Professional Documents

Culture Documents

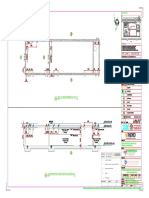

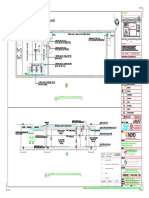

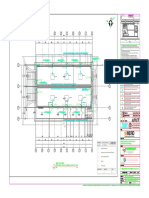

In Line Pump Min. Pressure

Uploaded by

SLPlanner PlannerOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

In Line Pump Min. Pressure

Uploaded by

SLPlanner PlannerCopyright:

Available Formats

22 11 23

DOMESTIC WATER PUMPS

C. Packaged booster pumps shall be listed and labeled as pumping systems by testing agency

acceptable to Royal Commission

1.07 DELIVERY, STORAGE AND HANDLING

A. The Contractor shall deliver, handle and store equipment and material units in accordance

with SECTIONS 01 65 00 and 01 66 00, as well as the following requirements:

1. All products shall be inspected at time of delivery for damage and for compliance with

specifications

2. All products shall be handled and stored as recommended by the manufacturer

3. Pipe, fittings, valves, alarm valves and sprinkler heads shall be stored with open ends

sealed until removed for installation

4. Materials shall be protected from weather, soil; and damage during delivery, storage and

construction

5. Any products that are damaged or found not to be in accordance with the specifications

shall be immediately replaced

B. Preparation for shipping: After assembly and testing, prepare pumps for long term outdoor

covered storage. Clean flanges and exposed machined metal surfaces and treat with

anticorrosion compound. Flush internal surface of the pump with a suitable rust preventative

C. Cover all openings to protect against contamination. Protect flanges, pipe openings, and

nozzles with full diameter flange covers or with screwed in plugs

D. Ship shaft seal packing separate for field installation

E. Provide lifting lugs and clearly mark lifting points

F. On site, store pumps, drivers and controllers in a clean, dry location

G. Retain shipping flange protective covers and protective coatings during storage

H. Protect bearings and couplings against damage from sand, grit, or other foreign matter

I. Extended Storage Greater Than 5 Days: Dry internal parts with hot air or a vacuum

producing device. After drying, coat internal parts with light oil, kerosene, or antifreeze.

Dismantle bearings and couplings, dry and coat with an acid free heavy oil, and tag and store

in a dry location

J. Comply with pump manufacturer's rigging instructions for handling

PART 2 PRODUCTS

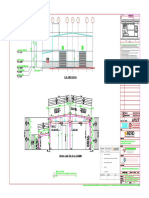

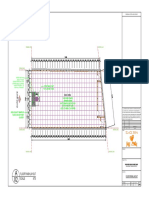

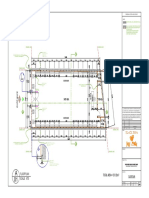

2.01 CONSTANT OR VARIABLE SPEED, MULTIPLE BOOSTER PUMPS

A. Description: Factory-assembled and -tested, packaged booster pump with multiple pumps,

piping, valves, sensors, pressure vessel, and controls on skids or base

B. System Working-Pressure Rating: 1200 kPa minimum

C. Pumps: In-line, multistage, centrifugal or end suction pumps. Comply with UL 778

D. Each Pump:

1. Construction: Stainless-steel fitted

a. Casing: Cast-iron base and head sections

b. Impellers, Diffusers, and Discharge Sleeve: Stainless steel

c. Shaft: Stainless steel

d. Seal: Mechanical

Rev 2 3 of 10 Contract No. XXX-XXX

You might also like

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Notes:: Key PlanDocument1 pageNotes:: Key PlanSLPlanner PlannerNo ratings yet

- Key site plan layout and emergency exitsDocument1 pageKey site plan layout and emergency exitsSLPlanner PlannerNo ratings yet

- The Site: Electrical Equipment Elevation (MS) BuildingDocument1 pageThe Site: Electrical Equipment Elevation (MS) BuildingSLPlanner PlannerNo ratings yet

- Floor Finish Layout Scale: NTS: Black RoseDocument1 pageFloor Finish Layout Scale: NTS: Black RoseSLPlanner PlannerNo ratings yet

- TOTAL AREA 131.83m : Fitting RoomDocument1 pageTOTAL AREA 131.83m : Fitting RoomSLPlanner PlannerNo ratings yet

- Notes:: Key PlanDocument1 pageNotes:: Key PlanSLPlanner PlannerNo ratings yet

- Notes:: Key PlanDocument1 pageNotes:: Key PlanSLPlanner PlannerNo ratings yet

- Notes:: Key PlanDocument1 pageNotes:: Key PlanSLPlanner PlannerNo ratings yet

- Emergency Site Plan KeyDocument1 pageEmergency Site Plan KeySLPlanner PlannerNo ratings yet

- 02Document1 page02SLPlanner PlannerNo ratings yet

- 06Document1 page06SLPlanner PlannerNo ratings yet

- uPVC PIPES STORAGEDocument2 pagesuPVC PIPES STORAGESLPlanner PlannerNo ratings yet

- True key plan for the Makka site emergency exitsDocument1 pageTrue key plan for the Makka site emergency exitsSLPlanner PlannerNo ratings yet

- Guard House Electrical Plan Key NotesDocument1 pageGuard House Electrical Plan Key NotesSLPlanner PlannerNo ratings yet

- 02Document1 page02SLPlanner PlannerNo ratings yet

- Fire Pump SpecsDocument23 pagesFire Pump SpecsSLPlanner PlannerNo ratings yet

- Sewer & Water Pipe CoordinationDocument1 pageSewer & Water Pipe CoordinationSLPlanner PlannerNo ratings yet

- Pump Casing SpecsDocument2 pagesPump Casing SpecsSLPlanner PlannerNo ratings yet

- Ac Drain Indirect To FDDocument1 pageAc Drain Indirect To FDSLPlanner PlannerNo ratings yet

- Trench Backfilling Req.Document1 pageTrench Backfilling Req.SLPlanner PlannerNo ratings yet

- Water Line TestingDocument1 pageWater Line TestingSLPlanner PlannerNo ratings yet

- CV Inline PipeDocument1 pageCV Inline PipeSLPlanner PlannerNo ratings yet

- RC Plumbing Pipes Color CodingDocument2 pagesRC Plumbing Pipes Color CodingSLPlanner PlannerNo ratings yet

- Technical Issues Mom #001Document2 pagesTechnical Issues Mom #001SLPlanner PlannerNo ratings yet

- Water Tank DrawingDocument1 pageWater Tank DrawingSLPlanner PlannerNo ratings yet

- Water Tank Sump Pit Location-Layout1Document1 pageWater Tank Sump Pit Location-Layout1SLPlanner PlannerNo ratings yet

- FF Design ManualDocument1 pageFF Design ManualSLPlanner PlannerNo ratings yet

- Price Quotation: Dear Engr. RyanDocument2 pagesPrice Quotation: Dear Engr. RyanSLPlanner PlannerNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Tutorial Shallow Water FoamDocument26 pagesTutorial Shallow Water FoamdeechibaNo ratings yet

- IDBI Sample Test - 1Document5 pagesIDBI Sample Test - 1LalBabuNo ratings yet

- 1900 Series Multi-Stage Split Case Pumps Technical DataDocument8 pages1900 Series Multi-Stage Split Case Pumps Technical DataKenneth CastroNo ratings yet

- Fig. 15 Transmission (Clutch Type) (2/2) : Item No. Part No. Description Q'ty Remarks or Series No Code NoDocument2 pagesFig. 15 Transmission (Clutch Type) (2/2) : Item No. Part No. Description Q'ty Remarks or Series No Code NoWalter FormigoniNo ratings yet

- מפרט רכש טורבינות - - BoBo - UTEXDocument8 pagesמפרט רכש טורבינות - - BoBo - UTEXYoninNo ratings yet

- A Scheduling Approach For Ship Design Project With Fields Constraint in Tasks and Human ResourcesDocument6 pagesA Scheduling Approach For Ship Design Project With Fields Constraint in Tasks and Human ResourcesavciahmNo ratings yet

- 511123-200 S2770 3370 RT BE FEB12 sn10210 C.PSDocument134 pages511123-200 S2770 3370 RT BE FEB12 sn10210 C.PSOliver HuangNo ratings yet

- Dhanora To JamkhedDocument39 pagesDhanora To JamkhedSangram MundeNo ratings yet

- Canon Irc3200 Parts CatalogDocument313 pagesCanon Irc3200 Parts CatalogStratis SiderisNo ratings yet

- Parts Quotation for ENGKITDocument1 pageParts Quotation for ENGKITEslam MansourNo ratings yet

- Vol06 Tab02Document387 pagesVol06 Tab02D2FNo ratings yet

- Case Study Extension of The East London Line enDocument4 pagesCase Study Extension of The East London Line enPedro HenriquesNo ratings yet

- Rapport Pa ConsultingDocument34 pagesRapport Pa ConsultingLong NguyenNo ratings yet

- General Construction Safety Requirements for Lusail DevelopmentDocument35 pagesGeneral Construction Safety Requirements for Lusail DevelopmentAnthony PapadopoulosNo ratings yet

- Limiting FactorDocument4 pagesLimiting FactorVanesh Thakur0% (2)

- Problems On VC CycleDocument8 pagesProblems On VC Cyclesushil.vgiNo ratings yet

- SAP QM: Quality Management Module OverviewDocument34 pagesSAP QM: Quality Management Module OverviewAna Luque100% (1)

- Gemology PDFDocument65 pagesGemology PDFNamwangala Rashid Natindu50% (2)

- Configuring A Serial PortDocument56 pagesConfiguring A Serial PortRajeshKaushal0288No ratings yet

- Resume PDFDocument1 pageResume PDFeminentlypracticalNo ratings yet

- Waste Production: Defined As, The Production of Unwanted Materials As A By-Product of Economic ProcessesDocument6 pagesWaste Production: Defined As, The Production of Unwanted Materials As A By-Product of Economic ProcessesFlordelyn Mendez RamirezNo ratings yet

- Microsoft Powerpoint 2013 Tutorial Student Technology Assistant CenterDocument12 pagesMicrosoft Powerpoint 2013 Tutorial Student Technology Assistant CenterBosko LjubisavljevicNo ratings yet

- Burj Al Baher Curtain Wall SpecsDocument73 pagesBurj Al Baher Curtain Wall SpecsmcbluedNo ratings yet

- Purlins Cold Formed SectionDocument5 pagesPurlins Cold Formed SectionHarjasa AdhiNo ratings yet

- Login Example Using Spring MVC 3.0Document14 pagesLogin Example Using Spring MVC 3.0harithasrinivasanNo ratings yet

- Mechanical Characterization of 3D Printable Concrete PDFDocument12 pagesMechanical Characterization of 3D Printable Concrete PDFManu K MohanNo ratings yet

- Flex Wing Rotary Cutter (John Deere) MX15-HX15-HX20-CX15-CX20 Operator's ManualDocument100 pagesFlex Wing Rotary Cutter (John Deere) MX15-HX15-HX20-CX15-CX20 Operator's ManualJoe ZhaoNo ratings yet

- Profile of NeoVChem, a Manufacturer and Exporter of Specialty Chemicals/TITLEDocument12 pagesProfile of NeoVChem, a Manufacturer and Exporter of Specialty Chemicals/TITLEShalimarNo ratings yet

- Ovation Enterprise Data Solutions: Immediate, Secure Remote Access To Critical Plant Data For Better Decision SupportDocument2 pagesOvation Enterprise Data Solutions: Immediate, Secure Remote Access To Critical Plant Data For Better Decision SupportJeremiah CayondongNo ratings yet

- Badsey EMX Racer Scooter ManualDocument19 pagesBadsey EMX Racer Scooter ManualgeoffffNo ratings yet