Professional Documents

Culture Documents

SSE RC Beam Designer EC2 Sheet v1.21

Uploaded by

SES DESIGNCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SSE RC Beam Designer EC2 Sheet v1.21

Uploaded by

SES DESIGNCopyright:

Available Formats

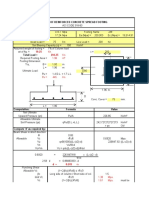

SSE RC Beam Designer - EC2 Sheet SSE-EXCEL-SECTION

Refs: EN1992-1-1, Maîtrise EC2, Technique d'Ingénieur C2 332 The author will not be responsible for the uses of this program

30x80x6.4m v1.21

1. Inputs Job: KA-1F-G1-1

bw= 0.3 m width of beam beff= 0.2 m >=bw (effective flange) TYPE OF BEAM Serviceability Data:

h= 0.8 m height of beam hf= 0.1 m <=h (slab thickness) CONTINUE BEAM

Ms: Mw Mmid Me t.m f(cm) w= west

CANTILEVER

e= 0.09 m (cover to axe of tension bars) 1 -11.1 33 -19.7 g =sw+sdl 1.05 e= east

d'= 0.05 m (cover to axe of compr. bars) Pos. End Mid Factored Loads Data 2 -13.4 40 -24 g+q 1.54 g= dead load

c= 0.05 m (cover to axe of bar for shear) Mu= -33.2 57 t.m factored moment fck= 25 Mpa concrete strength 3 -11.8 35.1 -21 t.m auto vba 1.38 q= live load

Vu= 55 20 t factored shear fyk= 390 Mpa bending reinf' OK

Design as= 1 1=as a beam, 2=as a slab Tu= 4 0 t.m factored torsion fyw= 235 Mpa shear reinf' L= 6.4 m span of beam where end moments are considered

used for Asmini SD: Conti.= 1 If cantilever, Conti=2 n= 0 =Es/Ec (0=auto calculation)

At+Ab= 8 cm2/m slab's reinforcement in flage T a= 90 deg. Link angle (90) Ratio(<=1)= 1 Mpoint / Mlinear load Ψ= 0.3 coeficient of sustaine live load (0.2 to 0.33)

beff= 0.3 m =max(bw, min(bw+L/4, bw+16*hf, beff)) av= 0 m point load from support (0=no shear reduction) for cantilever beam φef= 0 creep coeffisent 1.4 to 3 (by default 1.4 for EC2 ANF) (0=auto)

beff= 0.81 m, bf max by shear check in flange q= 36 deg. [21.8 to 45] fct= 0.15 factor to Ie for supports (by default 0.15)

OK a= 0.3 m dimension of column support to verif struct. Ig= 2 1) Include As in cal Ig, 2) Exclude As in cal Ig

cal f: 2 1) cal at g+q, 2) g+ψq (by default 2)

2. Design >> PAUSE >> CAL >> PDF cal As: 2 1) cal with Asreq 2) cal with Asprov

Section: Ma Mmid assum a=hf v1.12 -33.2 -33.2

-24

d= 0.71 0.75 m, d for moment/dt for shear Ratio=134kg/m3 Double reinf' -13.4

beff= 0.3 0.3 m 2.13m Ma Mmid

Mu= 33.2 57 t.m design moment 4-DB16-[T1] 4-DB16-[T1] 4-DB16-[T1] Rlim= 0.39 0.39 =0.3916 if fyk<=400, otherwise 0.3717

MT= 0 0 t.m =beff*hf*fck/1.5*(d-hf/2) 4-DB16-[T2] 4-DB16-[T2] Mulim= 99 99 t.m =(b*d^2*fck/1.5)*Rlim

Sec= T T T if Mu>MT, otherwise REC Mu'= 0 0 t.m =max(0,Mu-fMulim) 40

8DB10@0.11 DB10@0.47 8DB10@0.11

bw= 0.3 0.3 If Sec=REC, take bw=beff alm= 0.38 0.38 m =d*(1-sqrt(1-2Rlim))

Mu= 33.2 57 t.m if T, take =Mu-MT*(beff-bw)/beff clim= 0.47 0.47 m =alim/0.8 BMD, t.m

8-DB16-[B1] 8-DB16-[B2] 8-DB16-[B1]

Singly Reinf' ε's= 0 0 =εb*(clim-d')/clim

57

R= 0.13 0.23 unitless =Mu*0.01/(b*d^2*fck/1.5)

4-DB16-[B1] f's= 339 339 Mpa =max(-fy,min(fy, εs*E))

0.8m

Rlim= 0.39 0.39 =0.3916 if fyk<=400, otherwise 0.3717 6.4m As'= 0 0 cm2 =Mu'/((d-d')*f's)

A's=0? OK OK ok=signly rein'f, no=doubly reinf' Ends Mid-span

a= 0.1 0.18 m =d*(1-sqrt(1-2R)) Mu= 99 99 t.m =Mulim

z= 0.66 0.62 m =min(0.95*d, d-a/2) z= 0.52 0.52 m =min(0.95d,d-alim/2)

As= 14.8 27.2 cm2 =Mu/(z*fy/1.15)+(beff-bw)*hf*fcd/fyd As= 0 0 cm2 =Mu/(z*fy/1.15)+(beff-bw)*hf*fck/1.5/(fy/1.15)+A's*f's/(fy/1.15)

0.8 0.8

Asmini= 3.6 3.6 cm2 =b*d*max(0.26*fctm/fy, 0.13%) Asmini= 3.6 3.6 cm2 =b*d*max(0.26*fctm/fy, 0.13%)

Asreq= 14.8 27.2 cm2 =max(As,Asmini) Asreq= 3.6 3.6 cm2 =max(As,Asmin)

Results: At end-span At mid-span v1.13 End Mid Mid-span

Sec= SINGLY At Sup. no. dia.

Asprov Sec= SINGLY A mid. no. dia. Asprov Shear Reinf' no. Dia. spc. sreq sreq Deflection Check

A's= 0 cm2 [T1]: 4 16 8.04 cm2 A's= 0 cm2 [T1]: 4 16 8.04 cm2 OK Legs: 4 10 0.1 0.106 0.469 m hmini= 0.3 m 1/ 21 OK ratio

As= 14.8 cm2 [T2]: 4 16 8.04 cm2 As= 27.2 cm2 [B2]: 8 16 16.08 cm2 Asw= 3.14 (Asw/s)req= 29.71 6.70 cm2/m fa= 0.33 cm L/500= 1.28 OK 0.26

ΦMn= 36.7 t.m [B]: 8 16 16.1 cm2 ΦMn= 53.9 t.m [B1]: 4 16 8.04 cm2 (Asw/s)prov= 31.42 20.94 cm2/m ft= 1.38 cm L/250= 2.56 OK 0.54

ratio= 0.9 <=1? OK Atop_total= 16.1 OK ratio= 1.06 <=1? NO Asprov= 24.13 cm2 NO side bars: nb ratio= 1.02 0.24 <1

εst= 0.03 OK OK Asliding: 16.2 NO εst= 0.01 OK Asmax= 85.3 cm2 =4%bd w m e NO OK wk= 0.23 mm limit= 0.4 OK 0.59

ρ= 0.01 ρ= 0.01 Mcr= 8.21 8.21 12.2 t.m σs2= 99.2 Mpa limit= 390 OK 0.25

Ich; Icr= 128 105 *1E-4 m4

Unity Check: Ma= 0.90 Stress: L MID R ratio to Ic= 1 0.82 Struct. chk Point load (t) fs(q)= immediate deflection due to LL

Mt= 1.06 σc= 3.5 11.1 6.3 Mpa =Ms*x / Ie <= f'c Cracked sEd,1= 13 4.71 55.0 20.0 fa= deflection after construction due to SL

fa= 0.26

ft= 0.54 σsc= -51.1 -172 -91.4 Mpa = n.Ms.(d'-x)/Ie : comp. bars sRd,max= 12.8 12.8 0.0 0.0 ft= total deflection due to SL

SSE (T+V)/(lim)= 1.02 σs1= 130 266 232 Mpa = n.Ms.(d-x)/Ie : tensive bars NO OK OK OK SL= sustained load

SSE, Since 2014 1/6 6/20/2021 9:58 PM

1.02

0 1

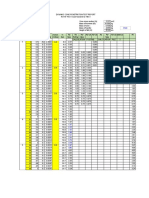

Find ΦMn Ma Mmid Ratio m kg/m kg Shear and Torsion Design to EN1992-1-1

c= 0.06 0.14 m goalseek variable [T1] 3.2 6.31 20.2 Ref: EN992-1-1

c= 0.06 0.14 =abs(c) [T2] 3.2 6.31 20.2

a= 0.05 0.11 =0.8*c [TT] 3.20 6.31 20.2 1. Inputs

[B2] 2.56 12.6 32.3 x= 0 or d L/2 b= 0.3 m fck= 25 MPa

A's= 16.1 8.04 cm2 =max(0,χ*As) [B1] 3.2 6.31 20.2 Vu= 55 20 t h= 0.8 m fyk= 390 MPa

As= 16.1 24.1 cm2 Link 16 2.47 39.5 Tu= 4 0 t.m cv= 0.09 m fyw= 390 MPa

e= 0.09 0.09 m [B1] 21.3 2.47 52.6 Nu= 0 0 t>0 comp z= m if imposed

d'= 0.05 0.05 m sum= 205 kg As= 16.1 24.13 cm2 longi.reinf d= 0.71 m =h-cv fctm= 2.56 Mpa =0.3*fck^(2/3)

d= 0.71 0.71 m =h-e Con= 1.54 m3 b= 1 1 m =av/2*d fctk,005= 1.8 Mpa =0.7*fctm

ε's= 0 0 =3.5/1000*(c-d')/c density=

Ratio=134kg/m3

kg/m3 a= 90 deg. Link angle (90deg) fctd= 1.2 Mpa =fctk,005/1.5

f's= 179 339 Mpa =max(-fy, min(fy,e's*Es)) x= 0 q= 36 deg. Strut angle (21.8 to 45deg)

εst= 0.03 0.01 =3/1000*(d-c)/c y= 1.2

fs= 339 339 Mpa =max(-fy, min(fy,e's*Es)) 2. Design

equ0= -3E-04 0 =fck/1.5*b*a+fck/1.5*(beff-bw)*min(a,hf)+A's*f's-As*fs x= 0 or d L/2 Verif. Struct

Φ= 1 1 =1 v= 0.54 0.54 =0.6*(1-fck/250) lbd= 0.25 0.25 m =a-5cm

ΦMn= 36.7 53.9 t.m* cotq= 1.38 1.38 cotqA= 0.88 0.88 =lbd/2*z+(0.5+d1/z).cotq

ΦMn= 38.2 55.2 t.m. exact CAL OK OK z= 0.64 0.64 =0.9*d if not imposed qA= 48.8 48.8 deg

ratio= 0.9 1.06 =ΦMn/Mu <=1 OK NO v1.15 scp= 0 0 Mpa =min(0.2*fcd, Nu/Ac) sEd,1= 13 4.71 Mpa =Ved/(lbd*bw*sin^2q

*ΦMn=Φ*[0.85*f'c*bw*a*(d-a/2)+0.85*f'c*(beff-bw)*min(a,hf)*{d-min(a,hf)/2}+A's*10^-4*f's*(d-d')]*100 k= 1.53 1.53 =min(2,1+sqrt(0.2/d)) sEd,2= 8.45 3.07 Mpa =Ved/(lbd*bw*sin^2q

ro= 0.01 0.01 =As/(b*d) sRd= 12.8 12.8 Mpa =0.85.(1-fck/250).fcd

6. Find bf to BAEL91 vrd,c= 0.47 0.54 Mpa =0.18/1.5*k*(100*ro*fck)^( 1/3) + 0.15*scp 1.02 0.37 *Ref1: Jean Marie Paillé

tlim= 3.33 Mpa =min(0.2*f'c/1.5, 5Mpa) vmin= 0.33 0.33 Mpa =0.035*k^(3/2)*sqrt(fck) + 0.15*scp Ref2: Pratique de l'EC2

bw= 0.3 m =bw VRd,c= 9.02 10.3 t =bw*z*max(vrd,c; vmin) sEd,bael= 14.7 5.33 Mpa =2Vu/(lbd*b)

At+Ab= 8 cm2/m slab's reinf' sRd= 13.3 13.3 Mpa =0.8*fck/1.5

bf1= 1.34 m =bw/(1-2*tlim*hf*0.9*d/Vu) Vrdmax= 82.2 82.2 t =bw.z.v.fcd.(cotq+cota) / (1+cot2q)) ratio= 1.1 0.4

bf2= 0.81 m =bw/(1-2*As*fyd*0.9*d/Vu) ratio= 0.67 0.24 =Vu/Vrdmax NO OK

bf= 0.81 m =max(bw,min(bf1, bf2) chk= OK OK

Verif. Point load

Asw/s= 18.4 6.7 cm2/m =Vu*tanq / (z*fyd) 0.75*av= 0 0

Unity Check 0.85 1 1 Creep to EC2 Asw/s min= 3.08 3.08 cm2/m =0.08*sqrt(fck)/fyk*bw*sina

Ma= 0.9 φ(∞, t0)= 2.14 =φRH*β(fcm)*β(t0) Asw/s req= 18.41 6.70 cm2/m =max Asw= 0 0 cm2 over 0.75*av

Mt= 1.06 t0= 28 number days for oading (28days) Abot,sliding= 16.22 5.90 cm2 =(Vu-Nu)/fyd VRd,red= 0 0 t =Asw*fywd*sin a

fa= 0.26 RH= 70 =50 to 70, (%) Ved,red= 55 20 t =Ved*b

ft= 0.54 β(fcm)= 2.92 =16.8/sqrt(fck+8) tef,i= 0.18 0.18 m =max(2.cv; Ac/u) ratio= #### #### <1

(T+V)/(lim)= 1.02 β(t0)= 0.49 =1/(0.1+t0^0.2) Ak= 0.08 0.08 m2 =(bw-tef,i)*(h-tef,i)

h0= 218 mm 2*Ac/u Trd,c= 3.23 3.23 t.m =2.Ak.tef,i.fctd

α1= 1.04 =(35/(fcm))^0.7 where fcm=fck+8 Trdmax= 11.6 11.6 t.m =2.v.acw.fcd.Ak.tef,i.sinq.cosq

α2= 1.01 =(35/(fcm))^0.2 where fcm=fck+8 ratio= 1.02 0.24 =Tu/Trdmax + Vu/Vrdmax

φRH= 1.5 =1+(1-RH/100)/(0.1*h0^(1/3)) chk= NO OK <1 OK

φef= 1.88 =φ(∞, t0) * M0qp1 / M0ed

Mqp/Mser= 0.88 uk= 1.49 1.49 m =2*[(b-tef)+(h-tef)]

Along= 11.56 0.00 cm2 =Tu*uk*cotq/ (2*Ak*fyd)

Ast/s= 5.65 0.00 cm2/m =Tu*tanq/(2*Ak*fyd ; by face

Atv/s= 29.71 6.70 cm2/m =Asw/s+if(Tu<Trdc,0,2*Ast/s)

SSE, Since 2014 2/6 6/20/2021 9:58 PM

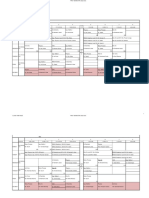

4. Deflection Check

n= 18.3 =Es/Ec,eff

fctm= 2.56 Mpa =0.3*fck^(2/3)

Ecm= 31476 MPa =22000*((fck+8)/10)^0.3

Ec,eff= 10936 Mpa =if(short-term loading=Ecm, long-term=Ec/(1+jef))

left support mid-span right support

bw= 0.3 m bw= 0.3 m bw= 0.3 m

beff= 0.3 m beff= 0.3 m beff= 0.3 m

h= 0.8 m h= 0.8 m h= 0.8 m

hf= 0.1 m hf= 0.1 m hf= 0.1 m

e= 0.09 m e= 0.09 m e= 0.09 m

d'= 0.05 m d'= 0.05 m d'= 0.05 m

d= 0.71 m d= 0.71 m d= 0.71 m

A's= 16.1 cm2 A's= 8.04 cm2 (impose A's /4) A's= 16.1 cm2

As= 16.1 cm2 As= 24.1 cm2 As= 16.1 cm2

Calculate critical Moment Mcr (include reinforcement for option1)

Ach= 0.3 m2 Ach= 0.3 m2 Ach= 0.3 m2 = bw*h+(beff-bw)*hf+n*(As+A's)

v'= 0.4 m v'= 0.43 m v'= 0.4 m =1/Ach*(bw*h^2/2+(beff-hw)*hf^2/2+n(As1*d+As2*d')

v= 0.4 m v= 0.37 m v= 0.4 m =h-v'

Ich= 0.02 m4 Ich= 0.02 m4 Ich= 0.02 m4 =bw*h^3/3+(beff-bw)*hf^3/3+n*(As*d2+A's*d'2)-Ach*v'^2

Mcr= 12.2 t.m Mcr= 12.9 t.m Mcr= 12.2 t.m = fr*Ig/v

ACI Formular (neglige reinforcement for option 2) v1.13

yt=y= 0.4 yt=y= 0.4 yt=y= 0.4 m =(bf*hf^2/2+bw*(h-hf)*(h+hf)/2)/(bf*hf+bw*(h-hf)

Ig= 0.01 Ig= 0.01 Ig= 0.01 m =(bf*hf^3/12+bw*(y-hf/2)^2+bw*(y-hf)^3/3+bw*(h-y)^3/3

Mcr= 8.21 t.m Mcr= 8.21 t.m Mcr= 8.21 t.m = fr*Ig/v

Mcr= 8.21 t.m Mcr= 8.21 t.m Mcr= 8.21 t.m = fr*Ig/v

Ma= -12 t.m Ma= 35.1 t.m Ma= -21 t.m

Mcr/Ma= 0.7 Mcr/Ma= 0.23 Mcr/Ma= 0.39

Calculate cracked inertia Icr

x= 0.24 m x= 0.31 m x= 0.24 m variable goalseek

equ0= -0 equ0= 0 equ0= -0 '=bw*x^2/2+x*[ (bf-bw)*hf+n*(As+A's) ] - [(bf-bw)*hf^2/2+n*(As*d+A's*d')]

Icr_T= 0.01 m4 Icr_T= 0.01 Icr_T= 0.01 m4 =bf*x^3/3-(beff-bw)*(x-hf)^3/3+n*(As*(x-d)^2+A's*(x-d')^2)

x= 0.24 x= 0.31 x= 0.24 m variable goalseek

equ0= -0 equ0= 0 equ0= -0 =bf*x^2/2+x*n*(As+A's) - n*(As*d+A's*d')

Icr_Rec= 0.01 Icr_Rec= 0.01 Icr_Rec= 0.01 m4 =bf*x^3/3+n*(As*(x-d)^2+A's*(x-d')^2)

Icr= 0.01 m4 Icr= 0.01 Icr= 0.01 m4 =if(x>hf, Icr_T, Icr_Rec)

89.9 10^-4 m4 111 10^-4 m4 89.9 10^-4 m4

Icr= 0.01 Icr= 0.01 m4 Icr= 0.01 =Icr

111

SSE, Since 2014 3/6 6/20/2021 9:58 PM

Calculate Equivalent inertie Ie

factor= 0.15 =user input above 0.7 0.15

Ich,cor= 0 m4 Ich,cor= 0.01 m4 Ich,cor= 0 m4

Ich,av= 0.013 m4 =sum, average

128 *10^-4 m4

Ig= 0.01 m4 Ig= 0.01 m4 Ig= 0.01 m4 =bw*h^3/12

Ie= 0.01 m4 Ie= 0.01 m4 Ie= 0.01 m4 =min(Ig, (Mcr/Ma)^3*Ig+(1-(Mcr/Ma)^3)*Icr)

89.9 *10^-4 m4 111 *10^-4 m4 89.9 *10^-4 m4

factor= 0.15 =user input above 0.7 0.15

Ie,cor= 0 m4 Ie,cor= 0.01 m4 Ie,cor= 0 m4

Ie,av= 0.01 m4 =sum, average

105 *10^-4 m4

Deflection due to skinkages (retrait) (Ref: Maîtrise EC2)

Uncracked: Uncracked:

ds= 0.32 ds= 0.28 m d=d-v'

S= 5E-04 S= 0.0007 m4 =As*ds

Ich= 0.013 Ich= 0.0128

1/rcsI= 2E-04 =M/EI 1/rcsI= 0.0003 1/m =Mcs/(Ec.I)

Cracked Cracked

ds= 0.48 ds= 0.4 m =d-x

S= 8E-04 S= 0.001 m4 =As*ds

Icf= 0.01 Icf= 0.0105 m4 =Icf

1/rcsII= 4E-04 1/rcsII= 0.0005 1/m =Mcs/(Ec.I)=ecs.n.S/Icf

1/rcs= 4E-04 1/rcs= 0.0005 1/m=x*II+(1-x)*I

b= 0.9339 =(Mw+Me)/Mt

k= 0.0943 =0.104*(1-b/10)

f= 0.541 cm f= 0.1945 cm

Calculate stress in concrete and steel

case 3 case

x= 0.24 m x= 0.31 m x= 0.24 m

I= 0.01 m4 I= 0.01 m4 I= 0.01 m4 uncracked or cracked inertie

σc= 3.09 Mpa σc= 9.77 Mpa σc= 5.49 Mpa =Ms*x / Ie <= f'c

σsc= -45 Mpa σsc= -151 Mpa σsc= -80 Mpa = n. Ms.(d'-x) / Ie : compressive bars

σs1= 114 Mpa σs1= 233 Mpa σs1= 203 Mpa = n. Ms.(d-x) / Ie : tensive bars

case 2

x= 0.24 m x= 0.31 m x= 0.24 m

I= 0.01 m4 I= 0.01 m4 I= 0.01 m4

σc= 3.51 Mpa σc= 11.1 Mpa σc= 6.28 Mpa

σsc= -51 Mpa σsc= -172 Mpa σsc= -91.4 Mpa

σs1= 130 Mpa σs1= 266 Mpa σs1= 232 Mpa

Calculate deflection

fI= -0.2 cm fI= 1.57 cm uncracked fI= -0.38 cm =(Ma1/16+M0/9.6+Ma2/16)*L^2/Eceff Ich,av

SSE, Since 2014 4/6 6/20/2021 9:58 PM

fII= -0.3 cm fII= 1.92 cm cracked fII= -0.47 cm =(Ma1/16+M0/9.6+Ma2/16)*L^2/Eceff Icr,av

b= 0.5 1=short ; 0.5=long-term b= 0.5 1=short ; 0.5=long-term

x= 0.76 =1-b*(Mcr/Ma)^2 x= 0.97 =1-b*(Mcr/Ma)^2; =0 if Mcr>Ma

fI= 0.97 cm uncracked =sum fI

fII= 1.19 cm cracked =sum fII

f= 1.18 cm =x*fII+(1-x)*fI

SSE, Since 2014 5/6 6/20/2021 9:58 PM

Case of cantilever

fI= 0.76 cm =(1/4*(1-rato)+1/3*ratio)*Ma*Lu^2/Eceff/Ie

fII= 1.64 cm

f= 1.43 cm =x*fII+(1-x)*fI

fcal= 1.38 cm final deflection (cantilever or not)

f(g)= 1.05 cm due to dead load Data Table

f(g+q)= 1.54 cm due to g+q fa ft

f(g+ y*q)= 1.38 cm due to g+ψ*q cal f: 0.33 1.38

fa= 0.33 cm =f(g+ ψ*q) - f(g) 1 0.16 0.6

ft= 1.38 cm =f(g+ ψ*q) 2 0.16 0.6

5. Crack width - Check

x1= 0.31 m Ned= 0

I= 0.01 m4 σc=Ned/bh= 0

σc= 9.77 Mpa Ms/I x1 kc= 0.4

σst= 233 Mpa fissuré h k

Ac eff= 0.05 m2 =bw*min(2.5*cov, (h-x1)/3, h/) 0.3 1

ρp, eff= 0.05 =As / Ac, eff 0.8 0.65

Φeq= 16 mm =sum(n*d^2)/sum(n*d) 0.30 1

sr, max= 0.24 m =k3*c + 0.425*k1*k2*Φ / ppeff

k3= 3.4 =3.4*(fck/c)^(2/3) fcteff= 2.565 Mpa

c= 55 mm =(cover-feq*nb/2-0.01)*1000 σs= 390 Mpa =fyk

k1= 0.8 HA Act= 0.12 m2 =bw.h/2

k2= 0.5 Bending As,min= 3.157 cm2 =kc.k.fcteff.Act/σs

αe= 18.3 Es/Ecm σs2= 99.2 Mpa = (1+αe.ppeff).fctm/ppeff must be smaller than ss1

εsm-εcm= 0.001 >=0.6.σs/Es= 0.0007

fcteff= 2.56

wk= 0.23 mm =sr,max (εsm-εcm)

SSE, Since 2014 6/6 6/20/2021 9:58 PM

You might also like

- SSE RC Beam Designer ACI Sheet v1.12Document4 pagesSSE RC Beam Designer ACI Sheet v1.12Sophea PhanNo ratings yet

- SSE Shear Design - EC2v1 - 07 - G1 - 20211027 - 2234 - 32Document1 pageSSE Shear Design - EC2v1 - 07 - G1 - 20211027 - 2234 - 32SES DESIGNNo ratings yet

- Design Sheet: DPWH DesignedDocument5 pagesDesign Sheet: DPWH DesignedEdward Albert Mendoza BañagaNo ratings yet

- SSE Shear Design - EC2v1 - 07 - G1 - 20211027 - 2233 - 53Document4 pagesSSE Shear Design - EC2v1 - 07 - G1 - 20211027 - 2233 - 53SES DESIGNNo ratings yet

- Beam 20x40Document3 pagesBeam 20x40chhay longNo ratings yet

- Design of Trade Off III Precast ConcreteDocument9 pagesDesign of Trade Off III Precast ConcretemateojullieanneNo ratings yet

- Purlin Design - Hat-Section@170 (r0)Document4 pagesPurlin Design - Hat-Section@170 (r0)Prince MittalNo ratings yet

- Busugan Part 2 Design BSDSDocument257 pagesBusugan Part 2 Design BSDSmarco miguelNo ratings yet

- Deck Girder ExampleDocument28 pagesDeck Girder ExampleEng'r Mohammed HamzaNo ratings yet

- Helical Staircase: Design of SectionDocument11 pagesHelical Staircase: Design of SectionlaxmiNo ratings yet

- Project:-Date: - Description: - By:-: Dimension MaterialDocument2 pagesProject:-Date: - Description: - By:-: Dimension MaterialMustefa Mohammed AdemNo ratings yet

- Purlin and Girth Design for Roof StructureDocument11 pagesPurlin and Girth Design for Roof StructureRajveer SinghNo ratings yet

- Design stairway from EL 1500 to 6500Document10 pagesDesign stairway from EL 1500 to 6500Thomas StephenNo ratings yet

- App 10 Longitudial Shear 2 UC 283Document3 pagesApp 10 Longitudial Shear 2 UC 283yuNo ratings yet

- 15m RC TG Superstructure DesignDocument22 pages15m RC TG Superstructure DesignEngineeri TadiyosNo ratings yet

- Sse RC Beam: Continue Beam Section CantileverDocument3 pagesSse RC Beam: Continue Beam Section Cantileverchhay longNo ratings yet

- Staircase Beam Design - 2Document28 pagesStaircase Beam Design - 2Sai Sushank67% (3)

- Column Design Using Balance Loading C1 (Foundation To 2nd FLR LVL)Document8 pagesColumn Design Using Balance Loading C1 (Foundation To 2nd FLR LVL)Farly VergelNo ratings yet

- Two-way slab designDocument88 pagesTwo-way slab designSushil KumarNo ratings yet

- Long Col.Document6 pagesLong Col.HAITHAM ALINo ratings yet

- 3-Slab (2nd Floor)Document40 pages3-Slab (2nd Floor)JuNe RaMos JavierNo ratings yet

- Slabs AauDocument26 pagesSlabs AauEngineeri TadiyosNo ratings yet

- Is IsolatedDocument21 pagesIs IsolatedRoshan KejariwalNo ratings yet

- 2-Slab (RoofDeck)Document17 pages2-Slab (RoofDeck)JuNe RaMos JavierNo ratings yet

- Design One Way SlabDocument22 pagesDesign One Way Slabjohn rey toledoNo ratings yet

- Design of Pile and Pile Cap - PC1: Working Loads: FCK FyDocument5 pagesDesign of Pile and Pile Cap - PC1: Working Loads: FCK Fyvikas WaghmareNo ratings yet

- Design of Precast PanelDocument2 pagesDesign of Precast PanelGaurav BhabadNo ratings yet

- Valve Pit (2.5X2.5)Document8 pagesValve Pit (2.5X2.5)rachanaNo ratings yet

- Attachment 1 - Bi-Axial Bending CheckDocument2 pagesAttachment 1 - Bi-Axial Bending CheckYang W OngNo ratings yet

- Design of two-way reinforced concrete slabDocument15 pagesDesign of two-way reinforced concrete slabMohammed Saleem Syed KhaderNo ratings yet

- Two Way SlabDocument9 pagesTwo Way SlabMehul Paþel100% (1)

- Design of Reinforced Concrete Spread Footing Specification:: Kn. Kn. 1.96 MDocument6 pagesDesign of Reinforced Concrete Spread Footing Specification:: Kn. Kn. 1.96 MRyan TagaNo ratings yet

- Steel Beam DesignDocument4 pagesSteel Beam Designanshutomar7915100% (1)

- 18 M T Girder Bridge-statica-August-2012Document14 pages18 M T Girder Bridge-statica-August-2012Mitiku AregieNo ratings yet

- VIAK - Strap - Neighboring Foting Design 22.06Document14 pagesVIAK - Strap - Neighboring Foting Design 22.06mukim0201004No ratings yet

- Slab DesignDocument16 pagesSlab DesignpasangbhpNo ratings yet

- Analysis of Deck Slabs - Pigeaud's TheoryDocument11 pagesAnalysis of Deck Slabs - Pigeaud's TheoryAkarshGowdaNo ratings yet

- Stair Case CalcuationsDocument2 pagesStair Case CalcuationsraghavendraNo ratings yet

- Example 20m Span RCDGDocument17 pagesExample 20m Span RCDGIyœ Møsisæ100% (2)

- Two Way SlabDocument9 pagesTwo Way SlabArovet IrineoNo ratings yet

- 3.0 Butterfly Valve Chamber Precast Panel DesignDocument2 pages3.0 Butterfly Valve Chamber Precast Panel DesignGaurav BhabadNo ratings yet

- Slab DesignDocument9 pagesSlab Designsuleiman.ahNo ratings yet

- Structural Design AnalysisDocument9 pagesStructural Design AnalysisJomin Dennis MiembroNo ratings yet

- Strap Footing Sample PDFDocument6 pagesStrap Footing Sample PDFshaimenneNo ratings yet

- Strap Footing Sample PDFDocument6 pagesStrap Footing Sample PDFshaimenneNo ratings yet

- Slab Design (Typical Floor Tower-A)Document72 pagesSlab Design (Typical Floor Tower-A)Prolay MannaNo ratings yet

- Untitled SpreadsheetDocument75 pagesUntitled SpreadsheetAddin hanifNo ratings yet

- Sample Structural AnalysisDocument9 pagesSample Structural AnalysisKaJong JaclaNo ratings yet

- BW - Calculation Sheet - Rev01Document15 pagesBW - Calculation Sheet - Rev01Ernest NavarroNo ratings yet

- Slab Design 2 Way IsDocument3 pagesSlab Design 2 Way IsRam LangheNo ratings yet

- Two Way Slab DesignDocument1 pageTwo Way Slab DesignShakil AkhterNo ratings yet

- Structural Design AnalysisDocument9 pagesStructural Design AnalysisJomin Dennis MiembroNo ratings yet

- Bearing Capacity Calculation Shallow Found - FinalDocument2 pagesBearing Capacity Calculation Shallow Found - Finalabcd efghNo ratings yet

- 2.0 Sluice Valve Chamber Precast Panel DesignDocument2 pages2.0 Sluice Valve Chamber Precast Panel DesignGaurav BhabadNo ratings yet

- Study For Roof Louver Effect On Parapet WallDocument3 pagesStudy For Roof Louver Effect On Parapet WallKhawaja Kashif QadeerNo ratings yet

- R.C. Slab Design Calculation Sheet for Two Way Slab S1Document1 pageR.C. Slab Design Calculation Sheet for Two Way Slab S1sallysel90No ratings yet

- s1 Slab DesignDocument1 pages1 Slab DesignDaante VermaNo ratings yet

- Aa - Bracket DesignDocument2 pagesAa - Bracket Design4geniecivilNo ratings yet

- Solution Manual for an Introduction to Equilibrium ThermodynamicsFrom EverandSolution Manual for an Introduction to Equilibrium ThermodynamicsNo ratings yet

- Strength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresFrom EverandStrength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresRating: 4 out of 5 stars4/5 (1)

- DCP SSE v1.03 BH1 NEWDocument4 pagesDCP SSE v1.03 BH1 NEWSES DESIGNNo ratings yet

- SSE Global Structural Stability Analysisv1.20 - CW1 - 20220530 - 2117 - 55Document1 pageSSE Global Structural Stability Analysisv1.20 - CW1 - 20220530 - 2117 - 55SES DESIGNNo ratings yet

- SSE PFA-v1.18 - Portal Frame 1 - 20221026 - 2041 - 20Document2 pagesSSE PFA-v1.18 - Portal Frame 1 - 20221026 - 2041 - 20SES DESIGNNo ratings yet

- DCP SSE v1.03 BH1 NEWDocument4 pagesDCP SSE v1.03 BH1 NEWSES DESIGNNo ratings yet

- Pile Cap Design Sheet v1.09Document4 pagesPile Cap Design Sheet v1.09SES DESIGNNo ratings yet

- SSE Bridge Design AASHTO LRFD - v1.04 - BR2-Highway-Superstructures - 20220623 - 2159 - 12Document2 pagesSSE Bridge Design AASHTO LRFD - v1.04 - BR2-Highway-Superstructures - 20220623 - 2159 - 12SES DESIGNNo ratings yet

- 15.11 - SSE Slope Stability - v1.03 - 20220927 - 2130 - 55Document1 page15.11 - SSE Slope Stability - v1.03 - 20220927 - 2130 - 55SES DESIGNNo ratings yet

- SSE REC TANK DESIGN SHEETv1.01Document1 pageSSE REC TANK DESIGN SHEETv1.01SES DESIGNNo ratings yet

- SSE RC Corbel Designer - EC2v1 - 11 - TM-GB-G9-5 - 20211023 - 2003 - 08Document1 pageSSE RC Corbel Designer - EC2v1 - 11 - TM-GB-G9-5 - 20211023 - 2003 - 08SES DESIGNNo ratings yet

- SSE Frame Analysis v1.10Document1 pageSSE Frame Analysis v1.10SES DESIGNNo ratings yet

- SSE RC Corbel Designer - EC2v1 - 11 - TM-GB-G9-5 - 20211023 - 1952 - 45Document1 pageSSE RC Corbel Designer - EC2v1 - 11 - TM-GB-G9-5 - 20211023 - 1952 - 45SES DESIGNNo ratings yet

- SSE RC Corbel Designer - EC2v1 - 11 - TM-GB-G9-5 - 20211023 - 1952 - 45Document1 pageSSE RC Corbel Designer - EC2v1 - 11 - TM-GB-G9-5 - 20211023 - 1952 - 45SES DESIGNNo ratings yet

- Highway Bridge Ex5.6 - SSE Bridge Design AASHTO LRFD - v2.02 - 20220704 - 2113 - 53Document1 pageHighway Bridge Ex5.6 - SSE Bridge Design AASHTO LRFD - v2.02 - 20220704 - 2113 - 53SES DESIGNNo ratings yet

- SSE RC Column-General Method EC2 - v1.06Document1 pageSSE RC Column-General Method EC2 - v1.06SES DESIGNNo ratings yet

- SSE RC Beam Designer - EC2v1 - 05 - DB Journal Wright Wing - 20211104 - 2305 - 52Document1 pageSSE RC Beam Designer - EC2v1 - 05 - DB Journal Wright Wing - 20211104 - 2305 - 52SES DESIGNNo ratings yet

- SSE Sub-Frame Analysisv1 - 07 - F1 - 20211109 - 2238 - 11Document1 pageSSE Sub-Frame Analysisv1 - 07 - F1 - 20211109 - 2238 - 11SES DESIGNNo ratings yet

- SSE Truss AnalysisDocument1 pageSSE Truss AnalysisSES DESIGNNo ratings yet

- SSE Circular Column Designer - EC2v1 - 07 - C15 - 20211109 - 0009 - 54Document9 pagesSSE Circular Column Designer - EC2v1 - 07 - C15 - 20211109 - 0009 - 54SES DESIGNNo ratings yet

- SSE Retaining Wall Analysis Sheet v1.14Document3 pagesSSE Retaining Wall Analysis Sheet v1.14SES DESIGNNo ratings yet

- SSE Analysis Beam - v1 - 09 - G1 - 20210819 - 2147 - 37Document1 pageSSE Analysis Beam - v1 - 09 - G1 - 20210819 - 2147 - 37SES DESIGNNo ratings yet

- SSE RC Beam Designer - v1 - 11 - S1 - 20210810 - 2222 - 31Document1 pageSSE RC Beam Designer - v1 - 11 - S1 - 20210810 - 2222 - 31SES DESIGNNo ratings yet

- SSE Analysis Beam - v1 - 09 - G1 - 20210819 - 2223 - 54Document1 pageSSE Analysis Beam - v1 - 09 - G1 - 20210819 - 2223 - 54SES DESIGNNo ratings yet

- SSE Analysis Beam - v1 - 09 - G1 - 20210819 - 2223 - 31Document1 pageSSE Analysis Beam - v1 - 09 - G1 - 20210819 - 2223 - 31SES DESIGNNo ratings yet

- EC2 EC2 0.225: Mpa 0.4 0.6 (1-fck/250) fck/1.5 M U0+4 PI DDocument2 pagesEC2 EC2 0.225: Mpa 0.4 0.6 (1-fck/250) fck/1.5 M U0+4 PI DSES DESIGNNo ratings yet

- SSE Truss Analysis v1.05Document1 pageSSE Truss Analysis v1.05SES DESIGNNo ratings yet

- EC2 EC2 0.225: Mpa 0.4 0.6 (1-fck/250) fck/1.5 M U0+4 PI DDocument2 pagesEC2 EC2 0.225: Mpa 0.4 0.6 (1-fck/250) fck/1.5 M U0+4 PI DSES DESIGNNo ratings yet

- EC2 EC2 0.225: Mpa 0.4 0.6 (1-fck/250) fck/1.5 M U0+4 PI DDocument2 pagesEC2 EC2 0.225: Mpa 0.4 0.6 (1-fck/250) fck/1.5 M U0+4 PI DSES DESIGNNo ratings yet

- Probs in AMP PDFDocument3 pagesProbs in AMP PDFwilliam taloNo ratings yet

- Mechanical Engineering Dynamics ProblemsDocument6 pagesMechanical Engineering Dynamics Problemsizel valerianoNo ratings yet

- Principles of Electromagnetics 6th Edition (Asian Edition) SolutionsDocument502 pagesPrinciples of Electromagnetics 6th Edition (Asian Edition) SolutionsAdeeb85% (118)

- 28 Roark Flat PlatesDocument14 pages28 Roark Flat Platesgutmont0% (1)

- Acronal V210 Na AdhesivesDocument3 pagesAcronal V210 Na AdhesivesCanchindoNo ratings yet

- DiodeDocument32 pagesDiodejit_72No ratings yet

- UntitledDocument7 pagesUntitledKushank GuptaNo ratings yet

- EE8702 - PSOC Syllabus 2017RDocument2 pagesEE8702 - PSOC Syllabus 2017RRaja Sekar100% (2)

- Active and Passive Cooling Technologies For Thermal Management of AvionicsDocument10 pagesActive and Passive Cooling Technologies For Thermal Management of AvionicsdavidNo ratings yet

- Fib LiDocument13 pagesFib LiSanjay GohilNo ratings yet

- Engineering Analysis Ii: Partial Differential Equations (Pdes) and Applications To EngineeringDocument24 pagesEngineering Analysis Ii: Partial Differential Equations (Pdes) and Applications To EngineeringAram Nasih MuhammadNo ratings yet

- Phi For "Neo-Phi-tes": Phi (Golden Number)Document2 pagesPhi For "Neo-Phi-tes": Phi (Golden Number)Bushra HashmiNo ratings yet

- Lect 1 Limit State DesignDocument31 pagesLect 1 Limit State DesignWaleed Yahia100% (1)

- Performance Standards For Transmission (PST) Philippine Grid Code Performance Standards For Transmission (PST) PST 3.1. PurposeDocument10 pagesPerformance Standards For Transmission (PST) Philippine Grid Code Performance Standards For Transmission (PST) PST 3.1. PurposeBhea Grace Del-oNo ratings yet

- Cause and Effect LawDocument44 pagesCause and Effect Lawsubhendu DasNo ratings yet

- Fluid MechanicsDocument27 pagesFluid MechanicsKarl Radison AbreaNo ratings yet

- Adsorption Column Design PDFDocument61 pagesAdsorption Column Design PDFazizkhouribga75% (4)

- Take Home WorksheetDocument3 pagesTake Home WorksheetXu ShennaNo ratings yet

- Curriculum Map for Grade 9 Mathematics at Sulipan, Apalit PampangaDocument13 pagesCurriculum Map for Grade 9 Mathematics at Sulipan, Apalit PampangaRalph Francis BautistaNo ratings yet

- Definition Isolated System Pure SubstanceDocument3 pagesDefinition Isolated System Pure Substanceadilah rusdiNo ratings yet

- Chapter 5Document19 pagesChapter 5waqas ITNo ratings yet

- Black Holes A Very Short Introduction by Katherine BlundellDocument150 pagesBlack Holes A Very Short Introduction by Katherine BlundellSalman Ali100% (2)

- Manual Intended Use: Piinline Plus AQR/AQR Low PressureDocument5 pagesManual Intended Use: Piinline Plus AQR/AQR Low PressureMario PortillaNo ratings yet

- Quiz For International Candidates of CUHK-Shenzhen - 2020214-Session 2Document2 pagesQuiz For International Candidates of CUHK-Shenzhen - 2020214-Session 2Fadhilah DefayanaNo ratings yet

- UNI Engineering ManualDocument144 pagesUNI Engineering ManualJorch GalvanNo ratings yet

- (Mai 1.6) Geometric SequencesDocument22 pages(Mai 1.6) Geometric SequencesShivSantosh JhaNo ratings yet

- Chapter 5: Technology: Technology Is Not Demonic, But Its Essence Is MysteriousDocument37 pagesChapter 5: Technology: Technology Is Not Demonic, But Its Essence Is MysteriousBrille Adrian FernandoNo ratings yet

- Gravity MethodDocument38 pagesGravity Methodzain828No ratings yet

- Datacolor ColorTheory Webinar Part1 PDFDocument36 pagesDatacolor ColorTheory Webinar Part1 PDFdamarNo ratings yet