Professional Documents

Culture Documents

uPVC PIPES STORAGE

Uploaded by

SLPlanner PlannerCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

uPVC PIPES STORAGE

Uploaded by

SLPlanner PlannerCopyright:

Available Formats

33 05 05

BURIED PIPING INSTALLATION

6. The Contractor shall unload all products singly from delivery trucks. Unless cranes are

used, pipes shall be unloaded by means of skids and check ropes and no pipe shall be

dropped or be allowed to roll.

7. Each pipe unit shall be site stored, stacked and handled into its position in the trench only

in such manner and by such means that affords total protection for it from damage of any

kind. Site stacking of pipework shall be such that the pipework shall not deform or be

damaged in any way through storage or retrieval. The manufacturer's recommendations

shall be taken as the minimum requirement. All site areas for pipes shall be shaded.

8. All straight pipes shall be stored on shelves under sunshade roofs in such a way that the

pipe shall not become distorted or exposed to sunlight.

9. Fittings shall be stored under shade conditions preferably in boxes or sacks which allow a

free passage of air.

10. No piping shall be exposed to the direct sunlight for more than 3 days during storage,

transportation, handling and/or installation.

11. The period of storage prior to installation shall be minimized and records shall be kept of

the production date of the pipes.

12. The pipes shall be stored in such a way that bell and spigot ends shall be arranged

alternately so that pipes are evenly supported. Larger pipes shall be placed on the

bottom if different sizes of pipes are stacked together.

13. Pipe having been bent to a radius of less than 300 times the outer diameter per 6 m

length shall be rejected.

14. Rubber gaskets shall be stored in an air-conditioned room, preferably in boxes or sacks.

B. The Contractor shall observe and implement as part of his field procedures the following

requirements for UPVC piping:

1. UPVC pipes shall be stacked on a flat surface free from sharp projections, stones or

other protuberances likely to deform them. It may be necessary to level the ground at the

storage point by means of a bulldozer or vehicle fitted with a scraper blade in order that

pipes may be uniformly supported throughout their length.

2. Side supports shall be wooden posts, not less than 75 mm wide. They shall be provided

at not more than 1.5 m intervals along the pipe length. Stack widths shall not exceed 3

m.

3. When rocketed pipes are stacked, the sockets shall be placed at alternate ends of the

stack with the sockets protruding so that pipes are evenly supported along their entire

length.

4. Height of pipe stacks shall not exceed 4 layers of pipe or 1 m whichever is less.

5. Pipes of different sizes or wall thicknesses shall be stored separately or where this is not

possible, those with larger diameters and thicker walls shall be at the bottom.

6. No piping shall be exposed to the direct sunlight for more than 2 weeks during storage,

transportation, handling and/or installation. The pipes shall be stored under a protective

tarpaulin cover, which shall not leave any pipe surface or pipe ends exposed. The cover

shall be arranged to allow air circulation within its volume or confinement of fixing

tarpaulin to wooden support posts.

7. Fittings shall be stored under shade conditions preferably in boxes or sacks- which allow

a free passage of air.

8. When loading, unloading or retrieving pipes from storage, they shall be handled carefully

so as not to score, impact crack, abrasion damage, gage or cut or other damage prior to

installation. Pipes shall not be dropped but shall be lowered into trenches. Bell joints

Rev 2 12 of 39 Contract No. XXX-XXX

33 05 05

BURIED PIPING INSTALLATION

shall not be stressed and level ends shall not be damaged. Pipes shall be lowered from

trucks, not dropped.

9. UPVC pipes shall be transported to the jobsite in special pile rack type containerized

units to facilitate loading, unloading, onsite storage, retrieval and protection of piping from

sunlight and ultraviolet (UV) radiation.

10. When repairing already installed UPVC piping systems, pipes shall not be exposed to the

sun and shall be covered against solar radiation exposure.

11. Full consideration shall be given to safety aspects when locating planning and

constructing stacking areas and while stacking pipes.

12. Consideration should be given to any visible deterioration in UPVC piping. If any signs of

discoloration are seen, the pipe shall be rejected due to harmful effects of exposure to

ultra violet radiation.

PART 2 PRODUCTS

2.01 POTABLE WATER MATERIALS

A. Provide products that comply with applicable code(s).

B. Ductile Iron Pipe: ASTM A746, Pressure Class 350, bell and spigot end.

C. Joint Seals for Ductile Iron Pipe: AWWA C111/A21.11; styrene butadiene rubber (SBR) or

vulcanized SBR gaskets.

D. Concrete Pipe: Non-reinforced, ASTM C14 or ASTM C14M, Class 1; bell and spigot end

joints.

E. Joint Seals for Concrete Pipe: ASTM C443 (ASTM C443M) rubber compression gaskets.

F. Poly(Vinyl Chloride) PVC Pipe: ASTM D3034.

G. Joint: ASTM D2855 Solvent Cemented Joints.

H. High density Polyethylene Pipe: ASTM D2239.

I. Joint: ASTM F2620 Butt Fusion.

J. Glass-Fiber Reinforced Thermosetting Resin Pipe: ASTM D3517.

K. Joints Seals for Glass Fiber Reinforced Thermosetting Resin Pipe.: ASTM D4161.

L. Joints : Butt and Wrap Joints, Bell and Spigot with Adhesive, and Flanged Joint.

M. Fittings: Same material as pipe molded or formed to suit pipe size and end design, in

required tee, bends, elbows, cleanouts, reducers, traps and other configurations required.

2.02 SANITARY AND INDUSTRIAL WASTEWATER COLLECTION

A. Poly(Vinyl Chloride) PVC Pipe: ASTM D3034.

B. Joint: ASTM D2855 Solvent Cemented Joints.

C. High density Polyethylene Pipe: ASTM D2239.

D. Joint: ASTM F2620 Butt Fusion.

E. Glass-Fiber Reinforced Thermosetting Resin Pipe: ASTM D3517.

F. Joints Seals for Glass Fiber Reinforced Thermosetting Resin Pipe.: ASTM D4161.

G. Joints : Butt and Wrap Joints, Bell and Spigot with Adhesive, and Flanged Joint.

H. Fittings: Same material as pipe molded or formed to suit pipe size and end design, in

required tee, bends, elbows, cleanouts, reducers, traps and other configurations required.

Rev 2 13 of 39 Contract No. XXX-XXX

You might also like

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- 4 - SPC-FD-Part 4 of 5-Division 26Document1 page4 - SPC-FD-Part 4 of 5-Division 26Fathy RamadanNo ratings yet

- 16110s01 Conduit and RacewayDocument3 pages16110s01 Conduit and RacewayVICTOR JOSE VILORIANo ratings yet

- Bus Duct ErectionDocument11 pagesBus Duct ErectionkarthiknmanuNo ratings yet

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!From EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Rating: 5 out of 5 stars5/5 (2)

- Section 16110-RacewaysDocument5 pagesSection 16110-RacewayskdpmansiNo ratings yet

- A Short Guide to the Types and Details of Constructing a Suspension Bridge - Including Various Arrangements of Suspension Spans, Methods of Vertical Stiffening and Wire Cables Versus Eyebar ChainsFrom EverandA Short Guide to the Types and Details of Constructing a Suspension Bridge - Including Various Arrangements of Suspension Spans, Methods of Vertical Stiffening and Wire Cables Versus Eyebar ChainsNo ratings yet

- CH9 Inst and Const ProceduresDocument65 pagesCH9 Inst and Const ProceduresSaad AliNo ratings yet

- Electrical ConduitsDocument6 pagesElectrical ConduitsMohammed Hussain OMNo ratings yet

- Installation Instructions: Plastic Pipe Industry AssociationDocument27 pagesInstallation Instructions: Plastic Pipe Industry Associationahmedmohamed2014No ratings yet

- Eu002 ReviewerDocument6 pagesEu002 ReviewerjunalynnerosaNo ratings yet

- 16100-Basic Materials & MethodDocument6 pages16100-Basic Materials & Methodtristan guarinoNo ratings yet

- Size of Conduits - SpecDocument1 pageSize of Conduits - SpecJelak ChandranNo ratings yet

- SECTION 23 21 00: Underground Chilled Water Systems (Issued Ad-6)Document4 pagesSECTION 23 21 00: Underground Chilled Water Systems (Issued Ad-6)vuhalamNo ratings yet

- 08 WiringDocument7 pages08 WiringVijay PatelNo ratings yet

- Bondstrand Series 7000 M Installation ManualDocument84 pagesBondstrand Series 7000 M Installation ManualPavel Vicentiu0% (1)

- Method of StatementDocument5 pagesMethod of StatementreedNo ratings yet

- BG Tunisia: Maintenance DepartmentDocument17 pagesBG Tunisia: Maintenance Departmentghazi kallelNo ratings yet

- QCS 2010 Section 22 Part 5Document15 pagesQCS 2010 Section 22 Part 5Abdelazim Mohamed0% (1)

- Fire Fighting Inside BuildingDocument3 pagesFire Fighting Inside BuildingHamada ELarabyNo ratings yet

- EIM 11-Q4 Week 1-2 Module 1Document14 pagesEIM 11-Q4 Week 1-2 Module 1Wilbert EleccionNo ratings yet

- General Specification For The Construction OF Elevated Water TankDocument30 pagesGeneral Specification For The Construction OF Elevated Water TankHani Ibrahim AbdoulayeNo ratings yet

- Dynamic Engineering Consultant Mina Al Arab Precinct - 5 MEP SpecificationDocument8 pagesDynamic Engineering Consultant Mina Al Arab Precinct - 5 MEP SpecificationBala Krishna GallaNo ratings yet

- Method Statement - Water RecDocument6 pagesMethod Statement - Water Rechadi putraNo ratings yet

- Compliance On Qcs SpecsDocument16 pagesCompliance On Qcs Specsvhin84No ratings yet

- SECTION - 16465 Bus-Way & Power FeedersDocument7 pagesSECTION - 16465 Bus-Way & Power FeedersWaleed Abd El-HamiedNo ratings yet

- Method Statement Pipe Re-Routing Saudi BinladinDocument11 pagesMethod Statement Pipe Re-Routing Saudi BinladinShyju MelepurathNo ratings yet

- FinalDocument4 pagesFinalggts.99114833No ratings yet

- SECTION 03251 Expansion and Construction Joints: Part 1 GeneralDocument4 pagesSECTION 03251 Expansion and Construction Joints: Part 1 GeneralJojolasNo ratings yet

- UG IV 3 Concrete Encased Duct Bank PDFDocument8 pagesUG IV 3 Concrete Encased Duct Bank PDFpmpeieNo ratings yet

- FLOLINE 3-W Manual & Technical SpecsDocument39 pagesFLOLINE 3-W Manual & Technical SpecsChen YishengNo ratings yet

- 3 Codified Requirements For MORE THAN 2 LPG CYLINDERDocument5 pages3 Codified Requirements For MORE THAN 2 LPG CYLINDERMrigank AggarwalNo ratings yet

- Alkhobar Swro Desalination Plant: Storage, Preservation & Handling Check ListDocument1 pageAlkhobar Swro Desalination Plant: Storage, Preservation & Handling Check ListGhulam MustafaNo ratings yet

- Basic MaterialsDocument7 pagesBasic MaterialsCristina Marie BatoNo ratings yet

- Erection Operation & Maintenance Manual For 415V, 3000A NSPBDDocument66 pagesErection Operation & Maintenance Manual For 415V, 3000A NSPBDthegemishere100% (1)

- I. Plumbing Works & Specifications: A. GeneralDocument4 pagesI. Plumbing Works & Specifications: A. Generaljoe rommel rivera100% (2)

- Building Technology: - Wood - ConcreteDocument20 pagesBuilding Technology: - Wood - ConcreteerickNo ratings yet

- IPBD MANUAL-Info Catagory PDFDocument26 pagesIPBD MANUAL-Info Catagory PDFTirthankar DattaNo ratings yet

- Project - Sport CityDocument30 pagesProject - Sport CityAdmin DepartmentNo ratings yet

- Used Water SES 5 Construction of Tunnels Ancillaries 2012Document28 pagesUsed Water SES 5 Construction of Tunnels Ancillaries 2012Mark BenjieNo ratings yet

- Section 334110 - Storm Drainage: TA1056 MBI Sampang Agung Brewery ExtensionDocument3 pagesSection 334110 - Storm Drainage: TA1056 MBI Sampang Agung Brewery Extensionery achjariNo ratings yet

- NON-METALLIC RIGID CONDUIT - Lesson PlanDocument5 pagesNON-METALLIC RIGID CONDUIT - Lesson PlanBriant King Peñas100% (1)

- 15056-Builder's WorkDocument5 pages15056-Builder's WorkAdamNo ratings yet

- A Good Practice Guide For The Electrofusion Jointing of Larger Diameter Polyethylene Pressure PipesDocument20 pagesA Good Practice Guide For The Electrofusion Jointing of Larger Diameter Polyethylene Pressure PipesHilal Al KhuzaimiNo ratings yet

- Catalogue - New QPF PDFDocument32 pagesCatalogue - New QPF PDFShaiju EbrahimNo ratings yet

- How To Install and Erect TrunkingDocument13 pagesHow To Install and Erect TrunkingDaniel Madulu CharlesNo ratings yet

- SPC Occ 221423 MeDocument4 pagesSPC Occ 221423 Metarekhisham1234No ratings yet

- L s3 Low Voltage Underground CableDocument20 pagesL s3 Low Voltage Underground CableAsith Savinda100% (4)

- Concrete Encased Duct Bank PDFDocument8 pagesConcrete Encased Duct Bank PDF101079No ratings yet

- Installation Guide For PVC Sewer Pipe: (ASTM D3034 & F679)Document26 pagesInstallation Guide For PVC Sewer Pipe: (ASTM D3034 & F679)dep_vinNo ratings yet

- HDPE Handling and StorageDocument2 pagesHDPE Handling and StorageFiras DabboucyNo ratings yet

- Osma Below Ground Installation Guide Od107 Revjan07Document52 pagesOsma Below Ground Installation Guide Od107 Revjan07VCS1978No ratings yet

- Drain PipeDocument4 pagesDrain PipeNur HaryatiNo ratings yet

- Insulation: Page 1 of 4Document4 pagesInsulation: Page 1 of 4Elankumaran PeriakaruppanNo ratings yet

- Handling Installation Rev 21Document23 pagesHandling Installation Rev 21yildirimonlineNo ratings yet

- Division 22: PlumbingDocument6 pagesDivision 22: PlumbingRaya VillafloresNo ratings yet

- Sodium Hypo FRP SpecDocument6 pagesSodium Hypo FRP SpecZeroRecoNo ratings yet

- Electrical Manhole and Handhole Design GuideDocument8 pagesElectrical Manhole and Handhole Design Guidelilama45-1100% (1)

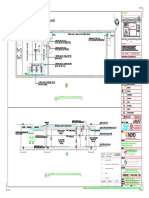

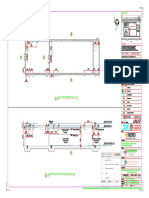

- Notes:: Key PlanDocument1 pageNotes:: Key PlanSLPlanner PlannerNo ratings yet

- Notes:: Key PlanDocument1 pageNotes:: Key PlanSLPlanner PlannerNo ratings yet

- Notes:: Key PlanDocument1 pageNotes:: Key PlanSLPlanner PlannerNo ratings yet

- Notes:: Key PlanDocument1 pageNotes:: Key PlanSLPlanner PlannerNo ratings yet

- Notes:: Key PlanDocument1 pageNotes:: Key PlanSLPlanner PlannerNo ratings yet

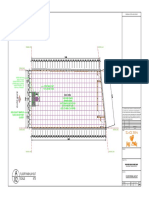

- Floor Finish Layout Scale: NTS: Black RoseDocument1 pageFloor Finish Layout Scale: NTS: Black RoseSLPlanner PlannerNo ratings yet

- TOTAL AREA 131.83m : Fitting RoomDocument1 pageTOTAL AREA 131.83m : Fitting RoomSLPlanner PlannerNo ratings yet

- 02Document1 page02SLPlanner PlannerNo ratings yet

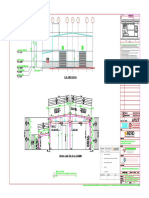

- The Site: Electrical Equipment Elevation (MS) BuildingDocument1 pageThe Site: Electrical Equipment Elevation (MS) BuildingSLPlanner PlannerNo ratings yet

- 06Document1 page06SLPlanner PlannerNo ratings yet

- 04Document1 page04SLPlanner PlannerNo ratings yet

- 02Document1 page02SLPlanner PlannerNo ratings yet

- 05Document1 page05SLPlanner PlannerNo ratings yet

- Silos 01Document1 pageSilos 01SLPlanner PlannerNo ratings yet

- Fire Pump SpecsDocument23 pagesFire Pump SpecsSLPlanner PlannerNo ratings yet

- CV Inline PipeDocument1 pageCV Inline PipeSLPlanner PlannerNo ratings yet

- Trench Backfilling Req.Document1 pageTrench Backfilling Req.SLPlanner PlannerNo ratings yet

- Pump Casing SpecsDocument2 pagesPump Casing SpecsSLPlanner PlannerNo ratings yet

- Water Line TestingDocument1 pageWater Line TestingSLPlanner PlannerNo ratings yet

- RC Plumbing Pipes Color CodingDocument2 pagesRC Plumbing Pipes Color CodingSLPlanner PlannerNo ratings yet

- Sewer & Water Pipe CoordinationDocument1 pageSewer & Water Pipe CoordinationSLPlanner PlannerNo ratings yet

- In Line Pump Min. PressureDocument1 pageIn Line Pump Min. PressureSLPlanner PlannerNo ratings yet

- Technical Issues Mom #001Document2 pagesTechnical Issues Mom #001SLPlanner PlannerNo ratings yet

- FF Design ManualDocument1 pageFF Design ManualSLPlanner PlannerNo ratings yet

- Ac Drain Indirect To FDDocument1 pageAc Drain Indirect To FDSLPlanner PlannerNo ratings yet

- Water Tank Sump Pit Location-Layout1Document1 pageWater Tank Sump Pit Location-Layout1SLPlanner PlannerNo ratings yet

- Water Tank DrawingDocument1 pageWater Tank DrawingSLPlanner PlannerNo ratings yet

- Price Quotation: Dear Engr. RyanDocument2 pagesPrice Quotation: Dear Engr. RyanSLPlanner PlannerNo ratings yet

- Ipex - 43729 - Catalog-PVC PIPEDocument100 pagesIpex - 43729 - Catalog-PVC PIPEjechurchNo ratings yet

- 3M - Фолио за фарове - 2017.7Document5 pages3M - Фолио за фарове - 2017.7PlamenNo ratings yet

- SONGLIGHT® 2920 - SongwonDocument2 pagesSONGLIGHT® 2920 - SongwonVaittianathan MahavapillaiNo ratings yet

- FMRC 1612 Polyvinyl Chloride (PVC) Pipe and Fittings For Underground Fire Protection Service PDFDocument30 pagesFMRC 1612 Polyvinyl Chloride (PVC) Pipe and Fittings For Underground Fire Protection Service PDFdyıldırım_4No ratings yet

- Used Water SES 2 Materials 12nov2018Document42 pagesUsed Water SES 2 Materials 12nov2018Mark BenjieNo ratings yet

- Fire Rated SiliconeDocument3 pagesFire Rated SiliconeOliver ShumNo ratings yet

- Finished Product Data Sheet: Landline: (221) 33 879 19 90 Fax: (221) 33 834.97.82 Email: Lcs@lcs - SNDocument2 pagesFinished Product Data Sheet: Landline: (221) 33 879 19 90 Fax: (221) 33 834.97.82 Email: Lcs@lcs - SNUmeshNo ratings yet

- Say NO To PVC Concrete Spacers PDFDocument1 pageSay NO To PVC Concrete Spacers PDFSOURAV RANJAN KHANRANo ratings yet

- Chemtrol PVC CPVCDocument60 pagesChemtrol PVC CPVCWakko20IPNNo ratings yet

- BAT PlasticsDocument37 pagesBAT PlasticsmilenadoncevNo ratings yet

- 90-Mechanical and Rheological PPties of Epoxidized Soybean Oil Plasticized PLA 2009Document7 pages90-Mechanical and Rheological PPties of Epoxidized Soybean Oil Plasticized PLA 2009TOUFIKNo ratings yet

- Par 302unit 2Document80 pagesPar 302unit 2SivaRamanNo ratings yet

- Nonyl Phenol EthoxylateDocument9 pagesNonyl Phenol EthoxylateWaqar Ahmed100% (1)

- Road and BridgeDocument119 pagesRoad and BridgeM Choudhary100% (1)

- Infinity NBR PVC Insulation Sheet Tube 2Document3 pagesInfinity NBR PVC Insulation Sheet Tube 2Kumar JbsNo ratings yet

- KODAK 7000 Photo Printer: Downloaded From Manuals Search EngineDocument42 pagesKODAK 7000 Photo Printer: Downloaded From Manuals Search Engineshivanibaraily7_3514No ratings yet

- Jointing Systems: - PVC Pipe Jointing - Rubber Ring Jointing - Solvent Cement JointingDocument16 pagesJointing Systems: - PVC Pipe Jointing - Rubber Ring Jointing - Solvent Cement JointingFrancisco M. RamosNo ratings yet

- PZ SeriesDocument28 pagesPZ SeriesSomiar TradingNo ratings yet

- Hand Safety: National Institute of Occupational Safety and HealthDocument48 pagesHand Safety: National Institute of Occupational Safety and HealthTir Dan Knight100% (1)

- Masterbatch Producrers in IndiaDocument39 pagesMasterbatch Producrers in IndiaFuture Innovations100% (1)

- IP0275 Ceilcote 232-282 Flakeline - US - LRDocument2 pagesIP0275 Ceilcote 232-282 Flakeline - US - LRchusnadiantyNo ratings yet

- Section 01830 - Operation and Maintenance: Whole Building Design Guide Federal Green Construction Guide For SpecifiersDocument3 pagesSection 01830 - Operation and Maintenance: Whole Building Design Guide Federal Green Construction Guide For SpecifiersAnonymous NMytbMiDNo ratings yet

- Project: Location:: Description QTY Unit U-Price AmountDocument3 pagesProject: Location:: Description QTY Unit U-Price AmountLemuel Kim Cera TabinasNo ratings yet

- Curso de Ingles Nivel MedioDocument4 pagesCurso de Ingles Nivel MedioAlberto DiazNo ratings yet

- Standard For Safety UL ADocument49 pagesStandard For Safety UL ANhất NgônNo ratings yet

- Chryso-Reinjecto 8370 4441Document2 pagesChryso-Reinjecto 8370 4441velmurug_balaNo ratings yet

- MoldexDocument3 pagesMoldexAnissa Panlaqui100% (1)

- PRE DVS Technical Codes On Plastics Joining TechnologiesDocument11 pagesPRE DVS Technical Codes On Plastics Joining TechnologiesAmr Mohamed SolimanNo ratings yet

- Tablas de Perfiles Estructurales. Beer & Johnston & DeWolf & Mazurek. 6th Edition. 2012 PDFDocument17 pagesTablas de Perfiles Estructurales. Beer & Johnston & DeWolf & Mazurek. 6th Edition. 2012 PDFJGibson FiestasNo ratings yet

- EPL-0000143 Article PDFDocument7 pagesEPL-0000143 Article PDFAmirhosein FazilatiNo ratings yet

- How to Estimate with RSMeans Data: Basic Skills for Building ConstructionFrom EverandHow to Estimate with RSMeans Data: Basic Skills for Building ConstructionRating: 4.5 out of 5 stars4.5/5 (2)

- A Place of My Own: The Architecture of DaydreamsFrom EverandA Place of My Own: The Architecture of DaydreamsRating: 4 out of 5 stars4/5 (242)

- The Complete Guide to Building Your Own Home and Saving Thousands on Your New HouseFrom EverandThe Complete Guide to Building Your Own Home and Saving Thousands on Your New HouseRating: 5 out of 5 stars5/5 (3)

- Welding for Beginners in Fabrication: The Essentials of the Welding CraftFrom EverandWelding for Beginners in Fabrication: The Essentials of the Welding CraftRating: 5 out of 5 stars5/5 (5)

- Field Guide for Construction Management: Management by Walking AroundFrom EverandField Guide for Construction Management: Management by Walking AroundRating: 4.5 out of 5 stars4.5/5 (3)

- The Everything Woodworking Book: A Beginner's Guide To Creating Great Projects From Start To FinishFrom EverandThe Everything Woodworking Book: A Beginner's Guide To Creating Great Projects From Start To FinishRating: 4 out of 5 stars4/5 (3)

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedFrom EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedRating: 5 out of 5 stars5/5 (1)

- THE PROPTECH GUIDE: EVERYTHING YOU NEED TO KNOW ABOUT THE FUTURE OF REAL ESTATEFrom EverandTHE PROPTECH GUIDE: EVERYTHING YOU NEED TO KNOW ABOUT THE FUTURE OF REAL ESTATERating: 4 out of 5 stars4/5 (1)

- Building Construction Technology: A Useful Guide - Part 1From EverandBuilding Construction Technology: A Useful Guide - Part 1Rating: 4 out of 5 stars4/5 (3)

- The Art of Welding: Featuring Ryan Friedlinghaus of West Coast CustomsFrom EverandThe Art of Welding: Featuring Ryan Friedlinghaus of West Coast CustomsNo ratings yet

- Markup & Profit: A Contractor's Guide, RevisitedFrom EverandMarkup & Profit: A Contractor's Guide, RevisitedRating: 5 out of 5 stars5/5 (11)

- Nuclear Energy in the 21st Century: World Nuclear University PressFrom EverandNuclear Energy in the 21st Century: World Nuclear University PressRating: 4.5 out of 5 stars4.5/5 (3)

- Civil Engineer's Handbook of Professional PracticeFrom EverandCivil Engineer's Handbook of Professional PracticeRating: 4.5 out of 5 stars4.5/5 (2)

- How to Build a Tiny Portable House: With Plans and InstructionsFrom EverandHow to Build a Tiny Portable House: With Plans and InstructionsRating: 4 out of 5 stars4/5 (1)

- 1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideFrom Everand1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideRating: 3.5 out of 5 stars3.5/5 (7)

- Post Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&AFrom EverandPost Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&ANo ratings yet

- An Architect's Guide to Construction: Tales from the Trenches Book 1From EverandAn Architect's Guide to Construction: Tales from the Trenches Book 1No ratings yet

- Building Construction Technology: A Useful Guide - Part 2From EverandBuilding Construction Technology: A Useful Guide - Part 2Rating: 5 out of 5 stars5/5 (1)

- Green Roofs, Facades, and Vegetative Systems: Safety Aspects in the StandardsFrom EverandGreen Roofs, Facades, and Vegetative Systems: Safety Aspects in the StandardsNo ratings yet

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationFrom EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationRating: 4 out of 5 stars4/5 (18)

- Building Construction and DrawingFrom EverandBuilding Construction and DrawingRating: 2.5 out of 5 stars2.5/5 (3)