Professional Documents

Culture Documents

Lifting Plan For Tower

Uploaded by

Shafie ZubierOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lifting Plan For Tower

Uploaded by

Shafie ZubierCopyright:

Available Formats

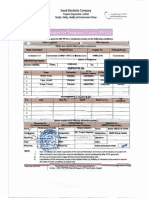

CONTRACT NO: 4400012358 Contract No.

CONSTRUCTION OF 380KV DC OHTL IN QIDDIYA 4400012358

AREA

Version 0

LIFTING PLAN FOR TOWER Issued

25/08/202

0

LIFTING PLAN FOR TOWER

PREPARED BY: REVIEWED BY CHECKED BY: APPROVED BY:

IQBAL

NAME: MHAMMAD ABULLAH IBRAHIM ALI

POSITION ESH MANAGER CONSTRUCTION MANAGER PROJECT MANAGER SEC

SIGNATURE

DATE: 25th August 2020

AL-HAIDER COMPANY CONTRACT No. 4400012358

CONTRACT NO: 4400012358 Contract No.

CONSTRUCTION OF 380KV DC OHTL IN QIDDIYA 4400012358

AREA

Version 0

LIFTING PLAN FOR TOWER Issued

25/08/202

0

CONTENTS

1.0 Purpose

2.0 Scope & Activities

3.0 Responsibilities

4.0 Persons Responsible For Planning Lifting

5.0 Supervisor

6.0 Execution

7.0 Lifting Workers Safety

10 Questions For A Safe Lift

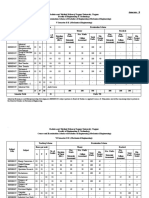

Detail Of Lifted Materials

1,0 PURPOSE

This document replaces the “Method Statement for Lifting Operation up to 10 Tones”

with current tile “Lifting Plan for Tower Components (Transmission tower lattice)” to

provides the procedure to be used for crane operational practices. The key to safe

crane operation is having AHC Competent Person using the correct equipment in a safe

manner. This procedure will outline the issues relating to the selection of the correct

people for the task. It will describe the operational practices to be used by these people

as part of a safe and effective crane and rigging program. In particular, below standards

of Lifting Operations shall be complied. Safety manager shall ensure that every Lifting

operation involving Lifting equipment is:

Properly planned by a competent person

Appropriately supervised

Carried out in a safe manner

In this regulation "Lifting operation" means an operation concerned with the Lifting or

lowering of a load.

AL-HAIDER COMPANY CONTRACT No. 4400012358

CONTRACT NO: 4400012358 Contract No.

CONSTRUCTION OF 380KV DC OHTL IN QIDDIYA 4400012358

AREA

Version 0

LIFTING PLAN FOR TOWER Issued

25/08/202

0

2.0 SCOPE & ACTIVITIES

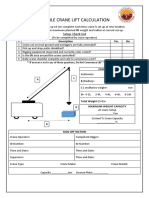

Lifting of Transmission tower lattice from 1.5 TONS to 7.00 TONS USING 60 T MOBILE

CRANE.

This procedure applies to all AHC lifting operations. The lift plan process describes the

systematic assessment of important load factors and site factors. It is as applicable to

“simple” routine lifts as well as non-routine lifts. Planning a non-routine lift requires

considerable effort. In a lift determined to be non- critical, many of the elements can be

determined "by inspection"; and the depth involved in a non-routine lift will not be

required. Nevertheless, the planning process must be followed. This procedure

prohibits a person from riding or travelling on the load, lifting hook, sling, platform or

other lifting medium.

This document should be used as a reference, to aide for Lifting operations and Lifting

equipment and AHC workers to consider the safety factors when they assess, plan,

supervise and carry out Lifting activities.

3.0 RESPONSIBILITIES

PROJECT MANAGER

Responsible for the overall execution of the project and ensure the full implementation

of the work Safety Plan in accordance with the project specification.

CONSTRUCTION MANAGER

Responsible for Work Planning, Organizing, Control the execution of the work and

evaluate the construction department under the direction of the project manager and

ensure that all works are carried out as per project drawings and specification,

Responsible for giving assign task and giving correct instruction to Site Engineers, Site

Supervisors including assigned Lifting Supervisors.

SAFETY ENGINEER

Responsible for Implementation of SEC Safety Standards to all AHC personnel and All

workers with coordination to Project and Construction Manager.Monitor all Safety

Incident Report and take proper action with clear and effective control measures.

Direct report to project manager and call of immediate stop works if there this

imminent danger occurring to lifting operations.

AL-HAIDER COMPANY CONTRACT No. 4400012358

CONTRACT NO: 4400012358 Contract No.

CONSTRUCTION OF 380KV DC OHTL IN QIDDIYA 4400012358

AREA

Version 0

LIFTING PLAN FOR TOWER Issued

25/08/202

0

Review all lifting documents and provide lift Risk assessment.

Monitor Lifting activities in all aspects.

Monitor Safety Officer Incident reports.

Take necessary action if unsafe act and unsafe condition identified and call of

immediate stop work if needed.

Provide proper and clear recommendation for safe lifting process.

SAFETY OFFICER

Safety officer Must make themselves aware of this guidance document ;

understand their responsibilities with regard to Lifting operations and Lifting

equipment and the links to the relevant health and safety legislation around

Lifting operations. Monitor safe system of works and all the lift calculation sheets

ensure TBT is been implemented.

Conduct pre-task briefing and Tool Box meeting prior to start of lifting activities.

All Lifting equipment within their areas of control are identified. Ensure that all Lifting

equipment used for Lifting operations is appropriate for the task, used correctly and that

employees involved in the organizing, planning and use of Lifting equipment are suitably

trained. Report all incident happen involving workers to Unsafe act and near messes. Call

immediate temporary stop works if imminent danger is arising during lifting process and

direct report to AHC Site Manager.

LIFTING COMPETENT PERSON

Site lifting supervisor has overall responsibility for the lift. Supervision must plan all

phases of operation, cooperating fully with the operator who has the final say

regarding the safety of the lifting operation. Site supervision is specifically responsible

for.

Verifying that the crane certification and inspection records are up to date before

allowing the crane on the project. Organizing a pre-lift meeting and ensuring all the

appropriate people are present.

Establishing a lift plan and ensuring it is followed.

Providing a well prepared working area for the crane before it arrives on the job. This

involves ensuring that: Access roads are adequately prepared. There is room to erect

and/or extend the boom. Operating locations are graded, level, and compacted. The

crane operator & rigger will be told if the ground is soft and if hardwood mats or

cribbing are needed. Operating locations are far enough away from shoring,

excavations, trenches, buried utilities, foundations, etc. to eliminate the risk of collapse.

Cones, warning tape or barricades are positioned to prevent entry into hazardous areas

around and especially behind the crane.

AL-HAIDER COMPANY CONTRACT No. 4400012358

CONTRACT NO: 4400012358 Contract No.

CONSTRUCTION OF 380KV DC OHTL IN QIDDIYA 4400012358

AREA

Version 0

LIFTING PLAN FOR TOWER Issued

25/08/202

0

Access to the lift area is prohibited and barricades are available. Supervising all work

involving the crane. Determining the correct load weight and radius, and informing the

operator.

Ensuring that the rigger 3 experienced and competent. They must be capable of

establishing weights; judging distances, heights and clearances; selecting tackle and

lifting gear suitable for the loads; and rigging the load safely and securely.

Supervising the Lifting Activity. Ensuring that the load is properly rigged.

Ensuring that the signalpersons are competent and capable of directing the crane and

load to ensure the safety and efficiency of the operation. Knowing the international

hand signals is a must. Designating signalpersons and ensuring that the operator

knows who they are. Ensuring the safety of the rigging crew and all other personnel

affected by the rigging operation. Controlling the movements of all personnel within

the area affected by the lift. Ensuring that all required safety precautions are taken

when the lift is in the vicinity of power lines.

Ensuring that all personnel involved in the operation understand their jobs and

responsibilities. Ensuring that an emergency response plan is in place and is

communicated to all relevant personnel.

CRANE OPERATOR

Knowing the machine well. The operator must understand its functions and limitations

as well as its particular operating characteristics.

Having a thorough knowledge of the information contained in the crane's operating

manual. Being familiar with the crane's load chart. The operator must understand the

correct meaning of all notes and warnings and be able to calculate or determine the

crane's actual net capacity for every possible configuration of the machine.

Inspecting and maintaining the crane regularly as prescribed by both the owner and

manufacturer. Daily crane check list or report the details of all inspections,

maintenance, and other work done on the crane while in the field. Checking that the

site is adequately prepared for the crane. Finding out the load and rigging weight and

determining where the load is to be placed. Determining the number of parts of hoist

line required. Checking the load chart to ensure that the crane has sufficient net

lifting capacity for every lift. Selecting (from the range diagram) the best boom, jib,

and crane configuration to suit the load, site and lift conditions.

Assembling, setting up and rigging the crane properly.

AL-HAIDER COMPANY CONTRACT No. 4400012358

CONTRACT NO: 4400012358 Contract No.

CONSTRUCTION OF 380KV DC OHTL IN QIDDIYA 4400012358

AREA

Version 0

LIFTING PLAN FOR TOWER Issued

25/08/202

0

Following the manufacturer's operating instructions in accordance with the load chart.

Considering all factors that might reduce crane lift capacity and adjusting the load

weight to suit. This will include such factors as weather conditions and ground

conditions. Knowing basics of rigging procedures and ensuring that they are applied

(this is possible only when the load is visible to the operator). Maintaining

communication with signalpersons. Operating in a smooth, controlled, and safe

manner.

Shutting down and securing the machine properly when it is unattended. Exercising

the right to refuse to operate the crane if there is cause to suspect the lift might be

unsafe.

AL-HAIDER COMPANY CONTRACT No. 4400012358

CONTRACT NO: 4400012358 Contract No.

CONSTRUCTION OF 380KV DC OHTL IN QIDDIYA 4400012358

AREA

Version 0

LIFTING PLAN FOR TOWER Issued

25/08/202

0

RIGGER LEVEL 3

Responsible for signaling for lifting work and secure the lifting and moving of

materials, and machines, while utilizing power operated equipment such as hoists,

winches, cranes, etc. Assists and determines the proper method of lifting equipment for

each assigned project; Assists with the set-up of crane; Conducts basic loading of heavy

lift projects by rigging the crane equipment and ensuring the proper use of each

equipment method. Directs crane operators to move equipment to and from work

areas. Ability to optimize resources (manpower, equipment and materials) to ensure

efficient and timely completion of the project. Ensures that work crews are properly

supplied with tools, equipment and materials. Prevents the misuse of equipment,

materials and tools. Ability to read, interpret and follow procedures. Competent in

reading and understanding specifications, Keeps records of all work completed.

Specifies locations for movement of machinery using knowledge of various methods of

sliding and lifting equipment. Directs workers engaged in splicing ropes and metal

cables to form hoisting slings. Familiar with and enforces strict compliance with all

Safety procedures, including all Company rules and regulations.

Performs other duties as assigned.

4.0 PERSONS RESPONSIBLE FO R WORKING FIXING

TOWER/LINEMAN

AHC LINEMAN

Been given the responsibility for planning lifting operations should have the

sufficient technical, practical and theoretical training, knowledge and experience

of the work they are like to plan lifts for. These linemen (persons) will vary

depending on the type of lifting work being carried out and are likely to be

different to the other labors referred to in regulation

.

They should:

Be capable of identifying the hazards and risks associated to lifting operations

within their area of work or the environment where the lifting operation will

take place/and fixing towers. Be able to select the correct fixing equipment for

the work .Understand the characteristics of the tower lattice fixing equipment they

are selecting and the nature of the work it will be carrying out.

Carry out t h e w o r k and know the risk assessments (lifting operation/fixing

towers) have the ability to communicate their findings to those involved in and

affected by the f i x i n g lifted lattice parts. Be able to know method statements or

lifting plans and safe systems of work for tower fixing operations.

Where appropriate seek additional support and expertise including the use of

external specialists to assist them with the fixing of lifted tower parts operation

AL-HAIDER COMPANY CONTRACT No. 4400012358

CONTRACT NO: 4400012358 Contract No.

CONSTRUCTION OF 380KV DC OHTL IN QIDDIYA 4400012358

AREA

Version 0

LIFTING PLAN FOR TOWER Issued

25/08/202

0

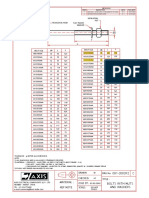

5.0 EXECUTION

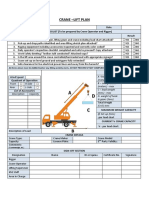

LIFTING LEG EXTENSION/BODY EXTENSION/BASIC BODY/CROSS ARMS

AHC Construction will Lift the ground assembled transmission tower parts to the point

of the towers, and it is divided in to different components, as shown in the drawing e.g.

tower parts No.1, No.2, No.3, No.4 & No.5 with a travel distance as per radius mention

on drawing 4 Meter to 8 Meters from fixing point of the towers to the Mobile crane.

(Please see attach Plan View of Lifting Location)

COMMUNICATION OF LIFT PLAN

Prior to starting of lifting operations a competent person/Site Engineer shall hold a

toolbox talk with all personnel assigned to carry out the lift. Application of the

questions for a safe lift’ to the lift shall be covered during the toolbox talk. The person-

in-charge shall be clearly identified and made known to all members of the lift team

and personnel in the proximity. All personnel involved in the lifting/fixing operation

shall have their individual responsibilities clearly allocated. All personnel should have

the opportunity to review the findings of the risk assessment and the details of the lift

plan to ensure that everyone clearly understands and agrees with the methods and

control measures to be used.

CONDUCTING THE LIFTING OPERATION

Lifting operations shall be conducted in strict accordance with the approved by SEC lift

plan. Any variation from the lift plan shall result in the job being stopped and

reassessed to ensure continued safe operation. The lifting operator shall obey an

emergency stop signal at all times, no matter who gives it. When lifting operations

need to be controlled by signals, a designated signal person/Rigger shall be assigned.

Signals between the lifting crane operator and the designated signal person (rigger)

shall be audible or visible at all times. The appropriate load-radius chart for the lifting

appliance configuration in use shall be visible to the operator. Load to be lifted shall be

confirmed to be within the rated capacity of the lifting equipment and attached by

means of suitable lifting accessories. The operator of the lifting appliance shall not

leave the operating controls while the load is suspended.

Tower is been on sequence step start from Tower part No. 1, 2 ,3, 4 & 5 the lifting area

must be barred and Lifting Signage should be installed with the present rigger

AL-HAIDER COMPANY CONTRACT No. 4400012358

CONTRACT NO: 4400012358 Contract No.

CONSTRUCTION OF 380KV DC OHTL IN QIDDIYA 4400012358

AREA

Version 0

LIFTING PLAN FOR TOWER Issued

25/08/202

0

AHC Safety Engineer/Officer must ensure that the lifting area is been properly

barricaded and all workers must wear proper PPE’S

TOOLS & EQUIPMENT:

One hook, Slings as required, Shackles. Signal Flag (Red & Green)

Barricades, Full body harness, Life line, Warning Signage (e.g. On Going Lifting)

PPE (Adequate personal protective equipment)

Crane 60 T, Ambulance, First Aider.

WORK METHODOLOGY:

Prior to carry out any work all materials & equipment shall be ready and inspected at

site by rigger, operator including AHC Safety Engineer/Officer. All workers involve in

this job should be oriented properly by pre-task briefing prior to start lifting process

and tool box meeting. The planned positions of the crane must be marked before

working. A safety clear zone consisting of the radius + 10m should be identified 360

degrees around all cranes. The load must be controlled by tag line only. The operator

must make sure that the safe angle inserted in the crane computer. Use chain pullers to

connect the lifting belt & chiller body in the bump side to avoid any swinging. Control

the length of the hook to get perfect balance by using spirit level for indication.

Note:

All workers must use helmet, safety shoes, vest, gloves & glasses. The communication

must be by the rigger only by using lifting signals.

MOVING THE LOAD

Prior to lifting the Rigger & Safety Engineer/Officer shall be satisfied that the load is

secure and properly balanced and that the load path is clear of obstructions.

At commencement of the first lift the Crane Operator shall carefully check the

operation of the hoist brake to ensure no slippage occurs Take up sling slack to confirm

that the Lifting Appliance hook has been positioned centrally over the load lifting point,

adjust the Lifting Equipment as necessary to minimize any ‘drift’ of the load as it is

lifted No external forces shall be applied to the load that create significant side loading

of the Lifting Equipment, For crane operations appropriate tag lines shall be used to

control the load– large or long loads with flat sides that could act as a ‘sail’ are

particularly prone to spinning and tag lines shall be used – tag lines shall be secured to

the load and not to the rigging slings. Cranes shall not be used for dragging a load.

AL-HAIDER COMPANY CONTRACT No. 4400012358

CONTRACT NO: 4400012358 Contract No.

CONSTRUCTION OF 380KV DC OHTL IN QIDDIYA 4400012358

AREA

Version 0

LIFTING PLAN FOR TOWER Issued

25/08/202

0

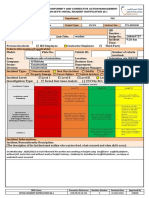

REACTING TO CHANGING CONDITIONS

All critical lifting parameters (e.g. weather, (raining, sand storm, visibility, stability and

slope, surrounding operations and installations, site access and egress, Lifting

Equipment, personnel) shall be identified during the risk assessment and preparation

of the Lift Plan.

AHC Safety will not allowed any lifting activities in site, if the present wind speed will

above 32KPH all lifting activity in site shall be suspended. During heavy sand storm and

zero visibility condition AHC Site lifting activity will be suspended not and less if the

climate and weather condition will be on normal condition including wind speed.

The AHC Safety ensure that these conditions are monitored as lifting operations

proceed to ensure continued safety of Lifting Process. If, as part of the operation and

maintenance of equipment, the computer system shuts down the operation, the load

must be placed on the ground and a new lift plan must be developed, eliminating the

condition that caused the shutdown. Procedures for recovering and landing the load in

the event of the lift being aborted shall be clearly identified.

6.0 CRANE

Daily / Pre-Use Inspections

These inspections must be performed and documented by the CRANE operator prior to

first use each day or shift the CRANE is used. These checks ensure that audible and

visual warning equipment is working correctly by carrying out function tests prior to

any lifting operations.

Before each operation or series of operations, the Operator shall:

Perform a pre-operational check to demonstrate operational readiness of the crane. If

controls do not operate properly, the Operator is responsible for notifying the

supervisor. Repairs and adjustments are made before operations begin. Ensure the

equipment is within inspection and testing intervals by examination of the periodic

certification tags and/or documentation. Adhere to all tags on the controls Ensure, if

fitted, that seat belts are worn when operating must be repaired

AL-HAIDER COMPANY CONTRACT No. 4400012358

CONTRACT NO: 4400012358 Contract No.

CONSTRUCTION OF 380KV DC OHTL IN QIDDIYA 4400012358

AREA

Version 0

LIFTING PLAN FOR TOWER Issued

25/08/202

0

During operations, crane Operator shall Comply all SEC Requirement in

Construction Site:

Drive at speeds limit which 20 KPH in al SEC Construction Site for the existing

conditions (space, load, lighting, surface conditions, etc.) and at or below

posted limits Keep all parts of the body inside the Operator compartment

during operations Not start or operate the crane or any of its attachments from

any place other than from the Operators position Ensure other personnel are

not in the swing radius prior to performing turning maneuvers, Sound the horn

when approaching, locations where pedestrians may step into the path of

crane travel.

Verify sufficient headroom under overhead installations, lights, wiring, pipes,

sprinkler systems etc. Ensure they are driven on suitable surfaces. Road humps

and rough or soft surfaces are to be avoided, Movement with loads in

excessively raised positions shall not be carried out to avoid the danger of

toppling, especially on uneven surfaces and while cornering shall only be used

for loads, which can be carried safely on the attachments fitted.

Unauthorized personnel shall not be permitted to ride on crane. A safe place to

ride (i.e. another seat) should be. Provided where riding of truck is authorized.

Equipment shall not be loaded beyond its rated load (capacity) except for

required testing. Trucks should not be driven up to anyone standing in front of

an object

When parked:

The engine shall be switched off, the key removed and the hand-brake applied.

The keys shall be kept in a secure place and only issued to authorized

operators for the duration of the duty period or task. They shall be parked in

secure areas to deter access by unauthorized personnel. They do not block

access to fire aisles, stairways, or fire equipment

While refueling, the engine shall be stopped. No Lifting operation will be take

place, is not allowed.

LIFTING WORKERS SAFETY

AL-HAIDER COMPANY CONTRACT No. 4400012358

CONTRACT NO: 4400012358 Contract No.

CONSTRUCTION OF 380KV DC OHTL IN QIDDIYA 4400012358

AREA

Version 0

LIFTING PLAN FOR TOWER Issued

25/08/202

0

Lifting Personnel & Worker shall:

Keep all parts of the body, tools, and equipment inside the work platform

periphery during raising, lowering, and travelling operations Hold onto a

moving tag line using both hands, Secure tools and other objects in canvas bags

or by other methods so that both hands are free and do not present a snagging

hazard. Wear fall protection with a lanyard attached to an authorized lanyard

anchorage point. If needed Detailed technical operating procedures describing

personnel lifting device operation, emergency steps, communication

requirements, and special requirements should be prepared, Consideration

shall be given to prevailing environmental conditions (e.g. wind speed max.

12.5 m/s or as indicated by manufacturer), as well as aspects of the device

before commencing operations

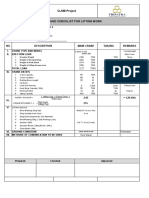

7.0 10 QUESTIONS FOR A SAFE LIFT

Is everyone aware of and do they fully understand the lifting and

hoisting procedure applicable to the lift?

Has everyone attended the toolbox talk?

Has a pre-use inspection of the Lifting Equipment been carried out and

are the Lifting Accessories tagged or marked with:

Safe Working Load

A unique identification number

A valid certification date

Are all safety devices working?

Does everyone know the Person-in-Charge of the lift?

Is everyone competent and aware of his tasks?

Is there a current Lift Plan and RA and does everybody understand the

job and precautions?

Does everyone know the environmental Limit? (e.g. maximum

permissible Wind speed) for the lift?

Is the lift area controlled and is everyone clear if the load falls or

swings?

Are signaling methods and communication agreed and clear to you?

AL-HAIDER COMPANY CONTRACT No. 4400012358

You might also like

- Shifting and placement of porta cabinDocument19 pagesShifting and placement of porta cabinshamshad ahamed50% (2)

- Lifting Plan HseDocument22 pagesLifting Plan HseRamod Kumar100% (3)

- U63b&c Lifting PlanDocument7 pagesU63b&c Lifting PlanIrshad Akhter100% (2)

- Lifting Plan For 62.07 RepairDocument6 pagesLifting Plan For 62.07 RepairLaith Salman100% (1)

- Lifting Plan for Generator Set at CB SPL MahakamDocument10 pagesLifting Plan for Generator Set at CB SPL MahakamAditya Permana PutraNo ratings yet

- Crane Lifting Calculation SheetDocument1 pageCrane Lifting Calculation SheetAkbar Dawood100% (1)

- Lifting Plan SheetDocument2 pagesLifting Plan SheetAalam Irshad100% (1)

- Crane Lift ChecklistDocument1 pageCrane Lift ChecklistHamid Ali100% (5)

- Crane Lift Plan: Company Name Project: ClientDocument5 pagesCrane Lift Plan: Company Name Project: Clientscottie Mailau100% (1)

- Rigging Study & Lifting Plan For Oil Storage Tank at NaimatDocument15 pagesRigging Study & Lifting Plan For Oil Storage Tank at NaimatEngr Arfan Ali Dhamraho100% (4)

- Subcontractor Hse Mobilization Checklist PDFDocument2 pagesSubcontractor Hse Mobilization Checklist PDFshareyhouNo ratings yet

- WMSRA For Loading Unloading of Office Containers and Installation of Office Containers - FinalDocument17 pagesWMSRA For Loading Unloading of Office Containers and Installation of Office Containers - FinalAnandu Ashokan50% (2)

- Lifting PlanDocument35 pagesLifting PlanAva GhaziNo ratings yet

- Lifting Plan For Med Risk Rev 11 FinalDocument2 pagesLifting Plan For Med Risk Rev 11 FinalŠhiññ ŠóhäïNo ratings yet

- Mobile Crane Lift PlanDocument2 pagesMobile Crane Lift PlanSagar Sharma100% (1)

- Document No: Date: 17-03-12: Method Statement For The Lifting of E & I RoomDocument3 pagesDocument No: Date: 17-03-12: Method Statement For The Lifting of E & I RoomShaikh Mohd QaisarNo ratings yet

- Method Statement For Tower CraneDocument11 pagesMethod Statement For Tower Cranenavani100% (1)

- Tower Crane Method StatmentDocument6 pagesTower Crane Method StatmentMosarub HossainNo ratings yet

- Method Statement For Lifting WorksDocument12 pagesMethod Statement For Lifting WorksBeomHee Lee100% (1)

- Rescue Plan SRS 1Document4 pagesRescue Plan SRS 1Salah Abd EldayemNo ratings yet

- Lifting Plan: General Information: LP - 01 / Rev 00Document8 pagesLifting Plan: General Information: LP - 01 / Rev 00Ram BeesettiNo ratings yet

- Generic lifting plan titleDocument3 pagesGeneric lifting plan titlemuhammad umarNo ratings yet

- G18-2-LP-003 DG - Lifting PlanDocument25 pagesG18-2-LP-003 DG - Lifting PlanMohammed JassimNo ratings yet

- Lifting Plan For Equipment - MMSPDocument14 pagesLifting Plan For Equipment - MMSPClifford100% (1)

- Critical Lift Plan FormDocument1 pageCritical Lift Plan FormMuhammad Afif MansorNo ratings yet

- Lift PlanDocument25 pagesLift Plansea_man100% (1)

- General lifting layout and checklistDocument2 pagesGeneral lifting layout and checklistMohd Firdaus KamaruddinNo ratings yet

- Lifting PlanDocument23 pagesLifting PlanSameer KmNo ratings yet

- Risk Assessment - Backfilling Around Foul Sewer and Storm Warter ManholesDocument6 pagesRisk Assessment - Backfilling Around Foul Sewer and Storm Warter Manholesloveson70950% (2)

- Concreting and ShutteringDocument3 pagesConcreting and ShutteringAnuj Kjoy0% (1)

- Lifting Plan FormDocument3 pagesLifting Plan FormFahrul Andi100% (3)

- Safety Attachment-4 - Lifting PlanDocument4 pagesSafety Attachment-4 - Lifting Planvisanu100% (1)

- Rmdjv-pj74-Hiradc-subc 08l (Steel Structure Erection)Document2 pagesRmdjv-pj74-Hiradc-subc 08l (Steel Structure Erection)myn maliQueNo ratings yet

- Lift PlanDocument26 pagesLift Planvinodhyper89% (9)

- Lifting Plan Site InspectionDocument5 pagesLifting Plan Site Inspectionkhaled redaNo ratings yet

- Lifting PlanDocument9 pagesLifting Plansatyabrath dhalNo ratings yet

- Lifting Plan for PipesDocument5 pagesLifting Plan for Pipesjafo_211No ratings yet

- Construction Logistics Plan: Project: TolworthDocument28 pagesConstruction Logistics Plan: Project: TolworthSRIRAM D100% (1)

- Lifting Calculation - Erection Container 20ft Dan 40ftDocument22 pagesLifting Calculation - Erection Container 20ft Dan 40ftMuhammad Teguh100% (1)

- Checklist FormworkDocument2 pagesChecklist FormworkSreyleap Nhet100% (2)

- DWall Cage Lifting PlanDocument13 pagesDWall Cage Lifting PlanShreedhar100% (3)

- Mobile Crane Lift Calculation PDFDocument1 pageMobile Crane Lift Calculation PDFIrham M AF0% (2)

- Lifting Plan For Off-Loading of Tanks at Mazari YardDocument9 pagesLifting Plan For Off-Loading of Tanks at Mazari Yardmeshahan100% (1)

- Water Tank Base Construction Hazard Identification and Risk ControlDocument5 pagesWater Tank Base Construction Hazard Identification and Risk Controlramod100% (2)

- 3074 - Use of Genie Man LiftDocument1 page3074 - Use of Genie Man Liftcmrig74No ratings yet

- Unloading Material Method StatementDocument4 pagesUnloading Material Method StatementPaul LadjarNo ratings yet

- JSA-Construction Right of WayDocument3 pagesJSA-Construction Right of Wayfrancis_e_tan100% (5)

- RISK ASSESSMENT - Tower Crane DraftDocument12 pagesRISK ASSESSMENT - Tower Crane Draftloveson70933% (3)

- Mobilization and Installation of CHW PipesDocument8 pagesMobilization and Installation of CHW PipesYounis KhanNo ratings yet

- CoP - 34.0 - Safe Use of Lifting Equipment and Lifting AccessoriesDocument23 pagesCoP - 34.0 - Safe Use of Lifting Equipment and Lifting AccessoriesMuhammadHabibUrRehman100% (3)

- UPC-MSS-ER006P02-00021rev01-Method Statement and Risk Assessment For The Erection of Tower Crane (UPC TC 02)Document35 pagesUPC-MSS-ER006P02-00021rev01-Method Statement and Risk Assessment For The Erection of Tower Crane (UPC TC 02)Julius Ceasar Sanorjo100% (4)

- PMF 015 HSE 151 v1 Lifting PlanDocument8 pagesPMF 015 HSE 151 v1 Lifting Plansikandar1234No ratings yet

- Critical Lifting Plan 10T, 80% Capacity, One Side 10m: Al-Dur Ii Iwpp ProjectDocument1 pageCritical Lifting Plan 10T, 80% Capacity, One Side 10m: Al-Dur Ii Iwpp ProjectJianping KeNo ratings yet

- Appendix - Nlng-lp-017 - Lift Plan For Lifting and Installation of Roof Trusses of Amenities Building (19418) - Comments From MosesDocument32 pagesAppendix - Nlng-lp-017 - Lift Plan For Lifting and Installation of Roof Trusses of Amenities Building (19418) - Comments From MosesAdebayo M JayeolaNo ratings yet

- LIFTING PLAN FOR Foundation and Miscelanious Items Using Telehandler - AUHJ460Document16 pagesLIFTING PLAN FOR Foundation and Miscelanious Items Using Telehandler - AUHJ460Balram Kumar PandeyNo ratings yet

- Job Safety Analysis for Pipeline LoadingDocument8 pagesJob Safety Analysis for Pipeline LoadingMoaatazz NouisriNo ratings yet

- Lift Plan Drawing GCC - Tandem LiftDocument1 pageLift Plan Drawing GCC - Tandem LiftBrijesh 'Robin'0% (1)

- 20SWCG00051 1 100 0000le Ie0 MS 001007 - 00aDocument14 pages20SWCG00051 1 100 0000le Ie0 MS 001007 - 00afayaz5233No ratings yet

- Lifting Plan for Installation of ChillersDocument9 pagesLifting Plan for Installation of ChillersAbid RehmanNo ratings yet

- Method Statement For GIS.1Document8 pagesMethod Statement For GIS.1Jaafar Lagayan100% (9)

- Risk Assessment and Jop Safety Practice JSPDocument20 pagesRisk Assessment and Jop Safety Practice JSPShafie ZubierNo ratings yet

- ABC - ra.CWSS.19-HIRA-Erection of Precast Columns, BeamsDocument5 pagesABC - ra.CWSS.19-HIRA-Erection of Precast Columns, BeamsShafie ZubierNo ratings yet

- AVOIDINGDocument4 pagesAVOIDINGShafie ZubierNo ratings yet

- ABC-SFOP-36 Fall Protection PlanDocument25 pagesABC-SFOP-36 Fall Protection PlanShafie ZubierNo ratings yet

- JSA For Erection of Precast..Document18 pagesJSA For Erection of Precast..Shafie ZubierNo ratings yet

- CONFIDocument5 pagesCONFIShafie ZubierNo ratings yet

- ConfinedDocument5 pagesConfinedShafie ZubierNo ratings yet

- Back InjDocument4 pagesBack InjShafie ZubierNo ratings yet

- Wen-Jing ZHANG, Li-Mao ZHANG, Xian-Guo WU and Yang LIUDocument6 pagesWen-Jing ZHANG, Li-Mao ZHANG, Xian-Guo WU and Yang LIUShafie ZubierNo ratings yet

- Alrajhi-0 24197511330724852Document1 pageAlrajhi-0 24197511330724852Shafie ZubierNo ratings yet

- 4 WK No. 05 (Month) 2022 Sepdc-Central - Weekly Kpi - (Project Name) - Rev. 02 (Individual)Document5 pages4 WK No. 05 (Month) 2022 Sepdc-Central - Weekly Kpi - (Project Name) - Rev. 02 (Individual)Shafie ZubierNo ratings yet

- Nebosh Jan 2014 Unit IC Report Int. Dip. in H&SDocument11 pagesNebosh Jan 2014 Unit IC Report Int. Dip. in H&SJafar KhanNo ratings yet

- Cons TrucDocument3 pagesCons TrucShafie ZubierNo ratings yet

- Prevent Caught-In Hazards with Safe Work PracticesDocument6 pagesPrevent Caught-In Hazards with Safe Work PracticesShafie ZubierNo ratings yet

- WK No. - (Month) 2022 SEPDC-CENTRAL - WEEKLY KPI - (Project Name) - REV. 02 (INDIVIDUAL)Document5 pagesWK No. - (Month) 2022 SEPDC-CENTRAL - WEEKLY KPI - (Project Name) - REV. 02 (INDIVIDUAL)Shafie ZubierNo ratings yet

- Alrajhi-0 24197511330724852Document1 pageAlrajhi-0 24197511330724852Shafie Zubier100% (1)

- OHS-PR-09-26-F01 INITIAL INCIDENT NOTIFICATION SS8358 Misk City ABC, January 26, 2022Document2 pagesOHS-PR-09-26-F01 INITIAL INCIDENT NOTIFICATION SS8358 Misk City ABC, January 26, 2022Shafie ZubierNo ratings yet

- Environmental Inspection Model - Updated JanDocument2 pagesEnvironmental Inspection Model - Updated JanShafie ZubierNo ratings yet

- Safety issues at Misk City SS projectDocument13 pagesSafety issues at Misk City SS projectShafie ZubierNo ratings yet

- Salary Certificate LetterDocument1 pageSalary Certificate LetterShafie ZubierNo ratings yet

- W04 Safety Observations Report (8358 SS&L) MISK CITY PTS-20CN190 ABC, 22-01-2022Document5 pagesW04 Safety Observations Report (8358 SS&L) MISK CITY PTS-20CN190 ABC, 22-01-2022Shafie Zubier100% (1)

- Quality, Safety, Health and Environment Group: Saudi Electricity Company Projects Department-CentralDocument3 pagesQuality, Safety, Health and Environment Group: Saudi Electricity Company Projects Department-CentralShafie ZubierNo ratings yet

- RRC ME Dubai - Course Booking Form v1.03 1908 (2418)Document3 pagesRRC ME Dubai - Course Booking Form v1.03 1908 (2418)Shafie ZubierNo ratings yet

- Reasonable Adjustments Request Form - New (2) (2) (3262)Document2 pagesReasonable Adjustments Request Form - New (2) (2) (3262)Shafie ZubierNo ratings yet

- Elshafie Elzubier Elsiddig Ali: EducationDocument4 pagesElshafie Elzubier Elsiddig Ali: EducationShafie ZubierNo ratings yet

- A.1 General A.2 Normative References A.3 Terms and Definitions A.4 Context of The OrganizationDocument2 pagesA.1 General A.2 Normative References A.3 Terms and Definitions A.4 Context of The OrganizationShafie ZubierNo ratings yet

- HVPD-C Decemberr 2021-SS8358 MISK-Manpower and Man-Working HourDocument354 pagesHVPD-C Decemberr 2021-SS8358 MISK-Manpower and Man-Working HourShafie ZubierNo ratings yet

- Diploma Questions Unit IC Element WiseDocument68 pagesDiploma Questions Unit IC Element WiseShafie ZubierNo ratings yet

- HVPD-C Decemberr 2021-SS8358 MISK-Manpower and Man-Working HourDocument354 pagesHVPD-C Decemberr 2021-SS8358 MISK-Manpower and Man-Working HourShafie ZubierNo ratings yet

- MR Khurram Chakwal 6kw Hybrid - 024627Document6 pagesMR Khurram Chakwal 6kw Hybrid - 024627Shahid HussainNo ratings yet

- ExcelDocument1 pageExcelJosh KempNo ratings yet

- Soc 1 Report Salesforce Services - 5EwWEDocument75 pagesSoc 1 Report Salesforce Services - 5EwWEArif IqbalNo ratings yet

- Material: Ref Note: Rev # Description Appv. Rev DateDocument1 pageMaterial: Ref Note: Rev # Description Appv. Rev DateNimish TaterhNo ratings yet

- Document 10Document5 pagesDocument 10Filza FatimaNo ratings yet

- 2015 Idmp Employee Intentions Final PDFDocument19 pages2015 Idmp Employee Intentions Final PDFAstridNo ratings yet

- Lab Exercise 3 SoilScie Group4Document10 pagesLab Exercise 3 SoilScie Group4Jhunard Christian O. AsayasNo ratings yet

- DENR CC 2022 1st - Edition FIN 25 - March - 2022Document234 pagesDENR CC 2022 1st - Edition FIN 25 - March - 2022CENRO BANGUED PLANNINGNo ratings yet

- Handling Precautions: Butterfly Valves (Common To All Models)Document9 pagesHandling Precautions: Butterfly Valves (Common To All Models)xaaabbb_550464353No ratings yet

- Adb Doc Easa Reliance 8 Centerline Stopbar Declaracao de Conformidade EasaDocument2 pagesAdb Doc Easa Reliance 8 Centerline Stopbar Declaracao de Conformidade Easagiant360No ratings yet

- Incidentrequest Closed Monthly JunDocument250 pagesIncidentrequest Closed Monthly Junأحمد أبوعرفهNo ratings yet

- Moisture Control Guidance For Building Design, Construction and Maintenance (2013)Document144 pagesMoisture Control Guidance For Building Design, Construction and Maintenance (2013)Schreiber_Dieses100% (1)

- BSW, BS,,AF, BA and Metric Tool SizeDocument4 pagesBSW, BS,,AF, BA and Metric Tool SizeUNES100% (1)

- Mil STD 1686CDocument18 pagesMil STD 1686CNam NguyenNo ratings yet

- Lecture 9 - StatisticsDocument4 pagesLecture 9 - StatisticsMohanad SulimanNo ratings yet

- Republic of The Philippines, Petitioner, vs. Sandiganbayan, Major General Josephus Q. Ramas and Elizabeth Dimaano, RespondentsDocument23 pagesRepublic of The Philippines, Petitioner, vs. Sandiganbayan, Major General Josephus Q. Ramas and Elizabeth Dimaano, RespondentsKenzo RodisNo ratings yet

- Auditing Theory - Audit ReportDocument26 pagesAuditing Theory - Audit ReportCarina Espallardo-RelucioNo ratings yet

- The Beatles Album Back CoverDocument1 pageThe Beatles Album Back CoverSophia AvraamNo ratings yet

- Citect SCADA 2018 R2 - Configuration - Study GuideDocument19 pagesCitect SCADA 2018 R2 - Configuration - Study GuideAlex Sales0% (1)

- Meritor 210 220 230 240 2SpeedSingleAxlesDocument27 pagesMeritor 210 220 230 240 2SpeedSingleAxlesYhojan DiazNo ratings yet

- 06 Plastic Model KitsDocument1 page06 Plastic Model KitsLeonidas MianoNo ratings yet

- Indian Standard: Specification For Reels and Drums For Bare ConductorsDocument13 pagesIndian Standard: Specification For Reels and Drums For Bare ConductorsUppala Krishna ChaitanyaNo ratings yet

- PMDC Renewal FormDocument3 pagesPMDC Renewal FormAmjad Ali100% (1)

- ASSIGNMENTDocument5 pagesASSIGNMENTClifford Jay CalihatNo ratings yet

- Mechanical Engineering Semester SchemeDocument35 pagesMechanical Engineering Semester Schemesantvan jagtapNo ratings yet

- Tutorial MagIC Net 2.XDocument99 pagesTutorial MagIC Net 2.XJuan Diego Aznar Fernández100% (1)

- J-19-16-III - Bengali - FDocument24 pagesJ-19-16-III - Bengali - FDebayanbasu.juNo ratings yet

- Service Driven Logistics System - Basic Service CapabilityDocument12 pagesService Driven Logistics System - Basic Service CapabilityAnusha Sunkara80% (5)

- Standards in Nursing Education ProgrammeDocument13 pagesStandards in Nursing Education ProgrammeSupriya chhetryNo ratings yet

- Challenging Cognitive Distortions HealthyPsych - ComDocument1 pageChallenging Cognitive Distortions HealthyPsych - ComLeila MargaridaNo ratings yet