Professional Documents

Culture Documents

WPS 01 - Pipe - SS

Uploaded by

Advanced Quality Centre AQCOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

WPS 01 - Pipe - SS

Uploaded by

Advanced Quality Centre AQCCopyright:

Available Formats

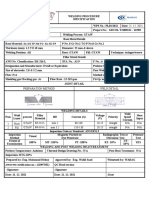

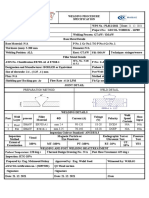

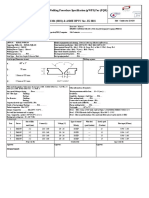

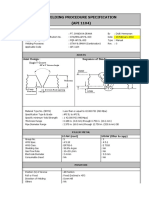

SABARI WELDING PROCEDURE SPECIFICATION (WPS)

ENGINEERING as per ASME BPVC Section IX, 2019

CONTRACTORS (applicable to any P No.8 Stainless Steel Pipe & Plate)

Material specification/ Grade : SS 304L or similar to SS 304 L or similar

Company : Sabari Engineering Contractors WPS No : SEC/WPS/GMAW/SS/001

Location : Coimbatore, Tamilnadu, India Rev No. :0

Standard : ASME BPVC Section IX,2019 Date : 15.09.2022

Process : GMAW (Manual) Ref. PQR No. : SEC/PQR/GMAW/SS/001, Rev. 0

Edge preparation : Single V Pre heat temperature : 24 °C (min)

Welding direction : Down hill Check Method : Contact or Infrared Thermometer

Positions : All Positions Inter run temperature : 85°C (max)

Thickness qualified : 1.5 mm to 6 mm PWHT : N/A

Dia. Qualified : Any Diameter Hold : N/A

Sketch Joint details

Joint details : Pipe to Pipe, single V Butt

Root gap : 1 to 2mm

Root face : 1 mm

Incl. angle : 60 ° + 5°

Backing : With or without

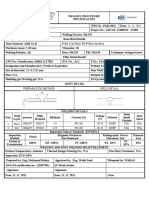

Welding Consumables:

Filler Metal Specification (root) : ER 308 L or any with F number-5 Remainder : ER 308 L

Classification :F#6 SFA: 5.9 Remainder : not listed

Shielding gas : Argon (99.9%) Shielding Flow rate : 10-18 LPM

Purge gas : Argon (99.9 %) Purging Flow rate : 5-10 LPM

Flux : N/A Make : Any

Weld run details Weld parameters

Filler Dia Inter Pass Amp Volt Current/ Speed Heat Input

Pass No. Side Process φ (mm) Temp (°C) (I) (V) Polarity (mm/min) (KJ/mm)

Root Single GMAW 1.2 mm Ambient 145-155 14.5-15.0 DC/ EP 70.28 1.58

Hot Single GMAW 1.2 mm 85 max 158-168 15.1-15.4 DC/ EP 85.45 1.45

Fill Single GMAW 1.2 mm 85 max 158-168 15.2-15.5 DC/EP 97.26 1.27

Technique : Single or Multi-run Stringer/ weave : Weave

Initial cleaning : Grinding Electrode Stick out : 17 mm

Inter run cleaning : Grinding, chisel and wire brush Back gouge : N/A

Tungsten elect. Size : N/A Gouge check : N/A

Wire feed rate : 200 IPM Maximum weave width : 10 mm

Notes/ Revisions:

The Procedure is also applicable to Fillet weld of any size and any base metal thickness as per clause QW-45.4, ASME BPVC Sec IX,2019

Prepared by Approved by

C.Vigneshwaran

(CSWIP3.1, API 510, ASNT Level II)

SABARI ENGINEERING CONTRACTORS Advanced Quality Centre

Page 1 of 1

AQC/WPS/ASME/ISO/FMT/002, Rev0 , Advanced Quality Centre, Coimbatore, Ph. 04224342244, +91 9489342244, email: info@aqcinspection.com

You might also like

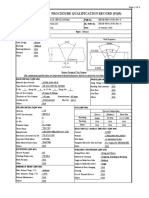

- Sabari Engineering PQRDocument3 pagesSabari Engineering PQRAdvanced Quality Centre AQC100% (1)

- WPS-2 InchDocument2 pagesWPS-2 InchKarthikeyan MpNo ratings yet

- Preliminary Welding Procedure Specification (PWPS)Document2 pagesPreliminary Welding Procedure Specification (PWPS)Maneesh0% (1)

- Preliminary Welding Procedure Specification (PWPS) : South Pars Gas Field Development Phase 14Document2 pagesPreliminary Welding Procedure Specification (PWPS) : South Pars Gas Field Development Phase 14Vijaya BaraniNo ratings yet

- Procedure Qualification SpecificationDocument4 pagesProcedure Qualification Specificationriyas.hvacworkNo ratings yet

- Pessing Libya INC: Fill: FCAW Sfa. No: 5.18&5.20 Post Weld Heat treatment:N/ADocument1 pagePessing Libya INC: Fill: FCAW Sfa. No: 5.18&5.20 Post Weld Heat treatment:N/AMahmoud HaggagNo ratings yet

- Welding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test CertificateDocument3 pagesWelding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test Certificateramesh rajaNo ratings yet

- Welding Procedure Specification GuideDocument2 pagesWelding Procedure Specification GuidepoulmackNo ratings yet

- WPQR Welding Procedure Qualification RecordsDocument3 pagesWPQR Welding Procedure Qualification Recordsramesh rajaNo ratings yet

- PQR 3G Fcaw SF71Document3 pagesPQR 3G Fcaw SF71long phamNo ratings yet

- Pessing Libya INC: Fill: GTAW Sfa. No: 5.14 Post Weld Heat Treatment: N/ADocument1 pagePessing Libya INC: Fill: GTAW Sfa. No: 5.14 Post Weld Heat Treatment: N/AMahmoud HaggagNo ratings yet

- Welding Procedure Qualification Records (WPQR) GuideDocument3 pagesWelding Procedure Qualification Records (WPQR) Guideramesh rajaNo ratings yet

- 螢幕截圖 2022-12-30 上午9.17.25Document1 page螢幕截圖 2022-12-30 上午9.17.25Dave CheungNo ratings yet

- Welding Procedure Specification: ST NDDocument1 pageWelding Procedure Specification: ST NDMaung SleeperNo ratings yet

- PQR Procedure Qualification Record Krishna SteelDocument2 pagesPQR Procedure Qualification Record Krishna SteelHarshit Adwani100% (2)

- WPS & PQRDocument13 pagesWPS & PQRValentin RadulescuNo ratings yet

- Welding Procedure Qualification Record (WPQR) (ISO 15614-1-2017)Document3 pagesWelding Procedure Qualification Record (WPQR) (ISO 15614-1-2017)ramesh rajaNo ratings yet

- WELDING PROCEDURE SPECIFICATION FOR TIE-IN WORKSDocument6 pagesWELDING PROCEDURE SPECIFICATION FOR TIE-IN WORKSAshishNo ratings yet

- WPS SampleDocument6 pagesWPS SampleAshishNo ratings yet

- Pessing Libya INC: SA 312 TP 316 TO SA 312 TPDocument1 pagePessing Libya INC: SA 312 TP 316 TO SA 312 TPMahmoud HaggagNo ratings yet

- PhuBia-WPS-AWS D1.1-8-6-2011Document3 pagesPhuBia-WPS-AWS D1.1-8-6-2011poulmack100% (1)

- PQR - Gmaw BCCDocument2 pagesPQR - Gmaw BCCBasel MohammadNo ratings yet

- Pessing Libya INC: Weld Detail Preparation MethodDocument1 pagePessing Libya INC: Weld Detail Preparation MethodMahmoud HaggagNo ratings yet

- Pessing Libya INC: Weld Detail Preparation MethodDocument1 pagePessing Libya INC: Weld Detail Preparation MethodMahmoud HaggagNo ratings yet

- Pessing Libya INC: Sfa. No: A5.9Document1 pagePessing Libya INC: Sfa. No: A5.9Mahmoud HaggagNo ratings yet

- Welding Procedure Specification (WPS) : Standard Applicable: BS EN ISO 15609 1:2019 & BS EN ISO 15614 1: 2017 Level 2Document2 pagesWelding Procedure Specification (WPS) : Standard Applicable: BS EN ISO 15609 1:2019 & BS EN ISO 15614 1: 2017 Level 2phong NguyenduyNo ratings yet

- Pessing Libya INC: Fill: SMAW Sfa. No: 5.28 & 5.1 Post Weld Heat Treatment: 655 Deg CDocument1 pagePessing Libya INC: Fill: SMAW Sfa. No: 5.28 & 5.1 Post Weld Heat Treatment: 655 Deg CMahmoud HaggagNo ratings yet

- WPS PQR FormulirDocument2 pagesWPS PQR FormulirAZaiNo ratings yet

- Pessing Libya INC: As Per P No.3,4 To As Per P No.3,4Document1 pagePessing Libya INC: As Per P No.3,4 To As Per P No.3,4Mahmoud HaggagNo ratings yet

- Pqr-Band Ring PDFDocument3 pagesPqr-Band Ring PDFamitNo ratings yet

- Pessing Libya INC: Fill: SMAW Sfa. No: 5.28 & 5.1 Post Weld Heat Treatment: 655 Deg CDocument1 pagePessing Libya INC: Fill: SMAW Sfa. No: 5.28 & 5.1 Post Weld Heat Treatment: 655 Deg CMahmoud HaggagNo ratings yet

- Pessing Libya INC: Fill: SMAW Sfa. No: 5.28&5.5 Post Weld Heat Treatment: 620-650 Deg CDocument1 pagePessing Libya INC: Fill: SMAW Sfa. No: 5.28&5.5 Post Weld Heat Treatment: 620-650 Deg CMahmoud HaggagNo ratings yet

- WPS - Merd-01Document3 pagesWPS - Merd-01Phuong NguyenNo ratings yet

- Welding Procedure Specification Sample - New EditionDocument2 pagesWelding Procedure Specification Sample - New EditiondanteNo ratings yet

- PQR 03 2014Document2 pagesPQR 03 2014vinuNo ratings yet

- PQR FLow LineDocument2 pagesPQR FLow Linesar sarNo ratings yet

- WPS GF170 As 1554.6Document1 pageWPS GF170 As 1554.6Syed Mahmud Habibur Rahman100% (1)

- Nisoc: Preliminary Welding Procedure Specification (PWPS) For (PQR)Document3 pagesNisoc: Preliminary Welding Procedure Specification (PWPS) For (PQR)pejman.imaniNo ratings yet

- WPS - 600 MW ChampaDocument7 pagesWPS - 600 MW ChampaAmjad PathanNo ratings yet

- Wps Aws d1.1 NEWDocument2 pagesWps Aws d1.1 NEWIkhy Tohepaly100% (1)

- Draft WPS For Carbon Steel PipeDocument2 pagesDraft WPS For Carbon Steel Pipeabet_singkong893025% (4)

- PQR DT Macro 60mm Smaw Astm A 516 Gr60Document4 pagesPQR DT Macro 60mm Smaw Astm A 516 Gr60Boran YelkenciogluNo ratings yet

- Draft WPS Welder R0Document51 pagesDraft WPS Welder R0R Bernanda Argandhi SaputraNo ratings yet

- Runsheet WPQT ModernDocument9 pagesRunsheet WPQT ModernYUDI IRMAWANTONo ratings yet

- WPS ExampleDocument2 pagesWPS ExampleMarcio Jr.No ratings yet

- QW 482 WPSDocument2 pagesQW 482 WPSsmit patelNo ratings yet

- Kaushik Shah Date: 2011 Form 001 - Format CDocument6 pagesKaushik Shah Date: 2011 Form 001 - Format CsriramNo ratings yet

- AWS D1.1 WPS for Butt Joint SMAW ProcedureDocument2 pagesAWS D1.1 WPS for Butt Joint SMAW ProcedureWahyu Lailil FaisNo ratings yet

- Form Wps JBL09-2011Document2 pagesForm Wps JBL09-2011fawad aliNo ratings yet

- Bridge & Roof Co - (I) LTD: Iocl Tankage Work (M&I) in PHBPL Paradip, OdishaDocument5 pagesBridge & Roof Co - (I) LTD: Iocl Tankage Work (M&I) in PHBPL Paradip, Odishaniraj mouryaNo ratings yet

- Welding Procedure SpecificationDocument3 pagesWelding Procedure SpecificationVISAKHAPATNAM MALAYALEES WELFARE ASSOCIATIONNo ratings yet

- Welding Process: Mma/Smaw TYPES: Manual: Preliminary Welding Procedure Specification (PWPS) Nama: Shah Nadzri Bin JasmirDocument3 pagesWelding Process: Mma/Smaw TYPES: Manual: Preliminary Welding Procedure Specification (PWPS) Nama: Shah Nadzri Bin Jasmirshahaljawaie87100% (2)

- WPS for Welding HY80 SteelDocument2 pagesWPS for Welding HY80 Steelsrb metallurgNo ratings yet

- DraftDocument32 pagesDraftAnilkumarNo ratings yet

- WB920410(20)Document1 pageWB920410(20)nima mniNo ratings yet

- ARL-AL-WPS-001 welding procedureDocument2 pagesARL-AL-WPS-001 welding procedurerajuajiNo ratings yet

- 07.3 111 FW ML PF WPS 20mm EngDocument1 page07.3 111 FW ML PF WPS 20mm EngViktorNo ratings yet

- Essential welding procedure qualification recordDocument2 pagesEssential welding procedure qualification recordmainur mechanical engineer0% (1)

- WCBDocument5 pagesWCBSuresh KrishnanNo ratings yet

- Greenville Chapter NRHS Aug 2009 NewsletterDocument8 pagesGreenville Chapter NRHS Aug 2009 Newsletterjshopper1No ratings yet

- Set 1Document4 pagesSet 1insan biasaNo ratings yet

- Compound Sentences FANBOYS WorksheetDocument7 pagesCompound Sentences FANBOYS WorksheetVerenice SuarezNo ratings yet

- mPassBook 161022 150423 2918Document4 pagesmPassBook 161022 150423 2918Ashish kumarNo ratings yet

- DENR CC 2022 1st - Edition FIN 25 - March - 2022Document234 pagesDENR CC 2022 1st - Edition FIN 25 - March - 2022CENRO BANGUED PLANNINGNo ratings yet

- Auditing Case 3Document12 pagesAuditing Case 3Kenny Mulvenna100% (6)

- April 2016Document4 pagesApril 2016Albert CorderoNo ratings yet

- Llave de Impacto PDFDocument21 pagesLlave de Impacto PDFmasterfiera1No ratings yet

- 4 Way Test of The Things We Think, Say or DoDocument5 pages4 Way Test of The Things We Think, Say or DoObakoma JosiahNo ratings yet

- Del Monte Golf Club in BukidnonDocument1 pageDel Monte Golf Club in BukidnonJackieNo ratings yet

- SPE Estimating Fracture Gradient in Gulf of Mexico Deepwater, Shallow, Massive Salt SectionsDocument9 pagesSPE Estimating Fracture Gradient in Gulf of Mexico Deepwater, Shallow, Massive Salt SectionsTHiago LOpesNo ratings yet

- Segilola Gold ProjectDocument11 pagesSegilola Gold ProjectaishaNo ratings yet

- RELATED STUDIES AND LITERATURE ON EGGSHELL POWDER USE IN CONCRETEDocument5 pagesRELATED STUDIES AND LITERATURE ON EGGSHELL POWDER USE IN CONCRETEReiBañez100% (2)

- Maputo Port Approach Passage PlanDocument1 pageMaputo Port Approach Passage PlanRitesh ChandraNo ratings yet

- 4 - ASR9K XR Intro Routing and RPL PDFDocument42 pages4 - ASR9K XR Intro Routing and RPL PDFhem777No ratings yet

- Pangilinan, Zobel de Ayala, Sy Sr., Dangote, Rupert, Jameel - Power and influence of business leaders in Asia and AfricaDocument20 pagesPangilinan, Zobel de Ayala, Sy Sr., Dangote, Rupert, Jameel - Power and influence of business leaders in Asia and AfricaGwenNo ratings yet

- Storytelling Tips from Salesforce CEO Marc BenioffDocument2 pagesStorytelling Tips from Salesforce CEO Marc BenioffvsrajkumarNo ratings yet

- Product Data Sheet: Standard Auxiliary Contact, Circuit Breaker Status OF/SD/SDE/SDV, 1 Changeover Contact TypeDocument2 pagesProduct Data Sheet: Standard Auxiliary Contact, Circuit Breaker Status OF/SD/SDE/SDV, 1 Changeover Contact TypeChaima Ben AliNo ratings yet

- 2021 Subsector OutlooksDocument24 pages2021 Subsector OutlooksHungNo ratings yet

- Lb-Xp12-350-Pd-En-V1.3-201912 - EquivalenteDocument2 pagesLb-Xp12-350-Pd-En-V1.3-201912 - EquivalenteDaniel Oliveira Freitas RochaNo ratings yet

- Nevada Reports 1882-1883 (17 Nev.) PDFDocument334 pagesNevada Reports 1882-1883 (17 Nev.) PDFthadzigsNo ratings yet

- Bayes Slides1Document146 pagesBayes Slides1Panagiotis KarathymiosNo ratings yet

- Kami Export - Exercise Lab - Mini-2Document3 pagesKami Export - Exercise Lab - Mini-2Ryan FungNo ratings yet

- The Difficult Patient' As Perceived by Family Physicians: Dov Steinmetz and Hava TabenkinDocument6 pagesThe Difficult Patient' As Perceived by Family Physicians: Dov Steinmetz and Hava TabenkinRomulo Vincent PerezNo ratings yet

- IWR 0174 Ed12 - Jabra Headsets Amplifiers - OmniPCXplatforms - SoftphonesDocument83 pagesIWR 0174 Ed12 - Jabra Headsets Amplifiers - OmniPCXplatforms - SoftphonesAsnake TegenawNo ratings yet

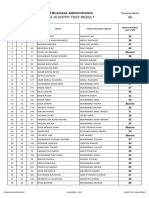

- Entry Test Result MPhil 2014 PDFDocument11 pagesEntry Test Result MPhil 2014 PDFHafizAhmadNo ratings yet

- A Study On Consumer Changing Buying Behaviour From Gold Jewellery To Diamond JewelleryDocument9 pagesA Study On Consumer Changing Buying Behaviour From Gold Jewellery To Diamond JewellerynehaNo ratings yet

- Study of The Pre-Processing Impact in A Facial Recognition SystemDocument11 pagesStudy of The Pre-Processing Impact in A Facial Recognition Systemalmudena aguileraNo ratings yet

- ADUHAI @herman & Rhoca - Lyrics and Music by Rhoma Irama Arranged by - HERMAN - BOY - SmuleDocument4 pagesADUHAI @herman & Rhoca - Lyrics and Music by Rhoma Irama Arranged by - HERMAN - BOY - SmuleHERMAN BOYNo ratings yet

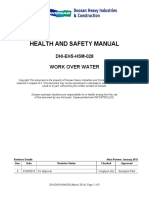

- Dhi-Ehs-Hsm-028 Work Over Water Rev0Document5 pagesDhi-Ehs-Hsm-028 Work Over Water Rev0Phạm Đình NghĩaNo ratings yet