Professional Documents

Culture Documents

QP 2155at 1 Plumbing

Uploaded by

ahmed fouadOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

QP 2155at 1 Plumbing

Uploaded by

ahmed fouadCopyright:

Available Formats

GTC-05/197/ED ECS FOR MULTI-PURPOSE ADMINISTRATION COMPLEX-RAS LAFFAN

PARTICULAR SPECIFICATION

SECTION D3 – PLUMBING WORKS

SECTION D3

PLUMBING WORKS

1 General

1.1 Generally

• The Specification for the works defines the minimum requirements for the design,

supply and execution and this Section and is to be read as a supplement to the

“Section 19 Plumbing Work” section of the “Qatar Construction Specification”,

QCS 2002 except and to the extent as modified / amplified below and relates to

Hot and Cold Water and medical gas installations.

• Works carried out at Ras Laffan City (RLC) are also required to be completed

based upon the local regulations and construction procedures of RLC details of

which are listed the reference documents.

• The material specification and performance is indicated upon the drawings.

• Manufacturers of materials to be used in the construction works are to be

selected from the Qatar Petroleum (QP) Onshore Engineering Department

Vendors List document No ED.00.15.001 latest version current at the time of

tendering.

1.2 Codes and standards

• The following documents in their latest revision shall be read in conjunction with,

and shall be part of this specification. In case of conflict the most stringent shall

apply.

1.2.1 National standards

• Qatar Construction Specification (QCS) 2002.

1.2.2 QP standards

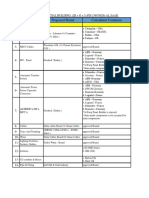

Document/

File Ref. Document Title Drawing Rev.

Number

QP/1 Specifications for NDT of Welds ES-S-60 4

Engineering Standards Draughting -

QP/2 Development of Technical Documents E.S.D.10 5

and Drawings (Manual)

QP Guide to Incident and Hazard

QP/3 QP-GDL-S-010 0

Reporting and Investigation

General Procedure for Magnetic

QP/4 QP-NDT-002 0

Particle Inspection

Leigh & Orange Ltd. Page D3/1

Document No. 2115-0-14-0002 - Revision 1 DDIFA – 21 December 2007

GTC-05/197/ED ECS FOR MULTI-PURPOSE ADMINISTRATION COMPLEX-RAS LAFFAN

PARTICULAR SPECIFICATION

SECTION D3 – PLUMBING WORKS

Document/

File Ref. Document Title Drawing Rev.

Number

General Procedure for the Ultrasonic

QP/5 Examination of Welds in Structural QP-NDT-005 0

and Piping Components

QP Corporate Philosophy for Fire and

QP/6 QP-PHL-S-001 1

Safety

Lifting Equipment Technical QP-REG-Q-00

QP/7 3

Regulation 1

QP/8 QP Safety Regulations for Contractors QP-REG-S-001 2

QP Technical Specification for

Painting and Wrapping of Metal

QP/9 QP-SPC-L002 1

Surfaces (New Construction and

Maintenance)

QP Accepted International, National &

QP/10 QP-STD-A-001 1

Industry Standards & Codes

QP/11 AutoCAD 2004 Configuration ES.0.01.0015 C

Master Records and Project

QP/12 ES.0.07.0014 D

Engineering Data Coding System

Equipment Identification and TAG

QP/13 ES.0.07.0025 E

Numbering System

QP/14 Electrical Engineering Philosophy ES.2.03.0001 B

Electrical Installation Recommended

QP/15 ES.2.06.0001 A

Practices

High Voltage Switchgear & Control

QP/16 ES.2.14.0010 A

Gear for Indoors

Low Voltage Switchgear & Control

QP/17 ES.2.14.0015 A

Gear for Indoors

QP/18 Busbar Ducting ES.2.14.0019 A

High Voltage Liquid Filled Power

QP/19 ES.2.14.0020 A

Transformers

Dry-Type Power Transformers (Cast

QP/20 ES.2.14.0022 A

Resin & Resin Integrated Type)

QP/21 Low Voltage Cage Induction Motors ES.2.14.0035 A

A.C. Uninterruptible Power Supply

QP/22 ES.2.14.0040 A

Systems

Leigh & Orange Ltd. Page D3/2

Document No. 2115-0-14-0002 - Revision 1 DDIFA – 21 December 2007

GTC-05/197/ED ECS FOR MULTI-PURPOSE ADMINISTRATION COMPLEX-RAS LAFFAN

PARTICULAR SPECIFICATION

SECTION D3 – PLUMBING WORKS

Document/

File Ref. Document Title Drawing Rev.

Number

D.C. Uninterruptible Power Supply

QP/23 ES.2.14.0044 A

Systems

Electrical Power Control Cables and

QP/24 ES.2.14.0070 A

Cable Glands

QP/25 Power System Studies ES.2.14.0095 A

Electrical Requirements for Package

QP/26 ES.2.14.0098 B

Equipment

Safety Instructions Electrical –

QP/27 ES.2.18.0001 1

General

Electrical Sub-station Indoor Typical

QP/28 ES.2.68.0001 A

Layout (Drawing)

QP Engineering Standard - Secondary

QP/29 Selective System ES.2.14.0060 A

QP Engineering Standard - Power

QP/30 Management System ES.2.14.0065 A

QP Engineering Standard - Diesel

QP/31 Engine Driven Generators ES.2.14.0002 A

QP Engineering Specification -

Electrical Specification for High

QP/32 Voltage Neutral Earthing Resistors ES.2.14.0085 A

QP Safety Performance Standard -

QP/33 Human Machine Interface ES.F.06 0

Standard Specification for Civil Works

QP/34 (Second Edition Volume 1) E.S.C.20 -

Regulations for the Installation of

Feb2006

QP/35 Electrical Wiring, Electrical Equipment -

Edition

and Air Conditioning Equipment

Allocation of Offices, Office Furniture

QP/36 & Furnishings IP-GS-002 -

Corporate House Support –

Ergonomic Standard for Office

QP/37 Furniture STD-HSE-004 A1

Design Guidelines for Road Pavement

QP/38 and Road Crossings in Ras Laffan RID/11/01 0

Leigh & Orange Ltd. Page D3/3

Document No. 2115-0-14-0002 - Revision 1 DDIFA – 21 December 2007

GTC-05/197/ED ECS FOR MULTI-PURPOSE ADMINISTRATION COMPLEX-RAS LAFFAN

PARTICULAR SPECIFICATION

SECTION D3 – PLUMBING WORKS

Document/

File Ref. Document Title Drawing Rev.

Number

Industrial City, Guide to Accident

Reporting and Investigation, Safety

Regulations for Contractors

Onshore Engineering Preferred

QP/39 Vendors List (04 June 2006) ED.00.15.001 A

1.2.3 British Standards:

BS5480

BS7159

BS6400

BS476 and 477

BS874

BS2972

BS6700

BS3402

BS4305

BS8300-2001(revised 2005)

BS 8010

1.3 Description of works

• The works shall generally comprise the following:

• A Potable Water Supply System. The primary water supply is located within

Ras Laffan City Western Development area and is shown on the Utility

Interface Drawings. This contract includes the extension of the primary RLC

network adjacent to the new road network including the provision of future

isolation and capped connections for extension by others and a branch

connection into the Complex. The Primary connection point will be provided

by others with an isolation valve and flanged connection for these works

extension. These works are to be identified separately in the tender

submission.

• Within the Complex will comprise an externally located below ground bulk

metering arrangement at the site boundary of the Complex with a utility

supply line that serves the Central Plant building. Potable water at day one

of the Complex will provide all the water supplies required to operate the site

Leigh & Orange Ltd. Page D3/4

Document No. 2115-0-14-0002 - Revision 1 DDIFA – 21 December 2007

GTC-05/197/ED ECS FOR MULTI-PURPOSE ADMINISTRATION COMPLEX-RAS LAFFAN

PARTICULAR SPECIFICATION

SECTION D3 – PLUMBING WORKS

including irrigation and firewater.

• Potable water will be stored within the Central Plant Building in a tank

providing 3 days storage capacity and pumped through pressurised ring

mains from the Central Plant building to the network within the Complex.

Within the Complex the internal network of distribution pipelines will serve

locally mounted building water meters fixed in external wall-mounted

cabinets.

• Flushing water will be stored in the central plant building and in addition to

there being a potable water supply make up this tank storage will also utilise

waste water from the blow down process of the cooling towers.

• Flushing water will be distributed from the Central Plant Building, pumped

through pressurised ring mains to the network within the Complex. Within

the Complex the internal network of distribution pipelines will serve locally

mounted building water meters fixed in external wall-mounted cabinets in

City Hall, Office and Canteen and Corporate Training Building only.

• All tanks within the Central Plant Building will be constructed in Concrete

with two divided sections to allow appropriate maintenance and cleansing

without interruption of the supply and a cross flow inlet and outlet

connections to reduce stagnant water.

• For description of Fire and Irrigation water supplies refer to that section of

the specification.

• External Potable and flushing water is to be laid below grade with concrete

valve boxes for all valves and access points. All entry and exit pipelines

shall be provided with proprietary spacers between the casing pipe and the

carrier pipe and the end of the casing fitted with a proprietary casing end

seal. All valves have extended spindle for above ground operation. The

minimum depth of cover shall be 1000mm from the top of pipe to finished

grade level and potable water and irrigation water supplies are to be a

minimum of 400mm apart with the invert level of the irrigation pipeline lower

than the potable water invert level. No trees are to be planted within 3

metres either side of the water pipelines. Vent and drain requirements are

indicated upon the drawings in accordance with eth pipeline profile however

the contractor is to note that at least one drain valve and one vent valve is

required between two main line isolation valves and any additional points

shall be provided. Drain valves are also to be arranged to drain down

sections of pipelines within a maximum period of 24hrs. All drainage water

from drain valves is to discharge into collection chambers where water may

be uplifted by portable sump pump into a mobile tanker. Vents drains and

Leigh & Orange Ltd. Page D3/5

Document No. 2115-0-14-0002 - Revision 1 DDIFA – 21 December 2007

GTC-05/197/ED ECS FOR MULTI-PURPOSE ADMINISTRATION COMPLEX-RAS LAFFAN

PARTICULAR SPECIFICATION

SECTION D3 – PLUMBING WORKS

associated pipelines below ground shall be constructed form Stainless

Steel.

• Potable water and flushing water pipelines size 80 NB and above shall be

of GRP material in accordance with BS5480 suitably rated for the booster

pump shut off pressure. GRP material shall be UV resistant. GRP pipe joints

are to be butt joint with overlay in accordance with BS7159. Installation shall

be done in accordance with BS8010 All Materials shall be British Standard

Kite marked. The design temperature for pipe work is to be 50 deg C for

below ground and 84 deg C for above ground installations.

• The GRP pipeline vendor is shall have specialised experience in supply and

installation of GRP pipeline within the Middle East region and shall include

as part of the supply provision a hydraulic and stress analysis taking into

account routing of pipe work as shown on the contractors installation

drawings to determine the system flexibility and anchoring requirements

together with the thrust block design. Qualified field personnel from thwe

specialist vendor shall be involved in installation and jointing.

• Potable Water and Flushing Water pipelines of size below 80NB shall be of

MDPE material suitably rated for the booster pump shut off pressure. MDPE

pipelines shall be UV resistant.

• Within the major buildings tank rooms will be provided with air conditioning

and water storage tanks accommodated to supply potable and flushing

water. Small buildings are provided with direct mains fed systems only.

• Water storage tanks within the buildings are to be of fibreglass or

polyethylene material and of one piece or sectional as described on the

drawings. Tanks shall be provided with full thermal insulation covering.

• Hot water systems are indicated upon the drawings and water heating is

either by local storage / non storage pressure type electric water heater or

central water heater using electrical power as the primary heating medium.

For central systems duplicate duty and standby circulating pumps have

been provided.

• All internal hot and cold water pipelines within buildings are of copper

construction with thermal insulation applied to reduce heat gain / loss and

stop condensation occurring. Local connections to final fittings are to be

carried out using polyethylene cross-linked (PE-X) pipe systems. The

change of material type from external to internal is to take place at the

building entry point isolation valve.

• The following clauses from the QNCS have been modified as indicated:

• General:

Leigh & Orange Ltd. Page D3/6

Document No. 2115-0-14-0002 - Revision 1 DDIFA – 21 December 2007

GTC-05/197/ED ECS FOR MULTI-PURPOSE ADMINISTRATION COMPLEX-RAS LAFFAN

PARTICULAR SPECIFICATION

SECTION D3 – PLUMBING WORKS

• All references to Qatar General Electricity & Water Corporation are to be

replaced with Kahramaa (KM).

• All references to British Standards shall mean the latest published

version of such standard.

• Service connections to equipment and plant shall be made with

decoupling adjacent to the equipment such that any removable section,

cover or the complete unit can be readily withdrawn or removed without

the removal or disturbance to large sections of adjacent services

systems. In addition it shall be possible to isolate and drain down any

equipment without isolation of large sections of the remaining system.

• Metal pipelines conveying water shall be protected from electrolytic

action by the installation of non-conductive or fibre type nipples to

mechanically separate copper pipes from galvanized materials. In the

case of acidic water approval shall be obtained of the protection

required to avoid possible corrosion due to electrolytic action.

• At points where services cross building expansion joints flexible

connections, compensators or expansion joints shall be provided to

cater for any potential building movement within the pipeline installation

unless it can be demonstrated that there is sufficient flexibility in the

pipeline installation.

• Specific clauses

1.3.2 Approval also required from the Engineer.

2.2.2 All cold water draw off points are to be provided with a water supply

as indicated upon the drawings which in some cases will be direct

feed form the Complex network or in other cases from the local

storage tanks. All water supplies will be fed via the central plant

water storage pumping and sterilization system.

2.2.3 Each water outlet is to have a maximum water outlet flow rate as

follows:

Appliance Draw off per fitting

Hot Water Cold Water

Sanitary Appliance BS6400 BS6400

Urinals are considered as discharging at 0.003 litres / sec per bowl

or stall.

2.2.4 Method (b) and (c) are to be adopted.

2.4.2 Pipeline materials are indicated above.

2.7.2 The contractor is to take into account thermal expansion and

contraction during the preparation of the installation drawings.

Leigh & Orange Ltd. Page D3/7

Document No. 2115-0-14-0002 - Revision 1 DDIFA – 21 December 2007

GTC-05/197/ED ECS FOR MULTI-PURPOSE ADMINISTRATION COMPLEX-RAS LAFFAN

PARTICULAR SPECIFICATION

SECTION D3 – PLUMBING WORKS

2.8.1 Thermal insulation work shall be undertaken by a specialist firm

who is registered and recognised as a thermal insulation sub

contractor. Manufacturers assessed and registered in accordance

with British Standard quality systems shall supply all materials. All

material shall be applied in accordance with the manufacturers

recommendations and instructions. The contractor is required to

ensure that all insulated materials are suitably prepared in

readiness for the application of the insulation and take appropriate

measures to protect such completed insulation works up to practical

completion. All insulation is to be suitable rated to satisfy the

surface spread of flame requirements to Class 1 of BS 476-7. All

vapour barriers installed to prevent penetration of moist ambient air

to cold surfaces that would allow condensation are to be suitable

sealed and be continuous. Thermal conductivity shall be in

accordance with BS 874 and BS 2972. Insulation that may be

subject to physical damage is to be suitably protected. Phenolic

Foam shall be CFC and HCFC free and have a thermal conductivity

of not more than 0.018 W.mK at 10 deg C mean temperature.

Mineral wool shall be manufactured using materials that do not

contain fibres that can be classified as a possible human

carcinogen as detailed in the European Directive 97/69/EC and the

approved supplier list of CHIP98. Mineral Wool shall have a thermal

conductivity not exceeding 0.038 W/mK at 50 deg C mean

temperature.

3.4.1 All pipelines installed in trenches is to be provided with identification

tape continuously laid along the length of the pipeline.

4.2.1 Tanks within the central plant building are above ground but are of

concrete construction.

6.4 Disinfection of the pipeline systems shall be carried out using

Sodium Hypochlorite in accordance with BS6700.

7.0 Medical gasses pipeline systems are to be installed using an

approved medical gas installation sub contractor including the

complete setting to wok commissioning and charging / testing the

installation. These installations are confined the Medical Centre

where there is a compressed air system and Oxygen system that

are to operate to human medical standards.

Leigh & Orange Ltd. Page D3/8

Document No. 2115-0-14-0002 - Revision 1 DDIFA – 21 December 2007

GTC-05/197/ED ECS FOR MULTI-PURPOSE ADMINISTRATION COMPLEX-RAS LAFFAN

PARTICULAR SPECIFICATION

SECTION D3 – PLUMBING WORKS

2 Performance requirements and tolerances

3 Materials and system components

3.1 Sanitaryware Products

1. SN01 shall be water closet with flush valve cistern as follows:

• Ceramic wall mounted water closet with toilet seat and cover.

• Dimensions: 640mm(L) x 360mm(W).

• Colour: White.

• Accessories:

• Plastic water closet pan connector.

• Concealed type flush valve cistern with C.P. lever.

• Hanger for water closet.

2. SN02 shall be water closet with flush valve cistern as follows:

• Composition:

• Wall mounted water closet pan with horizontal outlet and fixing bolts.

• In-wall system 880mm high, for wall mounted water closet.

• Wall frame: Painted galvanised steel.

• Cistern: Plastic.

• Regulating valve on inlet.

• Soil pipe outlet connection.

• Supporting bolts for water closet.

• Dual flush flushing plate, chromium plated.

• White plastic seat and cover.

• Material: Vitreous china.

• Dimensions: 530mm(L) x 380mm(W).

• Weight:

• Water closet pan: 26.3 g.

• In-wall system: 14.0 kg.

• Seat and cover: 3.2 kg.

• Colour: White.

• Standard: Vitreous china shall conform to BS 3402.

3. SN03 shall be washbasin as follows:

• Under-counter type.

• Material: Vitreous china.

• Dimensions: 415mm(Diameter) x 210mm(H).

• Weight: 7.0 kg.

• Colour: White.

• Standard: Vitreous china to conform to BS 3402.

Leigh & Orange Ltd. Page D3/9

Document No. 2115-0-14-0002 - Revision 1 DDIFA – 21 December 2007

GTC-05/197/ED ECS FOR MULTI-PURPOSE ADMINISTRATION COMPLEX-RAS LAFFAN

PARTICULAR SPECIFICATION

SECTION D3 – PLUMBING WORKS

4. SN04 shall be washbasin as follows:

• Wall mounted washbasin, single central taphole with overflow.

• Material: Fireclay.

• Dimensions: 500mm(L) x 455mm(W) x 170mm(H).

• Weight: 12.7 kg.

• Colour: White.

• Standard: Vitreous china to conform to BS 3402.

5. SN05 shall be washbasin as follows:

• Counter top type.

• Material: Vitreous china.

• Dimensions: 500mm(L) x 380mm(W) x 150mm(H).

• Colour: White.

6. SN06 shall be bathtub as follows:

• Composition:

• White bathtub without taphole.

• Silver 3 hole deck bath mixer, swanneck nozzle, chromium plated.

• Combined pop up waste and overflow.

• Operating handle and waste cover, chromium plated.

• White 1700mm acrylic front panel.

• White 800mm acrylic back panel.

• Dimensions: 1700mm(L) x 800mm(W) x 500mm(H).

• Capacity: 51 gallons / 230 litres (to overflow).

• Weight:

• Bath: 61 kg.

• Front panel: 3.4 kg.

• End panel: 3.1 kg.

• Colour: White.

• Standard: Constructed to BS 4305, EN 198.

7. SN07 shall be urinal as follows:

• Wall mounted back inlet and back outlet.

• Material: Vitreous china.

• Dimensions: 350mm(L) x 350mm(W).

• Colour: White.

• Accessories:

• Siphon for horizontal outlet.

• Urinal plastic plug.

8. SN10 shall be single lever mixer as follows:

• Wall mounted type thermostatic mixer, horizontal outlet nozzle, concealed

Leigh & Orange Ltd. Page D3/10

Document No. 2115-0-14-0002 - Revision 1 DDIFA – 21 December 2007

GTC-05/197/ED ECS FOR MULTI-PURPOSE ADMINISTRATION COMPLEX-RAS LAFFAN

PARTICULAR SPECIFICATION

SECTION D3 – PLUMBING WORKS

inlet connections incorporating sterilization system.

• Material: brass.

• Dimensions: 262mm(L) x 225mm(W) x 141mm(H).

• Weight: 3.0 kg.

• Conforms to HTM64 (2006), HTM04, HFN40.

9. SN11 shall be basin mixer as follows:

• Thermostatic lever action basin mixer pillar tap, inlets with connectors for

15mm copper tube.

• Weight: 2.6kg.

• Dimensions: 154mm(L) x 189mm(H).

• It shall be suitable for high and low pressure systems.

• Flow rate shall stay constant even when temperature setting is changed

(providing supply pressure is 1.0 bar or higher).

• Thermostatically set to 41ºC.

• It shall conform to the following standards:

• NHS Model Engineering specification D08 TMV3.

• BS 8300:2001 (revised 2005).

10. SN12 shall be single lever mixer and spout as follows:

• Single control concealed washbasin mixer, quarter turn ceramic disc

operation, 150mm projection spout with alternative aerator or flow

straightener outlet, flexible inlet tails with integral combined filter and

regulating valves.

• Finish: Chromium plated.

• Dimensions:

• Mixer: 75mm diameter.

• Spout: 50mm diameter.

• Weight: 2.5 kg.

• Head inlet pressure: Minimum 0.3 bar (3 metres); maximum 5.0 bar (50

metres).

11. SN13 shall be shower set as follows:

• Composition:

• Handshower

• Wall bar

• Length: 900mm.

• Shower hose

• Length: 1600mm.

• Finish: Chrome.

12. SN14 shall be shower mixer as follows:

Leigh & Orange Ltd. Page D3/11

Document No. 2115-0-14-0002 - Revision 1 DDIFA – 21 December 2007

GTC-05/197/ED ECS FOR MULTI-PURPOSE ADMINISTRATION COMPLEX-RAS LAFFAN

PARTICULAR SPECIFICATION

SECTION D3 – PLUMBING WORKS

• Dimensions: 170mm(L) x 170mm(W).

• Operating pressure: Maximum 1 MPa.

• Recommended operating pressure: 0.1 – 0.5 MPa.

• Test pressure: 1.6 MPa (1 MPa = 10 bar – 147 PSI).

• Hot water temperature: Maximum 80ºC.

• Recommended hot water temp.: 65ºC.

• Rate of flow at 0.3 MPa = 321/min.

13. SN15 shall be hand shower with wall outlet as follows:

• Finish: Chrome plated.

• Origin: Indonesia.

14. SN16 shall be shower mixer as follows:

• Single lever.

• Dimensions: 162mm(Diameter) x 115.5mm(W).

• Finish: Chrome plated.

15. SN17 shall be two handle basin mixer as follows:

• Finish: Chrome plated.

• With fixed spout.

• Origin: Denmark.

16. SN18 shall be shower rail with hand shower as follows:

• One handle built-in mixer with ceramic disc technology with the option of

25mm, 55mm or 100mm lever, hand shower and shower rail.

• Finish: Chrome plated.

17. SN19 shall be mixing valve as follows:

• ¾” double stop valve.

• Finish: Chrome plated.

• Origin: Denmark.

18. SN20 shall be two handle mixer with double swivel spot as follows:

• For bath filling.

• Finish: Chrome plated.

• Origin: Denmark.

19. SN21 shall be sink mixer with swivel spout and mouser shall be as follows:

• Angled swivel spout design with extractable mousser.

• Dimensions: 217mm(L) x 779mm(H).

• Finish: Chrome.

• 20. SN38 shall be disabled toilet pack as follows:Components:

• Wall-mounted water closet having following properties:

• horizontal outlet, back inlet and solid surface spacer unit.

• Cistern, 6 litre capacity for side supply and internal overflow,

Leigh & Orange Ltd. Page D3/12

Document No. 2115-0-14-0002 - Revision 1 DDIFA – 21 December 2007

GTC-05/197/ED ECS FOR MULTI-PURPOSE ADMINISTRATION COMPLEX-RAS LAFFAN

PARTICULAR SPECIFICATION

SECTION D3 – PLUMBING WORKS

siphon fittings, microvalve HP/LP ballvalve, side supply, internal

overflow and inlet connector.

• dual flush plate.

• Accessories:

• Toilet seat without cover.

• Cushioned back support with clips.

• Backrest rail 40cm x 22cm.

• Support bracket assembly

• Washbasin having the following properties:

• central taphole.

• Shall include:

• Lever action thermostatic sequential basin mixer tap.

• 32 mm (1 ¼ inch) brass strainer waste.

• Concealed hangers.

• 32 mm (1 ¼ inch) chromium plated bottle trap.

• Chromium-plated (AA) hinged support rails

• Chromium-plated (AA) handrails: 45mm Φ pull rail (at back of door

and 60mm Φ grab rail.

• Semi-recessed chromium plated toilet roll holder 15cm x 15cm.

• Material: Vitreous china.

• Dimensions: 2200mm(L) x 1500mm(W).

• Weight: Complete boxed set 70.0 kg.

• Colour: White.

• Standards:

• Vitreous china shall conform to BS 3402.

• LANTAC approval number 255-5-46.

21. SN40 shall be disable shower room pack as follows:

• Dimensions: 2200mm(L) x 2000mm(W).

• Components:

• Folding shower seat in grey.

• Back support in grey.

• 60cm grab rails in white (3).

• Hinged grab rails in white (2).

• 45cm handrail in white.

• Lever operated concealed thermostatic mixer in chromium plate.

• Handset holder.

• Handset and hose in chromium plate.

• Short projection fixed overhead shower.

Leigh & Orange Ltd. Page D3/13

Document No. 2115-0-14-0002 - Revision 1 DDIFA – 21 December 2007

GTC-05/197/ED ECS FOR MULTI-PURPOSE ADMINISTRATION COMPLEX-RAS LAFFAN

PARTICULAR SPECIFICATION

SECTION D3 – PLUMBING WORKS

• Lever operated shower diverter.

• White 45cm pull rail (for back of door).

• 1200 x 1200mm shower curtain.

• Clothes hook, white (x2).

• Standards: LANTAC approval number 359-5-46.

22. SN41 shall be squatting water closet pan with cistern as follows:

• Composition:

• Squatting water closet pan.

• P trap.

• Cistern:

• Material: Plastic with stainless steel push button body.

• 6 litre capacity with pastic siphon fittings.

• ½” microvalve HP/LP ballvalve.

• Side supply.

• Internal overflow.

• Inlet connector.

• Plastic flushpipe.

• Angle valve with flexible hose, jet and wall hooks, cp metal handle.

• Material: Vitreous china.

• Weight:

• Pan: 12.0 kg.

• Trap 3.0 kg.

• Cistern: 3.0 kg.

• Colour: White.

• Standards:

• Vitreous china to conform to BS 3402.

23. SN42 shall be disable shower room pack as follows:

• Composition:

• 510mm sink with fitted bucket grating.

• ½” lever operated quarter turn bib taps.

• ½” wall mounts for exposed plumbing.

• 1 ½” unslotted strainer waste.

• 1 ½” white plastic resealing bottle trap with 75mm seal.

• Aluminium alloy built-in brackets.

• Mounting screws.

• Material: Fireclay.

• Weight: 43.0 kg.

• Colour: White.

Leigh & Orange Ltd. Page D3/14

Document No. 2115-0-14-0002 - Revision 1 DDIFA – 21 December 2007

GTC-05/197/ED ECS FOR MULTI-PURPOSE ADMINISTRATION COMPLEX-RAS LAFFAN

PARTICULAR SPECIFICATION

SECTION D3 – PLUMBING WORKS

• Legs can be reduced in height on site.

24. SN43 shall be quarter turn bib taps as follows:

• Quarter turn bib taps with ceramic discs and lever handles.

• Finish: Chrome plated.

• ½” wall mounts for concealed plumbing.

25. SN45 shall be washbasin as follows:

• Wall mounted corner type.

• Material: Vitreous china.

• Dimensions: 470mm(L) x 430mm(W) x 225mm(H).

• Weight: 8.0 kg.

• Colour: White.

• Standard: Vitreous china to conform to BS 3402.

26. SN46 shall be pillar taps as follows:

• ½ in quarter turn with ceramic discs.

• Finish: Chrome plated.

• ½ in inlet screwed.

27. SN47 shall be watercloset as follows:

• Composition:

• Water closet pan with bottom outlet.

• 6 litre capacity cistern for bottom supply and internal overflow with free

flow valve fittings.

• ½ in bottom supply ballvalve with whisperflo refill unit, close coupling

bolts and chrome plated top push button assembly.

• Seat and cover.

• Plastic outlet connector for connection to 102 bore soil pipe.

• Material: Vitreous china.

• Dimensions: 670mm(L) x 415mm(W).

• Weight:

• Water closet pan: 15.0 kg.

• Cistern: 19.0 kg.

• Seat and cover: 2.3 kg.

• Colour: White.

• Standard: Vitreous china shall conform to BS 3402.

4 Workmanship

4.1 General

• The delivery, storage, handling, application, installation, protection, cleaning of

all proprietary materials, products and equipments shall comply with their

Leigh & Orange Ltd. Page D3/15

Document No. 2115-0-14-0002 - Revision 1 DDIFA – 21 December 2007

GTC-05/197/ED ECS FOR MULTI-PURPOSE ADMINISTRATION COMPLEX-RAS LAFFAN

PARTICULAR SPECIFICATION

SECTION D3 – PLUMBING WORKS

manufacturer’s recommendation. In case of any conflict between the

manufacturer’s recommendation and this Specification on a specific material,

product or equipment, the project manager’s decision governs.

Leigh & Orange Ltd. Page D3/16

Document No. 2115-0-14-0002 - Revision 1 DDIFA – 21 December 2007

GTC-05/197/ED ECS FOR MULTI-PURPOSE ADMINISTRATION COMPLEX-RAS LAFFAN

PARTICULAR SPECIFICATION

SECTION D3 – PLUMBING WORKS

SECTION D3

PLUMBING WORKS

TABLE D3-1 PREFERRED VENDORS LIST

Ref. Item/ Location Brand Name Preferred Alternative Alternative

Vendor Vendor Vendor

GRP Underground

1 Ameron Gulf Eternite Bondstrand Ltd

Pipelines

(France) UAE

Internal Copper

2 Wednesbury IMI Yorkshire Mueller UK

Pipework

Internal plastic

3 Terrain UK Hepworth UK Sappco Aplaco

Ppework

KSA

Water Circulating

4 Pullen UK Grundfos UK Holden &

Pumps

Brooke UK

Pressurisation

5 Pullen UK Grundfos UK Holden &

Packaged Units

Brooke UK

Water Storage

6 Bridgestone Mitsubishi Sekusui Japan

Tanks

Japan Japan

Water Meters

7 Kent

Thermal Insulation

8 Kimmco Izocam Arabian

Fibreglass

Electric water

9 IMI Stanton A O Smith USA Inventum

heaters Storage

Type

Electric water

10 IMI Stanton A O Smith USA Inventum

heaters non

storage type

Hydraulic

11 Pullen UK Grundfos UK Holden &

Expansion Vessels

Brooke UK

Ancillaries inc

12 As ED.00.15.001 As ED.00.15.001 As ED.00.15.001

pressure gauges

Leigh & Orange Ltd. Page D3/17

Document No. 2115-0-14-0002 - Revision 1 DDIFA – 21 December 2007

GTC-05/197/ED ECS FOR MULTI-PURPOSE ADMINISTRATION COMPLEX-RAS LAFFAN

PARTICULAR SPECIFICATION

SECTION D3 – PLUMBING WORKS

Ref. Item/ Location Brand Name Preferred Alternative Alternative

Vendor Vendor Vendor

Safety Valves relief

valves

Thermometers

Leigh & Orange Ltd. Page D3/18

Document No. 2115-0-14-0002 - Revision 1 DDIFA – 21 December 2007

GTC-05/197/ED ECS FOR MULTI-PURPOSE ADMINISTRATION COMPLEX-RAS LAFFAN

PARTICULAR SPECIFICATION

SECTION D3 – PLUMBING WORKS

Ref. Item/ Location Brand Name Preferred Alternative Alternative

Vendor Vendor Vendor

Valves

13 Peglers Wednesbury Hattersley

Fittings

14 As ED.00.15.001 As ED.00.15.001 As ED.00.15.001

Expansion Joints

15 As ED.00.15.001 As ED.00.15.001 As ED.00.15.001

Plastic Marker Tape

16 As ED.00.15.001 As ED.00.15.001 As ED.00.15.001

Pressure Pipeline

17 As ED.00.15.001 As ED.00.15.001 As ED.00.15.001

Marker Posts

Air Compressors

18 Ingersoll-Rand Sullair (France) As ED.00.15.001

and associate

(UK)

medical quality

equipment

Plastic Pipeline

19 As ED.00.15.001 As ED.00.15.001 As ED.00.15.001

Contractor

Thermal Insulation

20 As ED.00.15.001 As ED.00.15.001 As ED.00.15.001

Contractor

Medical Gas

21 As ED.00.15.001 As ED.00.15.001 As ED.00.15.001

Pipeline Contractor

Commissioning

22 As ED.00.15.001 As ED.00.15.001 As ED.00.15.001

Engineer

Any Other

23 As ED.00.15.001 As ED.00.15.001 As ED.00.15.001

Equipment

Any Other Supplier

24 As ED.00.15.001 As ED.00.15.001 As ED.00.15.001

3 Materials

3.1 Sanitaryware Products

Ref. Code Item/ Brand Name Preferred Alternative Alternative

Location Vendor Vendor Vendor

1 SN01 Water Valsir 8205XX Duravit AG Twyfords Armitage

closet with Shanks

fl h l

Leigh & Orange Ltd. Page D3/19

Document No. 2115-0-14-0002 - Revision 1 DDIFA – 21 December 2007

GTC-05/197/ED ECS FOR MULTI-PURPOSE ADMINISTRATION COMPLEX-RAS LAFFAN

PARTICULAR SPECIFICATION

SECTION D3 – PLUMBING WORKS

flush valve

cistern

2 SN02 Water Washpoint wm Armitage Twyfords Duravit AG

closet with shanks

flush valve

cistern

3 SN03 Wash basin Cherwell 42 Armitage Twyfords Duravit AG

under-coun shanks

ter type

4 SN04 Wash basin E1221 Ideal Twyfords Duravit AG

wall-mount standard

ed type

5 SN05 Wash basin Vero Duravit AG Twyfords Armitage

counter-top #04456000000 Shanks

6 SN06 Bathtub White 170 Ideal Twyfords Duravit AG

standard

7 SN07 Urinal “KS”499A Duravit AG Twyfords Armitage

Shanks

8 SN10 Single lever S8247AA Armitage Twyfords Duravit AG

mixer shanks

wall-mount

ed type

9 SN11 Basin mixer Nuastyle Armitage Twyfords Duravit AG

thermostatic shanks

basin mixer

10 SN12 Single lever Contour Armitage Twyfords Duravit AG

mixer and shanks

spout

11 SN13 Shower set 27980 000 Hansgrohe Twyfords Duravit AG

12 SN14 Shower 10645 000 Hansgrohe Twyfords Duravit AG

i

Leigh & Orange Ltd. Page D3/20

Document No. 2115-0-14-0002 - Revision 1 DDIFA – 21 December 2007

GTC-05/197/ED ECS FOR MULTI-PURPOSE ADMINISTRATION COMPLEX-RAS LAFFAN

PARTICULAR SPECIFICATION

SECTION D3 – PLUMBING WORKS

mixer

13 SN15 Hand TX472SES TOTO Twyfords Armitage

shower Shanks

with wall

outlet

14 SN16 Shower TX443SES TOTO Twyfords Armitage

mixer Shanks

15 SN17 Two handle Vola 1511 Vola Twyfords Armitage

basin mixer Shanks

16 SN18 Shower rail Vola T34 + 172 Vola Twyfords Armitage

with hand Shanks

shower

17 SN19 Mixing Vola S42 Vola Twyfords Armitage

valve Shanks

18 SN20 Two handle Vola BK6 Vola Twyfords Armitage

mixer with Shanks

double

swivel spot

19 SN21 Sink mixer Minta 32 168 Minta Twyfords Armitage

with swivel Shanks

spout and

mousser

20 SN38 Disable Doc m standard Armitage Twyfords Duravit AG

toilet pack pack shanks

21 SN40 Disable Doc m shower Armitage Twyfords Duravit AG

shower room pack shanks

room pack

22 SN41 Squatting V412301 + Armitage Twyfords Duravit AG

water S362267 + shanks

closet pan S4512MY

with cistern

Leigh & Orange Ltd. Page D3/21

Document No. 2115-0-14-0002 - Revision 1 DDIFA – 21 December 2007

GTC-05/197/ED ECS FOR MULTI-PURPOSE ADMINISTRATION COMPLEX-RAS LAFFAN

PARTICULAR SPECIFICATION

SECTION D3 – PLUMBING WORKS

23 SN42 Disable S5929 Armitage Twyfords Duravit AG

shower shanks

room

pack –

cleaner’s

sink

24 SN43 Quarter S7190AA Armitage Twyfords Duravit AG

turn bib shanks

taps

25 SN45 Corner S2725 Armitage Twyfords Duravit AG

wash basin shanks

26 SN46 Pillar taps S7004 Armitage Twyfords Duravit AG

shanks

27 SN47 Water S3090 + S3857 Armitage Twyfords Duravit AG

closet shanks

Leigh & Orange Ltd. Page D3/22

Document No. 2115-0-14-0002 - Revision 1 DDIFA – 21 December 2007

You might also like

- Computer Programs for ChemistryFrom EverandComputer Programs for ChemistryDeLos DeTarNo ratings yet

- QP 2170at 1 Fire Services FF FaDocument25 pagesQP 2170at 1 Fire Services FF Faahmed fouadNo ratings yet

- QP 2150AT 1 DrainageDocument7 pagesQP 2150AT 1 Drainageahmed fouadNo ratings yet

- Optimization and Business Improvement Studies in Upstream Oil and Gas IndustryFrom EverandOptimization and Business Improvement Studies in Upstream Oil and Gas IndustryNo ratings yet

- QP 2145AT 1 SewerDocument11 pagesQP 2145AT 1 Sewerahmed fouadNo ratings yet

- Transistor Electronics: Use of Semiconductor Components in Switching OperationsFrom EverandTransistor Electronics: Use of Semiconductor Components in Switching OperationsRating: 1 out of 5 stars1/5 (1)

- QP 2165at 1 AcmvDocument44 pagesQP 2165at 1 Acmvahmed fouadNo ratings yet

- Bridge Technology ReportFrom EverandBridge Technology ReportNo ratings yet

- GGL LucknowDocument525 pagesGGL LucknowPraveen KumarNo ratings yet

- Presentation Gis Cam August 2016Document114 pagesPresentation Gis Cam August 2016anmohieyNo ratings yet

- Yanbu Industrial City, KSA: Itp For Hvac (Heating Ventilation and Air Conditioning) System InstallationDocument5 pagesYanbu Industrial City, KSA: Itp For Hvac (Heating Ventilation and Air Conditioning) System InstallationHARSHAL100% (2)

- 6 of 16 E-1 - Electrical Tech SpecsDocument122 pages6 of 16 E-1 - Electrical Tech SpecsHari HaranNo ratings yet

- I1912 Ai Opr Itp 0070 00 Itp For Pelmet WorkDocument4 pagesI1912 Ai Opr Itp 0070 00 Itp For Pelmet WorkAiplshubh ChavanNo ratings yet

- 000 Pe DS 0001Document5 pages000 Pe DS 0001Dar FallNo ratings yet

- q11017 0100d Lps Sta Pk2 Ele MST 00010 c3 Gi and Flexible ConduitDocument77 pagesq11017 0100d Lps Sta Pk2 Ele MST 00010 c3 Gi and Flexible ConduitJobish ManikulathNo ratings yet

- Spec - Fuel Gas Conditioning SystemDocument416 pagesSpec - Fuel Gas Conditioning SystemVijaya Kumar S100% (3)

- Itp For STR Steel WorksDocument9 pagesItp For STR Steel WorksGauravSinghNo ratings yet

- Circulating Water Pipes and Fittings - Rev 1Document14 pagesCirculating Water Pipes and Fittings - Rev 1Yurizal firmansyahNo ratings yet

- Pcba Process Manual: Manual WHQ-SQD - Man003 Rev.7 Effective From: ReleasedDocument40 pagesPcba Process Manual: Manual WHQ-SQD - Man003 Rev.7 Effective From: ReleasedTuan Hung NguyenNo ratings yet

- QPR-RLP-011 - Rev 0 - Guidelines For End User Technical Submissions To RLCDocument42 pagesQPR-RLP-011 - Rev 0 - Guidelines For End User Technical Submissions To RLCakshayNo ratings yet

- Wash Column - E1172-U81-PS-DS-101408 - B PDFDocument13 pagesWash Column - E1172-U81-PS-DS-101408 - B PDFrutujaNo ratings yet

- Technical Specification N SOW For G 7 Sector 8 Dwarka 66 11KV Grid Substation NIT 316Document453 pagesTechnical Specification N SOW For G 7 Sector 8 Dwarka 66 11KV Grid Substation NIT 316KAVITA100% (2)

- CRS R12-S00c01-Tie-Mat-Ci-0004Document1 pageCRS R12-S00c01-Tie-Mat-Ci-0004alamfb243No ratings yet

- KCC Jec (Ons) 38281 MST 0126 00Document95 pagesKCC Jec (Ons) 38281 MST 0126 00Riaz AhmadNo ratings yet

- QP SPC L 002 Rev 1Document80 pagesQP SPC L 002 Rev 1Vinod Kumar100% (3)

- ONSHORE TO RISER-FYP-NG01011278-ESTA1-LA-4306-00001-001 Pipeline Material Take Off R02Document17 pagesONSHORE TO RISER-FYP-NG01011278-ESTA1-LA-4306-00001-001 Pipeline Material Take Off R02margaret aideNo ratings yet

- P Package List: PKG Description RemarksDocument119 pagesP Package List: PKG Description RemarksEric IbisNo ratings yet

- RMU TenderDocument167 pagesRMU TenderbadriharishNo ratings yet

- Letter To Camtech For Mtc. ManualDocument16 pagesLetter To Camtech For Mtc. ManualElectrical General Northern RailwayNo ratings yet

- DRP001 Ouf Twe MTS e 000 002 O1Document17 pagesDRP001 Ouf Twe MTS e 000 002 O1ibrahimNo ratings yet

- Ismb ItpDocument3 pagesIsmb ItpKumar AbhishekNo ratings yet

- Upper Zakum 750 Islands Surface Facilities Project - EPC2 PROJECT No. P7512Document15 pagesUpper Zakum 750 Islands Surface Facilities Project - EPC2 PROJECT No. P7512Anonymous xyZH2OaUVNo ratings yet

- Tender DetailsDocument531 pagesTender Detailsvinaykumar cNo ratings yet

- Section C Technical Specifications of Stores PDFDocument77 pagesSection C Technical Specifications of Stores PDFVikin JainNo ratings yet

- Write Up-Civil-Structural and Architechtural C191022-00-CS-RPT-1001 - C1 (06-02-2020)Document18 pagesWrite Up-Civil-Structural and Architechtural C191022-00-CS-RPT-1001 - C1 (06-02-2020)nivedita vermaNo ratings yet

- Work Instruction For Overall Plot Plan: 1 13.05.2020 First Issue TV UV KRTDocument8 pagesWork Instruction For Overall Plot Plan: 1 13.05.2020 First Issue TV UV KRTvishal bhamreNo ratings yet

- Qap (T183-E-Qp-003) For LT PanelDocument14 pagesQap (T183-E-Qp-003) For LT PanelTejendra TambeNo ratings yet

- 11kV SWGR EP-MS-P4-S2-082 2013Document86 pages11kV SWGR EP-MS-P4-S2-082 2013dimaomar89% (9)

- Wa0024.Document133 pagesWa0024.ilavarasanNo ratings yet

- Attachment 2 - Comments On App 5&6Document7 pagesAttachment 2 - Comments On App 5&6gauravNo ratings yet

- 1798 CaRs R2 03july2023 Analog Loop Logic Diagram For Fly Ash Handling SystemDocument6 pages1798 CaRs R2 03july2023 Analog Loop Logic Diagram For Fly Ash Handling SystemVao Van Ngam VaoNo ratings yet

- K2S-CWS230907-GEN-BA6070-00007 - A01 - Work Method Statement For The Installation of 8mva TransfomerDocument16 pagesK2S-CWS230907-GEN-BA6070-00007 - A01 - Work Method Statement For The Installation of 8mva TransfomerAzeta Robert100% (1)

- SP - DS LSDocument5 pagesSP - DS LSsakhr fahdNo ratings yet

- API Standards For Safe Offshore Operations BrochureDocument1 pageAPI Standards For Safe Offshore Operations BrochureVõ Quang Kiệt100% (1)

- 1796 CaRs R2 09mar23 400V Schematic Wiring Diagram For Fly Ash Handling System - HDEC ReplyDocument4 pages1796 CaRs R2 09mar23 400V Schematic Wiring Diagram For Fly Ash Handling System - HDEC ReplyVao Van Ngam VaoNo ratings yet

- Datos Adjuntos Sin Título 00680Document9 pagesDatos Adjuntos Sin Título 00680Carlos AvendañoNo ratings yet

- Less Than Three Vendors of RdsoDocument11 pagesLess Than Three Vendors of RdsoYOU COMFY YOU LOSENo ratings yet

- IDBU-CW-LSPDS-000029 Rev G - Upstream Piping Comp. SelectDocument115 pagesIDBU-CW-LSPDS-000029 Rev G - Upstream Piping Comp. Selectjoey garciaNo ratings yet

- 8015-0151-SECL-00-000-ME-BD-00004 - 02 - Design Basis For Rotating and Package Equipment PDFDocument26 pages8015-0151-SECL-00-000-ME-BD-00004 - 02 - Design Basis For Rotating and Package Equipment PDFDamiano TondelliNo ratings yet

- DRP001-OUF-SPE-Q-000-512 B1 Pipeline Weld Numbering ProcedureDocument11 pagesDRP001-OUF-SPE-Q-000-512 B1 Pipeline Weld Numbering ProcedureDaniel Martinez100% (1)

- Aa-152-Sg - Common-Cabling - 2020376Document9 pagesAa-152-Sg - Common-Cabling - 2020376Venki TekkaliNo ratings yet

- HU-01 - Node 12Document3 pagesHU-01 - Node 12gusyahri001No ratings yet

- Barracuda and Caratinga Crude Oil Fields Production Facilities ProjectDocument87 pagesBarracuda and Caratinga Crude Oil Fields Production Facilities ProjectneivaprojetosNo ratings yet

- Grt-E-01-A1-Cs-001 - Cable Size Calc - Rev 0 PDFDocument21 pagesGrt-E-01-A1-Cs-001 - Cable Size Calc - Rev 0 PDFFarah Diba Pos-PosNo ratings yet

- 4001 Rev.9 - FS For CP System For Offshore StructureDocument9 pages4001 Rev.9 - FS For CP System For Offshore Structuresridar rNo ratings yet

- Signature Not Verified: Digitally Signed by Manish Kumar Date: 2019.07.26 15:58:08 IST Reason: CAT I Location: NtpceocDocument56 pagesSignature Not Verified: Digitally Signed by Manish Kumar Date: 2019.07.26 15:58:08 IST Reason: CAT I Location: NtpceocpraveshjhambNo ratings yet

- Enclouser 2Document4 pagesEnclouser 2Trishul Nath PallayNo ratings yet

- Engineering Standards Manual STD-342-100: Chapter 6, Mechanical Section D10+E10 EquipmentDocument8 pagesEngineering Standards Manual STD-342-100: Chapter 6, Mechanical Section D10+E10 EquipmentmanuNo ratings yet

- Draft Spect No Ti-Psi-Hvcb-0121Document38 pagesDraft Spect No Ti-Psi-Hvcb-0121Lanka SatyavathiNo ratings yet

- 2275AT 1 IrrigationDocument13 pages2275AT 1 Irrigationahmed fouadNo ratings yet

- 2250at 1 HelicopterDocument10 pages2250at 1 Helicopterahmed fouadNo ratings yet

- 2255at 1 Special RoofDocument16 pages2255at 1 Special Roofahmed fouadNo ratings yet

- 2265at 1 External WorksDocument30 pages2265at 1 External Worksahmed fouadNo ratings yet

- 2240at 1 External Duct Qtel ElvDocument5 pages2240at 1 External Duct Qtel Elvahmed fouadNo ratings yet

- Al-Othman Design Criteria-Rev2Document13 pagesAl-Othman Design Criteria-Rev2ahmed fouadNo ratings yet

- ICAO Annex14 AviationDocument2 pagesICAO Annex14 Aviationahmed fouadNo ratings yet

- Battery Room Ventilation Fan - Electric..Document3 pagesBattery Room Ventilation Fan - Electric..ahmed fouadNo ratings yet

- Key Plan:: Emergency Lighting SchematicDocument1 pageKey Plan:: Emergency Lighting Schematicahmed fouadNo ratings yet

- Design CRITERIA Report SAUDDocument13 pagesDesign CRITERIA Report SAUDahmed fouadNo ratings yet

- SECTION 16721 Fire Alarm SystemDocument8 pagesSECTION 16721 Fire Alarm Systemahmed fouadNo ratings yet

- Loop Isolator Module - SHIELD Fire, Safety & Security LTDDocument3 pagesLoop Isolator Module - SHIELD Fire, Safety & Security LTDahmed fouadNo ratings yet

- QP Fire and Safety Philosophy - QP-PHL-S-0001 Rev.03 2013 46-60Document15 pagesQP Fire and Safety Philosophy - QP-PHL-S-0001 Rev.03 2013 46-60ahmed fouadNo ratings yet

- QP Fire and Safety Philosophy - QP-PHL-S-0001 Rev.03 2013 31-45Document15 pagesQP Fire and Safety Philosophy - QP-PHL-S-0001 Rev.03 2013 31-45ahmed fouadNo ratings yet

- Vendor List 02dec2021Document3 pagesVendor List 02dec2021ahmed fouadNo ratings yet

- QP Fire and Safety Philosophy - QP-PHL-S-0001 Rev.03 2013 1-15Document15 pagesQP Fire and Safety Philosophy - QP-PHL-S-0001 Rev.03 2013 1-15ahmed fouadNo ratings yet

- QP Fire and Safety Philosophy - QP-PHL-S-0001 Rev.03 2013Document23 pagesQP Fire and Safety Philosophy - QP-PHL-S-0001 Rev.03 2013ahmed fouadNo ratings yet

- QP Fire and Safety Philosophy - QP-PHL-S-0001 Rev.03 2013 16-30Document15 pagesQP Fire and Safety Philosophy - QP-PHL-S-0001 Rev.03 2013 16-30ahmed fouadNo ratings yet

- HAFB POL Proposal PDFDocument74 pagesHAFB POL Proposal PDFEmily FergusonNo ratings yet

- Construction and Performance of Curtain Wall Systems For Super Highrise Buildings - The Hong Kong's ExperienceDocument13 pagesConstruction and Performance of Curtain Wall Systems For Super Highrise Buildings - The Hong Kong's ExperienceHeronijosh DgNo ratings yet

- 10 1016@j Energy 2018 06 128Document25 pages10 1016@j Energy 2018 06 128luminita vlongaNo ratings yet

- Plumbing Pipe Insulation Specification Submitted By: Armacell LLCDocument5 pagesPlumbing Pipe Insulation Specification Submitted By: Armacell LLCKarthy GanesanNo ratings yet

- Bill of Quantity: Baner Lifespaces LLPDocument7 pagesBill of Quantity: Baner Lifespaces LLPSales AlufacadesNo ratings yet

- Fundamental of Motor ThermalDocument18 pagesFundamental of Motor ThermalOmarMatSlsNo ratings yet

- Cap - 8 - Libro Jeffrey D. Spitler PDFDocument44 pagesCap - 8 - Libro Jeffrey D. Spitler PDFChristian Gabriel Vargas SolanoNo ratings yet

- SCGT Catalog 2012 PDFDocument54 pagesSCGT Catalog 2012 PDFChanna SannNo ratings yet

- 09 Zeta Hafif Celik Galvenizli Celik Yapi Teknik Sartname - Tr.enDocument2 pages09 Zeta Hafif Celik Galvenizli Celik Yapi Teknik Sartname - Tr.enVengatesh HariNo ratings yet

- Climatology - QUESTION BANK (NTU)Document8 pagesClimatology - QUESTION BANK (NTU)Vinoth KumarNo ratings yet

- SOS Children's Village Aqaba, JordanDocument24 pagesSOS Children's Village Aqaba, JordanSadia SamiNo ratings yet

- C177 - Test Method For Steady-State Heat Flux Measurements & Thermal Transmission Properties by Means of The Guarded-Hot-Plate ApparatusDocument22 pagesC177 - Test Method For Steady-State Heat Flux Measurements & Thermal Transmission Properties by Means of The Guarded-Hot-Plate ApparatusLech Ray Gomez CordobaNo ratings yet

- STEICO Tec Guide Construction en IDocument40 pagesSTEICO Tec Guide Construction en Ijoker63000No ratings yet

- BASF Rigid Foam enDocument14 pagesBASF Rigid Foam enSathya PrakashNo ratings yet

- Receptor Terasa VerdeDocument1 pageReceptor Terasa VerdeIonut SomneaNo ratings yet

- Teace Housing ThesisDocument9 pagesTeace Housing ThesisMedha GuptaNo ratings yet

- Eea - Unit 1Document121 pagesEea - Unit 1Mohammed MuthaharNo ratings yet

- Horno kd250Document48 pagesHorno kd250Steeve FigueroaNo ratings yet

- WEB bbb4 Catalog PDFDocument128 pagesWEB bbb4 Catalog PDFDiego PascualNo ratings yet

- Whole-Building Hygrothermal Modeling in IEA Annex 41Document15 pagesWhole-Building Hygrothermal Modeling in IEA Annex 41Ahmad Fazlizan AbdullahNo ratings yet

- Conclusion Sheet For StrategiesDocument4 pagesConclusion Sheet For StrategiesRashi KondwilkarNo ratings yet

- The HamletDocument20 pagesThe HamletswathiNo ratings yet

- Soudal Trade BrochureDocument52 pagesSoudal Trade BrochureComillaNo ratings yet

- BUILD YOUR OWN SHIPPING CONTAINER HOME 3rd EdDocument217 pagesBUILD YOUR OWN SHIPPING CONTAINER HOME 3rd EdAlejandro Mata89% (9)

- NAIMA BI475 Comparing Fiber Glass and Cellulose InsulationDocument6 pagesNAIMA BI475 Comparing Fiber Glass and Cellulose InsulationBehailu FelekeNo ratings yet

- Coconut Shell Building Blocks: Propject Proposal Ref. No.: 39S - Be - 0241Document3 pagesCoconut Shell Building Blocks: Propject Proposal Ref. No.: 39S - Be - 0241Tanzeem AhmedNo ratings yet

- Tray Drying ChamberDocument4 pagesTray Drying ChamberAcmas IndiaNo ratings yet

- Optim-R IRMA Brochure US 1809Document10 pagesOptim-R IRMA Brochure US 1809Loan ÁnhNo ratings yet

- Technical Data of Vacuum Formed Ceramic Fiber PDFDocument2 pagesTechnical Data of Vacuum Formed Ceramic Fiber PDFba ajinNo ratings yet

- Research Papers ICCMS 2K18 International Conference On Constrction MaterialsDocument194 pagesResearch Papers ICCMS 2K18 International Conference On Constrction MaterialsSriramNo ratings yet

- Gas-Liquid And Liquid-Liquid SeparatorsFrom EverandGas-Liquid And Liquid-Liquid SeparatorsRating: 3.5 out of 5 stars3.5/5 (3)

- Well Testing Project Management: Onshore and Offshore OperationsFrom EverandWell Testing Project Management: Onshore and Offshore OperationsNo ratings yet

- Machine Learning and Data Science in the Oil and Gas Industry: Best Practices, Tools, and Case StudiesFrom EverandMachine Learning and Data Science in the Oil and Gas Industry: Best Practices, Tools, and Case StudiesPatrick BangertRating: 3 out of 5 stars3/5 (2)

- Machine Learning Guide for Oil and Gas Using Python: A Step-by-Step Breakdown with Data, Algorithms, Codes, and ApplicationsFrom EverandMachine Learning Guide for Oil and Gas Using Python: A Step-by-Step Breakdown with Data, Algorithms, Codes, and ApplicationsRating: 4 out of 5 stars4/5 (4)

- Well Control for Completions and InterventionsFrom EverandWell Control for Completions and InterventionsRating: 4 out of 5 stars4/5 (10)

- Practical Reservoir Engineering and CharacterizationFrom EverandPractical Reservoir Engineering and CharacterizationRating: 4.5 out of 5 stars4.5/5 (3)

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- Biostratigraphic and Geological Significance of Planktonic ForaminiferaFrom EverandBiostratigraphic and Geological Significance of Planktonic ForaminiferaRating: 4 out of 5 stars4/5 (5)

- Essentials of Coating, Painting, and Lining for the Oil, Gas and Petrochemical IndustriesFrom EverandEssentials of Coating, Painting, and Lining for the Oil, Gas and Petrochemical IndustriesRating: 5 out of 5 stars5/5 (5)

- Gas and Oil Reliability Engineering: Modeling and AnalysisFrom EverandGas and Oil Reliability Engineering: Modeling and AnalysisRating: 4.5 out of 5 stars4.5/5 (6)

- Mooring System Engineering for Offshore StructuresFrom EverandMooring System Engineering for Offshore StructuresRating: 5 out of 5 stars5/5 (1)

- Advanced Biomass Gasification: New Concepts for Efficiency Increase and Product FlexibilityFrom EverandAdvanced Biomass Gasification: New Concepts for Efficiency Increase and Product FlexibilityRating: 3 out of 5 stars3/5 (2)

- Advanced Production Decline Analysis and ApplicationFrom EverandAdvanced Production Decline Analysis and ApplicationRating: 3.5 out of 5 stars3.5/5 (4)

- Asphaltene Deposition Control by Chemical Inhibitors: Theoretical and Practical ProspectsFrom EverandAsphaltene Deposition Control by Chemical Inhibitors: Theoretical and Practical ProspectsNo ratings yet

- Machinery Lubrication Technician (MLT) I and II Certification Exam GuideFrom EverandMachinery Lubrication Technician (MLT) I and II Certification Exam GuideRating: 2 out of 5 stars2/5 (1)

- Petroleum Production Engineering, A Computer-Assisted ApproachFrom EverandPetroleum Production Engineering, A Computer-Assisted ApproachRating: 4.5 out of 5 stars4.5/5 (11)