Professional Documents

Culture Documents

Pipeline Cut-Out Procedure

Uploaded by

mahmoudOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pipeline Cut-Out Procedure

Uploaded by

mahmoudCopyright:

Available Formats

Pipeline Cut-Outs

Doc. No.: <DocumentNumber*

Revision No.: 1

Release Date: 02/22/2017

PURPOSE and SCOPE

This subject outlines the procedure for cutting out a section of pipeline when

required. As a standing rule, cold equipment is used at TNPI if cutting into a line

that has been operational.

Cold cuts are performed on the pipeline in order to remove a section of pipe for

new installations of piping or equipment, rerouting the pipeline or to replace

defective pipe sections. No electrical or hot equipment is used.

Before cold cutting can be done, the pipeline section must be shut down, isolated

and drained or purged of product Once the pipeline has been cut open, any

trapped product has been drained and removed and the atmosphere has tested

safe, you can continue with the next portion of the work using power equipment

and/or torches.

Cold cutting on the pipeline will usually be only one part of a larger scope of

work. This procedure, along with procedures covering the other aspects of the

scope of work, such as work area protection and co-ordination of multiple crews

will have to be considered when doing a risk assessment and developing a

written plan or Job Specific Execution Plan.

REFERENCES

Procedure - Safe Work Permits

Procedure- Penetration of Pressure Piping

Procedure- Nitrogen Purging

Procedure- Drain Down Pipeline

Procedure- Excavating and Excavations Greater than 1.2M

Engineering Procedure- Section 9- Welding Procedures

ASSOCIATED DOCUMENTS

Form - Safe Work-Confined Space Entry Permit

Uncontrolled when printed Page 1 of 7

Pipeline Cut-Outs

Doc. No.: <DocumentNumber*

Revision No.: 1

Release Date: 02/22/2017

DEFINITIONS

The Cold Cutting equipment used to cut pipelines are a much larger version of

the simple tool used by plumbers to cut copper pipe.

EXAMPLE OF A HAND OPERATED PIPE CUTTING TOOL. Suitable for cutting

piping up to 42” in diameter.

Competent or Qualified

An appointed, authorized or designated person who has knowledge and

understanding, through experience and training on specific equipment that

is sufficient to meet all job requirements as determined by the employer.

PROCEDURE DETAILS

Hazards and Precautions:

1. A Safety Supervisor (Safety Watch) is required during a Pipeline

Cutout as per the TNPI Safety Manual, Piping systems tend to stay

electrically charged for a period of time after the cathodic systems

have been de-energized, and may be bonded to other piping systems.

The cathodic protection should be powered off, where possible with a

discharge time of 24 hours prior to the cut0out work.

2. Bonding cables shall be used when breaking apart piping and draining

hydrocarbons to another vessel (e.g. truck, metal pail) to prevent

ignition hazards. Grounding should also be used to equalize work area

potentials.

Uncontrolled when printed Page 2 of 7

Pipeline Cut-Outs

Doc. No.: <DocumentNumber*

Revision No.: 1

Release Date: 02/22/2017

3. Some springing from misalignment, especially in pipeline risers, should

be expected.

4. Care should be taken to prevent sparks from mechanical ditching if the

soil is contaminated with oil, particularly if it contains high levels of light

ends.

5. If the pipeline is damaged, whenever possible, the damage should be

repaired temporally with a Plidco sleeve, or equivalent and the lines

should be purged of fluid.

Site Preparation:

1. The job coordinator will:

a. specify the location at which the cut out is being performed

b. arrange for the required section of pipeline to be exposed

c. schedule downtime through the Products Movement department

d. arrange for isolation of section of line with four nearest block

valves (two each upstream and downstream)

e. arrange for purging of the line or drain down as appropriate.

f. prepare a Job Specific written plan and complete a Risk

Assessment as required.

2. Prepare work site and arrange for equipment to be on site in advance

of the cut out date.

3. Review procedures and job specific execution plan and tour site(s) to

understand specific job requirements.

4. Excavate if required and fence the site if it is to be left unguarded.

Ensure excavation is wide, deep and long enough for adequate work

access. At the cut out points, ensure there is adequate clearance

below the pipeline for the cutter to work. Take into consideration water

accumulation and removal when excavating, prepare excavation

accordingly.

SUGGESTED TOOLS & SAFETY EQUIPMENT that may be required:

1. Pipe cutters and handle (as appropriate for size of pipe)

2. Extra cutting wheels

3. Bonding clamps and length of bonding cable

4. Knives and files

5. Drip tubs and tarps and absorbent

6. Fire extinguishers

7. 4 gas atmosphere monitors

Uncontrolled when printed Page 3 of 7

Pipeline Cut-Outs Critical

Doc. No.: 005704

Revision No.:

Release Date: 02/22/2017

PROCEDURE

Applicable Responsible

Yes/No Person

1)_____ ENSURE all pre-planning is complete.

a. _____ ENSURE all appropriate site preparations are

complete and all required tools and equipment are

available such as:

i. EXCAVATION is complete (COMPLETE Ground

Disturbance Checklist.)

ii. ISOLATIONS (4 valves if possible) is complete.

(COMPLETE Lockout List.)

iii. DRAIN DOWN or PURGING is complete

iv. EQUIPMENT is in place including required

firefighting equipment for contingency plans

v. HOLD a tailgate meeting with all personnel

involved.

ENSURE Safety Supervisor (Safety Watch) is available as per:

Safety Manual: ENSURE all required PPE is being used

ENSURE the atmosphere in the excavation(s) is being continuously

monitored.

ENSURE communication is completed involving all other parties.

2)_____ POSITION tarps and drip tubs under proposed

section(s) of pipe to be cut.

a. _____ ENSURE proper bonding and grounding.

3)_____ ENSURE vacuum truck is ready to assist with spills.

a. _____ HOSES in trench at appropriate locations

b. _____ OPERATOR is on standby

c. _____ SUFFICIENT capacity in tanks for potential spill

d. _____ TRUCK is grounded, hose joints are secure

4)_____ REMOVE coating and primer from pipe sections

upstream and downstream for bonding cable

installation.

a. _____ REMOVE sufficient section of coating for

installation of proper bonding

Uncontrolled when printed Page 4 of 7

Pipeline Cut-Outs Critical

Doc. No.: 005704

Revision No.:

Release Date: 02/22/2017

5)_____ INSTALL bonding clamps with cable: (cable is

connected from exposed section of pipe on one side of

cutting site to exposed section of pipe on other side of

cutting site, contact points on pipe should be at girth

welds).

a. _____ CHECK for continuity

b. _____ ENSURE a good bond

6)_____ REMOVE pipe coating from area(s) of cold cut(s).

7)_____ INSTALL skids and drip tub under pipe and:

a. _____ STABILIZE pipe with boom crane and slings.

b. _____ INSTALL on one or both sides of expected cut

as appropriate to prevent pipe from moving or swinging

after cut is completed.

8)_____ ENSURE pipe penetration is complete if required (

SEE: Procedure- Penetration of Pressure Piping)

a. _____ ENSURE pipe atmosphere has been tested.

9)_____ INSTALL cold cutters around pipe.

a. _____ ENSURE both adjustment screws are evenly

set.

10)_____ START cold cutting:

a. _____ INSERT handle into protrusions and pulling

down

b. _____ ENSURE other members of work crew are clear

of ditch

c. _____ ENSURE anyone in ditch is clear of free side

(after cut)

11)_____ COMPLETE cold cut:

a. _____ CONTINUE to rotate cold cutter around pipe,

increasing depth of cut frequently.

b. _____ OBSERVE for completion of cold cutting:

i. Residual product may spill around cut.

ii. Pipe tends to swing down and sideways after

cut.

Uncontrolled when printed Page 5 of 7

Pipeline Cut-Outs Critical

Doc. No.: 005704

Revision No.:

Release Date: 02/22/2017

12)_____ REMOVE cutting tool by backing off the adjusting

screws.

13)_____ REMOVE any residual product from pipe at cold cut

location.

a. _____ LOWER pipe if required.

14)_____ COMPLETE all scheduled cold cuts required by scope

of work.

Sometimes it is necessary to cut the piping back further. If this is required, the preferred method

is cold cutting. Hot cutting can be done, but not until the appropriate gas testing is completed.

15)_____ IF the planned cut is greater than 30 cm back from the

open pipe, i.e., the initial cold cut, a re-penetration of

the pipe is required for proper gas testing.

a. _____ REFER to Procedure- Penetration of Pressure

Piping

16)_____ INFORM appropriate parties, when cold cutting is

complete and pipe atmosphere has been tested, that

the remaining scope of work can commence as per the

Job Specific Execution Plan or written plan.

a. _____ INSTALL Gel or Vented Plugs if necessary.

b. _____ VENT both ends of the pipeline if gel plugs are

used.

17)_____ CLEAN and repair tools as required.

a. _____ RETURN tools to appropriate storage location.

Installation of New Pipe

18)_____ HYDROSTATICALLY TEST the pipe section to be

used for repair in the preparation phase to ensure that

the new pipe meets the specifications of the existing

pipe.

19)_____ PREPARE the replacement section for venting if required.

20)_____ by exceptional circumstances

a. _____ INSTALL a weldolet to allow venting on short

replacement sections.

Uncontrolled when printed Page 6 of 7

Pipeline Cut-Outs Critical

Doc. No.: 005704

Revision No.:

Release Date: 02/22/2017

21)_____ WELD IN the replacement section.

a. _____ USE the proper welding procedure appropriate

to the type of pipe being welded. Refer to Engineering

Procedures Section 9, Welding Procedures.

b. _____ ENSURE proper pipeline alignments before

welding.

c. _____ INSTALL a vent plug and back weld if venting

was required.

22)_____ REMOVE bonding cables when all work has been

completed.

23)_____ CO-ORDINATE non-destructive examination services

and complete radiography work.

a. _____ 100 % x-ray on tie-in welds is required.

magnetic particle and ultrasonic inspection of weldolet and

seal welds required to confirm integrity

24)_____ COAT the repair section with the appropriate coating.

a. _____ SEAL the weldolet and plug if applied

25)_____ COMPLETE Tie-In record including reference to pipe

and heat numbers, hydrostatic test records,

dimensions, reference weld, new weld NDE records,

GPS co-ordinates, etc.

26)_____ COMPLETE back-filling and area clean-up.

a. _____ ENSURE that all contaminated soil has been

removed from the site in accordance with provincial

waste management requirements.

27)_____ RE-ENERGIZE the cathodic protection system.

28)_____ FORWARD the removed section for analysis as

required.

29)_____ FOLLOW re-commissioning steps in Procedure- Drain

Down Pipeline.

APPENDIX:

There are no attachments to this procedure.

Uncontrolled when printed Page 7 of 7

You might also like

- Blanking and Blinding PracticeDocument8 pagesBlanking and Blinding PracticeBabyface888100% (1)

- Method Statement For Plumbing WorksDocument4 pagesMethod Statement For Plumbing WorksVeronica De JesusNo ratings yet

- TS For Pipe-Duct DismantlingDocument10 pagesTS For Pipe-Duct DismantlingAmitava SilNo ratings yet

- Method Statement For Conduits WiringDocument8 pagesMethod Statement For Conduits WiringÖmeralp SakNo ratings yet

- Pipeline Maintenance ProceduresDocument55 pagesPipeline Maintenance Procedurestenneti CHALAPATHY RAONo ratings yet

- 13-OM-QC-PL-MS-06 - MS FIXED TUBE TYPE EXCHANGER'S INSPECTION & CLEANING (Rev.00)Document7 pages13-OM-QC-PL-MS-06 - MS FIXED TUBE TYPE EXCHANGER'S INSPECTION & CLEANING (Rev.00)SANDEEP100% (1)

- Method Statement Pipe Handling and AssemblyDocument6 pagesMethod Statement Pipe Handling and AssemblyDanny NguNo ratings yet

- Method of StatementDocument9 pagesMethod of StatementSunil Anto100% (2)

- Method Statement For Sprinkler & Stand PipeDocument7 pagesMethod Statement For Sprinkler & Stand Pipeguruupto100% (1)

- MST For Below Ground UPVC Drainage PipesDocument13 pagesMST For Below Ground UPVC Drainage Pipesمقاول تكييف كهرباء وصحيNo ratings yet

- Nitrogen Purging ProcedureDocument22 pagesNitrogen Purging ProcedureAndrea HernandezNo ratings yet

- Amended MS For Pipe DemolationDocument5 pagesAmended MS For Pipe DemolationahmadNo ratings yet

- Ledge Wall ConstructionDocument3 pagesLedge Wall ConstructionGabriel Gabe100% (1)

- Method Statement For Pre FabricationDocument5 pagesMethod Statement For Pre FabricationFs67% (3)

- Method Statement For Fabrication and Erection of Piping: Krueng Geukueh, North Aceh, IndonesiaDocument10 pagesMethod Statement For Fabrication and Erection of Piping: Krueng Geukueh, North Aceh, IndonesiaFendik NewbieNo ratings yet

- Floating Head Exchanger Cleaning MethodDocument7 pagesFloating Head Exchanger Cleaning MethodSANDEEPNo ratings yet

- Pipes Welding Works MS For Stream 56&57 - Flare8&12 InchDocument6 pagesPipes Welding Works MS For Stream 56&57 - Flare8&12 InchahmadNo ratings yet

- 14) SWP-14 Concrete Core Drilling MachineDocument4 pages14) SWP-14 Concrete Core Drilling MachineFIKdtec duplicateNo ratings yet

- Pipes Cladding and Insullations MSDocument8 pagesPipes Cladding and Insullations MSahmadNo ratings yet

- Method Statement Refrigerant Copper PipingDocument9 pagesMethod Statement Refrigerant Copper PipingWasim AhmedNo ratings yet

- Pipework Maintenance: 15.1 Maintenance-Key To Trouble-Free ServiceDocument6 pagesPipework Maintenance: 15.1 Maintenance-Key To Trouble-Free ServiceAde Sari TrianaNo ratings yet

- Method Statement For Prestressing I-Girder CastingDocument6 pagesMethod Statement For Prestressing I-Girder CastingArifur Rahman Apu90% (10)

- Scope of WorkDocument6 pagesScope of WorkChukwuma Emmanuel OnwufujuNo ratings yet

- Damaged Spool Replacement GuideDocument12 pagesDamaged Spool Replacement GuideMohsen KeramatiNo ratings yet

- The Journal of Protective Coatings & Linings - Large-Diameter Cooling Water Pipe and Penstocks - Selecting and Applying LiningsDocument7 pagesThe Journal of Protective Coatings & Linings - Large-Diameter Cooling Water Pipe and Penstocks - Selecting and Applying Liningsemanuele.zanNo ratings yet

- Piping Design L-002Document20 pagesPiping Design L-002Prakhar Deep KulshreshthaNo ratings yet

- Procedure For Cable Laying - 03Document14 pagesProcedure For Cable Laying - 03RamaKrishna ANo ratings yet

- SS Piping Method StatementDocument10 pagesSS Piping Method StatementNishar BalkavadeNo ratings yet

- Method Statement For Installation of RO Skids Pressure Vessels and Connecting Pipes R1Document8 pagesMethod Statement For Installation of RO Skids Pressure Vessels and Connecting Pipes R1abimanyubawonoNo ratings yet

- 6.4 Procedure For InsulationDocument11 pages6.4 Procedure For Insulationrendra syamNo ratings yet

- LOCG-GEN-Guideline-007 Rev 0 - Offshore PipelinesDocument50 pagesLOCG-GEN-Guideline-007 Rev 0 - Offshore PipelinesTomkel Voon100% (1)

- Underground Sewers and Piping Installation ProceduresDocument7 pagesUnderground Sewers and Piping Installation ProceduresYusufNo ratings yet

- Hot Tap Procedure Checklist: Estlake VinylsDocument3 pagesHot Tap Procedure Checklist: Estlake VinylsNiraNo ratings yet

- Method statement for duct installationDocument7 pagesMethod statement for duct installationShaikh MateenNo ratings yet

- 23 0700 - HVAC InsulationDocument38 pages23 0700 - HVAC InsulationMohamedHanyNo ratings yet

- 16-OM-QC-PL-MS-06 - MS FLOATING HEAD TYPE EXCHANGER'S INSPECTION & CLEANING (IRIS, ECT) (Rev.00)Document7 pages16-OM-QC-PL-MS-06 - MS FLOATING HEAD TYPE EXCHANGER'S INSPECTION & CLEANING (IRIS, ECT) (Rev.00)SANDEEPNo ratings yet

- DOP 206 - Rev 4Document12 pagesDOP 206 - Rev 4Fernando AybarNo ratings yet

- Design Basis For Fire-Fighting SystemDocument10 pagesDesign Basis For Fire-Fighting Systemsohail1985100% (2)

- Shell Petroleum Cable Trench ProjectDocument7 pagesShell Petroleum Cable Trench ProjectOGBONNAYA MARTINS100% (1)

- ONGC Effluent Plant Pipe Installation GuideDocument14 pagesONGC Effluent Plant Pipe Installation GuideNithin Mathai100% (1)

- Pcsa Checklist Cross Country PipelinesDocument22 pagesPcsa Checklist Cross Country PipelinesAnoop PrajapatiNo ratings yet

- Method Statement For NITROGEN PURGING (SAMPLE)Document12 pagesMethod Statement For NITROGEN PURGING (SAMPLE)Hasann MaawiaNo ratings yet

- MICROTUNNELING AND PIPE JACKING CONSTRUCTION SPECIFICATIONDocument16 pagesMICROTUNNELING AND PIPE JACKING CONSTRUCTION SPECIFICATIONadalcayde2514No ratings yet

- Method Statement For Roofing WorksDocument4 pagesMethod Statement For Roofing WorksVeronica De JesusNo ratings yet

- 13 PiggingDocument14 pages13 PiggingDaniel DamboNo ratings yet

- Report of The Inspection Carried Out On Construction of byDocument4 pagesReport of The Inspection Carried Out On Construction of byaloysius akpanNo ratings yet

- MOS - Fire FightingDocument23 pagesMOS - Fire FightingMohammad Hadoumi SaldanNo ratings yet

- Re-Welding, Expansion & HT ProcedureDocument6 pagesRe-Welding, Expansion & HT Proceduresuria qaqcNo ratings yet

- Factory Applied External Pipeline Coatings For Corrosion ControlDocument32 pagesFactory Applied External Pipeline Coatings For Corrosion ControlMatt AgonyaNo ratings yet

- Method Statement For FormworkDocument8 pagesMethod Statement For FormworkEng hassan hussienNo ratings yet

- MUK-62-MGT-AIC-09004 Rev A WTP Install. & Erec. Proc. 110314Document36 pagesMUK-62-MGT-AIC-09004 Rev A WTP Install. & Erec. Proc. 110314Suresh MahalingamNo ratings yet

- Welding & Cutting SOPDocument16 pagesWelding & Cutting SOPmahandhieNo ratings yet

- Revised - MosDocument15 pagesRevised - MosNadeesha BandaraNo ratings yet

- MS For HDPE Pipes Laying ActivityDocument7 pagesMS For HDPE Pipes Laying ActivityJust Do LoveNo ratings yet

- Method Statement For Ug Piping 6423dp420!00!00200 00 - Rev03Document20 pagesMethod Statement For Ug Piping 6423dp420!00!00200 00 - Rev03mister pogi100% (2)

- Bulk Earthworks - Method StatementDocument4 pagesBulk Earthworks - Method Statementmemekenya0% (1)

- Work Method Statement For Piping PrefabricationDocument11 pagesWork Method Statement For Piping Prefabricationsoumaya yahyaoui100% (3)

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!From EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Rating: 5 out of 5 stars5/5 (2)

- Technical Aspects Related to the Design and Construction of Engineered Containment Barriers for Environmental RemediationFrom EverandTechnical Aspects Related to the Design and Construction of Engineered Containment Barriers for Environmental RemediationNo ratings yet

- Spesific Quality Control Management PlanDocument26 pagesSpesific Quality Control Management PlanmahmoudNo ratings yet

- Spesific Quality Control Management PlandDocument27 pagesSpesific Quality Control Management PlandmahmoudNo ratings yet

- Itr-Pgr (GRP Piping)Document10 pagesItr-Pgr (GRP Piping)mahmoudNo ratings yet

- Spesific Quality Control Management PlandDocument27 pagesSpesific Quality Control Management PlandmahmoudNo ratings yet

- ITR-MFH (Fired Heater)Document30 pagesITR-MFH (Fired Heater)mahmoudNo ratings yet

- ITR-MRE (Rotating Equip.)Document25 pagesITR-MRE (Rotating Equip.)mahmoudNo ratings yet

- ITR-FPR (Fire Proofing)Document6 pagesITR-FPR (Fire Proofing)mahmoudNo ratings yet

- Itr-Msa (Air Cooler)Document13 pagesItr-Msa (Air Cooler)mahmoudNo ratings yet

- Itr-Pag (Ag Piping)Document24 pagesItr-Pag (Ag Piping)mahmoudNo ratings yet

- Ku TWK 50 PR Pid 0078 - 0 T 78 5g Wellhead PidDocument1 pageKu TWK 50 PR Pid 0078 - 0 T 78 5g Wellhead PidmahmoudNo ratings yet

- ITR-MSE (Stationary Equip.)Document27 pagesITR-MSE (Stationary Equip.)mahmoudNo ratings yet

- ITR INL (Insulation)Document2 pagesITR INL (Insulation)mahmoudNo ratings yet

- KU-TWK-50-ME-PLP-0016 R-A1-2 T-22 T-57 T-31 T-78 Wellhead LayoutDocument1 pageKU-TWK-50-ME-PLP-0016 R-A1-2 T-22 T-57 T-31 T-78 Wellhead LayoutmahmoudNo ratings yet

- ITR-STR (Steel Strcture)Document23 pagesITR-STR (Steel Strcture)mahmoudNo ratings yet

- ITR-CNI (Instrument)Document21 pagesITR-CNI (Instrument)mahmoudNo ratings yet

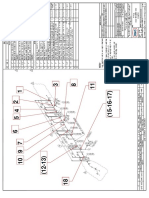

- Ku TWK 50 Pi Iso 2085 - 0 T 78 WH Perimeter Skid HookupDocument1 pageKu TWK 50 Pi Iso 2085 - 0 T 78 WH Perimeter Skid HookupmahmoudNo ratings yet

- ITR-MCR (Hoist - Crane)Document6 pagesITR-MCR (Hoist - Crane)mahmoudNo ratings yet

- DNO QC inspection of T-31N wellhead hookupDocument2 pagesDNO QC inspection of T-31N wellhead hookupmahmoudNo ratings yet

- Ku TWK 50 Pi Iso 0095 - 2 - Typ 300 Class Perimeter Skid WHDocument1 pageKu TWK 50 Pi Iso 0095 - 2 - Typ 300 Class Perimeter Skid WHmahmoudNo ratings yet

- ULTRASONIC WELD SCAN REPORTDocument1 pageULTRASONIC WELD SCAN REPORTmahmoudNo ratings yet

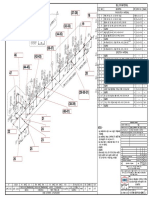

- Ku TWK 50 Pi Iso 2083 - 0 T 78 WH Skid HookupDocument1 pageKu TWK 50 Pi Iso 2083 - 0 T 78 WH Skid HookupmahmoudNo ratings yet

- Piping & Metals Fabrication Quality Manual Sample: Selected Pages Sample IncludesDocument20 pagesPiping & Metals Fabrication Quality Manual Sample: Selected Pages Sample IncludesRicardo BNo ratings yet

- Ku-twk-50-Pi-Iso-0090 - 2 - Scada & Wellhead Control System - 300# Flow-Line Instruments Skid Isometric-WhDocument1 pageKu-twk-50-Pi-Iso-0090 - 2 - Scada & Wellhead Control System - 300# Flow-Line Instruments Skid Isometric-WhmahmoudNo ratings yet

- CSWIP-HT-15-05 1st Edition November 2012 PDFDocument13 pagesCSWIP-HT-15-05 1st Edition November 2012 PDFMahmoud ElemamNo ratings yet

- IR-04-IPICC-TWK T-31N-5Jun22-HydrotestDocument2 pagesIR-04-IPICC-TWK T-31N-5Jun22-HydrotestmahmoudNo ratings yet

- Ir 08 Ipicc TWK T 31n 30july22 Hydro TestDocument2 pagesIr 08 Ipicc TWK T 31n 30july22 Hydro TestmahmoudNo ratings yet

- Itp For Structural Steel Work 4 PDF FreeDocument12 pagesItp For Structural Steel Work 4 PDF FreemahmoudNo ratings yet

- 2-Mahmoud Ghoutani CV .Last 2021Document2 pages2-Mahmoud Ghoutani CV .Last 2021mahmoudNo ratings yet

- Sitescan 500s D-50Document6 pagesSitescan 500s D-50Erika Mae EnticoNo ratings yet

- A Design Approach & Selected Wind-Tunnel Results at High Subsonic Speeds For Wing-Tip Mounted Winglets PDFDocument33 pagesA Design Approach & Selected Wind-Tunnel Results at High Subsonic Speeds For Wing-Tip Mounted Winglets PDFsubha_aeroNo ratings yet

- Qualified Fluid Type IIDocument1 pageQualified Fluid Type IIRash MoNo ratings yet

- Oil and Gas Custody Transfer PetroleumDocument5 pagesOil and Gas Custody Transfer PetroleumMohammad OkourNo ratings yet

- Ansys Fluent Tutorials List PDFDocument12 pagesAnsys Fluent Tutorials List PDFengNo ratings yet

- Minor Loss of HydraulicsDocument37 pagesMinor Loss of Hydraulicsjdj2007No ratings yet

- Mixtures and Solutions GuideDocument44 pagesMixtures and Solutions GuideMelissa DiazNo ratings yet

- Calculo de GabinetesDocument5 pagesCalculo de GabinetesMiguel J.No ratings yet

- 0752 ARMAFLEX in Mechanical Piping InsulationDocument15 pages0752 ARMAFLEX in Mechanical Piping InsulationAgung Pramu AjiNo ratings yet

- Filtration BasicsDocument55 pagesFiltration BasicsLorena Dominguez100% (2)

- FiltrationDocument39 pagesFiltrationAli HyderNo ratings yet

- Adetunji & Olaniran, 2021Document19 pagesAdetunji & Olaniran, 2021Ericke Nandita MaharaniNo ratings yet

- The Impact of Hydrogen Admixture Into Natural Gas On Residential and Commercial Gas AppliancesDocument13 pagesThe Impact of Hydrogen Admixture Into Natural Gas On Residential and Commercial Gas AppliancesAndrea ButtafavaNo ratings yet

- 3130507-Group Wise Topics For Online PresentationDocument2 pages3130507-Group Wise Topics For Online PresentationKaushal BaldhaNo ratings yet

- Start Up Slug Catcher and Train 1Document43 pagesStart Up Slug Catcher and Train 1Larbi HammounNo ratings yet

- The Use of Air Cooled Heat Exchangers in Mechanical Seal Piping Plans - SnyderDocument7 pagesThe Use of Air Cooled Heat Exchangers in Mechanical Seal Piping Plans - SnyderJaime Ocampo SalgadoNo ratings yet

- Intermediate Well Control Equipment InspectionDocument4 pagesIntermediate Well Control Equipment InspectionEdwin MP0% (1)

- Hydraulic Pump Unit BT-1,2 TCT-165Document5 pagesHydraulic Pump Unit BT-1,2 TCT-165Aruljyothy PCNo ratings yet

- Simulation of A Wet Sulfuric Acid Process (WSA)Document12 pagesSimulation of A Wet Sulfuric Acid Process (WSA)Ahmed AliNo ratings yet

- Process Data Sheet of Incinerator Package Unit 113X-X1: Biturox ProjectDocument15 pagesProcess Data Sheet of Incinerator Package Unit 113X-X1: Biturox ProjecthhvgNo ratings yet

- Design of Shell Tube Heat Exchanger by Kern Method 2 57 Excel TemplateDocument7 pagesDesign of Shell Tube Heat Exchanger by Kern Method 2 57 Excel TemplateneelNo ratings yet

- CFD Application in Automotive Industry: Aerodynamics & TurbulenceDocument2 pagesCFD Application in Automotive Industry: Aerodynamics & Turbulencemogali4486No ratings yet

- Oil Firing SystemDocument19 pagesOil Firing Systemvale.jimmyjrNo ratings yet

- Turbomachinery PDF Turbomachinery TurbineDocument1 pageTurbomachinery PDF Turbomachinery Turbine63201130No ratings yet

- Gasco Brochure EnglishDocument12 pagesGasco Brochure Englishsurag1982100% (1)

- 795F AC Off-Highway Truck Air SystemDocument2 pages795F AC Off-Highway Truck Air SystemEugenio Pizarro MondacaNo ratings yet

- Sysmex KX-21 Service ManualDocument210 pagesSysmex KX-21 Service ManualEng-Ahmed KhalifaNo ratings yet

- Air Demand 2002Document12 pagesAir Demand 2002tranquangtrungxdNo ratings yet

- Smscom Manual Twin Controller Pro MK2 2017Document6 pagesSmscom Manual Twin Controller Pro MK2 2017saborespurpuraagroNo ratings yet

- Heat Exchanger PresentationDocument27 pagesHeat Exchanger PresentationHIPAP100% (1)

- Modified Phase RuleDocument1 pageModified Phase RulearpanNo ratings yet