Professional Documents

Culture Documents

Type DN-5 Corrosion Resistant Duct Nozzle, Open Medium Velocity General Description

Uploaded by

hungOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Type DN-5 Corrosion Resistant Duct Nozzle, Open Medium Velocity General Description

Uploaded by

hungCopyright:

Available Formats

Worldwide

www.tyco-fire.com

Contacts

Type DN-5

Corrosion Resistant Duct Nozzle, Open

Medium Velocity

General The owner is responsible for maintain-

ing their fire protection system and

Description devices in proper operating condition.

The installing contractor or nozzle man-

The TYCO Type DN-5 Corrosion Resis- ufacturer should be contacted with any

tant Duct Nozzle is an open (non- questions.

automatic) directional spray nozzle In all cases, the appropriate FM Global

designed for use in water spray fixed Property Loss Prevention Data Sheets,

systems for fire protection applications NFPA standards, or other applica-

in extremely corrosive duct environ- ble standards, must be referenced

ments. It is an external deflector type to ensure applicability and to obtain

nozzle that discharges medium velocity complete installation guidelines. The

water droplets. general guidelines in this data sheet

The Type DN-5 Corrosion Resistant are not intended to provide complete

Duct Nozzle is effective in discharging installation criteria.

water to vertical, horizontal, curved,

and irregular shaped surfaces within Technical

a duct to achieve fire suppression and

potential extinguishment. Data Design

The Type DN-5 Corrosion Resistant Approvals

FM Approved

Criteria

Duct Nozzle is equipped with a snugly Obtain guidance for use of the TYCO

fitting Blow-Off Plug which protects the Pipe Thread Connections Type DN-5 Corrosion Resistant Duct

system piping from intrusion of corro- 1/2 in. NPT Nozzle in a deluge system protecting

sive gases as well as the accumulation ventilation ductwork handling corro-

of debris within the nozzle orifice. Discharge Coefficient

K = 6.0 gpm/psi½ (86,5 lpm/bar½) sive gases from the Technical Services

Department.

NOTICE Minimum Operating Pressure

15 psi (1,0 bar)

The TYCO Type DN-5 Corrosion Resis-

tant Duct Nozzle described herein Maximum Continuous Operating

must be installed and maintained in Temperature

compliance with this document, FM 150 °C (302 °F)

Global Property Loss Prevention Data

Coating

Sheets, the applicable standards of the HALAR (ECTFE)

NATIONAL FIRE PROTECTION ASOCI-

TION (NFPA), in addition to the stan- Physical Characteristics

dards of any other authorities having Frame . . . . . . . . . . . . . . . . . . . . . . Stainless Steel

jurisdiction. Failure to do so may Deflector �������������������������������������� Stainless Steel

Splitter. . . . . . . . . . . . . . . . . . . . . . Stainless Steel

impair the performance of this device. Blow-Off Plug. . . TECONFLON Fluoroelastomer

IMPORTANT

Refer to Technical Data Sheet

TFP2300 for warnings pertaining to

regulatory and health information.

Always refer to Technical Data

Sheet TFP700 for the “INSTALLER

WARNING” that provides cautions

with respect to handling and instal-

lation of sprinkler systems and com-

ponents. Improper handling and

installation can permanently damage

a sprinkler system or its compo-

nents and cause the sprinkler to fail

to operate in a fire situation or cause

it to operate prematurely.

Page 1 of 2 AUGUST 2018 TFP808

TFP808

Page 2 of 2

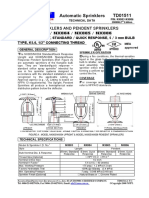

1/2" NPT WATERWAY

THREAD

BLOW-OFF

PLUG WITH

2-9/16" INTEGRATED

(65,1 mm) O-RING

1-15/16"

FRAME

(49,2 mm)

NOMINAL

SPLITTER

DEFLECTOR

1-7/8" NOTE: HALAR coating on all nozzle

(47,6 mm) surfaces except 1/2" NPT thread.

FIGURE 1

TYPE DN-5 CORROSION RESISTANT DUCT NOZZLE

ASSEMBLY

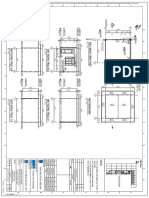

RADIAL DISTANCE FROM RADIAL DISTANCE FROM

NOZZLE CENTERLINE, FEET NOZZLE CENTERLINE, METERS

8 7 6 5 4 3 2 1 0 0,5 1,0 1,5 2,0 2,5

NOZZLE DEFLECTOR, METERS

0 0

NOZZLE DEFLECTOR, FEET

AXIAL DISTANCE FROM

AXIAL DISTANCE FROM

1

0,5

2

3

1,0

GRAPH A

TYPE DN-5 CORROSION DUCT NOZZLE

SPRAY PROFILE

Care and The owner is responsible for the

inspection, testing, and maintenance of Limited

Maintenance their fire protection system and devices

in compliance with this document, FM Warranty

The TYCO Type DN-5 Corrosion Resis- Global Property Loss Prevention Data For warranty terms and conditions, visit

tant Duct Nozzle must be maintained Sheets, the applicable standards of the www.tyco-fire.com.

and serviced in accordance with this NATIONAL FIRE PROTECTION ASSO-

Ordering

section. CIATION, in addition to the standards

of any other authorities having jurisdic-

The Type DN-5 Nozzles must never be

Procedure

tion. The installing contractor or nozzle

painted, plated, coated or altered in any manufacturer should be contacted with

way after leaving the factory; otherwise, any questions.

the effectiveness may be impaired. Contact Johnson Controls Customer

Service for availability.

Care must be exercised to avoid

damage to the nozzles before, during,

and after installation. Type DN-5

Nozzles damaged by dropping, strik-

ing, or the like, must be replaced.

1400 Pennbrook Parkway, Lansdale, PA 19446 | Telephone +1-215-362-0700

© 2018 Johnson Controls. All rights reserved. All specifications and other information shown were current as of document revision date and are subject to change without notice.

NATIONAL FIRE PROTECTION ASSOCIATION and NFPA are registered trademarks of National Fire Protection Association;

TECONFLON and HALAR are trademarks of The Solvay Solexis Corporation

You might also like

- Series TY-B - 2.8, 5.6, and 8.0 K-Factor Upright, Pendent, and Recessed Pendent Sprinklers Standard Response, Standard CoverageDocument8 pagesSeries TY-B - 2.8, 5.6, and 8.0 K-Factor Upright, Pendent, and Recessed Pendent Sprinklers Standard Response, Standard CoverageLucila BordenaveNo ratings yet

- Series ELO-231B - 11.2 K-Factor Upright and Pendent Sprinklers Standard Response, Standard Coverage General DescriptionDocument6 pagesSeries ELO-231B - 11.2 K-Factor Upright and Pendent Sprinklers Standard Response, Standard Coverage General DescriptionMónica BaqueNo ratings yet

- B TY LDocument4 pagesB TY Lcvproyectos.01No ratings yet

- Sprinkler-Tyco-Ex5985Document27 pagesSprinkler-Tyco-Ex5985NOMANNo ratings yet

- Series TY-FRB - 2.8, 4.2, 5.6, and 8.0 K-Factor Upright, Pendent, and Recessed Pendent Sprinklers Quick Response, Standard CoverageDocument14 pagesSeries TY-FRB - 2.8, 4.2, 5.6, and 8.0 K-Factor Upright, Pendent, and Recessed Pendent Sprinklers Quick Response, Standard Coveragemy.work.ksabNo ratings yet

- tfp342 Ty5151Document4 pagestfp342 Ty5151Raúl Antonio MacíasNo ratings yet

- Type D3 Protectospray Directional Spray Nozzles, Open, Medium Velocity General DescriptionDocument6 pagesType D3 Protectospray Directional Spray Nozzles, Open, Medium Velocity General DescriptionVils ArabadzhievaNo ratings yet

- Rociador Ty LDocument8 pagesRociador Ty LOscar Fernandez SanchezNo ratings yet

- Data Shett FP Valiant MachineDocument47 pagesData Shett FP Valiant MachineRICARDONo ratings yet

- TycoDocument10 pagesTycoTahseenNo ratings yet

- TY-L Series Sprinklers Technical Data SheetDocument6 pagesTY-L Series Sprinklers Technical Data SheetJimenez FerchoNo ratings yet

- TFP412 09 2019Document6 pagesTFP412 09 2019Richard TorresNo ratings yet

- TFP 3153Document6 pagesTFP 3153Diego PinedaNo ratings yet

- Series TY-FRL - 2.8, 5.6, and 8.0 K-Factor Upright, Pendent, and Recessed Pendent Sprinklers Quick Response, Standard Coverage General DescriptionDocument6 pagesSeries TY-FRL - 2.8, 5.6, and 8.0 K-Factor Upright, Pendent, and Recessed Pendent Sprinklers Quick Response, Standard Coverage General DescriptionnicolasNo ratings yet

- TFP110 08 2018Document6 pagesTFP110 08 2018SamiYousifNo ratings yet

- TY3231Document10 pagesTY3231anon-952920100% (2)

- Rociador TY3131Document10 pagesRociador TY3131Pavel RamirezNo ratings yet

- Rociador Ty FRBDocument10 pagesRociador Ty FRBOscar Fernandez SanchezNo ratings yet

- TFP321 03 2021Document4 pagesTFP321 03 2021Richard TorresNo ratings yet

- Series TY-FRB, 5.6 K-Factor Upright, Pendent, and Recessed Pendent Sprinklers Quick Response, Standard CoverageDocument4 pagesSeries TY-FRB, 5.6 K-Factor Upright, Pendent, and Recessed Pendent Sprinklers Quick Response, Standard CoverageWidier Duarte SandovalNo ratings yet

- TFP344 04 2022Document4 pagesTFP344 04 2022INGENIERIA8 FYSNo ratings yet

- Extintor SG SSTDocument4 pagesExtintor SG SSTDamalpa LopezNo ratings yet

- D3 Spray Nozzle PDFDocument6 pagesD3 Spray Nozzle PDFwahyuNo ratings yet

- TFP802!05!2009 - D3 Spray NozzlesDocument6 pagesTFP802!05!2009 - D3 Spray NozzlesJoseph R. F. DavidNo ratings yet

- Tyco Tfp312Document8 pagesTyco Tfp312Cristi NechiforNo ratings yet

- TFP151 07 2018Document8 pagesTFP151 07 2018Mónica BaqueNo ratings yet

- Type MV Directional Spray Nozzles, Open Medium Velocity General DescriptionDocument14 pagesType MV Directional Spray Nozzles, Open Medium Velocity General Descriptionrusli bahtiarNo ratings yet

- Model SW-20 and SW-24 - 11.2 K-Factor Extended Coverage Ordinary Hazard Horizontal Sidewall Sprinklers (Standard Response)Document6 pagesModel SW-20 and SW-24 - 11.2 K-Factor Extended Coverage Ordinary Hazard Horizontal Sidewall Sprinklers (Standard Response)Mohammad IsmailNo ratings yet

- Rociador ESFR K16.8 PDFDocument4 pagesRociador ESFR K16.8 PDFLEONARDONo ratings yet

- TFP338 12 2019Document4 pagesTFP338 12 2019pippoNo ratings yet

- Series LFII Residential SprinklersDocument6 pagesSeries LFII Residential SprinklersAchraf BoudayaNo ratings yet

- Tyco Mlaznica TY BDocument8 pagesTyco Mlaznica TY BMilos StojanovicNo ratings yet

- TFP620 05 2014Document8 pagesTFP620 05 2014Furkan KadıNo ratings yet

- Technical Services: Model ESFR-17 Early Suppression Fast Response Pendent SprinklersDocument8 pagesTechnical Services: Model ESFR-17 Early Suppression Fast Response Pendent SprinklersZaira LorenaNo ratings yet

- Series TY-B - 2.8, 5.6, and 8.0 K-Factor Upright, Pendent, and Recessed Pendent Sprinklers Standard Response, Standard Coverage General DescriptionDocument10 pagesSeries TY-B - 2.8, 5.6, and 8.0 K-Factor Upright, Pendent, and Recessed Pendent Sprinklers Standard Response, Standard Coverage General DescriptionJennifer SalamancaNo ratings yet

- ASPERSORES TUNA UL-ULc-FM-MEADocument5 pagesASPERSORES TUNA UL-ULc-FM-MEAAndres Cortes RivasNo ratings yet

- TFP151 11 2021Document10 pagesTFP151 11 2021INGENIERIA8 FYSNo ratings yet

- Model ESFR-17 16.8 K-Factor Pendent Sprinkler Early Suppression, Fast Response General DescriptionDocument4 pagesModel ESFR-17 16.8 K-Factor Pendent Sprinkler Early Suppression, Fast Response General DescriptionalbertoNo ratings yet

- Type D4a Protectospray Directional Spray Nozzles, Open, Medium Velocity General DescriptionDocument6 pagesType D4a Protectospray Directional Spray Nozzles, Open, Medium Velocity General DescriptionhungNo ratings yet

- Rociador Rango Extendido EC5Document6 pagesRociador Rango Extendido EC5victorNo ratings yet

- Technical Services Sprinkler Spec SheetDocument8 pagesTechnical Services Sprinkler Spec SheetMohammad IsmailNo ratings yet

- Ficha Tecnica Bancos de PruebaDocument8 pagesFicha Tecnica Bancos de Pruebalucerito718No ratings yet

- Model ESFR-17 16.8 K-Factor Pendent Sprinkler Early Suppression, Fast Response General DescriptionDocument4 pagesModel ESFR-17 16.8 K-Factor Pendent Sprinkler Early Suppression, Fast Response General DescriptionJUANA MONSERRATE PARRALES PILAYNo ratings yet

- Raiser Magnifull TFP963 - 08 - 2018Document8 pagesRaiser Magnifull TFP963 - 08 - 2018peterNo ratings yet

- Quick ResponseDocument12 pagesQuick ResponsenhacotungNo ratings yet

- Rociador EC 11Document8 pagesRociador EC 11Alejandro Chumpitaz MarchanNo ratings yet

- Ty6236 Esfr k14 ColganteDocument4 pagesTy6236 Esfr k14 ColganteRaúl Antonio MacíasNo ratings yet

- Diseño de Boquilla D3Document6 pagesDiseño de Boquilla D3samuelcordova36No ratings yet

- Type D3 Protectospray Directional Spray Nozzles, Open, Medium Velocity General DescriptionDocument6 pagesType D3 Protectospray Directional Spray Nozzles, Open, Medium Velocity General DescriptionJackNo ratings yet

- Models BB, SD, HIP, and AP Specific Application Sprinklers For Protecting Attics General DescriptionDocument28 pagesModels BB, SD, HIP, and AP Specific Application Sprinklers For Protecting Attics General Descriptionmatt12manyNo ratings yet

- ESFR Sprinkler Technical GuideDocument8 pagesESFR Sprinkler Technical GuideOscar Fernandez SanchezNo ratings yet

- Series LFII Residential Horizontal Sidewall Sprinklers 4.2 K-FactorDocument8 pagesSeries LFII Residential Horizontal Sidewall Sprinklers 4.2 K-FactorAchraf BoudayaNo ratings yet

- TFP220 11 2014Document8 pagesTFP220 11 2014ioan cristian cotorobaiNo ratings yet

- Tyco TY313+TY323 TFP172 - 09 - 2022Document5 pagesTyco TY313+TY323 TFP172 - 09 - 2022First LAstNo ratings yet

- Model ESFR-14 14.0 K-Factor Pendent Sprinklers Early Suppression, Fast Response General DescriptionDocument4 pagesModel ESFR-14 14.0 K-Factor Pendent Sprinklers Early Suppression, Fast Response General Descriptionlou32contrerasNo ratings yet

- Resilient-Seated Gate Valves Outside Screw and Yoke General DescriptionDocument6 pagesResilient-Seated Gate Valves Outside Screw and Yoke General DescriptionNikhil JaiswalNo ratings yet

- Radio Shack TRS-80 Expansion Interface: Operator's Manual Catalog Numbers: 26-1140, 26-1141, 26-1142From EverandRadio Shack TRS-80 Expansion Interface: Operator's Manual Catalog Numbers: 26-1140, 26-1141, 26-1142No ratings yet

- Geotextiles and Geomembranes HandbookFrom EverandGeotextiles and Geomembranes HandbookT.S. IngoldRating: 5 out of 5 stars5/5 (1)

- Model F822S Through F834S Mulsifyre Directional Spray Nozzles, Open, With Strainers High Velocity General DescriptionDocument6 pagesModel F822S Through F834S Mulsifyre Directional Spray Nozzles, Open, With Strainers High Velocity General DescriptionhungNo ratings yet

- Type 1 and 2 Cooling Tower Nozzles, Crossflow General DescriptionDocument4 pagesType 1 and 2 Cooling Tower Nozzles, Crossflow General DescriptionhungNo ratings yet

- Platform For Dust Collector R5Document1 pagePlatform For Dust Collector R5hungNo ratings yet

- DDS Duct Deluge System For The Protection of Ventilation Ductwork Handling Corrosive Gases General DescriptionDocument6 pagesDDS Duct Deluge System For The Protection of Ventilation Ductwork Handling Corrosive Gases General DescriptionhungNo ratings yet

- Type D4a Protectospray Directional Spray Nozzles, Open, Medium Velocity General DescriptionDocument6 pagesType D4a Protectospray Directional Spray Nozzles, Open, Medium Velocity General DescriptionhungNo ratings yet

- A-01 Architect Outline PlanDocument1 pageA-01 Architect Outline PlanhungNo ratings yet

- A-02 Finishing Schedule 20190919 A-01Document1 pageA-02 Finishing Schedule 20190919 A-01hungNo ratings yet

- Front View Right View: Takesho Viet Nam Can Tho Plant ProjectDocument1 pageFront View Right View: Takesho Viet Nam Can Tho Plant ProjecthungNo ratings yet

- Front View Right View: Takesho Viet Nam Can Tho Plant ProjectDocument1 pageFront View Right View: Takesho Viet Nam Can Tho Plant ProjecthungNo ratings yet

- Front View Right View: Takesho Viet Nam Can Tho Plant ProjectDocument1 pageFront View Right View: Takesho Viet Nam Can Tho Plant ProjecthungNo ratings yet

- For Seiko PMC Vietnam Co., Ltd. Strainer ListDocument4 pagesFor Seiko PMC Vietnam Co., Ltd. Strainer ListhungNo ratings yet

- Front View Right View: Takesho Viet Nam Can Tho Plant ProjectDocument1 pageFront View Right View: Takesho Viet Nam Can Tho Plant ProjecthungNo ratings yet

- Front View Right View: Takesho Viet Nam Can Tho Plant ProjectDocument1 pageFront View Right View: Takesho Viet Nam Can Tho Plant ProjecthungNo ratings yet

- Front View Right View: Takesho Viet Nam Can Tho Plant ProjectDocument1 pageFront View Right View: Takesho Viet Nam Can Tho Plant ProjecthungNo ratings yet

- Steam trap list for Seiko PMC VietnamDocument4 pagesSteam trap list for Seiko PMC VietnamhungNo ratings yet

- Front View Right View: Takesho Viet Nam Can Tho Plant ProjectDocument1 pageFront View Right View: Takesho Viet Nam Can Tho Plant ProjecthungNo ratings yet

- 6.7.10.flexible Hose - Expansion Joint ListDocument4 pages6.7.10.flexible Hose - Expansion Joint ListhungNo ratings yet

- Pump capacity specifications for paper mill processDocument6 pagesPump capacity specifications for paper mill processhungNo ratings yet

- SEIKO PMC VIETNAM CO., LTD. STRAINER LISTDocument11 pagesSEIKO PMC VIETNAM CO., LTD. STRAINER LISThungNo ratings yet

- Rotating Equipment List: A. ProcessDocument2 pagesRotating Equipment List: A. ProcesshungNo ratings yet

- 6.7.8. Steam Trap ListDocument11 pages6.7.8. Steam Trap ListhungNo ratings yet

- 6.7.10.flexible Hose - Expansion Joint ListDocument6 pages6.7.10.flexible Hose - Expansion Joint ListhungNo ratings yet

- 6.7.7. Instrument Valve List (Safety Valve)Document3 pages6.7.7. Instrument Valve List (Safety Valve)hungNo ratings yet

- 306068-PVE - DD-CI-DAL-045 (Mat Bang Cong Hop) Rev ACDocument1 page306068-PVE - DD-CI-DAL-045 (Mat Bang Cong Hop) Rev AChungNo ratings yet

- Pve DD Ci Dal 341 - Ac1Document1 pagePve DD Ci Dal 341 - Ac1hungNo ratings yet

- Support For CRC & CPL Building PDFDocument32 pagesSupport For CRC & CPL Building PDFhungNo ratings yet

- SAFETY RELIEF VALVE INSTRUMENT LISTDocument1 pageSAFETY RELIEF VALVE INSTRUMENT LISThungNo ratings yet

- Pipe Support SectionDocument11 pagesPipe Support SectionhungNo ratings yet

- Roll Shop CPL Building: Section of PipingDocument1 pageRoll Shop CPL Building: Section of PipinghungNo ratings yet

- API Training & ASNT NDT Level III Examination Preparatories From INDTT, Mumbia INDIADocument7 pagesAPI Training & ASNT NDT Level III Examination Preparatories From INDTT, Mumbia INDIAtraining6156No ratings yet

- John Constantine Rouge Loner Primordial Orphan Paranormal DetectiveDocument4 pagesJohn Constantine Rouge Loner Primordial Orphan Paranormal DetectiveMirko PrćićNo ratings yet

- Basic Vacuum Theory PDFDocument17 pagesBasic Vacuum Theory PDFada guevarraNo ratings yet

- Engine Cpta Czca Czea Ea211 EngDocument360 pagesEngine Cpta Czca Czea Ea211 EngleuchiNo ratings yet

- Oil & Gas Rig Roles Functions ProcessesDocument5 pagesOil & Gas Rig Roles Functions ProcessesAnant Ramdial100% (1)

- University of Delhi Third Admission List - Bachelor of Education (B.Ed.)-2021Document8 pagesUniversity of Delhi Third Admission List - Bachelor of Education (B.Ed.)-2021FERA Future electronics and research administrationNo ratings yet

- A Phenomenological Research Design IllustratedDocument15 pagesA Phenomenological Research Design IllustratedMATEI100% (1)

- Advantages of Chain Grate Stokers: Dept of Mechanical Engg, NitrDocument3 pagesAdvantages of Chain Grate Stokers: Dept of Mechanical Engg, NitrRameshNo ratings yet

- Driven by Passion. Eager To Grow. If That'S You, Join Bearingpoint!Document15 pagesDriven by Passion. Eager To Grow. If That'S You, Join Bearingpoint!Ana Maria PetreNo ratings yet

- Kathryn Stanley ResumeDocument2 pagesKathryn Stanley Resumeapi-503476564No ratings yet

- Latihan Soal ADS Bab 14-16Document1 pageLatihan Soal ADS Bab 14-16nadea06_20679973No ratings yet

- Lesson Plan Sir MarcosDocument7 pagesLesson Plan Sir MarcosJhon AgustinNo ratings yet

- Limit of Outside Usage Outside Egypt ENDocument1 pageLimit of Outside Usage Outside Egypt ENIbrahem EmamNo ratings yet

- Modern Tips For The Modern Witch (/)Document5 pagesModern Tips For The Modern Witch (/)Rori sNo ratings yet

- Netprobe 2000Document351 pagesNetprobe 2000Jordon CampbellNo ratings yet

- Methodology of Legal Research: Challenges and OpportunitiesDocument8 pagesMethodology of Legal Research: Challenges and OpportunitiesBhan WatiNo ratings yet

- MCA 312 Design&Analysis of Algorithm QuestionBankDocument7 pagesMCA 312 Design&Analysis of Algorithm QuestionBanknbprNo ratings yet

- Towards Innovative Community Building: DLSU Holds Henry Sy, Sr. Hall GroundbreakingDocument2 pagesTowards Innovative Community Building: DLSU Holds Henry Sy, Sr. Hall GroundbreakingCarl ChiangNo ratings yet

- ENG302 Part 2Document7 pagesENG302 Part 2Oğuzhan DalkılıçNo ratings yet

- Product Item Code Model Item Description MRP Count Down PricesDocument1 pageProduct Item Code Model Item Description MRP Count Down Pricesලහිරු විතානාච්චිNo ratings yet

- Vietnamese sentence structure: key rules for SVO ordering, adjective and adverb placementDocument7 pagesVietnamese sentence structure: key rules for SVO ordering, adjective and adverb placementvickyzaoNo ratings yet

- International Journal of Information Technology, Control and Automation (IJITCA)Document2 pagesInternational Journal of Information Technology, Control and Automation (IJITCA)ijitcajournalNo ratings yet

- Analyzing Reality vs Fantasy in English LessonsDocument7 pagesAnalyzing Reality vs Fantasy in English Lessonsjerico gaspanNo ratings yet

- DepEd CI GuidebookDocument244 pagesDepEd CI Guidebookasdfg100% (4)

- RCC Chimneys - CICIND Code PDFDocument23 pagesRCC Chimneys - CICIND Code PDFVasanth KumarNo ratings yet

- DLL in Science 5 Q1 W1Document3 pagesDLL in Science 5 Q1 W1Rhinalyn Andaya Barberan100% (2)

- Econometrics IIDocument4 pagesEconometrics IINia Hania SolihatNo ratings yet

- Using Sunspots To Measure Solar Rotation: Astronomy 104 Observing Laboratory Spring 2009Document6 pagesUsing Sunspots To Measure Solar Rotation: Astronomy 104 Observing Laboratory Spring 2009Jeko Betguen PalangiNo ratings yet

- FS2-EP-12 - LanceDocument9 pagesFS2-EP-12 - LanceLance Julien Mamaclay MercadoNo ratings yet

- Four Golden RuleDocument6 pagesFour Golden RulerundyudaNo ratings yet