Professional Documents

Culture Documents

Annex F (Table 1, SZ No.: Max Max

Annex F (Table 1, SZ No.: Max Max

Uploaded by

SvapneshOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Annex F (Table 1, SZ No.: Max Max

Annex F (Table 1, SZ No.: Max Max

Uploaded by

SvapneshCopyright:

Available Formats

IS 1154 : 2000

ANNEX F

[Table 1, SZNo. (xiii)]

TEST FOR CORROSIVE EFFECT ON LEAD

F-l APPARATUS F-2.2 Toluene or Acetone

F-l.1 Oven Same as described in A-2.3.

The oven shall be thermostatically controlled and F-2.3 Methanol

capable of maintaining a temperature of 50 2 1°C Same as describedin B-2.4.

F-l.2 Glass Container F-2.4 Dilute Acetic Acid

A wide-mouthed glass container fitted with liquid- Approximately 1 percent by volume.

tight ground-glass stopper shall be used. Its capacity

shall be approximately 500 ml and it shall be made F-3 CLEANING OF LEAD PANELS

from heat-resistant glass. F-3.1 Clean the panels on both sides and on all edges

to a smooth bright finish by scraping with a sharp

F-2 MATERIAL tool. Clean and degrease by swabbing with a cloth

saturated with toluene or acetone and then rinse with

F-2.1 Lead Test Panels methanol. Finally, dry the panels in a current of warm,

The test panels shall have the following composition: dry air, During and after degreasing, do not handle

the panel by bare hands, but with a pair of clean

a> Metallic lead, percent by mass, Min 99.99 forceps.

b) Copper, percent by mass, MUX 0.003

F-4 PROCEDURE

c> Antimony, percent by mass, Max 0.002

F-4.1 Carry out the test in triplicate.

4 Bismuth, percent by mass, MUX 0.005

F-4.2 Weigh each panel accurately. Place the weighed

4 Iron, percent by mass, Max 0.003

lead panels in the glass containers and add sufficient

0 Nickel and cobalt together, percent quantity of the corrosion preventive such that the

by mass, MUX 0.001 panels are immersed to a depth of 12 mm below the

surface of the corrosion preventive. Close the container

g) Silver, percent by mass, Max 0.002

with the stopper and place it for 8 hours in the oven

h) Zinc, percent by mass, Max 0.002 maintained at 50 f 1°C. Remove the container from

j> Tin, cadmium, arsenic and sulphur Traces the oven, withdraw the panels and cool. Remove the

film of corrosion preventive by swabbing lightly with

W Total of all impurities present, cotton wool soaked in toluene or acetone. Dip the

percent by mass, Max 0.01

panels in boiling dilute acetic acid for 1 to 2 minutes

F-2.1.1 The panel shall be approximately 75 mm x rinse with water, dry and weigh.

50 mm x 1.5 mm in size and shall be free from deep F-4.3 Express the average loss in mass of the panels

scratches and surface imperfections. in milligrams per square centimetre of surface.

You might also like

- Lab-Report-Dishwashing FinallDocument3 pagesLab-Report-Dishwashing FinallKyle BanceNo ratings yet

- (Table 1, SZ No. (Ix) ) : Annex BDocument1 page(Table 1, SZ No. (Ix) ) : Annex BSvapneshNo ratings yet

- Annex G (Table 1, SZ No.: A) B) 4 4 FL G) H)Document1 pageAnnex G (Table 1, SZ No.: A) B) 4 4 FL G) H)SvapneshNo ratings yet

- Muki Z 2001Document3 pagesMuki Z 2001Mohamed FarhanNo ratings yet

- Belzona 1341-3 - UnlockedDocument2 pagesBelzona 1341-3 - UnlockedimtiazNo ratings yet

- Annex E (Table 1, SZ No. (Xii) )Document1 pageAnnex E (Table 1, SZ No. (Xii) )SvapneshNo ratings yet

- Rdso Specification NO. M&C/PCN/110/2006: PriceDocument11 pagesRdso Specification NO. M&C/PCN/110/2006: PriceSudheep DuraiNo ratings yet

- Gebruiksinstructie 7111Document4 pagesGebruiksinstructie 7111Achwan FebNo ratings yet

- Annex D (Table 1, SZ No. (Xi) ) : Min - MinDocument1 pageAnnex D (Table 1, SZ No. (Xi) ) : Min - MinSvapneshNo ratings yet

- PU Clear LacquerDocument1 pagePU Clear LacquerA.F.M Salman AkterNo ratings yet

- мембраны ПАОА - 5Document14 pagesмембраны ПАОА - 5Адванс ТащитNo ratings yet

- Revise 111 2006 Annexure IIDocument12 pagesRevise 111 2006 Annexure IIchepurthiNo ratings yet

- Intumescent Paint BrochureDocument6 pagesIntumescent Paint Brochureirwanchem100% (2)

- C 325 - 81 R97 - QzmynqDocument2 pagesC 325 - 81 R97 - Qzmynqcurt volvoNo ratings yet

- En PF115 5 PDFDocument2 pagesEn PF115 5 PDFBNo ratings yet

- Preparation and Characterization of Foam Glass Based WasteDocument3 pagesPreparation and Characterization of Foam Glass Based WasteAlejandro Vargas CalderonNo ratings yet

- Hardtop AS AluminiumDocument3 pagesHardtop AS AluminiumMohamed FarhanNo ratings yet

- Hot-Pressed, Dry, Composite, PEO-based Electrolyte Membranes I. Ionic Conductivity CharacterizationDocument8 pagesHot-Pressed, Dry, Composite, PEO-based Electrolyte Membranes I. Ionic Conductivity CharacterizationPrapto PraptNo ratings yet

- StoPox WG 100 - TD - SE - 1704 - RV - 05.00 PDFDocument4 pagesStoPox WG 100 - TD - SE - 1704 - RV - 05.00 PDFAzizy YusofNo ratings yet

- Dokumen - Tips - Astm D 1102 84 Reapproved 2001 Ash in WoodDocument2 pagesDokumen - Tips - Astm D 1102 84 Reapproved 2001 Ash in WoodAndi ShevchenkoNo ratings yet

- Fomatest ThioDocument1 pageFomatest ThioTapan NayakNo ratings yet

- Epoxy HR PDFDocument3 pagesEpoxy HR PDFMohamed FarhanNo ratings yet

- Barrier 77: Technical DataDocument4 pagesBarrier 77: Technical DatakikoNo ratings yet

- Electrical and Optical Properties of Electron Beam Evaporated ITO Thin FilmsDocument4 pagesElectrical and Optical Properties of Electron Beam Evaporated ITO Thin FilmsAhmet KılıçNo ratings yet

- Roofpor en - Technical Data Sheet 17Document2 pagesRoofpor en - Technical Data Sheet 17amp.kaunasNo ratings yet

- Ultra Cote 101 PrimerDocument3 pagesUltra Cote 101 PrimerGilbert Dela Serna IINo ratings yet

- Toluene-Insoluble (TI) Content of Tar and Pitch: Standard Test Method ForDocument3 pagesToluene-Insoluble (TI) Content of Tar and Pitch: Standard Test Method ForCharlieNo ratings yet

- MX-99-2K MP SB: Multipurpose Epoxy CoatinglDocument2 pagesMX-99-2K MP SB: Multipurpose Epoxy CoatinglGo Joko AriefNo ratings yet

- Determination of Ethanol Extractives in Biomass: Standard Test Method ForDocument2 pagesDetermination of Ethanol Extractives in Biomass: Standard Test Method ForMadhanNo ratings yet

- Ceramics: Dentist 07 3 YearDocument6 pagesCeramics: Dentist 07 3 Yearmei krismahariyantoNo ratings yet

- FlintkoteDocument2 pagesFlintkoteDhim131267No ratings yet

- Futura AS: Technical DataDocument3 pagesFutura AS: Technical DataMohamed FarhanNo ratings yet

- MWDocument11 pagesMWjitendraNo ratings yet

- TDS - Durathane English Issued.09.05.2011Document4 pagesTDS - Durathane English Issued.09.05.2011vitharvanNo ratings yet

- Isoflex: Elastomeric, Liquid Waterproofing Membrane For Flat RoofsDocument3 pagesIsoflex: Elastomeric, Liquid Waterproofing Membrane For Flat RoofsAhmed TahsinNo ratings yet

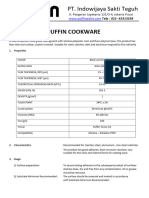

- TDS PUFFIN COOKWARE STOVING DoneDocument3 pagesTDS PUFFIN COOKWARE STOVING DoneYoga RahadianNo ratings yet

- Ep 280 WHG PDS EngDocument5 pagesEp 280 WHG PDS EngMajdi ShannibNo ratings yet

- CHEMOLINE-3-CN (Pressure Part)Document2 pagesCHEMOLINE-3-CN (Pressure Part)Naveed KhalidNo ratings yet

- Ep 211 Esd PDS EngDocument4 pagesEp 211 Esd PDS EngMajdi ShannibNo ratings yet

- Section 15080 - Plumbing InsulationDocument7 pagesSection 15080 - Plumbing InsulationAhmed AliNo ratings yet

- InsulationDocument2 pagesInsulationD.V.S.S Ram PrasadNo ratings yet

- Varnish-Pu 2K: Transparent, Two-Component, Polyurethane VarnishDocument2 pagesVarnish-Pu 2K: Transparent, Two-Component, Polyurethane VarnishMarco PoloNo ratings yet

- Prevention Corrosion in Paper Making Machines: by A. J. M. DrugliDocument4 pagesPrevention Corrosion in Paper Making Machines: by A. J. M. DrugliDeivi GarciaNo ratings yet

- ASTM D1644-01 Standar Test Methords For Novolatile Content oDocument2 pagesASTM D1644-01 Standar Test Methords For Novolatile Content oCarlos Raul Caballero LeonNo ratings yet

- Zinc Rich Epoxy For Damaged Steel Coatings: ZincfixDocument2 pagesZinc Rich Epoxy For Damaged Steel Coatings: Zincfix200365530No ratings yet

- Tsai 2003Document7 pagesTsai 2003Guilherme Alves MartinezNo ratings yet

- Atcoatr 111Document3 pagesAtcoatr 111farid bashaNo ratings yet

- PDA Compliance ReportDocument4 pagesPDA Compliance ReportScribdTranslationsNo ratings yet

- TDS Consol 131 FCDocument2 pagesTDS Consol 131 FCPEP GUDANGNo ratings yet

- Sheet Materials For Curing ConcreteDocument1 pageSheet Materials For Curing ConcreteFranz Richard Sardinas MallcoNo ratings yet

- Rockfon Hygenic PlusDocument2 pagesRockfon Hygenic PlusJuan RGNo ratings yet

- Hot Insulation Materials Glass Mineral Wool Needle MatDocument1 pageHot Insulation Materials Glass Mineral Wool Needle MatSagar PatilNo ratings yet

- Nitoflor FC145: Constructive SolutionsDocument3 pagesNitoflor FC145: Constructive SolutionstalatzahoorNo ratings yet

- Molecular Beam Evaporation-Grown Indium Oxide and Indium Aluminium Films For Low-Temperature Gas SensorsDocument4 pagesMolecular Beam Evaporation-Grown Indium Oxide and Indium Aluminium Films For Low-Temperature Gas SensorsSebastian GarciaNo ratings yet

- Bonderite M-NT eDocument4 pagesBonderite M-NT eTrifonovNo ratings yet

- TDS Jotun - Pioneer PrimerDocument4 pagesTDS Jotun - Pioneer PrimerANo ratings yet

- CM015 DS 01 2Document2 pagesCM015 DS 01 2Mohamed BeheiryNo ratings yet

- Watertite TE 30Document2 pagesWatertite TE 30Alexi ALfred H. TagoNo ratings yet

- Practical Woodwork for Laboratory Technicians: Pergamon Series of Monographs in Laboratory TechniquesFrom EverandPractical Woodwork for Laboratory Technicians: Pergamon Series of Monographs in Laboratory TechniquesNo ratings yet

- Compendium of Atomic Alkali Resistant Optical Thin Films, Diffusion and Electrical Mobility in Diode Pumped Alkali Lasers (DPALs)From EverandCompendium of Atomic Alkali Resistant Optical Thin Films, Diffusion and Electrical Mobility in Diode Pumped Alkali Lasers (DPALs)No ratings yet

- IS 1608: 2005 ISO 6892: 1998: 2,5 D From The GripDocument1 pageIS 1608: 2005 ISO 6892: 1998: 2,5 D From The GripSvapneshNo ratings yet

- (Rpo, 2) in The CaseDocument1 page(Rpo, 2) in The CaseSvapneshNo ratings yet

- Table K.1 - Results From Interlaboratory Tensile Tests: Test Programme ADocument1 pageTable K.1 - Results From Interlaboratory Tensile Tests: Test Programme ASvapneshNo ratings yet

- J2 J2 J2 J4 J2: Parameter Tensile PropertiesDocument1 pageJ2 J2 J2 J4 J2: Parameter Tensile PropertiesSvapneshNo ratings yet

- ISO 6892: 1998 Annex K: Related To Material. TestDocument1 pageISO 6892: 1998 Annex K: Related To Material. TestSvapneshNo ratings yet

- IS 1608: 2005 ISO 6892: 1998: C.2.3Original Gauge Length C.2.3.1 Proportional Test PiecesDocument1 pageIS 1608: 2005 ISO 6892: 1998: C.2.3Original Gauge Length C.2.3.1 Proportional Test PiecesSvapneshNo ratings yet

- Is 1608 - 2005 - 27Document1 pageIs 1608 - 2005 - 27SvapneshNo ratings yet

- Is 1608 - 2005 - 39Document1 pageIs 1608 - 2005 - 39SvapneshNo ratings yet

- IS 1608: 2005 ISO 6892: 1998: Width Original Gauge Lengtn Original Cross - Sec - Ronal Area Thickness MMDocument1 pageIS 1608: 2005 ISO 6892: 1998: Width Original Gauge Lengtn Original Cross - Sec - Ronal Area Thickness MMSvapnesh100% (1)

- Is 1608 - 2005 - 24Document1 pageIs 1608 - 2005 - 24SvapneshNo ratings yet

- J.2.3 Total Measurement Uncertainty: IS 1608: 2005 ISO 6892: 1998Document1 pageJ.2.3 Total Measurement Uncertainty: IS 1608: 2005 ISO 6892: 1998SvapneshNo ratings yet

- Is 1608 - 2005 - 36Document1 pageIs 1608 - 2005 - 36SvapneshNo ratings yet

- Is 1608 - 2005 - 25Document1 pageIs 1608 - 2005 - 25SvapneshNo ratings yet

- Is 1608 - 2005 - 30Document1 pageIs 1608 - 2005 - 30SvapneshNo ratings yet

- (Ijo) N: Is 1608: 2005 Iso 6892: 1998Document1 page(Ijo) N: Is 1608: 2005 Iso 6892: 1998SvapneshNo ratings yet

- Is 1608 - 2005 - 29Document1 pageIs 1608 - 2005 - 29SvapneshNo ratings yet

- Is 1608 - 2005 - 31Document1 pageIs 1608 - 2005 - 31SvapneshNo ratings yet

- Is 1608 - 2005 - 15Document1 pageIs 1608 - 2005 - 15SvapneshNo ratings yet

- Is 1608 - 2005 - 23Document1 pageIs 1608 - 2005 - 23SvapneshNo ratings yet

- Annex 0: D, and Its Shape Shall Be Such That It Does Not Interfere With The Gauge LengthDocument1 pageAnnex 0: D, and Its Shape Shall Be Such That It Does Not Interfere With The Gauge LengthSvapneshNo ratings yet

- IS 1608: 2005 ISO 6892: 1998: Figure 3 - Proof Strength, Non-Proportional ExtensionDocument1 pageIS 1608: 2005 ISO 6892: 1998: Figure 3 - Proof Strength, Non-Proportional ExtensionSvapneshNo ratings yet

- MM MM: A.2 Dimensions of The TestDocument1 pageMM MM: A.2 Dimensions of The TestSvapneshNo ratings yet

- 11 Determination of Percentage Elongation After FractureDocument1 page11 Determination of Percentage Elongation After FractureSvapneshNo ratings yet

- Is 1608 - 2005 - 10Document1 pageIs 1608 - 2005 - 10SvapneshNo ratings yet

- IS 1608: 2005 ISO 6892: 1998: III IIIDocument1 pageIS 1608: 2005 ISO 6892: 1998: III IIISvapneshNo ratings yet

- Is 1608 - 2005 - 18Document1 pageIs 1608 - 2005 - 18SvapneshNo ratings yet

- Figure 9 - Machined Test Pieces of Rectangular Cross SectionDocument1 pageFigure 9 - Machined Test Pieces of Rectangular Cross SectionSvapneshNo ratings yet

- IS 1608: 2005 ISO 6892: 998 11.4 in Order in May Described inDocument1 pageIS 1608: 2005 ISO 6892: 998 11.4 in Order in May Described inSvapneshNo ratings yet

- Is 1608 - 2005 - 14Document1 pageIs 1608 - 2005 - 14SvapneshNo ratings yet

- Is 1608 - 2005 - 11Document1 pageIs 1608 - 2005 - 11SvapneshNo ratings yet

- Kawasaki Gas TurbineDocument45 pagesKawasaki Gas Turbinepramasenja100% (2)

- Journal of Membrane Science: SciencedirectDocument11 pagesJournal of Membrane Science: SciencedirectbasselNo ratings yet

- En8591 - Municipal Solid Waste ManagementDocument16 pagesEn8591 - Municipal Solid Waste ManagementASHA BALASUBRAMANIAMNo ratings yet

- Aacc 28-42Document3 pagesAacc 28-42Angy Carolina Castaño OspinaNo ratings yet

- New Solvent For Polyamide 66 and Its Use For Preparing Single-Polymer Composite Coated-FabricDocument24 pagesNew Solvent For Polyamide 66 and Its Use For Preparing Single-Polymer Composite Coated-FabricSSNo ratings yet

- Aplication Latter For (Maintenance) PT Nok PrecisionDocument3 pagesAplication Latter For (Maintenance) PT Nok PrecisionJunion GultomNo ratings yet

- DNV OS D301 Fire ProtDocument42 pagesDNV OS D301 Fire ProtSaid ElhamydyNo ratings yet

- Valvula Manual Norgren m1704Document1 pageValvula Manual Norgren m1704Base SistemasNo ratings yet

- Datasheet Lm340t5 NationalDocument18 pagesDatasheet Lm340t5 Nationalelvis1281No ratings yet

- VCS 5036-5 Restricted Substance Management-IMDSDocument13 pagesVCS 5036-5 Restricted Substance Management-IMDSMemo Gonzalez AlemanNo ratings yet

- High Quality Facade Paint, Water-Based, Scrub Resistant, Good Water Vapor Diffusion (F 10105 - 2 - 13)Document2 pagesHigh Quality Facade Paint, Water-Based, Scrub Resistant, Good Water Vapor Diffusion (F 10105 - 2 - 13)Jhon Alexander Isaza JimenezNo ratings yet

- Perdele Economic B 2VVDocument4 pagesPerdele Economic B 2VVakitainupufNo ratings yet

- Forbo Flooring Allura Brochure UKDocument40 pagesForbo Flooring Allura Brochure UKFloorkitNo ratings yet

- BS&WDocument2 pagesBS&Wnikhil guptaNo ratings yet

- Sachpazis - Raft Foundation Design For Typical 2 Storey House Example - BS8110 - PART 1 - 1997Document5 pagesSachpazis - Raft Foundation Design For Typical 2 Storey House Example - BS8110 - PART 1 - 1997mushroom0320No ratings yet

- Page 1 - Location and Site PlanDocument1 pagePage 1 - Location and Site PlanElynor Acio MercadoNo ratings yet

- Viper Seal and Scraper Selection Guide 2013 - Rev 2Document2 pagesViper Seal and Scraper Selection Guide 2013 - Rev 2Vembu RajNo ratings yet

- Ndola City Council Calvert Edited Quote 2Document1 pageNdola City Council Calvert Edited Quote 2Foredesankho MhlongotiNo ratings yet

- Subsurface Ventilation Systems MVS-SVE - Chapter04Document36 pagesSubsurface Ventilation Systems MVS-SVE - Chapter04Ghita Noerma GuphitaNo ratings yet

- Cessna Citation XLS-Power Brake and Antiskid SystemDocument3 pagesCessna Citation XLS-Power Brake and Antiskid SystemAlan MaraNo ratings yet

- T&C of Fire Supression SystemDocument5 pagesT&C of Fire Supression Systemamg007100% (1)

- Expansion Valves - Working PrincipleDocument3 pagesExpansion Valves - Working PrinciplePradeep Sukumaran100% (1)

- Mitsubishi l200Document40 pagesMitsubishi l200Karl Jason Agraviador100% (3)

- 5.2. Classification of FuelsDocument16 pages5.2. Classification of FuelsadiNo ratings yet

- Rate Analyze PDFDocument13 pagesRate Analyze PDFmohamedNo ratings yet

- Ductulator May 2010Document10 pagesDuctulator May 2010Arshavin Watashi WaNo ratings yet

- Polymers For Electronic ComponentsDocument116 pagesPolymers For Electronic Componentslord_royerNo ratings yet

- Lighting PDFDocument204 pagesLighting PDFkikokadola100% (1)

- BS en 50264-3-1-2008Document28 pagesBS en 50264-3-1-2008Shivangi BhardwajNo ratings yet