Professional Documents

Culture Documents

Lock-Out Tag-Out Safe Work Procedures SWP-10

Uploaded by

ShafiqOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lock-Out Tag-Out Safe Work Procedures SWP-10

Uploaded by

ShafiqCopyright:

Available Formats

598082212.

docx VERSION: 01

SNK ENGINEERING & TRADING PTE.LTD.,

SAFE WORK PROCEDURES

DOCUMENT

LOCK-OUT, TAG-OUT

TITLE:

DOCUMENT

SWP-10

NO:

DOCUMENT

01

VERSION:

GENOCEAN ENTERPRISES PTE LTD PAGE 1 of 6

598082212.docx VERSION: 01

LOCK-OUT, TAG-OUT

1 Purpose and Scope

1.1 The purpose is to prevent any incidents and/or injuries due to inadvertent operation of

machinery or energizing of systems during servicing, maintenance and inspections.

1.2 This procedure applies to all situations where there exist the potential for exposure to

such inadvertent machine operation or system energizing.

1.3 This procedure does not apply to the following situations:

a) Servicing and/or maintenance during normal production unless an employee is

required to remove or bypass a guard or safety device and place any part of his

body in the area of a machine where work is actually being carried out or a

danger exist; and

b) Minor tool changes, adjustment or servicing that are routine, repetitive and

integral for production.

2 Definitions

Lock-Out - part of a machine that controls the energy

e.g. circuit breaker or switch, block or

isolation valve etc.

Tag-Out - putting a tag instructing people not to operate or use

machine/equipment.

3 Responsibilities

3.1 The Building Custodian Contractor/Managing Agents/technical departments shall be

responsible for the observance and enforcement of the requirements of this procedure.

3.2 The user/technical staff shall be responsible for following the requirements of this

procedure for the specified machinery or equipment.

4 Procedure

4.1 General Instructions and Guidelines

4.1.1 The department/section head concerned shall identify and designate the equipment,

machinery, systems and situations requiring the application of this procedure.

GENOCEAN ENTERPRISES PTE LTD PAGE 2 of 6

598082212.docx VERSION: 01

4.1.2 Log-out / tag-out (LOTO) is required during the repair or maintenance of equipment and

machinery that are run on electricity, hydraulics, pneumatics, steam or mechanical

energy, which if inadvertently activated or energized could cause injury to workers.

4.1.3 The lock shall be durable and be able to withstand heat, cold, humidity or corrosion and

strong enough to prevent accidental removal.

4.1.4 A lock-out device shall be accompanied by a durable and sufficiently strong tag to

indicate the identity of the person who affixed it.

4.1.5 All tags shall have the same print and format throughout the work place, be easy to read

and understand, tough enough so they cannot be removed accidentally. The tie for tag-

out shall be self locking and can be attached by hand.

4.1.6 The tags shall display warnings such as “DO NOT START’, ‘DO NOT OPEN’, ‘DO NOT

OPERATE’.

4.1.7 Proper handing over shall be observed during change of personnel.

4.2 Lock-Out Of Equipment and Machinery

4.2.1 The user/technical staff shall have sound knowledge of energy types, including that

which is stored in accumulators, receivers, associated hazards, controls and isolation

details of the machinery or equipment.

4.2.2 The following steps shall be followed for effective lockout:

a) Announce shut down - Notify the affected personnel of the machinery or

equipment to be shutdown and that lock out procedure will be implemented.

b) Shut down the machine/equipment - Proceed to shut down the machine.

c) Disconnect all energy sources - Disconnect all energy sources (including bleeding

off of pressure from accumulators, receivers, pipe systems, discharging

capacitors etc) supplying power to the machine. Energy isolation devices such as

manually operated circuit breakers may be used for disconnecting the energy

source.

d) Apply lock out - Use lock out devices such as padlocks over the energy isolating

devices to ensure that energy would not be restored unexpectedly or

accidentally while work is being carried out.

(Note: No lock will be needed if the equipment is installed with a push button.

The push button has to be engaged before work can be carried out).

GENOCEAN ENTERPRISES PTE LTD PAGE 3 of 6

598082212.docx VERSION: 01

e) Verify the isolation and lock out - Release any residual or stored energy such as

the energy in capacitors. Operate the machine’s controls to confirm that the

machine has been isolated and cannot be re-energized.

4.2.3 All energy control switches shall be in “OFF” or “SAFE” position to prevent accidental

start up or energy release.

4.2.4 Stored energy shall be released or blocked off before commencement of work.

4.2.5 After lock-out, attach the tag on the control panel to indicate that the system is under

maintenance.

4.3 Restoring The Machine/Equipment For Operation

4.3.1 Once the maintenance or repair work is completed, the machine/equipment shall be

returned to normal operation. The following steps shall be followed:

a) Check and ensure that all tools have been removed from the machine, that it is in a

safe condition to operate and safety guards if previously removed have been

replaced;

b) Verify that all personnel are safely clear of the machine;

c) Announce that the machine would be turned on;

d) Remove the lock-out devices and re-energize the machine. For push button devices,

re-activation must only be done by the user/technical staff who has the access

key; and

e) Inform the operators that the machine is ready for operation.

4.3.2 The user/technical staff who had applied the lock out shall remove the lock.

4.4 Training And Measures

4.4.1 Only qualified and trained personnel shall carry out LOTO and the service/maintenance

of machinery/equipment.

4.4.2 Training shall be provided to employees who have to carry out the inspection, cleaning,

repair or maintenance of plant, machinery or equipment.

4.4.3 Training shall be provided to employees responsible for the inspection, cleaning, repair,

modification and maintenance of plant, equipment and machinery.

4.4.4 Re-training shall be carried out to keep employees updated on any new hazards or

change in the lock-out procedures in identifying energy sources.

GENOCEAN ENTERPRISES PTE LTD PAGE 4 of 6

598082212.docx VERSION: 01

4.4.5 Briefing shall be provided to persons, if necessary, who are involved in the inspection,

cleaning, repair or maintenance to understand the purpose of lock-out procedures and

the prohibition to restart or re-energize any plant, machinery or equipment that is

locked-out.

5 Control Of Records

Storage

Title Responsibility Retention Period Medium

Master list of Building Custodian As long machine/ Hardcopy/

machines, equipment Contractor/Managing equipment is in Softcopy

and plants for LOTO Agents/Technical use

Departments

6 Documents Associated With This Procedure

CP 91 : 2001 - Code Of Practice for lock-out procedures

WSH (General Provision) Regulations 2006

7 Attachments

I - Lockout / Tagout Permit

GENOCEAN ENTERPRISES PTE LTD PAGE 5 of 6

598082212.docx VERSION: 01

Attachment I

LOCKOUT/TAGOUT PERMIT

Date Schedule for work: Time : From: To:

Brief description of task:

Name of authorized person(s) Person in charge : (Name & Signature)

who perform the task(s)

Others on the team :

Company name (if a contractor /

subcontractor) :

Contact number : Mobile phone / pager

Data Reviewed for Each Source of Hazardous Energy

Electrical: a/c d/c capacitor Disconnecting Means:

Voltage(s) :

Pneumatic: Disconnecting Means:

Pressure :

Hydraulic: Disconnecting Means:

Pressure :

Kinetic: Disconnecting Means:

Weight / Force :

Heat or Cold: Disconnecting Means:

Temperature :

Chemical Name: Disconnecting Means:

Hazard :

Others: Disconnecting Means:

Magnitude :

Personal Protective Equipment & Safety Equipment to be Used

Permit Authorized by :

Work Completed as per permit :

Signature of Person in Charge Date & Time Completed

GENOCEAN ENTERPRISES PTE LTD PAGE 6 of 6

You might also like

- NFPA 70E Sample Lockout-Tagout ProgramDocument4 pagesNFPA 70E Sample Lockout-Tagout ProgramJesus MolinaNo ratings yet

- 1910.147 Lockout-Tagout ProgramDocument13 pages1910.147 Lockout-Tagout Programquang06No ratings yet

- Qcs 2010 Section 11 Part 2.3.12 She Procedures - Control of Working ADocument9 pagesQcs 2010 Section 11 Part 2.3.12 She Procedures - Control of Working Abryanpastor106No ratings yet

- Lifting Operations Risk Assessment Crane Risk AssessmentDocument13 pagesLifting Operations Risk Assessment Crane Risk Assessment9853318441No ratings yet

- Suspended Loads Safety Tips (39Document3 pagesSuspended Loads Safety Tips (39my_agautamNo ratings yet

- WHS P11 Fatigue Management ProcedureDocument8 pagesWHS P11 Fatigue Management Procedurehse bptNo ratings yet

- 2014 Energized Electrical Work Permit - ByU-IdahoDocument2 pages2014 Energized Electrical Work Permit - ByU-Idahocarrot123456No ratings yet

- Rocky Mountain Safety ProceduresDocument5 pagesRocky Mountain Safety ProceduresSAMUEL POBRENo ratings yet

- A002 C NightclubDocument6 pagesA002 C NightclubBlas de LezoNo ratings yet

- Loading & Lifting ProcedureDocument5 pagesLoading & Lifting Procedurekhurram shahzadNo ratings yet

- Fatigue Management Procedure Sew39Document13 pagesFatigue Management Procedure Sew39Viem Abdul HalimNo ratings yet

- Akk Jha Installation of Diesel TankDocument3 pagesAkk Jha Installation of Diesel TankDouglas Delly0% (1)

- Blinding and De-blinding Safety EssentialsDocument42 pagesBlinding and De-blinding Safety EssentialsMayur NaikNo ratings yet

- 015 CH 10 Tool InspectionDocument3 pages015 CH 10 Tool InspectionLinda BooysenNo ratings yet

- Completed Example of A Risk Assessment - Example 1Document3 pagesCompleted Example of A Risk Assessment - Example 1Rahil Tasawar0% (1)

- Heat Stress ProcedureDocument13 pagesHeat Stress ProcedureKneekEy CastleNo ratings yet

- Risk Assessment Form: Project: Gem Residences Location: E. Rodriguez Ave. C5, Pasig CityDocument2 pagesRisk Assessment Form: Project: Gem Residences Location: E. Rodriguez Ave. C5, Pasig CityJhundel FactorNo ratings yet

- SAFETY ALERT, No.07-December 2009: Driving in FogDocument1 pageSAFETY ALERT, No.07-December 2009: Driving in FogratkoNo ratings yet

- Safe Work Procedure, Gem MaintenanceDocument46 pagesSafe Work Procedure, Gem MaintenanceAsif Khanzada100% (1)

- Consequence Management Sytem EsepplDocument1 pageConsequence Management Sytem Eseppluttam mishra100% (2)

- LOLER Inspection Checklist GuideDocument25 pagesLOLER Inspection Checklist GuideTatak Bay AhmedNo ratings yet

- Safety Alert 260 - Unsafe Cradle Installation and UsageDocument2 pagesSafety Alert 260 - Unsafe Cradle Installation and UsageAbdulKatherNo ratings yet

- Flagman/ Banksman TrainingDocument25 pagesFlagman/ Banksman TrainingAatif Patil100% (1)

- Lockout Tagout TRNG GuideDocument7 pagesLockout Tagout TRNG GuideSyed Mujtaba Ali Bukhari100% (1)

- Toolbox Talks Hand and Portable Power Tools EnglishDocument1 pageToolbox Talks Hand and Portable Power Tools EnglishsuhasNo ratings yet

- Working at Height Risk Assessment Mar 21Document2 pagesWorking at Height Risk Assessment Mar 21tariq1987No ratings yet

- Safe Work Method Statement For Survey Work: CMS Surveyors Pty LTD ABN: 79 096 240 201Document18 pagesSafe Work Method Statement For Survey Work: CMS Surveyors Pty LTD ABN: 79 096 240 201mkash028100% (1)

- Arc Welding Safe Work ProcedureDocument2 pagesArc Welding Safe Work ProcedureYoga PradiptaNo ratings yet

- Cherry Picker Inspection Checklist for Emami Cement Grinding UnitDocument1 pageCherry Picker Inspection Checklist for Emami Cement Grinding Unitsanjeev kumarNo ratings yet

- Safety Moment There Is No Shortcut To Safety 448cuoDocument6 pagesSafety Moment There Is No Shortcut To Safety 448cuoInnocent BhaikwaNo ratings yet

- Mobile Elevated Work Platforms (MEWP) Program: Provo, UtahDocument14 pagesMobile Elevated Work Platforms (MEWP) Program: Provo, UtahStephanie ScottNo ratings yet

- Flagman TrainingDocument58 pagesFlagman TrainingIndermohan MehtaNo ratings yet

- Risk assessment electrical workDocument2 pagesRisk assessment electrical workErni Tri LestariNo ratings yet

- JSO Cable Drum (02 Sept.'07)Document2 pagesJSO Cable Drum (02 Sept.'07)Francis Enriquez TanNo ratings yet

- Control of Working at Heights ProcedureDocument9 pagesControl of Working at Heights ProcedureFrancisco M. Ramos100% (1)

- MPSA-SOP - 07 Cranes and Lifting EquipmentDocument14 pagesMPSA-SOP - 07 Cranes and Lifting EquipmentLim PaNo ratings yet

- SWP 5 Excavations Shoring and Trenches PDFDocument4 pagesSWP 5 Excavations Shoring and Trenches PDFThanesh ManogaranNo ratings yet

- Heat Stress GuidelinesDocument22 pagesHeat Stress Guidelinesgajeel1991No ratings yet

- Thyssenkrupp Industrial Solutions (India) Job Safety AnalysisDocument11 pagesThyssenkrupp Industrial Solutions (India) Job Safety AnalysisNitesh kumar yadav100% (1)

- 50 MW Artistic Wind Power Project: Job Safety Analysis Worksheet (Equipment Lifting)Document3 pages50 MW Artistic Wind Power Project: Job Safety Analysis Worksheet (Equipment Lifting)Raza Muhammad SoomroNo ratings yet

- HSEDocument10 pagesHSEMohamad ZackuanNo ratings yet

- Visitor Safety Orientation - IMPIDocument13 pagesVisitor Safety Orientation - IMPIHSE IMPICNo ratings yet

- Emergency Plan For Rescue From HeightsDocument9 pagesEmergency Plan For Rescue From Heightsochieng denisNo ratings yet

- PDO LSRs Notes EnglishDocument24 pagesPDO LSRs Notes Englishcmrig74No ratings yet

- HSE-OCP-042 SRL - Access Control ProcedureDocument5 pagesHSE-OCP-042 SRL - Access Control ProcedureibrahimNo ratings yet

- Safety Manual Blue PeterDocument102 pagesSafety Manual Blue Peterfaraz ahmedNo ratings yet

- LCC DOCS-11568884-V1-HS-PRO-013 Working in On Over or Adjacent To WaterDocument13 pagesLCC DOCS-11568884-V1-HS-PRO-013 Working in On Over or Adjacent To WaterabogadieNo ratings yet

- Grating Safety AwarenessDocument25 pagesGrating Safety AwarenessMuneeb RehmanNo ratings yet

- SP2000 Road Safety StandardDocument120 pagesSP2000 Road Safety StandardSunder TrichyNo ratings yet

- SOP Module Unloading & StorageDocument1 pageSOP Module Unloading & StorageRahul SahaNo ratings yet

- TRA of Ladder & PlatformDocument2 pagesTRA of Ladder & PlatformandreNo ratings yet

- Pre Job Check List - Working at Height Using Scissor LiftDocument2 pagesPre Job Check List - Working at Height Using Scissor LiftSijo RajanNo ratings yet

- 28.1.1 Mobile Equipment Inspection ChecklistDocument1 page28.1.1 Mobile Equipment Inspection Checklistmohamed abdelmoniemNo ratings yet

- JSA - Crane Setuppdf PDFDocument12 pagesJSA - Crane Setuppdf PDFChoko ChokriNo ratings yet

- Slide 35-HCS Clamp EndorsementDocument14 pagesSlide 35-HCS Clamp EndorsementShafiqNo ratings yet

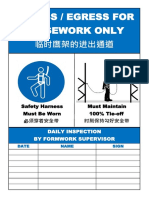

- FALSEWORK ACCESS With InspectionDocument1 pageFALSEWORK ACCESS With InspectionShafiqNo ratings yet

- HC+ Shoring System ScaffoldDocument31 pagesHC+ Shoring System ScaffoldShafiqNo ratings yet

- 5 - Emergency PrepardnessDocument24 pages5 - Emergency PrepardnessShafiqNo ratings yet

- Tower Crane SketchDocument20 pagesTower Crane SketchShafiqNo ratings yet

- SWP-09 Hand Tools SafetyDocument3 pagesSWP-09 Hand Tools SafetyShafiqNo ratings yet

- SWP-07 Electrical SafetyDocument4 pagesSWP-07 Electrical SafetyShafiqNo ratings yet

- SWP-08 Use of Electrical ToolsDocument5 pagesSWP-08 Use of Electrical ToolsShafiqNo ratings yet

- Scaffold Safety ProceduresDocument9 pagesScaffold Safety ProceduresShafiqNo ratings yet

- Design of Temporary Floating Road for Construction SiteDocument6 pagesDesign of Temporary Floating Road for Construction SiteAnonymous hRWwL7pZnCNo ratings yet

- Surat Kecil Untuk TuhanDocument9 pagesSurat Kecil Untuk TuhanAsgarPurnamaNo ratings yet

- management of burns readingDocument28 pagesmanagement of burns readinghimanshugupta811997No ratings yet

- Fetal and Placental Development - FETAL Sac, Umbilical Cord .Abnormalities of PlacentaDocument150 pagesFetal and Placental Development - FETAL Sac, Umbilical Cord .Abnormalities of PlacentaKripa SusanNo ratings yet

- KND 3200 eDocument0 pagesKND 3200 eGianna FrolaNo ratings yet

- M/S Majumder Construction: Valuation Statement of PropertyDocument3 pagesM/S Majumder Construction: Valuation Statement of PropertyManoj MajumderNo ratings yet

- Final Seminar ReportDocument35 pagesFinal Seminar ReportHrutik BhandareNo ratings yet

- Steel Grid StructureDocument2 pagesSteel Grid StructureKusum RawatNo ratings yet

- Mini ProjectDocument6 pagesMini Projectirene0% (1)

- 05.G. Before Takeoff CheckDocument4 pages05.G. Before Takeoff CheckUDAYAPRAKASH RANGASAMYNo ratings yet

- Fi & EiDocument3 pagesFi & EiPrasanna S Kulkarni100% (1)

- Calculation of Carbon Footprint: HouseDocument3 pagesCalculation of Carbon Footprint: HouseUmut ÇağırganNo ratings yet

- Module 2 Chem 1Document25 pagesModule 2 Chem 1melissa cabreraNo ratings yet

- PTC Document Status: (Updated 11 November 2015)Document5 pagesPTC Document Status: (Updated 11 November 2015)AndersonGabriel23No ratings yet

- Concept of StateDocument10 pagesConcept of StateAryansh ShuklaNo ratings yet

- Rites of Acceptance For Altar Servers PDFDocument3 pagesRites of Acceptance For Altar Servers PDFJohn Carl Aparicio100% (1)

- Maersk QuestionnaireDocument43 pagesMaersk QuestionnaireSahil SharmaNo ratings yet

- Mechanical Design of Turine EginesDocument51 pagesMechanical Design of Turine EginessriniNo ratings yet

- Akbh PSK (V), TRBH As Y: AdhimokṣADocument8 pagesAkbh PSK (V), TRBH As Y: AdhimokṣA张晓亮No ratings yet

- Empowerment Technologies: Quarter 3 - 8: Imaging and Design Fo R The Online Environment IDocument14 pagesEmpowerment Technologies: Quarter 3 - 8: Imaging and Design Fo R The Online Environment IShaira Jane Estrella UcolNo ratings yet

- Problem Set 3_Cross-Text ConnectionDocument31 pagesProblem Set 3_Cross-Text Connectiontrinhdat11012010No ratings yet

- Aula 4 - Wooten - Organizational FieldsDocument28 pagesAula 4 - Wooten - Organizational FieldsferreiraccarolinaNo ratings yet

- TCB E-F 015cukDocument2 pagesTCB E-F 015cukTempcoNo ratings yet

- Reading Test 7 - PassageDocument12 pagesReading Test 7 - PassageĐinh Quốc LiêmNo ratings yet

- Essay Writing-PTEDocument13 pagesEssay Writing-PTEAnita GajjarNo ratings yet

- Resume Curt JerromeDocument5 pagesResume Curt JerromeAashish MuraliNo ratings yet

- Enzyme ActivityDocument3 pagesEnzyme ActivityNabindra Ruwali100% (2)

- Mitsubishi Colt 2007 Rear AxleDocument2 pagesMitsubishi Colt 2007 Rear AxlenalokinNo ratings yet

- Common Carrier RulingDocument4 pagesCommon Carrier RulingChic PabalanNo ratings yet

- Captured Ammunition Bulletin No 1Document34 pagesCaptured Ammunition Bulletin No 1roberto porto100% (1)