT BE REMOVED FROM THE BOTTOM OF THE HOLE. (i) HIGH TENSILE STEEL WIRES OR STRANDS SHALL BE FIRST CLEANED WITH SAND PAPER,

COMPENSATE FOR SEATING LOSS. SEATING LOSSES SHALL BE RESTRICTED TO 6 MM. DESIGNED: RPA SCALE: NTS FORMAT: A1

(3) HOLES SHALL BE EITHER DRILLED BY ROTARY METHOD WITH WATER FLUSH OR PNEUMATIC (ii) IMMEDIATELY AFTERWARDS, A COAT OF SUITABLE PRIMER SHALL BE UNIFORMLY APPLIED BY DRAWN: DCP NTS [A3]

PERCUSSION METHOD WITH AIR AND / OR WATER FLUSH OR ANY OTHER TYPE SUCH THAT THE BRUSH,

DISTURBANCES TO THE ADJOINING ROCK ARE MINIMAL. USE OF BENTONITE, ROD GREASE OR CHECKED: SMM/JIT DRAWING No. REV. No.

OTHER LUBRICANTS ON DRILL RODS WILL NOT BE PERMITTED. (iii) WHEN THE COAT OF PRIMER IS SUFFICIENTLY DRY, A COAT OF EPOXY-BASED PAINT SHALL BE AFRY India Pvt. Ltd. APPROVED: SSE

UNIFORMLY APPLIED. FOR PLANNING PURPOSE Tower-1, Stellar IT Park, C-25, Sector-62, Noida - India DATE: 16.02.21

AFRY.4649.00.104 P1

You might also like

- Nail Head Construction: Surface Excavation & Rock Support General NotesDocument1 pageNail Head Construction: Surface Excavation & Rock Support General Notesஅம்ரு சாந்திவேலுNo ratings yet

- StrucDocument3 pagesStrucAlvin DeliroNo ratings yet

- Ipil - Main Building Structural Plan - 10.10.23Document9 pagesIpil - Main Building Structural Plan - 10.10.23Mark Andykenn Liaga MaglinteNo ratings yet

- E:/1. Hai Phat/Nh19/1. Detail Design/99. Xuat Ho So/General Notes/General Notes - DWG - Date: Thu, 22 Oct 2020 - 1:58Pm Pc:LamntDocument2 pagesE:/1. Hai Phat/Nh19/1. Detail Design/99. Xuat Ho So/General Notes/General Notes - DWG - Date: Thu, 22 Oct 2020 - 1:58Pm Pc:LamntHoang Nguyen HuyNo ratings yet

- Surface Excavation & Rock Support General Notes: AFRY.4649.00.102 P1Document1 pageSurface Excavation & Rock Support General Notes: AFRY.4649.00.102 P1அம்ரு சாந்திவேலுNo ratings yet

- General Slab On Ground Concrete Concrete Continued Chemical AnchorsDocument12 pagesGeneral Slab On Ground Concrete Concrete Continued Chemical AnchorsJelenaNo ratings yet

- PlanDocument8 pagesPlanMark Christian EsguerraNo ratings yet

- Typical Structural Abbreviations Typical Symbols Legend Typical Plan NotesDocument33 pagesTypical Structural Abbreviations Typical Symbols Legend Typical Plan NotesINNOBUNo7No ratings yet

- 1ST Flr-LightingDocument1 page1ST Flr-LightingAnu GraphicsNo ratings yet

- Demolition Notes General Notes General Notes: Creative Structures ServicesDocument1 pageDemolition Notes General Notes General Notes: Creative Structures ServicesHanif KhanNo ratings yet

- SMT-DWG-DD-ME-00-DW-6001-RB - SCHEMATIC - DOMESTIC WATER SYSTEM UpdateDocument1 pageSMT-DWG-DD-ME-00-DW-6001-RB - SCHEMATIC - DOMESTIC WATER SYSTEM UpdateJofanny Ferdian RahmansyahNo ratings yet

- Structual Plan 2-Storey ResidentialDocument9 pagesStructual Plan 2-Storey ResidentialMark Christian EsguerraNo ratings yet

- 05-DETAILS OF SOFFIT SLAB IN SUPER STRUCTURE-ModelDocument1 page05-DETAILS OF SOFFIT SLAB IN SUPER STRUCTURE-ModelManvendra Singh RaghuwanshiNo ratings yet

- General Notes For Earth Retaining StructureDocument12 pagesGeneral Notes For Earth Retaining StructureEric IbarraNo ratings yet

- 4239-AA-DC-21U50RN005-IS00 - TCM Check 021122Document1 page4239-AA-DC-21U50RN005-IS00 - TCM Check 021122amitNo ratings yet

- Sample Structural DrawingDocument1 pageSample Structural DrawingCherish Taguinod Aliguyon100% (1)

- Ttag NTC Sds Mep DP MB 01Document1 pageTtag NTC Sds Mep DP MB 01Đỗ Thanh HùngNo ratings yet

- Catch Basin Detail: LegendsDocument1 pageCatch Basin Detail: LegendsM VlogNo ratings yet

- C200-Roadworks Notes and Details-C240Document1 pageC200-Roadworks Notes and Details-C240Don WangNo ratings yet

- L&T Hydrocarbon Engineering: Approved For ConstructionDocument6 pagesL&T Hydrocarbon Engineering: Approved For ConstructionAnthony MayNo ratings yet

- NPP0085 Jec DD Me DWG 00132Document1 pageNPP0085 Jec DD Me DWG 00132himajcpNo ratings yet

- v9r49g3zk0pg - 12. KPLC Warehouse Revised May 2014 GFDocument1 pagev9r49g3zk0pg - 12. KPLC Warehouse Revised May 2014 GFEllyella ElormNo ratings yet

- S1-03 - Load MapsDocument1 pageS1-03 - Load MapsJason toraldeNo ratings yet

- Cps STRC Ifc Sept 25 2018Document57 pagesCps STRC Ifc Sept 25 2018Manimaran PNo ratings yet

- AB-036400 - Ceramic Board and Blanket Installation - SAUDI ARAMCODocument1 pageAB-036400 - Ceramic Board and Blanket Installation - SAUDI ARAMCOAkhil GeorgeNo ratings yet

- Drawings Electric Forklift Charging StationsDocument14 pagesDrawings Electric Forklift Charging StationsRafael de la cruzNo ratings yet

- Ttag NTC Sds Mep DP MB 00 1Document1 pageTtag NTC Sds Mep DP MB 00 1Đỗ Thanh HùngNo ratings yet

- St-Hidd-01 Security Room DetailsDocument1 pageSt-Hidd-01 Security Room Detailsmhazarath murariNo ratings yet

- Zc190ittc Cv0212aDocument1 pageZc190ittc Cv0212amohd solihin bin mohd hasanNo ratings yet

- DDHA021065001P00Document1 pageDDHA021065001P00Foumil Albatin IndusNo ratings yet

- Location Plan: Siddha AssocatesDocument1 pageLocation Plan: Siddha AssocatesSuyog PandeNo ratings yet

- Drainage Details Sheet 1Document1 pageDrainage Details Sheet 1Mohamed AdelNo ratings yet

- Roof Framing Plan: Construction NotesDocument1 pageRoof Framing Plan: Construction NotesNefritiri BlanceNo ratings yet

- General Notes:: Accu PlatformDocument1 pageGeneral Notes:: Accu PlatformNathaniel DreuNo ratings yet

- Structural Specifications and Standard DetailsDocument1 pageStructural Specifications and Standard Detailsdomin domNo ratings yet

- Spectrin - Prashant Sir - RCC Foundation - R3-CLDocument1 pageSpectrin - Prashant Sir - RCC Foundation - R3-CLMadhavi GanbavaleNo ratings yet

- PB PB: General NotesDocument1 pagePB PB: General NotesEli SuarezNo ratings yet

- General Specifications Legends and Symbols: Phase 6Document1 pageGeneral Specifications Legends and Symbols: Phase 6inno de los santosNo ratings yet

- Plumbing Permit Drawings PDFDocument3 pagesPlumbing Permit Drawings PDFJeremy BoyceNo ratings yet

- A22.22-0043 - Absa Providence Seychelles - Ar00 - Ground Floor - Rev ADocument1 pageA22.22-0043 - Absa Providence Seychelles - Ar00 - Ground Floor - Rev ANithin AbrahamNo ratings yet

- Zoleta Residence - Structural PlansDocument5 pagesZoleta Residence - Structural PlansJc SulitNo ratings yet

- 1245 F A0 0001Document1 page1245 F A0 0001Eugene Francis CastroNo ratings yet

- A Perspective: Lot 26 Block 14Document1 pageA Perspective: Lot 26 Block 14alvarez.johnernestpce1965No ratings yet

- 4124 Ai Du 21130i046s01 Is01 - Checkprint - DineshDocument1 page4124 Ai Du 21130i046s01 Is01 - Checkprint - Dineshamit bagchiNo ratings yet

- 9 13 Notes:: Construction IssueDocument1 page9 13 Notes:: Construction IssueХөгжилтэй ЗугаатайNo ratings yet

- Fa 3RDDocument1 pageFa 3RDAhmed KhalilNo ratings yet

- D 0000 1330 075 - 2 - 00001Document1 pageD 0000 1330 075 - 2 - 00001Mary DenizeNo ratings yet

- RA612003001P0A1Document1 pageRA612003001P0A1Muhammad AbrarNo ratings yet

- 9686-8360-85-712-2502 - B1 - Internal CP Potable Water TankDocument2 pages9686-8360-85-712-2502 - B1 - Internal CP Potable Water TankANIL PLAMOOTTILNo ratings yet

- H85 J BA-430471 001: Field Design ChangeDocument11 pagesH85 J BA-430471 001: Field Design ChangeKarim Abd El HamidNo ratings yet

- s3-11 - Tower 1 Shear Wall ElevationDocument1 pages3-11 - Tower 1 Shear Wall ElevationJason toraldeNo ratings yet

- 218140-100 RS-02 First Floor Reinforcement LayoutDocument1 page218140-100 RS-02 First Floor Reinforcement LayoutrendaninNo ratings yet

- ASTER-C 9 Kitchen Detail-Aster C Unit-3Document1 pageASTER-C 9 Kitchen Detail-Aster C Unit-3simranNo ratings yet

- Water TankDocument1 pageWater TankProject ManagerStructuresNo ratings yet

- ECE1Document1 pageECE1Casmir TayagNo ratings yet

- Construction Notes: 30 BAR. DIA. 30 BAR. DIA. 40Document1 pageConstruction Notes: 30 BAR. DIA. 30 BAR. DIA. 40MARKCHRISTMASNo ratings yet

- SLD - SIE 3rd Batching Plant - New-ModelDocument1 pageSLD - SIE 3rd Batching Plant - New-ModelRaj ConsultancyNo ratings yet

- General Notes BridgeDocument6 pagesGeneral Notes BridgeEnglish for KidsNo ratings yet

- Miami Inn 2.0Document4 pagesMiami Inn 2.0construdico serviceNo ratings yet

- W18X46 W3-7 1/2" NW 30 10 106: The Beam Design Is AdequateDocument7 pagesW18X46 W3-7 1/2" NW 30 10 106: The Beam Design Is Adequateஅம்ரு சாந்திவேலுNo ratings yet

- The Connection Design Is Adequate.: Weld Capacity of Eccentric Connection Based On AISC 360-05Document2 pagesThe Connection Design Is Adequate.: Weld Capacity of Eccentric Connection Based On AISC 360-05அம்ரு சாந்திவேலுNo ratings yet

- L&T Construction: Water & Renewable EnergyDocument5 pagesL&T Construction: Water & Renewable Energyஅம்ரு சாந்திவேலுNo ratings yet

- Pipe Conveyor System To Transport Coal From WCL Coal Mines To Koradi & Khaperkheda TpsDocument36 pagesPipe Conveyor System To Transport Coal From WCL Coal Mines To Koradi & Khaperkheda Tpsஅம்ரு சாந்திவேலு100% (1)

- Pipe Conveyor System To Transport Coal From WCL Coal Mines To Koradi & Khaperkheda TpsDocument37 pagesPipe Conveyor System To Transport Coal From WCL Coal Mines To Koradi & Khaperkheda Tpsஅம்ரு சாந்திவேலுNo ratings yet

- Web Tapered Frame Design Based On AISC-ASD 9th, Appendix F Input Data & Design SummaryDocument5 pagesWeb Tapered Frame Design Based On AISC-ASD 9th, Appendix F Input Data & Design Summaryஅம்ரு சாந்திவேலுNo ratings yet

- Annexure I - Beam DesignDocument1 pageAnnexure I - Beam Designஅம்ரு சாந்திவேலுNo ratings yet

- Kochadai Sheet-3Document1 pageKochadai Sheet-3அம்ரு சாந்திவேலுNo ratings yet

- Es0154-75440100-Cal-0083 - R0Document59 pagesEs0154-75440100-Cal-0083 - R0அம்ரு சாந்திவேலுNo ratings yet

- Kochadai Sheet 5Document1 pageKochadai Sheet 5அம்ரு சாந்திவேலுNo ratings yet

- 20 EPE TWAD STP 21.85MLD RJPM GA ADMIN 08 ModelDocument1 page20 EPE TWAD STP 21.85MLD RJPM GA ADMIN 08 Modelஅம்ரு சாந்திவேலுNo ratings yet

- Automation of Cooking Pasta With Wi-Fi ApplicationDocument4 pagesAutomation of Cooking Pasta With Wi-Fi Applicationஅம்ரு சாந்திவேலுNo ratings yet

- Aggregates For ConcreteDocument18 pagesAggregates For Concreteஅம்ரு சாந்திவேலுNo ratings yet

- HE AMS EwsletterDocument12 pagesHE AMS Ewsletterஅம்ரு சாந்திவேலுNo ratings yet

- Cognitive Expansion and Silent Communication in Evolving ConditionsDocument7 pagesCognitive Expansion and Silent Communication in Evolving Conditionsஅம்ரு சாந்திவேலுNo ratings yet

- CPSA Tech GuideDocument29 pagesCPSA Tech Guideஅம்ரு சாந்திவேலுNo ratings yet

- Block WallDocument12 pagesBlock WallBMZNo ratings yet

- TC WC W 37 Sept 23 7 Days.Document1 pageTC WC W 37 Sept 23 7 Days.Sabyasachi BangalNo ratings yet

- VNT Brochure NewDocument5 pagesVNT Brochure Newda vin ciNo ratings yet

- Tabelle Gewicht Rundstahl PDFDocument1 pageTabelle Gewicht Rundstahl PDFCécé Charles KoliéNo ratings yet

- Model Answer Paper Summer 2019Document16 pagesModel Answer Paper Summer 2019utkarshdeshmukhNo ratings yet

- Mosaico Full Formica 2024 - 2026Document15 pagesMosaico Full Formica 2024 - 2026nealmazzantiNo ratings yet

- ESTIMATIONDocument14 pagesESTIMATIONavmurugan87No ratings yet

- ZOLLERN-Broschuere ZGF Legierungen ENGDocument16 pagesZOLLERN-Broschuere ZGF Legierungen ENGPablo PadillaNo ratings yet

- MS - Sikadur-732 (Application of Epoxy Bonding Agent) (Ver.01)Document4 pagesMS - Sikadur-732 (Application of Epoxy Bonding Agent) (Ver.01)Jerome Li100% (2)

- Material InteriorDocument3 pagesMaterial InterioralyaNo ratings yet

- Estimate of PQCDocument6 pagesEstimate of PQCMital DamaniNo ratings yet

- VIN129 Polyethylene Pipe and Fittings SystemsDocument145 pagesVIN129 Polyethylene Pipe and Fittings SystemsKevin Tran0% (1)

- Review Dokumen PG. RendengDocument10 pagesReview Dokumen PG. RendengFarhan PutraNo ratings yet

- MachineDocument18 pagesMachineLouie Ludeña VillegasNo ratings yet

- MAR 20 2Q15:: Department of Public Works and HighwaysDocument6 pagesMAR 20 2Q15:: Department of Public Works and HighwaysFaustino AbadNo ratings yet

- May 2014-1Document412 pagesMay 2014-1Andi DumayNo ratings yet

- WISS CSWIP Technology Multiple Choice Exam 1 Version A 18 August 2014Document10 pagesWISS CSWIP Technology Multiple Choice Exam 1 Version A 18 August 2014rinhycraNo ratings yet

- Alloy TheoryDocument3 pagesAlloy TheoryDanish Saifi100% (1)

- OMC-6050 Chain InclinometerDocument2 pagesOMC-6050 Chain InclinometerJavier VillasmilNo ratings yet

- Estimation and Budget FormatDocument8 pagesEstimation and Budget Formatlinga2014No ratings yet

- Emerging Trends in Advancement of Formwork: March 2021Document14 pagesEmerging Trends in Advancement of Formwork: March 2021leovinNo ratings yet

- Moihq Abf b01 Arc SHD 2710 00Document1 pageMoihq Abf b01 Arc SHD 2710 00ayman ammarNo ratings yet

- Panel Design SpecificationDocument28 pagesPanel Design SpecificationGPSTECNO100% (1)

- REPORTTT (Repaired) PDFDocument161 pagesREPORTTT (Repaired) PDFHeartless GuitaristNo ratings yet

- Construction and Demolition Waste PlasticsDocument2 pagesConstruction and Demolition Waste PlasticsMBA103003No ratings yet

- BOQ and MeasurmentDocument12 pagesBOQ and MeasurmentBipin Ramesh JainNo ratings yet

- Sample Specifications: Mechanical Joint C153 Ductile Iron Compact FittingsDocument8 pagesSample Specifications: Mechanical Joint C153 Ductile Iron Compact FittingsJohanAndrésVillarrealNo ratings yet

- Butt Weld Tee Dimension - Penn MachineDocument1 pageButt Weld Tee Dimension - Penn MachineEHT pipeNo ratings yet

- ASME B31.4-Wall Thickness CalDocument2 pagesASME B31.4-Wall Thickness CalBagus Sukoco Koco100% (1)

- Heat-Shrinkable Tubing (WCSM) : Heavy Low Voltage Insulation and Outer Sealing TubingsDocument2 pagesHeat-Shrinkable Tubing (WCSM) : Heavy Low Voltage Insulation and Outer Sealing TubingshenriquezrsNo ratings yet