Professional Documents

Culture Documents

Confined Space Entry Risk Assessment Cutting and Welding in Void Tank 22 October 2019

Uploaded by

ananthOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Confined Space Entry Risk Assessment Cutting and Welding in Void Tank 22 October 2019

Uploaded by

ananthCopyright:

Available Formats

Version 1.

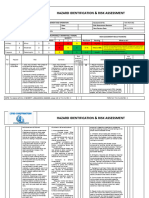

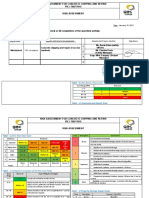

CONFINED SPACE RISK ASSESSMENT

Confined Space Identification name / number: Void Tank Date of Assessment: 22 October 2019

Description of the Confined Space: Void Tank

Description of work to be performed: Cut and replace drainage Pipework

Assessment performed by: Stephen Jubb

Is it possible to eliminate work inside the Confined Space? Yes No If No, Identify the hazards associated with the

confined space and then control measures to

minimise risk.

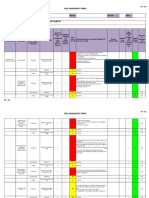

Risk Classification Matrix

Likelihood Consequences

1. Insignificant 2. Minor 3. Moderate 4. Major 5. Catastrophic

A. Almost Certain 5 L (5) M (10) H (15) H (20) H (25)

B. Likely 4 L (4) M (8) M (12) H (16) H (20)

C. Possible 3 L (3) M (6) M (9) M (12) H (15)

D. Unlikely 2 L (2) L (4) M (6) M (8) M (10)

E. Rare 1 L (1) L (2) L (3) L (4) M (5)

(Refer Appendix A for Risk Analysis Reference tables)

Confined Space Operation PRO-04-0557 Page 1 of 9

Version 1.1

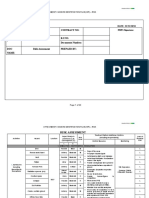

Hazard Assessment Description of the Hazard Risk Detail the Control Measures that will Risk

Before minimise / eliminate risk After

Controls controls

(H,M,L) (H,M,L)

1. Are there means by which the oxygen level Oxygen concentration must range between Cleaning, purging, ventilation, alternate processes?

may be depleted? 19.5% and 22% Is BA required if this concentration range cannot be

achieved and there is no other practical solution?

If Atmospheric testing is required, outline the frequency.

Corrosion processes? i.e. surface corrosion of Nil L Ventilation L

the walls or equipment inside. Gas Test 0%, oxygen 20.9

Has oxygen been displaced by other gases No L Nil L

within the space, or intentionally purged with

an inert gas

Combustion processes? i.e. use of open flame No L Nil L

hot work processes, welding, etc.

Absorption by materials within the confined No L Nil L

space? (Product in the space that absorbs

oxygen)

Physical activity? i.e. small confined space, small confined space, labour intensive work M Frequent Breaks L

labour intensive work to be performed, many

people inside space (depletion through

respiration)

2. Can the level of oxygen be increased within Identify any means by which oxygen levels

the confined space e.g., leaks in fittings could be increased.

containing oxygen?

Can any type of oxygen source be introduced Yes, Oxy acetylene for cutting M Check Equipment before use, work site preparation L

into the confined space? e.g. oxygen hoses

Can a chemical reaction occur inside the No L Nil L

space which generates oxygen? e.g. reaction

of catalyst.

3. What contaminants may be in the confined Consider process materials, by products of If Atmospheric testing is required, outline the frequency.

space either from when it was in service or process, residues, scale or contaminants

through the work that is to be performed brought in or generated during the work

Confined Space Operation PRO-04-0557 Page 2 of 9

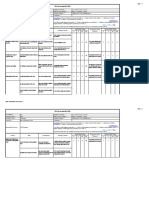

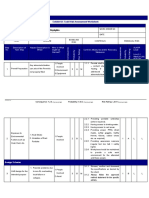

Version 1.1

Hazard Assessment Description of the Hazard Risk Detail the Control Measures that will Risk

Before minimise / eliminate risk After

Controls controls

(H,M,L) (H,M,L)

Materials stored or used in the confined Nil L Pit have been emptied for a month due to rig move L

space? Identify them.

By-products of materials, e.g. decomposition of Nil L Nil L

sludge or organic materials, removal of scale?

Use of hazardous materials, i.e. cleaning Nil L Ventilation L

agents, solvents, paints, NDT materials Gas Test 0%, oxygen 20.9

Operations performed, welding, cutting, No L Nil L

heating of surfaces, painting, brazing

Contamination on the surface of the confined Nil L Nil L

space, i.e. scale, paint, or hazardous materials

absorbed into the surface

4. Is there any internal equipment that may Agitators, paddles, fans, mixers, rake arms In addition to isolation, is it necessary to restrain the

move either through mechanical means or etc.? equipment with chains or ropes etc.?

through gravity, air movement, or by hand

What are the internal moving equipment Agitators coupling M Electrical Isolation Certificate 0022 L

hazards?

5. Are there any means for any solid, liquid or Water, slurry, steam, gasses, flare headers, All lines, pipe work, ducting, conveyors, feeders, etc.

gaseous materials to enter the confined conveyors, flooding from external sources? must be isolated in a manner that minimises risk.

space Explain that isolation.

What are those means for solid, liquid or Nil L Nil L

gaseous materials to enter the space?

6. Are there any stored energy sources within Back torque in gearboxes, hydraulics, How will these sources be de energised?

the confined space pneumatics, coils, springs, or pressurised

equipment?

What hazards are associated with stored Agitators coupling M Pit has not been used in some time L

energy sources? Equipment will be isolated 0022

Confined Space Operation PRO-04-0557 Page 3 of 9

Version 1.1

7. Can any material fall from above or from Falling of product or materials, or is there

the walls of the space to cause suffocation, product that a person could fall into?

engulfment or injury?

What materials could fall from the walls or the N/A L Nil L

roof of the space?

What other materials exist within the space N/A L Nil L

that a person could be engulfed by?

8. Is there a risk of explosion or fire Flammable, liquids, solids, gasses present? If Atmospheric testing is required, outline the frequency.

occurring? Ignition sources present? Flammable gas

limits must be below 5% of the Lower

Explosive Limit for that gas.

Are there any flammable materials present, No L Deep clean was the last fluid in the pit

any flammable materials introduced or near the Gas Test 0%, oxygen 20.9

confined space, or can the work process cause

a flammable gas or vapour to be generated

Are any ignition sources present from hot work No L Deep clean was the last fluid in the pit L

processes inside or outside of the confined Gas Test 0%, oxygen 20.9

space?

Identify any other ignition sources e.g. portable No L Nil L

electrical tools, lighting, grinding, and abrasive

blasting.

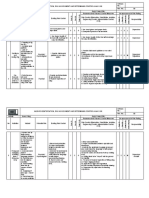

9. Are there any means by which a person Low voltage lighting, RCD’s for electrical equipment, air

could receive an electric shock? powered tools?

What welding operations are being performed? No L Nil L

What electrical tools and equipment are being Electric Drop light M Deep clean was the last fluid in the pit L

used? AIR POWERED TOOLS SHOULD BE Gas Test 0%, oxygen 20.9

USED TO ELIMINATE THE USE OF POWER

WHERE POSSIBLE.

1 Are there any sources of noise present

0 both internal and external to the confined

space?

What parts of the task may contribute to Nil L Nil L

excessive noise within the task?

Confined Space Operation PRO-04-0557 Page 4 of 9

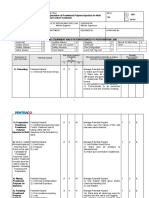

Version 1.1

11 Is the confined space subject to thermal Hot or cold conditions?

extremes?

What hazards are associated with thermal Nil L Nil L

extremes?

12 Are there any sources of radiation present? Radiation gauges, reflected welding flash,

NDT testing?

What hazards are associated with radiation Welding Flash: Radiation M Wear appropriate PPE: Welders Apron, Gloves and L

sources? Welders Helmet

13 How is entry to be gained into the confined Vertical entry, narrow, obstructed or difficult to Platforms, ramps, ladders, scaffolds, lowering devices?

space? access entry?

What hazards are associated with gaining Vertical entry, narrow, difficult to access M Harness, SRL, buddy to assist in getting welder and L

entry into the space, and then exiting? equipment into pit

Is there risk of slips, trips or falls?

14 Does the size or the internal layout of the Very small, obstructions, angled floors, remote

confined space create additional hazards regions, unsound internals or structure, etc.?

What hazards are associated with the internal Limited space M identified in PJSM before task commence L

layout of the space? Confined area

Is the confined space of sound structure? Yes L Nil L

15 Will the introduction of any tools and Leads, scaffolding, equipment etc., obstructing

equipment create additional hazards in the the entrance?

confined space?

What are the hazards associated with Welding equipment: Leads, Oxy Acetylene M Ensure work site preparation includes correct routing of L

introducing tools and equipment into the hoses, slip trip and fall hazards cables and hoses to minimise the potential of Slip and trip

space? Hazards,

1 Will the manual handling of equipment or Trolleys, chain blocks, or other lifting devices?

6 materials in to, out of or within the confined Breaking up of equipment into smaller pieces?

space create a hazard?

What are the hazards associated with manual Vertical entry, narrow, difficult to access M identified in PJSM before task commence L

handling within the confined space?

What hazards are associated with passing Vertical entry, narrow, difficult to access M buddy to assist in getting equipment into and out of pit L

equipment through the entrance to the space?

Confined Space Operation PRO-04-0557 Page 5 of 9

Version 1.1

17 Are there any processes or activities Combustion engine exhausts, vents, ducting,

external to the confined space that may overflows, local hazardous materials storage

affect the atmosphere or conditions within etc.?

the confined space?

What hazards are associated with external N/A L Nil L

processes or activities?

18 Are there any biological hazards present? Is special cleaning or fumigation required?

What hazards are associated with biological N/A L Nil L

contamination?

1 Are there any traffic or pedestrian hazards

9 present?

What hazards are associated with pedestrian N/A L Nil L

traffic around the confined space?

20 Where will the standby person be located

outside the confined space, and how are

they to communicate with the persons

inside?

Where will the sentry be located? Access point in accordance with standby L identified in PJSM before task commence

What hazards may impact on the health and watch duties and checklist

safety of the sentry?

Is more than 1 sentry required?

What hazards are associated with the number N/A L Nil L

of entrants that will be inside the space at the

same time?

2 Will the physical fitness of any individual

1 contribute to a hazard within the space?

What hazards may be associated with the If person doesn’t have valid medical then they L Nil L

physical fitness of individuals who must work in won’t be involved in the task

this space?

Confined Space Operation PRO-04-0557 Page 6 of 9

Version 1.1

22 Is specific firefighting equipment required

for this confined space entry?

What hazards exist that will require special N/A L Nil L

firefighting equipment?

23 Does the space require flushing or purging Include process risks.

prior to entry?

What hazards are associated with flushing or N/A L Gas Test 0%, oxygen 20.9 L

purging the space to make it safe for entry?

What hazards are associated with cleaning N/A L Gas Test 0%, oxygen 20.9 L

contaminants from the confined space?

25 Will the use of any extra PPE identified in Combinations of separate PPE items may not

this risk assessment introduce any further be compatible.

hazards?

What hazards are associated with additional N/A L Nil L

PPE?

26 Any other hazards not previously prompted

by this risk assessment?

N/A L Nil L

Further comment by the risk assessment team:

Confined Space Operation PRO-04-0557 Page 7 of 9

Version 1.1

RESCUE PLAN

The Rescue Plan for the Confined Space MUST be completed.

Rescue plan as per Confined Space Rescue attached to PTW

Rescue Plan reviewed and approved by: ____________________ Date: ______________

OIM

CONFINED SPACE RISK ASSESSMENT FINDINGS

What is the highest identified Risk after Controls, throughout this risk assessment? High

Moderate

Low

The highest identified risk will determine the Risk

Rank Approval Requirement

Risk Rank Approval Requirements

Low = Authorised Person (Permit Issuer) Approval

Moderate = Authorised Person (Permit Issuer) Approval plus Rig Safety Training Officer oversight

High = Never to be approved (pending further risk mitigation and reduction of rating)

This Confined Space Risk Assessment conducted and compiled by: Stephen Jubb Barge Captain Date: ______________

This Confined Space Risk Assessment approved by: Andre Clark OIM Date: ______________

Confined Space Operation PRO-04-0557 Page 8 of 9

Version 1.1

APPENDIX A:

RISK ANALYSIS REFERENCE TABLES

TABLE 1

Likelihood Description

A. Almost Certain Event happens several times per year on a typical company rig

B. Likely Event occurs more than 3 times per year in company’s operations

C. Possible Event has occurred in company’s operations

D. Unlikely Event has occurred in the drilling industry

E. Rare Event never heard of in the drilling industry

TABLE 2

Description

CONSEQUENCE Injury Illness Environment Property Damage/ Process Loss

1. Insignificant Minor Injury – Minor illness / Slight Little or no Low financial loss (<$2,000)

consultation only health effect e.g. environmental impact

headaches

2. Minor First Aid Injury Minor illness / Minor Small and/or localized Medium financial loss

health effect e.g., skin impact

rashes/ food poisoning ($2,000 - $10,000)

3. Moderate Medical Treatment Injury Lost time illness / Major Substantial High financial loss ($10,000 -

/ Restricted Work Case health effects / environmental impact $50,000)

Permanent partial

disability

4. Major Lost Time Injury or Lost time illness / Serious environmental Major financial loss ($50,000 -

Permanently Disabling Permanent disability impact. $500,000)

Injury

5. Catastrophic Fatality or Multiple Fatal disease – Disastrous and/or Huge financial loss (>$500,000)

Fatalities singular or multiple widespread

environmental impact.

Confined Space Operation PRO-04-0557 Page 9 of 9

You might also like

- The Healing Remedies SourcebookDocument433 pagesThe Healing Remedies Sourcebookgobitu100% (14)

- Working at Height Risk AssessmentDocument2 pagesWorking at Height Risk Assessmentvismay86% (7)

- JSA - RA 000-Water ProofingDocument5 pagesJSA - RA 000-Water ProofingNAGARJUNA100% (1)

- HIRA For Work at HeightDocument4 pagesHIRA For Work at Heightdinesattri100% (1)

- Measure and Integration: A Concise Introduction to Real AnalysisFrom EverandMeasure and Integration: A Concise Introduction to Real AnalysisNo ratings yet

- Distribution ReservoirsDocument14 pagesDistribution ReservoirsBinyam KebedeNo ratings yet

- Gas Porosity (GENERAL)Document28 pagesGas Porosity (GENERAL)Kmilo Giraldo100% (5)

- #402 Valve Overhauling in A Cargo TankDocument4 pages#402 Valve Overhauling in A Cargo TankTolias EgwNo ratings yet

- Yarn AssignmentDocument10 pagesYarn AssignmentHIMASHA SAMARANAYAKANo ratings yet

- #101 Anchoring & Weighing AnchorDocument6 pages#101 Anchoring & Weighing AnchorTolias Egw100% (1)

- AB8-ELE-54-HMO - Raw Water Pump Pullout For InspectionDocument2 pagesAB8-ELE-54-HMO - Raw Water Pump Pullout For Inspectionvikrant911No ratings yet

- #016 Underwater OperationsDocument3 pages#016 Underwater OperationsTolias Egw100% (1)

- Install 500 Ton Slips & ElevatorDocument1 pageInstall 500 Ton Slips & ElevatorAbdul Hameed OmarNo ratings yet

- AB8-ELE-05-HMO - PM On EM GeratorDocument2 pagesAB8-ELE-05-HMO - PM On EM Geratorvikrant911No ratings yet

- 1-Pedestal Crane MONTHLY Checklist Rev 04Document2 pages1-Pedestal Crane MONTHLY Checklist Rev 04ananthNo ratings yet

- #410 Heavy LiftDocument3 pages#410 Heavy LiftTolias EgwNo ratings yet

- #305 Tank Cleaning Operations - Cargo TanksDocument3 pages#305 Tank Cleaning Operations - Cargo TanksTolias EgwNo ratings yet

- AB8-ELE-75-HMO - Generator Dismantling For 5 Yearly MaintenanaceDocument2 pagesAB8-ELE-75-HMO - Generator Dismantling For 5 Yearly Maintenanacevikrant911No ratings yet

- #502 Tank Cleaning Operations - Engine DeptDocument3 pages#502 Tank Cleaning Operations - Engine DeptTolias EgwNo ratings yet

- Microbiology Facility QualificationDocument10 pagesMicrobiology Facility QualificationVilva Manikandan100% (1)

- Projectstoday Excel Services: Projects Added & ModifiedDocument131 pagesProjectstoday Excel Services: Projects Added & ModifiedRonak Panchal0% (1)

- Risk AssessmentDocument8 pagesRisk AssessmentJohn DNo ratings yet

- 1.08 Navigation in Restricted VisibilityDocument7 pages1.08 Navigation in Restricted Visibilitypokoko33% (3)

- Membrane Preparation Techniques AnisotropicDocument22 pagesMembrane Preparation Techniques AnisotropicAhammed Sherief Kizhakkethil YousephNo ratings yet

- #204 Navigation Through High Risk Piracy AreaDocument2 pages#204 Navigation Through High Risk Piracy AreaTolias EgwNo ratings yet

- #202 Navigation in Restricted VisibilityDocument2 pages#202 Navigation in Restricted VisibilityTolias EgwNo ratings yet

- Girbau HS4022 40 55 & 4110 TILTDocument6 pagesGirbau HS4022 40 55 & 4110 TILTValdir AzevedoNo ratings yet

- #106 Embarkation or Disembarkation Via LaunchesDocument4 pages#106 Embarkation or Disembarkation Via LaunchesTolias EgwNo ratings yet

- 9 RA Enclosed Space EntryDocument10 pages9 RA Enclosed Space EntryHitesh SiwachNo ratings yet

- Risk - Probability X Consequence Probability Consequence: How To Complete ERADocument35 pagesRisk - Probability X Consequence Probability Consequence: How To Complete ERAAadarshNo ratings yet

- Duct Laying RA 1Document10 pagesDuct Laying RA 1Senthilnathan NagarajanNo ratings yet

- Risk Assessment Guide 1Document3 pagesRisk Assessment Guide 1BaskyNo ratings yet

- AB8-ELE-73-HMO - Troubleshooting VFDDocument2 pagesAB8-ELE-73-HMO - Troubleshooting VFDvikrant911100% (1)

- Risk Assesment For LAB: Severity (S) Likelihood (L)Document9 pagesRisk Assesment For LAB: Severity (S) Likelihood (L)tnssbhaskarNo ratings yet

- #009 Hotwork-Welding On Pump Room - 01-03-10Document5 pages#009 Hotwork-Welding On Pump Room - 01-03-10Tolias EgwNo ratings yet

- #010 Hotwork-Cutting in Pump Room - 01-03-10Document6 pages#010 Hotwork-Cutting in Pump Room - 01-03-10Tolias EgwNo ratings yet

- JSA SC Treatment Injection SupervisionDocument3 pagesJSA SC Treatment Injection SupervisionShe DoelsNo ratings yet

- Sewer Plant Management and Operation Risk-AssessmentDocument33 pagesSewer Plant Management and Operation Risk-AssessmentvalveworkshseNo ratings yet

- Appendix 3 Environmental Aspects & Impacts RegisterDocument4 pagesAppendix 3 Environmental Aspects & Impacts RegisterHazim SyahmiNo ratings yet

- Environmental Aspects & Impacts Register 2023Document7 pagesEnvironmental Aspects & Impacts Register 2023Tamara Johnson-PariagNo ratings yet

- #013 Enclosed Space Entry 01-03-10Document4 pages#013 Enclosed Space Entry 01-03-10Tolias EgwNo ratings yet

- Practical Task (P) Composites)Document5 pagesPractical Task (P) Composites)Sri TharanNo ratings yet

- Appendix A. List of Abbreviations and AcronymsDocument29 pagesAppendix A. List of Abbreviations and AcronymsHina KarimNo ratings yet

- #107 Manual Handling - Deck DeptDocument6 pages#107 Manual Handling - Deck DeptTolias EgwNo ratings yet

- Risk Assessment RV 01-UDocument26 pagesRisk Assessment RV 01-Uabou bakarNo ratings yet

- #408 Steering Gear Overhaul or MaintenanceDocument3 pages#408 Steering Gear Overhaul or MaintenanceTolias EgwNo ratings yet

- RA Installation of Air Distribution Ducts Rev. 00Document14 pagesRA Installation of Air Distribution Ducts Rev. 00M AzharNo ratings yet

- Reactive Distillation: What, Why, and How?: Bob Huss East Tennessee AICHE Seminar Program November 17, 2015Document39 pagesReactive Distillation: What, Why, and How?: Bob Huss East Tennessee AICHE Seminar Program November 17, 2015Abdul Rahim KhanNo ratings yet

- #011 Hotwork-Welding Machinery Spaces - 01-03-10Document4 pages#011 Hotwork-Welding Machinery Spaces - 01-03-10Tolias EgwNo ratings yet

- Office Risk AssessmentDocument5 pagesOffice Risk AssessmentKedir DayuNo ratings yet

- Exp.3 Labs - CBRDocument24 pagesExp.3 Labs - CBRAiman Aqmal Bin Ahmad LutfeeNo ratings yet

- Exp.3 Labs - CBRDocument25 pagesExp.3 Labs - CBRAiman Aqmal Bin Ahmad LutfeeNo ratings yet

- AB8-ELE-04-HMO - PM On Mud Pumps Drive & Auxilary MotorsDocument2 pagesAB8-ELE-04-HMO - PM On Mud Pumps Drive & Auxilary Motorsvikrant911No ratings yet

- Basic Load CombinationsDocument4 pagesBasic Load CombinationsJheo TorresNo ratings yet

- R.A For Cleaning Sanitary Tanks (Underground)Document2 pagesR.A For Cleaning Sanitary Tanks (Underground)JemoNo ratings yet

- AB8-ELE-02-HMO - PM On DW Drive & AuxilaryDocument2 pagesAB8-ELE-02-HMO - PM On DW Drive & Auxilaryvikrant911No ratings yet

- Parra-Guevara 2021 J. Phys. Conf. Ser. 2090 012142Document17 pagesParra-Guevara 2021 J. Phys. Conf. Ser. 2090 012142BetoNo ratings yet

- Job Hazard Analysis Engineering Site Inspection 2Document5 pagesJob Hazard Analysis Engineering Site Inspection 2Nonsoufo ezeNo ratings yet

- Eli Reshotko Compressible Laminar BL StabilityDocument182 pagesEli Reshotko Compressible Laminar BL StabilityematlisNo ratings yet

- Effects of Ambient Temperature and Relative HumidiDocument19 pagesEffects of Ambient Temperature and Relative HumidiMeryl QuinteroNo ratings yet

- Hazard Identification, Risk Assessment and Determining Control AnalysisDocument6 pagesHazard Identification, Risk Assessment and Determining Control AnalysisKhaty JahNo ratings yet

- 28 - Del - Risk Management Considerate KineticDocument11 pages28 - Del - Risk Management Considerate KineticdelaunayNo ratings yet

- #004 Hot Work Cutting-Poop Deck Aft-01-03-10Document4 pages#004 Hot Work Cutting-Poop Deck Aft-01-03-10Tolias EgwNo ratings yet

- Ra Concrete Chipping 7514Document5 pagesRa Concrete Chipping 7514Charles DoriaNo ratings yet

- Eia Chapter 6.3 Methods of Impacts IdentificationDocument22 pagesEia Chapter 6.3 Methods of Impacts Identificationidamunfarida02100% (1)

- ENV KPC KPC MSE1.01 DOC TMPe 001Document13 pagesENV KPC KPC MSE1.01 DOC TMPe 001AgusNo ratings yet

- Trough Protection RA - RevDocument9 pagesTrough Protection RA - RevSenthilnathan NagarajanNo ratings yet

- Pre-Post Monsoon Inspection FormatDocument43 pagesPre-Post Monsoon Inspection FormatBHARATHNo ratings yet

- D160 Exxon Worksite Radiation ChecklistDocument10 pagesD160 Exxon Worksite Radiation ChecklistananthNo ratings yet

- Platform Emergency Plan Vs1Document1 pagePlatform Emergency Plan Vs1ananthNo ratings yet

- Contingency Organization Chart - Semi-TenderDocument2 pagesContingency Organization Chart - Semi-TenderananthNo ratings yet

- CH 5.18 - Avoidance of CollisionDocument4 pagesCH 5.18 - Avoidance of CollisionananthNo ratings yet

- V1.01 Daily Monitoring TemplateDocument3 pagesV1.01 Daily Monitoring TemplateananthNo ratings yet

- ISOS Coronavirus Disease 2019 - PPT Loop - v4Document10 pagesISOS Coronavirus Disease 2019 - PPT Loop - v4ananthNo ratings yet

- Movement Control by Government of MalaysiaDocument1 pageMovement Control by Government of MalaysiaananthNo ratings yet

- 1.well Control Workshop Presentation VHDocument28 pages1.well Control Workshop Presentation VHananthNo ratings yet

- Members Copy Team Western BicutanDocument72 pagesMembers Copy Team Western BicutanHomer BasagreNo ratings yet

- Magneto-Convective Non-Newtonian Nanofluid With Momentum and Temperature Dependent Slip Flow From A Permeable Stretching Sheet With Porous Medium and Chemical ReactionDocument18 pagesMagneto-Convective Non-Newtonian Nanofluid With Momentum and Temperature Dependent Slip Flow From A Permeable Stretching Sheet With Porous Medium and Chemical ReactionIOSRjournalNo ratings yet

- Material Balance PDFDocument5 pagesMaterial Balance PDFMayank VisalparaNo ratings yet

- Chapter 1 PowerPointDocument21 pagesChapter 1 PowerPointNauman LiaqatNo ratings yet

- Alcohol Gel (Aristoflex AVC) ProcedimientoDocument1 pageAlcohol Gel (Aristoflex AVC) ProcedimientoJanssen GomezNo ratings yet

- MSDS PPDocument11 pagesMSDS PPEduardo GarzaNo ratings yet

- Sabic Lldpe 118WJDocument3 pagesSabic Lldpe 118WJFahad MohamedNo ratings yet

- Curved Glass Testing Report RPT UvhDocument14 pagesCurved Glass Testing Report RPT UvhTj TalhaNo ratings yet

- Safety Data Sheet Soil-Off IIDocument14 pagesSafety Data Sheet Soil-Off IIGloria GarciaNo ratings yet

- Reviewer Quality ControlDocument25 pagesReviewer Quality ControlKC PalattaoNo ratings yet

- Motor PaintingDocument6 pagesMotor PaintingImran BagwanNo ratings yet

- An Assignment On Organizational Structure of VOLTASDocument7 pagesAn Assignment On Organizational Structure of VOLTASRaushan Kumar Naik100% (2)

- Regulation of Histidine and Hut OperonsDocument11 pagesRegulation of Histidine and Hut Operonsaditi_joshee419No ratings yet

- L2 - Nucleation and GrowthDocument14 pagesL2 - Nucleation and GrowthJagdeep Rahul100% (2)

- Exam 4 Review PDFDocument50 pagesExam 4 Review PDFT CNo ratings yet

- Pharma Compre SamplexDocument19 pagesPharma Compre SamplexStephanie BragatNo ratings yet

- Anti-Fungal Compound Library (96-Well) : Product DetailsDocument1 pageAnti-Fungal Compound Library (96-Well) : Product DetailsSenuke TestNo ratings yet

- Erbil H.Y. - Surface Chemistry of Solid and Liquid Interfaces (2006) (352s) - 12-21Document10 pagesErbil H.Y. - Surface Chemistry of Solid and Liquid Interfaces (2006) (352s) - 12-21amaterasu31416No ratings yet

- Argumentative EssayDocument2 pagesArgumentative EssayDianna BerishaNo ratings yet

- Wajid S Research PaperDocument6 pagesWajid S Research PaperMOGES ABERANo ratings yet

- AirLine Respirator MSA PDFDocument8 pagesAirLine Respirator MSA PDFbrecht1980No ratings yet