Professional Documents

Culture Documents

Effect of Shaft Misalignment On The Stresses Distribution of Spur Gears

Uploaded by

emreali1Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Effect of Shaft Misalignment On The Stresses Distribution of Spur Gears

Uploaded by

emreali1Copyright:

Available Formats

Eng. & Tech. Journal, Vol. 28, No.

7, 2010

Effect of Shaft Misalignment on The Stresses Distribution

of Spur Gears

Dr. Hani Aziz Ameen*

Received on :17/8/2009

Accepted on:7/1/2010

Abstract

Shaft misalignment is considered as one of the common repeated

problems in most rotating machineries , which leads to generate vibrations and

extra dynamic loads on transmitting gears teeth, also leads to non- uniformity in

distribution of applied load along the meshing tooth face by being concentrated on

one side of tooth face. The present work concentrated on the analysis of stresses

generated on transmitting gear tooth, also studied the effect of misalignment angle

on stress distribution and its concentration. This is important for the gear design

and those who works in gear maintenance , because fracture is expected to initiate

and propagate at locations of stress concentration . ANSYS program using finite

element technique had been used, as this program is efficient and accurate tool in

stress analysis, especially for complicated shapes. Gear tooth model had been

analyzed using finite element method in three dimensions. After calculating

transmitted load and dynamic load, misalignment angle had been changed from

(0°,0.2°,0.3°,0.4°,0.5°) then its effect on distribution of applied load had been

calculated. The finite element program (ANSYS) had been executed for cases of

misalignment angle (0°,0.2°,0.3°,0.4°,0.5°). The results showed clearly, that the

stresses distribution and its concentration on tooth changed with misalignment

angle and the equivalent stress is direct proportional with the misalignment angle.

According to the values of generated stresses, the tooth fracture can be predicted.

Keywords: Machine Design , Gear Design , Finite Element Method, Stresses

Analysis, ANSYS software, Misalignment

ﺘﺄﺜﻴﺭ ﻋﺩﻡ ﺍﻟﻤﺤﺎﺫﺍﺓ ﻓﻲ ﻋﻤﻭﺩ ﺍﻟﺩﻭﺭﺍﻥ ﻋﻠﻰ ﺘﻭﺯﻴﻊ ﺍﻻﺠﻬﺎﺩﺍﺕ ﻟﻠﺘﺭﻭﺱ ﺍﻟﻤﺴﺘﻘﻴﻤﺔ

ﺍﻟﺨﻼﺼﺔ

ﺘﻌﺩ ﻤﺴﺄﻟﺔ ﻋﺩﻡ ﺍﻟﻤﺤﺎﺫﺍﺓ ﻓﻲ ﻋﻤﻭﺩ ﺍﻟﺩﻭﺭﺍﻥ ﻤﻥ ﺍﻟﻤﺸﺎﻜل ﺍﻟﺘﺸﻐﻴﻠﻴﺔ ﺍﻟﺸﺎﺌﻌﺔ ﻭﺍﻟﻤﺘﻜﺭﺭﺓ ﻓﻲ

ﺍﺫ ﺘﺅﺩﻱ ﺍﻟﻰ ﺘﻭﻟﻴﺩ ﺍﻫﺘﺯﺍﺯﺍﺕ ﻭﺍﺤﻤﺎل ﺩﻴﻨﺎﻤﻴﻜﻴﺔ ﺍﻀﺎﻓﻴﺔ ﻋﻠﻰ ﺍﺴﻨﺎﻥ ﺍﻟﺘﺭﻭﺱ،ﻤﻌﻅﻡ ﺍﻟﻤﻜﺎﺌﻥ

ﻭﺍﻟﻰ ﻋﺩﻡ ﺍﻨﺘﻅﺎﻡ ﺘﻭﺯﻉ ﺍﻟﺤﻤل ﺍﻟﻤﺴﻠﻁ ﻋﻠﻰ ﺍﻤﺘﺩﺍﺩ ﺴﻁﺢ ﺍﻟﺴﻥ ﺍﻟﻤﻌﺸﻕ ﺒﺘﺭﻜﺯﻩ.ﺍﻟﻨﺎﻗﻠﺔ ﻟﻠﺤﺭﻜﺔ

ﻴﺭﻜﺯ ﺍﻟﺒﺤﺙ ﺍﻟﺤﺎﻟﻲ ﺤﻭل ﺘﺤﻠﻴل ﺍﻻﺠﻬﺎﺩﺍﺕ ﺍﻟﻤﺘﻭﻟﺩﺓ ﻋﻠﻰ ﺴﻥ ﺘﺭﺱ.ﻋﻠﻰ ﺠﺎﻨﺏ ﻤﻥ ﺴﻁﺢ ﺍﻟﺴﻥ

ﻭﺩﺭﺍﺴﺔ ﺘﺎﺜﻴﺭ ﺍﻟﺘﻐﻴﺭ ﻓﻲ ﺯﺍﻭﻴﺔ ﻋﺩﻡ ﺍﻟﻤﺤﺎﺫﺍﺓ ﻋﻠﻰ ﺘﻭﺯﻉ ﻫﺫﻩ ﺍﻻﺠﻬﺎﺩﺍﺕ ﻭﺘﺭﻜﺯﻫﺎ، ﻨﺎﻗل ﻟﻠﺤﺭﻜﺔ

ﻨﻅﺭﺍ ﻟﻤﺎ ﻟﺩﺭﺍﺴﺔ ﺘﺭﻜﺯ ﺍﻻﺠﻬﺎﺩﺍﺕ ﻤﻥ ﺍﻫﻤﻴﺔ ﺒﺎﻟﻨﺴﺒﺔ ﻟﻌﺎﻤﻠﻴﻥ ﻓﻲ ﻤﺠﺎﻻﺕ ﺘﺼﻤﻴﻡ ﺍﻟﺘﺭﻭﺱ

ﺘﻡ ﻓﻲ ﻫﺫﺍ. ﺍﺫ ﻴﺘﻭﻗﻊ ﺍﻥ ﻴﺒﺩﺃ ﺍﻟﻜﺴﺭ ﻭﻴﺘﻨﺎﻤﻰ ﻋﻨﺩ ﻤﻨﺎﻁﻕ ﺘﺭﻜﺯ ﺍﻻﺠﻬﺎﺩﺍﺕ.ﻭﺘﺸﻐﻴﻠﻬﺎ ﻭﺼﻴﺎﻨﺘﻬﺎ

ﺒﻭﺼﻔﻬﺎ ﺍﺩﺍﺓ ﻓﺎﻋﻠﺔ ﻭﺩﻗﻴﻘﺔANSYS ﺍﻟﺒﺤﺙ ﺍﺴﺘﺨﺩﺍﻡ ﻁﺭﻴﻘﺔ ﺍﻟﻌﻨﺎﻁﺭ ﺍﻟﻤﺤﺩﺩﺓ ﻤﻥ ﺨﻼل ﺒﺭﻨﺎﻤﺞ

ﺍﺠﺭﻱ ﺘﺤﻠﻴل ﻨﻤﻭﺫﺝ ﺴﻥ ﺍﻟﺘﺭﺱ ﺒﺘﻘﻨﻴﺔ ﺍﻟﻌﻨﺎﺼﺭ.ﻓﻲ ﺘﺤﻠﻴل ﺍﻻﺠﻬﺎﺩﺍﺕ ﻭﻻﺴﻴﻤﺎ ﻟﻼﺸﻜﺎل ﺍﻟﻤﻌﻘﺩﺓ

ﻭﺒﻌﺩ ﺤﺴﺎﺏ ﺍﻟﺤﻤل ﺍﻟﻤﻨﻘﻭل ﻭﺍﻟﺤﻤل ﺍﻟﺩﻴﻨﺎﻤﻴﻜﻲ ﺍﻻﻀﺎﻓﻲ ﺘﻡ ﺘﻐﻴﻴﺭ ﺯﺍﻭﻴﺔ، ﺍﻟﻤﺤﺩﺩﺓ ﺒﺜﻼﺜﺔ ﺍﺒﻌﺎﺩ

* Pumps Engineering Department, Technical College, Al-Musaib /Babylon

1321

PDF created with pdfFactory Pro trial version www.pdffactory.com

Eng. & Tech. Journal, Vol. 28, No. 7, 2010 Effect of Shaft Misalignment on The

Stresses Distribution of Spur Gears

ﻭﺤﺴﺎﺏ ﺘﺎﺜﻴﺭﻫﺎ ﻋﻠﻰ ﺘﻭﺯﻉ ﺍﻟﺤﻤل ﺍﻟﻤﺴﻠﻁ، ( °0.5 ، °0.4 ، °0.3 ، °0.2 ، °0) ﻋﺩﻡ ﺍﻟﻤﺤﺎﺫﺍﺓ

ﻟﻌﺩﺓ ﺤﺎﻻﺕ ﻤﻥ ﺯﻭﺍﻴﺎ ﻋﺩﻡ ﺍﻟﻤﺤﺎﺫﺍﺓANSYS ﺘﻡ ﺘﻨﻔﻴﺫ ﺒﺭﻨﺎﻤﺞ ﺍﻟـ.ﻋﻠﻰ ﺍﻟﺴﻥ ﺍﻟﻨﺎﻗل ﻟﻠﺤﺭﻜﺔ

ﻴﻤﻜﻥ ﻤﻼﺤﻅﺔ ﺍﻟﺘﻐﻴﺭ، ﻭﺒﻌﺩ ﻋﺭﺽ ﺍﻟﻨﺘﺎﺌﺞ ﺍﻟﻤﺴﺘﺤﺼﻠﺔ،( °0.5 ، °0.4 ، °0.3 ، °0.2 ، °0)

ﺍﻟﺫﻱ ﻴﻁﺭﺃ ﻋﻠﻰ ﺘﻭﺯﻉ ﺍﻻﺠﻬﺎﺩﺍﺕ ﻭﺘﺭﻜﺯﻫﺎ ﺒﻭﻀﻭﺡ ﻋﻠﻰ ﺴﻥ ﺍﻟﺘﺭﺱ ﻋﻨﺩ ﺘﻐﻴﺭ ﺯﺍﻭﻴﺔ ﻋﺩﻡ

وﺑﻤﻮﺟﺐ ﻗﯿﻢ ھﺬه، ﻭﺍﻥ ﺍﻻﺠﻬﺎﺩﺍﺕ ﺍﻟﻤﻜﺎﻓﺌﺔ ﺗﺘﻐﯿﺮ ﻃﺮدﯾﺎ ﻣﻊ زاوﯾﺔ ﻋﺪم اﻟﻤﺤﺎذاة، ﺍﻟﻤﺤﺎﺫﺍﺓ

. اﻻﺟﮭﺎدات اﻟﻤﺘﻮﻟﺪة ﯾﺘﻢ ﺗﺤﺪﯾﺪ اﻣﻜﺎﻧﯿﺔ ﺣﺪوث ﻛﺴﺮ ﻓﻲ اﻟﺴﻦ

Nomenclature a… constant depending on

T… applied torque pressure angle

P… transmitted power E p , E g Young modulus for the

ω … angular velocity pinion and gear

rb ... radius of base circle B′ … active gear width of contact

r… radius of pitch circle C z … spring constant

ψ … pressure angle f RW … directional error

m… module α … angle of misalignment

Z… number of teeth Introduction

Fi … load at contact point The reason of increasing the

d… pitch circle diameter (P.C.D.) stresses concentration on gear teeth is

δ ... total deflection at contact the misalignment of the shafts that

point transmitting the movement, this

δ B … bending deflection misalignment made non uniform

δS … shearing deflection distribution of transmitted loads along

gear face, which is caused generation

δ G … deflection due to the of the stresses concentration in

inclination of foundation specific region. Several researches

under load and studies have been done and used

δ P … compressive deflection different ways for the generated

ρ 2 ,ρ1 radii of curvature for the stresses analysis on the movement

B… width of gear transmitting gear teeth. Lewis

Sm… the location of applied load Equation which is treated the spur

E… Young modulus gear as a cantilever beam and it is the

υ … possion’s ration main method for calculating the

K… tooth stiffness at contact stresses in the root of the gear. Also

several studies have been done using

point

Fdyn … dynamic load Photoelasticity Technique to

determine the stresses concentration.

Ft … tangential component of

The widely used of finite element

applied load

method let the researchers to applied

V… linear velocity

c… parameter depending on the it on stress analysis of spur gear . Tae

material of gearing teeth and H. Chang and A. Kubo [1] studies the

pressure angle stresses distribution in spur gear , and

it is depended on the finite element

e… error in the shape of tooth

1322

PDF created with pdfFactory Pro trial version www.pdffactory.com

Eng. & Tech. Journal, Vol. 28, No. 7, 2010 Effect of Shaft Misalignment on The

Stresses Distribution of Spur Gears

method to analyze the stresses and Fi = T / rb ……. (2)

deformations in the gear and specify

rb = r. cos(ψ ) ……. (3)

the expected failure locations. V.

Simon [2] studies the loads and It is required to specify the basic

stresses distributions on the teeth for radius (r b), Pressure angle( ψ ),

spur and helical gears. M.Q. Abdullah module(m) and number of teeth (Z) ,

[3] studies the analysis of stresses and in order to calculate Fi , so in this

deformations on the gear teeth using study the following data are used :

finite element method, in this study a Pressure angle ( ψ ) = 20° , Module

complete program is built to generate ( m ) = 4 mm , No. of teeth (Z) = 50

the symmetry and unsymmetry spur teeth , (P.C.D) d= m.Z = 200 mm , r=

gear and analyze the stresses d/2 = 100 mm, hence, from Eq.(3)

distribution on it. D.G. Lewicki and r b = 93.969 mm , substituted into

R. Ballarini [4] studies the stresses Eq.(2) , the value of normal load can

distributions on the spur gear using be get

finite element methods. Fi=8133.843 N

In this paper the effect of Now to calculate the share of normal

misalignment of shaft on the stresses load at any contact point as follows:

distribution and its concentration on Total Deflection (δ) at Contact

the spur gear using finite element Point

method during ANSYS program is The total deflection at contact point

investigated. Also the effect of shaft can be calculated as follows[6]:

misalignment angle on the loads δ = δ B + δ S + δ G + δ P ..…. (4)

distribution and on the stresses where,

distribution and its concentration on

12 Fi cos2 (ψ) z 2 z2

the movement transmitted gear teeth δB = [S m + − Sm z]

E B SF 3 3

is studied.

Transmitted Load by Meshing of 6 Fi cos2 (ψ) (w - z)3

+ 3

Teeth E B SF

The load distribution on the gear ( w − Sm ) ( w − Sm )

width [5 ] is determined as the 4 −

following steps: ( w − z) ( w − z)

− 2 log e ( w − Sm ) − 3

Torque(T) =

Power (P)

…. (1) ( w − z)

ω(rad / sec) …..(5)

The values of transmitted power and

running speed are specified in order 2(1 + υ) Fi cos 2 (ψ )

to calculate the torque, in this study δS =

the values of P=400 kW and N=5000 E B SF

rpm w − z

So, from Eq.(1) , T = 764.331 N.m z + ( w − z) log e

The vertical load (Fi) which is w − Sm

transmitted by teeth meshing, can be …(6)

calculated by:

1323

PDF created with pdfFactory Pro trial version www.pdffactory.com

Eng. & Tech. Journal, Vol. 28, No. 7, 2010 Effect of Shaft Misalignment on The

Stresses Distribution of Spur Gears

nS F − zS K using the material of tooth and its size

w= …. (7) as follows:

S F − SK

δB

24 Fi S2m cos2 (ψ) = 181.635x10 −9 mm/N ,

δG = …. (8) Fi

π E B SF

δS

4 Fi (1 + υ2 ) ρ2 = 228.745x10 −9 mm/N

δP = … (9) Fi

πE B ρ1 + ρ2 δG

= 3682.788x10 −9 mm/N ,

where : Fi

δ B = Bending deflection δP

δ S = Shearing deflection = 83.848x10 −9 mm/N

Fi

δ G = Deflection due to the

δ tot δ B δS δ G δ P

inclination of foundation under = + + +

Fi Fi Fi Fi Fi

load

δ P = Compressive deflection = 4177.018 x10 − 9 mm/N

ρ 2 ,ρ1 = Radii of curvature for 1

K= = 239405.2 N/mm

the two teeth gearing at contact δ tot / Fi

point = Kc

Fig.(1) demonstrated the where

terms of teeth which are used in Kc = stiffness at point ( c ) .

calculated the deflection . The Dynamic Load

following data are used in this In order to demonstrate the

study: effect of the dynamic load ,

Sm = 6.338 mm , S F = 8.891 mm , Buckingham equation [7] is used,

SK = 4.93 mm, n = 9 mm , z = 1 according to this equation, the

mm dynamic load is depending on the

w = 18.957 mm , B = 40 mm , linear velocity (V), tangent load (Ft ),

ψ = 20° .Also , the Young tooth width (B) and the material

modulus (E) and Possion’s ratio properties of the gear .It can be

( υ ) of the material of tooth is : shown the Buckingham equation as

E = 207000 N/mm2 , υ = 0.3 follows[8]:

21V(Bce + Ft )

Fdyn = Ft + ...... (11)

21V + Bce + Ft

Tooth Stiffness at Contact Point

To Calculated the tooth stiffness at Ft = Fi cos( Ψ ) ....... (12)

contact point as follows[6]: where :

F e: error in the shape of tooth

K= i ….. (10) It can be found from tolerance

δ table in Refs[7,8] corresponding to

If the applied load equal to the

m= 4 mm

normal load , hence the load at

contact point ( c ) equal to : Fc = F i that e = 2 × 10 −6 m

=8133.843 N so, it can be explained

the stiffness of gear at point ( c )

1324

PDF created with pdfFactory Pro trial version www.pdffactory.com

Eng. & Tech. Journal, Vol. 28, No. 7, 2010 Effect of Shaft Misalignment on The

Stresses Distribution of Spur Gears

c: Parameter depending on the F( x ) = Fmax .[1 − (x/B ′) 3 ] ……. (14)

material of gearing teeth and the

It can be defined the tangential load

pressure on the gear width as follows [9] :

angle [8], B′ 3

a (E p E g ) F = Fm .B = ∫ F(x).dx= B′ Fmax … (15)

c= ….… (13) 0 4

(E p + E g ) Hence,

a: constant depending on pressure F

angle , when ψ = 20° , Fm = …… (16)

B

a ( Ψ = 20°) = 0.111 4F

Fmax = …… (17)

E p , E g : Young modulus for the 3 B′

pinion and gear , It is found experimentally that (Fmax )

E p = E g = 207 × 10 N/m

9 2 can be calculated as [9]:

B′

Substituting the values of a , E p , E g in Fmax = C z .f RW ……. (18)

B

Eq.(13), the value of c can be where :

obtained : c = 11488.5 N/mm 2 C z : Spring constant ( N / µmm) and

Hence , the dynamic load (Eq.(11) can be defined as [9]:

will be : Fdyn = 16204.94 N K

i.e that the applied load on the C z = × 10 −3 .…… (19)

B

analyzed gear increased by twice than K : gear stiffness at the location of

the transmitted load after the dynamic applied load ( N / mm.)

effect is calculated.

f RW : Directional error (µ) and can

Active Gear Width of Contact

When the teeth is meshing in be defined as [9]:

correct way the load is distributed f RW = 103.α .B ……. (20)

uniformly along the gear width as α : angle of misalignment (Radian)

shown in Fig.(2), and when the From Eq.(17) and Eq.(18) , it can be

misalignment is happen between deduced that :

shafts, so the meshing of teeth will be 4FB

not correct and the contact will be B′ = ……. (21)

subside in one side from the gear face 3 f RW .C z

without the other side as This equation represent the active

demonstrated in Fig.(3). gear width of contact, when the

The alteration of the applied misalignment of gears is occurred .

distribution load that concentrated on

one side and decreasing gradually to Load Distribution on Gear in Case

the other side and it can be of Shaft Misalignment [10-14]

approximated the applied distribution The load distribution on the gear

load as a cubic parabolic distribution. in case of misalignment can be

Fig.(4) explained this distribution on specified by putting a thin layer of

the active gear width of contact (B′) soft material, which is explained the

and can be described in the following pressure zone on gear face during the

equation[9] : meshing of teeth, and when the load

1325

PDF created with pdfFactory Pro trial version www.pdffactory.com

Eng. & Tech. Journal, Vol. 28, No. 7, 2010 Effect of Shaft Misalignment on The

Stresses Distribution of Spur Gears

is applied on the teeth , it can be Model Generation by ANSYS

shown that the stamp on the thin layer The ultimate purpose of a

as illustrated in Fig.(5). finite element analysis is to re-create

In this research the load mathematically the behavior of an

distribution is calculated on the gear actual engineering system[15]. In

for several cases of misalignment other words, the analysis must be an

angle α = 0.2° , 0.3° , 0.4° , 0.5° accurate mathematical model of a

,where (Β′) is determined for each α physical prototype[16].In the broadest

(Eq.(21)) and then find the centered sense, the model comprises all the

forces , which is represented the nodes, elements, material properties,

actual distributed load. real constants, boundary conditions

In order to facilitate and the other features that used to

representation of the load distribution represent the physical system.

on the gear width, the equivalent In ANSYS terminology, the

centered forces is calculated at term model generation usually takes

specific points on contact gear width on the narrower meaning of

( B′ ), the width is divided into several generating the nodes and elements

intervals , where in each interval that represent the special volume and

center the centered force is connectivity of the actual system.

calculated. Thus, model generation in this study

will mean the process of defining the

The centered force can be found by geometric configuration of the

the following equation: model's nodes and elements. The

program offers the following

x2 x 3 approaches to model generation[17-

F = ∫ Fmax 1 − dx … (22)

′

x1

B 18]:

a) Creating a solid model

Fig.(6) demonstrates the location of

b) Using direct generation

the coordinate (x) on the gearing

c) Importing a model created in a

teeth.

computer-aided design CAD system.

After calculation the centered

The method used in this

forces in which it sum equal to the

research is a creating solid model. In

tangential distributed load and to find

solid

the normal component of tangential

modeling one can describe the

centered forces [10] using the

boundaries of the model, establish

following equation.

controls over the size and desired

Fn = Ft tan(Ψ ) ……(23)

shape elements automatically, i.e.

Thus, to find the distribution forces drawing the two dimensional gear

on the gear width during model and meshing using meshtool

misalignment , equations(22) and and dragging it in z-direction to form

(23) are used with Simpson Rule to three dimensional gear model. Solid

achieve the integration in Eq.(22) and modeling is usually more powerful

the following forces can be get as in and versatile than other modeling,

Tables(1),(2),(3) & (4), and is and is commonly the preferred

illustrated in Fig.(7). method for generation models. The

1326

PDF created with pdfFactory Pro trial version www.pdffactory.com

Eng. & Tech. Journal, Vol. 28, No. 7, 2010 Effect of Shaft Misalignment on The

Stresses Distribution of Spur Gears

three Dimensional model of gear is B2=E*B*Sf

done by drawing and meshing two B3=(w-zz)/(w-Sm)

dimension gear plane with element DeltS=(B1/B2)*(zz+(w-zz)*log(B3))

plan42 and then dragging by solid45 DS=DeltS/Fi

to form three dimensional gear. ! DeltaG

Fig.(8) shows the gear model in C1=24*Fi*Sm**2*(cos(psi))**2

ANSYS. Fig.(9) shows the load C2=3.14*E*B*Sf

distribution when the misalignment DeltG=C1/C2

angle (α ) is zero, i.e. there is DG= DeltG/Fi

alignment of shafts, and it can be seen ! DeltaP

that the distribution of load is D1=4*Fi*(1+posi**2)

uniform. The load distribution is D2=3.14*E*B

applied in ANSYS according to D3= rb/(rb+rb)

equations (22) and (23) and its value DeltP=(D1/D2)*D3

depend on the misalignment angle DP= DeltP/Fi

(α), these equations are programmed Dtot=DB+DS+DG+DP

in ANSYS software by Ansys Kc=1/Dtot

Parametric Design Language (APDL) ! Data for dynamic force Fdyn

as follows : Ft=Fi*cos(psi)

/prep7 ee=2e-3 : aa=0.111: Ep=E:Eg=E

! Data for Force F cc= (aa*Ep*Eg)/(Ep+Eg)

P=400*1000 ! power = 400 kW V= omg*rb

N=5000 ! rpm E1=21*V*((B*cc*ee)+Ft)

omg=5000*(2*3.14/60) E2=21*V+sqrt((B*cc*ee)+Ft)

T=P/omg Fdyn=Ft+(E1/E2)

*afun,deg : Psi=20 ! Bdash

m=4 ! mm : Z=50 Alf=0.00349: fRW=1000*Alf*B

dpcd=m*Z ! mm : r=dpcd/2 ! mm Cz= (Kc/B)*1e-3: F1=4*Fdyn*B

rb=r*cos(psi) ! mm : Fi=T/(rb/1000) F2=3*fRW*Cz : Bdash=sqrt(F1/F2)

!Date for stiffness K Fmax=(4*Fdyn)/(3*Bdash)

Sm=6.338 : Sf=8.891 ! the function Fmax*(1-

Sk=4.93 : nn=9 (x/Bdash)**3)

zz=1 : w=18.957 X1=0: X2=1: N=1 ! no. of interval

B=40 : E=207000 :posi=0.3 *Dim,Xs,,10 : *Dim,Ys,,10

! DeltaB K1=0: K1=K1+1

A1=12*Fi*zz*(cos(psi))**2 N1=N+K1-1 : L=(X2-X1)/N1

A2=E*B*Sf**3 H=L: A1=0

A3=Sm**2+((zz**2)/3)-(Sm*zz) ! LOOP

A4=6*Fi*(cos(psi))**2*(w-zz)**3 *DO,I,1,N1 : *DO,J,1,2

A5=(w-Sm)/(w-zz) Xs(J)=X1+(I-1)*L+(J-1)*H

DeltB=((A1/A2)*A3)+(A4/A2)*(A5* Xso=Xs(J) :

(4-A5)-2*log(A5)-3) ! FUNCTION

DB=DeltB/Fi Yso=Fmax*(1-(Xso/Bdash)**3)

! DeltaS Ys(J)=Yso

B1=2*(1+posi)*Fi*(cos(psi))**2 *ENDDO

1327

PDF created with pdfFactory Pro trial version www.pdffactory.com

Eng. & Tech. Journal, Vol. 28, No. 7, 2010 Effect of Shaft Misalignment on The

Stresses Distribution of Spur Gears

A1=A1+H/2*(Ys(1)+Ys(2)) that the stress distribution is uniform

*ENDDO along the gear face. Fig.(12) explain

Ftag=A1 the stress distribution on the gear

Fnor=Ftag*tan(psi) width when α = 0.2°, Fig.(12-a)

Finish shows the

Tables(1),(2),(3)&(4) are contained distribution of stress is not uniform

the values of loads with (α = 0.2° , along the gear face, and Fig(12-b)

0.3° , 0.4° & 0.5° ). Fig.(10) shows shows the deformation occurs in spur

the load distribution according to the gear during misalignment. Fig.(13)

angles of misalignment. This figure demonstrates that when α = 0.3°,

shows that the loads become less stress distribution on the gear width

strong gradually in only one side of occurs; the non-uniformity of stress

the gear face, while it is concentrated distribution along the gear face is

on the other side. demonstrated by Fig.(13-a), while

Results and Discussions occurrence of deformation in spur

Misalignment of shaft causes gear during misalignment is

changes in the teeth gearing .This demonstrated by Fig(13-b).

changes the load distribution on the Fig.(14) demonstrates that

teeth. Manufacturing errors causes when α = 0.4°, stress distribution on

alternating loads on the gear. Local the gear width occurs; the non-

deformation at the point of applying uniformity of stress distribution along

the load and misalignment of the the gear face is demonstrated by

shaft causes stress concentration (i.e. Fig.(14-a), while occurrence of

the stresses are concentrated on one deformation in spur gear during

side of the teeth while gradually misalignment is demonstrated by

decreasing on the other side) . Fig(14-b).

Consequently, sudden fracture in the Fig.(15) demonstrates that

tooth occurs. Generally, there appears when α = 0.5°, stress distribution on

at the side of stress concentration, the gear width occurs; the non-

wearing or pitting and consequent uniformity of stress distribution along

damage. The contact region between the gear face is demonstrated by

the teeth of a sound gear may be Fig.(15-a), while occurrence of

represented by straight line parallel to deformation in spur gear during

the gear’s axes of rotation, i.e. load misalignment is demonstrated by

distribution along the gear width is Fig(15-b)

uniform (Fig.(9)). Misalignment is Fig.(16) shows the

due to manufacturing errors , bending relationship between the

in the involutes curve of the gear misalignment angle and the

…etc, with consequent changes in the equivalent stress at contact point on

teeth gearing spur gear, it can be shown that when

making concentrated load on one side the misalignment angle increases the

of the teeth (Fig.(10)) . equivalent stresses increase directly.

Fig.(11) explain the stress distribution Fig.(17) shows the relationship

on the gear width when α = 0° i.e. between the misalignment angle and

shaft alignment, and it can be seen max. deflection at contact point on

1328

PDF created with pdfFactory Pro trial version www.pdffactory.com

Eng. & Tech. Journal, Vol. 28, No. 7, 2010 Effect of Shaft Misalignment on The

Stresses Distribution of Spur Gears

spur gear , it can be seen that the [3] Abdullah M.Q, “ Analysis of

deflection is directly proportional to Gear Tooth Stresses using Finite

the misalignment angle. Element Technique”, M.Sc. thesis,

Fig.(18) shows the comparison University of Al-Nahreen,1994.

between the present results and the [4] Lewicki D.G., and Ballarini R., “

result from Ref. [3] for the tooth Effect of Rim Thickness on Gear

thickness and shear stress at zero Crack

angle of misalignment i.e. alignment Propagation Path”, 7th International

shafts. It can be shown that there are Power Transmission and Gearing

differences in the results, that due to Conference, U.S.A., California, 1996.

the mesh used in Ref.[3] is coarse [5] Maitra G.M., “ Hand Book of

mesh and due to that Gear Design”, Tata McGraw-Hill

their results were far from the Company, India, New Delhi , 1997.

ANSYS results. [6] Elkholy A.H., “ Tooth Load

Conclusions Sharing in High Contact Ratio Spur

From this study the following Gears”,

conclusion can be get : Journal of Mechanisms,

1-The values of equivalent stresses Transmissions, and Automation in

and its distribution is changed with Design , Vol. 107, No. 1, pp.11-16,

changing the misalignment angle, 1985.

where the stresses concentration is [7] Buckingham E., “ Analytical

increased in the contact region and in Mechanics of Gears”, McGraw-Hill,

the root of the tooth with increasing U.S.A., New York, 1949.

the misalignment angle, this is [8] Pandya N.C., and Shah C.S., “

occurred in the side of subside the Elements of Machine Design”,

load and decreasing in the other side Charotar Publishing House,

of the gear face. India,1986.

2- increasing the deformation of gear [9] Niemann G., “ Machine

with increasing misalignment angle. Elements”, Allied Publishers Private,

3- increasing the probability of Ltd., India, New Delhi, 1980 .

fracturing the gear in the root with [10] Al-Musawi A.K., “ Vibration

increasing the misalignment angle. Analysis and the Allowable Limits in

References Rotating Machinery”, M.Sc. thesis ,

[1] Chang T.H. and Kubo A., “ University of Baghdad , 1993.

Simple Stress Formulae for a Thin [11] “ Shaft Aligment is a Profitable

Rimmed Spur Gear” , Journal of Form of Preventative Maintenance”,

Mechanisms, Transmissions, and SKF Bearing Maintenance

Automation in Design, Vol.107,No.3, Handbook, Hane Training, Inc., 2001.

pp. 406-411, 1985. [12] Wowk V., “ Specifying Shaft

[2] Simon V., “ Load and Stress Alignment”, McGraw-Hill Company,

Distributions in Spur and Helical U.S.A., New York, 2000.

Gears”, Journal of Mechanisms, [13] Shigley J.E., and Mischke C.R.,

Transmissions, and Automation in “ Mechanical Engineering Design”,

Design”, Vol.110,No. 2, pp. 197-202, McGraw-Hill Company , U.S.A. ,

1988. New York, 1989.

1329

PDF created with pdfFactory Pro trial version www.pdffactory.com

Eng. & Tech. Journal, Vol. 28, No. 7, 2010 Effect of Shaft Misalignment on The

Stresses Distribution of Spur Gears

[14] Polak S., “ Gear box & Gear [17] User's manual of

System Problems”, Gears FEA/ANSYS/Version 5.4/1997.

Conference, U.K., London, 1999. [18] Basic structural, Training

[15] Saeed Mouveni “Finite Element Manual, (1996, ANSYS Inc.,

analysis” theory and application (ANSYS on-line-help).

With ANSYA, 1999.

[16] Tim Langlais "ANSYS Short

course ", 1999, from internet.

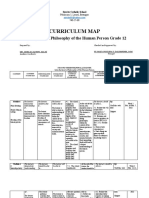

Table (1) when α = 0.2 , B′ = 32 mm

Point 1 2 3 4 5 6 7 8 9 10 11 12 13

Ft 671 671 671 670 669 668 666 663 659 654 648 640 632

Fn 244 244 244 244 243 243 242 241 239 238 235 233 230

Point 14 15 16 17 18 19 20 21 22 23 24 25 26

Ft 621 610 596 580 563 543 521 497 470 441 409 374 336

Fn 226 222 217 211 205 197 189 181 171 160 149 136 122

Point 27 28 29 30 31 32

Ft 295 251 203 152 40 21

Fn 107 91 74 55 14 7

Table(2) when α = 0.3 , B′ = 26 mm

Point 1 2 3 4 5 6 7 8 9 10 11 12 13

Ft 822 822 821 820 818 814 809 803 794 783 769 753 733

Fn 299 299 299 298 297 296 294 292 289 285 280 274 266

Point 14 15 16 17 18 19 20 21 22 23 24 25 26

Ft 710 683 652 618 578 534 485 431 370 305 233 154 69

Fn 258 248 237 224 210 194 176 156 135 111 84 56 25

Table (3) when α = 0.4 , B′ = 22 mm

Point 1 2 3 4 5 6 7 8 9 10 11 12 13

Ft 949 949 947 945 941 935 926 914 899 879 855 826 791

Fn 345 345 345 344 342 340 337 333 327 320 311 300 288

Point 14 15 16 17 18 19 20 21 22

Ft 750 702 648 586 516 438 351 254 147

Fn 273 255 236 213 188 159 127 92 53

1330

PDF created with pdfFactory Pro trial version www.pdffactory.com

Eng. & Tech. Journal, Vol. 28, No. 7, 2010 Effect of Shaft Misalignment on The

Stresses Distribution of Spur Gears

Table(4) when α = 0.5 , B′ = 20 mm

Point 1 2 3 4 5 6 7 8 9 10 11

Ft 1061 1061 1059 1056 1049 1040 1026 1008 983 952 914

Fn 386 386 385 384 382 378 373 366 358 346 333

Point 12 13 14 15 16 17 18 19 20

Ft 869 814 750 676 590 494 384 261 125

Fn 316 296 273 246 215 179 139 95 45

-a- -b-

Figure (1) Tooth terms [6]

Figure (2) Uniform distributed of load Figure (3) Subside of the contact

in along the gear width

one side of the gear

1331

PDF created with pdfFactory Pro trial version www.pdffactory.com

Eng. & Tech. Journal, Vol. 28, No. 7, 2010 Effect of Shaft Misalignment on The

Stresses Distribution of Spur Gears

Figure (4) Load distribution along the active gear width in contact when

misalignment is occur

Figure (5) Configurations of load the regions on the tooth face during

misalignment

1332

PDF created with pdfFactory Pro trial version www.pdffactory.com

Eng. & Tech. Journal, Vol. 28, No. 7, 2010 Effect of Shaft Misalignment on The

Stresses Distribution of Spur Gears

Figure (6) Configurations of the contact line between the gearing tooth

Figure (7) The components of equivalent forces for misalignment gear

1333

PDF created with pdfFactory Pro trial version www.pdffactory.com

Eng. & Tech. Journal, Vol. 28, No. 7, 2010 Effect of Shaft Misalignment on The

Stresses Distribution of Spur Gears

Figure (8) Gear Model in ANSYS

Figure (9) The load distributions at misalignment angle equal zero

α = 0.2°

1334

PDF created with pdfFactory Pro trial version www.pdffactory.com

Eng. & Tech. Journal, Vol. 28, No. 7, 2010 Effect of Shaft Misalignment on The

Stresses Distribution of Spur Gears

α = 0.3°

α = 0.4°

α = 0.5°

Figure (10) The load distributions at different misalignment angles

1335

PDF created with pdfFactory Pro trial version www.pdffactory.com

Eng. & Tech. Journal, Vol. 28, No. 7, 2010 Effect of Shaft Misalignment on The

Stresses Distribution of Spur Gears

(a) (b)

Figure (11) Explain the stress distribution on the gear width when α = 0°

(a) (b)

Figure (12) Explain the stress distribution on the gear width when α = 0.2°

1336

PDF created with pdfFactory Pro trial version www.pdffactory.com

Eng. & Tech. Journal, Vol. 28, No. 7, 2010 Effect of Shaft Misalignment on The

Stresses Distribution of Spur Gears

(a) (b)

Figure (13) Explain the stress distribution on the gear width when α = 0.3°

(a) (b)

Figure (14) Explain the stress distribution on the gear width when α = 0.4°

1337

PDF created with pdfFactory Pro trial version www.pdffactory.com

Eng. & Tech. Journal, Vol. 28, No. 7, 2010 Effect of Shaft Misalignment on The

Stresses Distribution of Spur Gears

(a) (b)

Figure (15) Explain the stress distribution on the gear width when α = 0.5°

8000

6000

Equivalent stress [MPa]

4000

2000

0

0.0 0.1 0.2 0.3 0.4 0.5

misaliagnment angle

Figure (16) The relationship between the misalignment angle

and the equivalent stress on spur gear

1338

PDF created with pdfFactory Pro trial version www.pdffactory.com

Eng. & Tech. Journal, Vol. 28, No. 7, 2010 Effect of Shaft Misalignment on The

Stresses Distribution of Spur Gears

0.08

0.06

Deflection [mm]

0.04

0.02

0.00

0.0 0.1 0.2 0.3 0.4 0.5

misaliagnment angle

Figure (17) The relationship between the misalignment

angle and the deflection on spur gear

Figure (18) The relationship between the tooth thickness

and shear stress when misalignment angle = 0

1339

PDF created with pdfFactory Pro trial version www.pdffactory.com

You might also like

- A Comparison of Gear Mesh Stiffness Modeling Strategies: Jim Meagher, Xi Wu, Dewen Kong, and Chun Hung LeeDocument9 pagesA Comparison of Gear Mesh Stiffness Modeling Strategies: Jim Meagher, Xi Wu, Dewen Kong, and Chun Hung LeecoroNo ratings yet

- Lab Manual Fall 2017Document68 pagesLab Manual Fall 2017Nil SabbirNo ratings yet

- Session 7 - Beyond Tests - Alternatives in AssessmentDocument53 pagesSession 7 - Beyond Tests - Alternatives in AssessmenttrandinhgiabaoNo ratings yet

- Assignment 1: InstructionsDocument6 pagesAssignment 1: InstructionsAsim MughalNo ratings yet

- Sensitivity Analysis For The Tolerancing of Gear Profiles With Stochastic ErrorsDocument10 pagesSensitivity Analysis For The Tolerancing of Gear Profiles With Stochastic ErrorsMaksat TemirkhanNo ratings yet

- Falah 和 Elkholy - 2008 - Load Sharing and Stress Analysis of Single EnvelopDocument10 pagesFalah 和 Elkholy - 2008 - Load Sharing and Stress Analysis of Single Envelop王磊No ratings yet

- Finite Element Simulation of Fretting Wear-Fatigue Interaction in Spline CouplingsDocument15 pagesFinite Element Simulation of Fretting Wear-Fatigue Interaction in Spline CouplingsAli Cherif MessellekNo ratings yet

- Design of Face-Hobbed Spiral Bevel Gears With Reduced Maximum Tooth Contact Pressure and Transmission ErrorsDocument14 pagesDesign of Face-Hobbed Spiral Bevel Gears With Reduced Maximum Tooth Contact Pressure and Transmission ErrorsBurak KoyuncuogluNo ratings yet

- Meshing StiffnessDocument36 pagesMeshing StiffnessHari KiranNo ratings yet

- Project PPT On Effect of Parameters On Bending and Contact Stresses Developed in GearsDocument21 pagesProject PPT On Effect of Parameters On Bending and Contact Stresses Developed in GearsHrushikesh S BharadwajNo ratings yet

- Analytical and Numerical Tooth Contact Analysis (TCA) of Standard and Modified Involute Profile Spur GearDocument19 pagesAnalytical and Numerical Tooth Contact Analysis (TCA) of Standard and Modified Involute Profile Spur GearHASAN ALAA MUSA Al-ShubberNo ratings yet

- 1 s2.0 S0094114X23000137 MainDocument30 pages1 s2.0 S0094114X23000137 MainLucas Araujo de AlmeidaNo ratings yet

- Analysis of Bending Stress at Root of The Spur Gear by Finite Element MethodDocument5 pagesAnalysis of Bending Stress at Root of The Spur Gear by Finite Element MethodAnil PatilNo ratings yet

- MECH 344/M Machine Element DesignDocument75 pagesMECH 344/M Machine Element DesignlitonNo ratings yet

- Article - Experimental Characterization of Bending Fatigue Strength in GearDocument8 pagesArticle - Experimental Characterization of Bending Fatigue Strength in Gearjavo0128No ratings yet

- Contact Stress and Bending Stress Analysis of Spur Gear by Analytical MethodDocument3 pagesContact Stress and Bending Stress Analysis of Spur Gear by Analytical MethodlitonNo ratings yet

- Approximate Equations For The Meshing Stiffness and The LoadDocument19 pagesApproximate Equations For The Meshing Stiffness and The Loadvickytechie03No ratings yet

- SpurDocument57 pagesSpurDangol RupeshNo ratings yet

- Mechanism and Machine Theory: Miryam B. Sánchez, Miguel Pleguezuelos, José I. PedreroDocument15 pagesMechanism and Machine Theory: Miryam B. Sánchez, Miguel Pleguezuelos, José I. PedreroJuanNo ratings yet

- Determination of The Effective Path of Contact of Undercut Involute Gear TeethDocument10 pagesDetermination of The Effective Path of Contact of Undercut Involute Gear Teethpriyanka moulikNo ratings yet

- GearsDocument78 pagesGearsL.K. Bhagi100% (1)

- 1-s2.0-S0094114X15002748-Yi Guo Gear Coupling 2016Document38 pages1-s2.0-S0094114X15002748-Yi Guo Gear Coupling 2016attiq ur RehmanNo ratings yet

- Transient Stress Analysis On Spur GearDocument8 pagesTransient Stress Analysis On Spur GearPrithviraj DagaNo ratings yet

- ZFK DB U U KKK ZZZ: Table B.14Document1 pageZFK DB U U KKK ZZZ: Table B.14Carlos GonzalesNo ratings yet

- Ijmet 07 05 023Document12 pagesIjmet 07 05 023SANDEEP BUDANIANo ratings yet

- Load Sharing Based Fillet Stress Analysis of Involute Helical GearsDocument5 pagesLoad Sharing Based Fillet Stress Analysis of Involute Helical GearsR Prabhu SekarNo ratings yet

- A New Photoelastic InvestigationDocument8 pagesA New Photoelastic Investigationmshebbal2212No ratings yet

- Artigo de Salles - 2017Document9 pagesArtigo de Salles - 2017Leonardo Pereira SilvaNo ratings yet

- AGMA Technical PaperDocument14 pagesAGMA Technical PaperLuis TestaNo ratings yet

- Research ArticleDocument9 pagesResearch ArticleADII 2701No ratings yet

- Contact Stress Analysis of Involute Spur Gear by Finite Element Method (Fem)Document8 pagesContact Stress Analysis of Involute Spur Gear by Finite Element Method (Fem)litonNo ratings yet

- D - Model - Localized Defect - Patil - Rajinderkumar - 2010Document9 pagesD - Model - Localized Defect - Patil - Rajinderkumar - 2010Vivek ParmarNo ratings yet

- E Visio1Document11 pagesE Visio1HamZerNo ratings yet

- Contact Stress Analysis of Spur Gear Teeth PairDocument7 pagesContact Stress Analysis of Spur Gear Teeth PairTejal IkharNo ratings yet

- Analysis of Stress and Deflection of Spur Gear by Using New Analytical Method Based On Taguchi Method and Finite Element AnalysisDocument7 pagesAnalysis of Stress and Deflection of Spur Gear by Using New Analytical Method Based On Taguchi Method and Finite Element AnalysisEditor IJTSRDNo ratings yet

- Fang 2013 Meas. Sci. Technol. 24 055008Document9 pagesFang 2013 Meas. Sci. Technol. 24 055008ranim najibNo ratings yet

- Reduction of Noise and Vibration of Spur Gear by Using Asymmetric Teeth Profiles With Tip ReliefDocument15 pagesReduction of Noise and Vibration of Spur Gear by Using Asymmetric Teeth Profiles With Tip ReliefHASAN ALAA MUSA Al-ShubberNo ratings yet

- A Study of Effects of Tooth Surface Wear On Time-Varying Mesh Stiffness of External Spur Gear Considering Wear Evolution ProcessDocument19 pagesA Study of Effects of Tooth Surface Wear On Time-Varying Mesh Stiffness of External Spur Gear Considering Wear Evolution ProcessJuan Jose Barrios OsorioNo ratings yet

- Weldment Design and SimplificationsDocument9 pagesWeldment Design and SimplificationsEswaran RajamaniNo ratings yet

- Influence of Gear Loads On Spline Couplings: C.H. Wink and M. NakandakarDocument8 pagesInfluence of Gear Loads On Spline Couplings: C.H. Wink and M. NakandakarJames TsaiNo ratings yet

- Computer Modeling of Rack-Generated Spur Gears: KnorrDocument10 pagesComputer Modeling of Rack-Generated Spur Gears: KnorrRobin MachargNo ratings yet

- An Investigation of The Fatigue and Fretting PerformanceDocument19 pagesAn Investigation of The Fatigue and Fretting PerformanceKrishna PrasadNo ratings yet

- Tooth Root StressDocument5 pagesTooth Root StressJitu Indu0% (1)

- Strain Energy Density Based Fatigue Cracking Assessment of Load-Carrying Cruciform Welded JointsDocument12 pagesStrain Energy Density Based Fatigue Cracking Assessment of Load-Carrying Cruciform Welded JointsNouman IqbalNo ratings yet

- Unit 1 GearsDocument51 pagesUnit 1 Gearsdawitdejene4361No ratings yet

- Experimental Mesh Stiffness AnalysisDocument14 pagesExperimental Mesh Stiffness Analysis0902au11mt14No ratings yet

- Chapter 3Document14 pagesChapter 3Kaung KhantNo ratings yet

- Transverse SensitivityDocument26 pagesTransverse SensitivityAtta Ur Rehman Shah MENo ratings yet

- Engineers, Part C: Journal of Mechanical Proceedings of The Institution of MechanicalDocument12 pagesEngineers, Part C: Journal of Mechanical Proceedings of The Institution of MechanicalluuthuanNo ratings yet

- Giảm Thiểu Lỗi Truyền Động Trong Truyền Đọng Bánh Răng XoắnDocument13 pagesGiảm Thiểu Lỗi Truyền Động Trong Truyền Đọng Bánh Răng XoắnDương CaoNo ratings yet

- A Fracture Mechanics Based Stress Approach For Fatig - 2023 - Theoretical and ApDocument15 pagesA Fracture Mechanics Based Stress Approach For Fatig - 2023 - Theoretical and Apayman aliNo ratings yet

- I J Merr Journal Published PaperDocument6 pagesI J Merr Journal Published PapergarciarodrigoNo ratings yet

- Elastic Analysis of Load Distribution in Wide Faced Spur GearsDocument208 pagesElastic Analysis of Load Distribution in Wide Faced Spur GearsJulian Steward100% (1)

- Static and Dynamic Transmissin Error in Spur GearsDocument5 pagesStatic and Dynamic Transmissin Error in Spur GearsKrishna PrasadNo ratings yet

- Liu 等 - 2022 - Rattle Dynamic Model and Vibration Behaviors of NoDocument8 pagesLiu 等 - 2022 - Rattle Dynamic Model and Vibration Behaviors of No王磊No ratings yet

- Maag, Tooth F Lank ModificationsDocument8 pagesMaag, Tooth F Lank ModificationsPeter CardenNo ratings yet

- Transmission Par EngrenageDocument7 pagesTransmission Par Engrenageigualdi53No ratings yet

- Efficiency Analysis of Spur Gears With A Shifting Profile: N N MaxDocument16 pagesEfficiency Analysis of Spur Gears With A Shifting Profile: N N MaxJuanNo ratings yet

- International Journal of Computational Engineering Research (IJCER)Document7 pagesInternational Journal of Computational Engineering Research (IJCER)International Journal of computational Engineering research (IJCER)No ratings yet

- Zhong Et Al. - 2020 - A Tip Loss Correction Model For Wind Turbine AerodDocument16 pagesZhong Et Al. - 2020 - A Tip Loss Correction Model For Wind Turbine AerodThiago EscorcioNo ratings yet

- Experimental Measurement of Gear Mesh Stiffness of Cracked Spur Gear by Strain Gauge TechniqueDocument10 pagesExperimental Measurement of Gear Mesh Stiffness of Cracked Spur Gear by Strain Gauge TechniqueRudolph ScheepersNo ratings yet

- Strength of Materials: An Introduction to the Analysis of Stress and StrainFrom EverandStrength of Materials: An Introduction to the Analysis of Stress and StrainRating: 5 out of 5 stars5/5 (1)

- Re29105 2018-12Document20 pagesRe29105 2018-12emreali1No ratings yet

- Crowned Tooth Gear Couplings: Type MTDocument31 pagesCrowned Tooth Gear Couplings: Type MTemreali1No ratings yet

- Spare Parts List Spin-On Filter MF/MFD: Up To 300 L/min, Up To 8 BarDocument5 pagesSpare Parts List Spin-On Filter MF/MFD: Up To 300 L/min, Up To 8 Baremreali1No ratings yet

- EN5231 3 0 01 20 - P4WEH - 10to32Document10 pagesEN5231 3 0 01 20 - P4WEH - 10to32emreali1No ratings yet

- Determination of Spray Angle and Flow Uniformity of Spray Nozzles With Image Processing OperationsDocument13 pagesDetermination of Spray Angle and Flow Uniformity of Spray Nozzles With Image Processing Operationsemreali1No ratings yet

- Research Article: Analysis of Contact Part of Error Tooth Surface and Dynamic Performance Prediction For Involute GearDocument12 pagesResearch Article: Analysis of Contact Part of Error Tooth Surface and Dynamic Performance Prediction For Involute Gearemreali1No ratings yet

- SKFDocument48 pagesSKFemreali1No ratings yet

- Pipe Flow Expert Results VerificationDocument63 pagesPipe Flow Expert Results VerificationFachrina PuspitasariNo ratings yet

- Heat Transfer3Document9 pagesHeat Transfer3emreali1No ratings yet

- User Guide: Pipeflow Is A Trading Name of Daxesoft LTDDocument205 pagesUser Guide: Pipeflow Is A Trading Name of Daxesoft LTDAhmad Salim Muttaqin100% (1)

- E4329 QuickGuideDocument52 pagesE4329 QuickGuidelumasNo ratings yet

- Heat Transfer1Document10 pagesHeat Transfer1emreali1No ratings yet

- An Improved Thermal Model For Machine Tool Bearings: Xu Min, Jiang Shuyun, Cai YingDocument10 pagesAn Improved Thermal Model For Machine Tool Bearings: Xu Min, Jiang Shuyun, Cai Yingemreali1No ratings yet

- Bearings and Gearbox DiagnosticsDocument37 pagesBearings and Gearbox DiagnosticsFelly AntaNo ratings yet

- Fractal Roughness PDFDocument6 pagesFractal Roughness PDFemreali1No ratings yet

- A10VO ManualDocument12 pagesA10VO Manualemreali1100% (12)

- 5Document46 pages5Vishal SirurNo ratings yet

- Bearings and Gearbox DiagnosticsDocument37 pagesBearings and Gearbox DiagnosticsFelly AntaNo ratings yet

- Practical Questions BookletDocument37 pagesPractical Questions BookletPrecious ChirangareNo ratings yet

- The Singapore Success StoryDocument14 pagesThe Singapore Success StoryMaria SchiporNo ratings yet

- Cambridge O Level: Art and Design 6090/01 May/June 2020Document4 pagesCambridge O Level: Art and Design 6090/01 May/June 2020Jack KowmanNo ratings yet

- Omm Tank, Combat, Full Tracked 105-MM Gun, M60a3 and TTS TurretDocument663 pagesOmm Tank, Combat, Full Tracked 105-MM Gun, M60a3 and TTS TurretSTGN100% (1)

- Ces511 - Structural Engineering Laboratory Lab Experiment: Bending Moment and Shear Force in Beams (Co2:Po5)Document13 pagesCes511 - Structural Engineering Laboratory Lab Experiment: Bending Moment and Shear Force in Beams (Co2:Po5)elhammeNo ratings yet

- Thermal Contact Conductance - Wikipedia PDFDocument20 pagesThermal Contact Conductance - Wikipedia PDFErwin MaryNo ratings yet

- 1020 Aseguramiento de Calidad GeneralDocument10 pages1020 Aseguramiento de Calidad GeneralJennifer Tatiana DíazNo ratings yet

- Electrical Circuits 2 AssignmentDocument5 pagesElectrical Circuits 2 Assignmentangelo dedicatoriaNo ratings yet

- Core10 Module1Document2 pagesCore10 Module1Sagbot Nga layaNo ratings yet

- Pile Foundations - Design, Construction and Testing Guide: What Is A Pile Foundation?Document3 pagesPile Foundations - Design, Construction and Testing Guide: What Is A Pile Foundation?Ashis MingalaNo ratings yet

- Competency Assessment FormDocument2 pagesCompetency Assessment FormLielet MatutinoNo ratings yet

- MKTED208071EN CatalogueDocument618 pagesMKTED208071EN Cataloguecarlos augustoNo ratings yet

- CH 9. Heat - Thermodynamics (Phy +1)Document84 pagesCH 9. Heat - Thermodynamics (Phy +1)tomyNo ratings yet

- FINALS - Technology Integration Planning 2023Document3 pagesFINALS - Technology Integration Planning 2023Keziah O. BarrientosNo ratings yet

- ISB 11 Information Systems For Business - FinalDocument8 pagesISB 11 Information Systems For Business - FinalOfelia RagpaNo ratings yet

- 2b FLUID STATIC - Pressure MeasurementDocument27 pages2b FLUID STATIC - Pressure Measurement翁绍棠No ratings yet

- OutputDocument5 pagesOutputCarlos FazNo ratings yet

- Progresive DPKDocument7 pagesProgresive DPKAmol WalunjNo ratings yet

- Curriculum Map in Introduction To The World ReligionDocument7 pagesCurriculum Map in Introduction To The World ReligionRaizza Vanizza SiguenzaNo ratings yet

- M16a3 Upper SpecsDocument1 pageM16a3 Upper SpecsMosinNo ratings yet

- Bituminous Construction TypesDocument3 pagesBituminous Construction TypesSiya Fal DesaiNo ratings yet

- 5 6316334533637570613Document5 pages5 6316334533637570613Nishant PathakNo ratings yet

- Dynamic Stochastic General Equilibrium (Dsge) Modelling:Theory and PracticeDocument34 pagesDynamic Stochastic General Equilibrium (Dsge) Modelling:Theory and PracticeRSNo ratings yet

- Inv - 2469306Document2 pagesInv - 2469306rajeshNo ratings yet

- FINALby REDAZADocument3 pagesFINALby REDAZANoreen RedazaNo ratings yet

- Reptilian Astral WarsDocument4 pagesReptilian Astral WarsAlienraces1No ratings yet

- Gas Cutting - by KiranDocument40 pagesGas Cutting - by KiransridharchebroluNo ratings yet