Professional Documents

Culture Documents

BTVTED3A

BTVTED3A

Uploaded by

Alvin Ejano0 ratings0% found this document useful (0 votes)

6 views1 pageThe document discusses three types of welding: arc welding, shielded metal arc welding (stick welding), and electroslag welding. It explains that choosing the right electrode is important for performing welding correctly based on factors like the welding method, materials, and conditions. Two welding techniques are described: the tough or tapping method, and the scratch or sweeping method.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document discusses three types of welding: arc welding, shielded metal arc welding (stick welding), and electroslag welding. It explains that choosing the right electrode is important for performing welding correctly based on factors like the welding method, materials, and conditions. Two welding techniques are described: the tough or tapping method, and the scratch or sweeping method.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

6 views1 pageBTVTED3A

BTVTED3A

Uploaded by

Alvin EjanoThe document discusses three types of welding: arc welding, shielded metal arc welding (stick welding), and electroslag welding. It explains that choosing the right electrode is important for performing welding correctly based on factors like the welding method, materials, and conditions. Two welding techniques are described: the tough or tapping method, and the scratch or sweeping method.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

Activity 3

I. Explain the following items:

1. Cite at least 3 types of welding and explain.

- ARC Welding is one of the most prominent types of welding. Arc processes involve

using the/ concentrated heat of an electric arc to join metal materials together. These

processes fall broadly into two categories: consumable electrode methods and

non-consumable electrode methods.

- Shielded Metal Arc Welding (Stick Welding) The arc melts the workpiece and

electrode into a molten pool that forms a joint when it cools. This type of welding is also

referred to as Flux Shielded Arc Welding due to the electrode’s flux coating

disintegrating into a shielding gas during heating.

- Electroslag Welding In this process, a wire is fed into the welding area and flux is

added to the electrical arc until the molten slag reaches the tip of the electrode and

extinguishes the arc. Electroslag welding operators use a DC power source and tend to

work with thick workpiece materials, such as low carbon steel plates and aluminum bus

bars.

2. How important is choosing electrodes in welding?

- Because as a professional welder, you must know the different types of electrodes and

their applications in order to perform the welding job correctly.Considerations include

welding method, welded materials, indoor/outdoor/conditions, and welding positions.

Practicing with various welding guns and electrodes can help you determine which

electrode to use for what welding project.

3. Give at least 2 welding techniques and explain.

- Tough or tapping method it is when using this method, the electrode should be held

in a vertical position and lowered until it is an inch or so above the point where the arc is

to be struck.Then, the electrode is lightly tapped on the work piece and immediately lifted

to form an arc approximately ¼-inch in length.

- Scratch or sweeping method To strike the arc by the scratch method, the electrode is

held just above the plate at an angle of 20°–25°.The arc should be struck by sweeping

the electrode with a wrist motion and lightly scratching the plate. The electrode is then

lifted immediately to form an arc. Either method takes some practice, but with time and

experience, it becomes

easy. The key is to raise the electrode quickly, but only about ¼-inch from the base or

the arc is lost. If it is raised too slowly, the electrode sticks to the plate.

You might also like

- Soldering Electronic Components 2nd EditionFrom EverandSoldering Electronic Components 2nd EditionRating: 3 out of 5 stars3/5 (2)

- Electronics for Artists: Adding Light, Motion, and Sound to Your ArtworkFrom EverandElectronics for Artists: Adding Light, Motion, and Sound to Your ArtworkRating: 3.5 out of 5 stars3.5/5 (2)

- Smaw (Stick Welding)Document57 pagesSmaw (Stick Welding)Vane VallejoNo ratings yet

- 1.introduction To SMAWDocument74 pages1.introduction To SMAWRumman Ul AhsanNo ratings yet

- Agitadores April06Document8 pagesAgitadores April06Karem Jeanette Saenz BernalNo ratings yet

- Arc Welding - Basic Steps ReadingDocument12 pagesArc Welding - Basic Steps Readingaddayesudas100% (1)

- ASME B31.1 Vs B31.3 Vs B31.8Document9 pagesASME B31.1 Vs B31.3 Vs B31.8Nguyen Anh Tung67% (3)

- Structural Design of Shotcrete Linings - WindsorDocument34 pagesStructural Design of Shotcrete Linings - WindsorMelissaRico100% (1)

- Teknologi Las Kapal: How Do Shielded Metal Arc Welding On PipingDocument42 pagesTeknologi Las Kapal: How Do Shielded Metal Arc Welding On Pipingardin0506No ratings yet

- Oxy-Acetylene Welding and Cutting Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- SAFE RC Design ForDocument425 pagesSAFE RC Design ForMarlon Braggian Burgos FloresNo ratings yet

- Design Manual-Stone Cladding FixingsDocument6 pagesDesign Manual-Stone Cladding FixingsvtalexNo ratings yet

- Masonry Wall 2Document25 pagesMasonry Wall 2Edmund Chui100% (2)

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- Polymaker - Brochure 2020 PDFDocument82 pagesPolymaker - Brochure 2020 PDFgav oviNo ratings yet

- Smaw PDFDocument10 pagesSmaw PDFArizapatazoNo ratings yet

- Sizing Pressure RelievingDocument20 pagesSizing Pressure RelievingNuch NapapornNo ratings yet

- Shielded Metal Arc Welding: By: Charles Lu Derwin Li Andrew Tan Renz Raquion Emil WangDocument44 pagesShielded Metal Arc Welding: By: Charles Lu Derwin Li Andrew Tan Renz Raquion Emil WangAndrew TanNo ratings yet

- Objectives of WeldingDocument8 pagesObjectives of WeldingSuhayl Azmin100% (3)

- Chapter 2 Arc WeldingDocument39 pagesChapter 2 Arc WeldingAbie RexoMen0% (1)

- Arc Welding ReportDocument6 pagesArc Welding ReportYe Chonn100% (6)

- Lab Report Welding (SMAW) - FizaDocument13 pagesLab Report Welding (SMAW) - FizaCheng Yee71% (7)

- Plasma CuttingDocument229 pagesPlasma CuttingTilak MoundekarNo ratings yet

- Smaw and Tig WeldingDocument46 pagesSmaw and Tig WeldingRajesh Kumar Ravi100% (1)

- Welding Lab Report. Part 1Document6 pagesWelding Lab Report. Part 1Ayuub Abdi Mahamed100% (2)

- BuildingMaterialsProductEmissionandCombustionHealthHazards 1Document343 pagesBuildingMaterialsProductEmissionandCombustionHealthHazards 1Mohammad Irshad ali100% (1)

- Arc Weld ReportDocument14 pagesArc Weld ReportAsyraf Razali67% (6)

- National Institute of Textile Engineering and Research (NITER)Document6 pagesNational Institute of Textile Engineering and Research (NITER)shahadat hossainNo ratings yet

- Shielded Metal Arc WeldingDocument7 pagesShielded Metal Arc WeldingSiraj JunaidNo ratings yet

- Laporan Praktikum Proses Manufaktur 2 Kelompok S25 Modul PM2-01 Shift Sabtu Siang PDFDocument30 pagesLaporan Praktikum Proses Manufaktur 2 Kelompok S25 Modul PM2-01 Shift Sabtu Siang PDFGilang Tito F.No ratings yet

- Power Point Essentials of WeldingDocument53 pagesPower Point Essentials of WeldingWilmerNo ratings yet

- 121Document39 pages121veerusiteNo ratings yet

- Welding PPMTDocument20 pagesWelding PPMTRadha BagriNo ratings yet

- Welding Persentation 444Document38 pagesWelding Persentation 444Raunak GuptaNo ratings yet

- Introduction To Arc Welding: Information Sheet - "Document14 pagesIntroduction To Arc Welding: Information Sheet - "Eahbm KaduNo ratings yet

- Shielded Metal Arc WeldingDocument8 pagesShielded Metal Arc WeldingAndrew TanNo ratings yet

- Chapter 5 Metal Joinig ProcessesDocument88 pagesChapter 5 Metal Joinig Processesdagimawgchew777No ratings yet

- Module-1: Electric Welding byDocument17 pagesModule-1: Electric Welding byveena bhatNo ratings yet

- SMAW Welding Section 8 Unit 26Document45 pagesSMAW Welding Section 8 Unit 26Ari WidyantoNo ratings yet

- Shield Metal Arc WeldingDocument4 pagesShield Metal Arc Weldingகோகுல் இராNo ratings yet

- Lab Session 04 - Arc WeldingDocument6 pagesLab Session 04 - Arc WeldingZaid BaigNo ratings yet

- Lab Report 2..weldingDocument7 pagesLab Report 2..weldingUsman Saeed Kiani100% (1)

- Arc Welding ReportDocument10 pagesArc Welding ReportHabibah ArbainNo ratings yet

- Arc Welding ProcessDocument3 pagesArc Welding Processaman abirNo ratings yet

- Exp 2Document5 pagesExp 2alexchong93No ratings yet

- Manufacturing Technology (BPB 23303)Document9 pagesManufacturing Technology (BPB 23303)liewyoungshinNo ratings yet

- ARCWELDINGDocument3 pagesARCWELDINGwindowshome84No ratings yet

- Specific Welding DetalsDocument17 pagesSpecific Welding DetalsradiantsteelNo ratings yet

- Welding Manual - B TechDocument28 pagesWelding Manual - B TechAditya UNo ratings yet

- F Arcwelding 131118222251 Phpapp02Document42 pagesF Arcwelding 131118222251 Phpapp02hassan aliNo ratings yet

- Principles in Shielded Metal Arc Welding (SMAWDocument22 pagesPrinciples in Shielded Metal Arc Welding (SMAWMichael Angelo ChuaNo ratings yet

- Metal JoiningDocument62 pagesMetal Joiningbhavna agarwalNo ratings yet

- WELD 116 Weld and OA SafetyDocument61 pagesWELD 116 Weld and OA SafetyFides MagistradoNo ratings yet

- 4 Welding ShopDocument9 pages4 Welding ShopMansi NegiNo ratings yet

- Lec 13 Unit 3 Arc Welding - HAFDocument23 pagesLec 13 Unit 3 Arc Welding - HAFZakyNo ratings yet

- Arc Welding: Prof. H. K. Khaira MSME Deptt., MANIT, BhopalDocument49 pagesArc Welding: Prof. H. K. Khaira MSME Deptt., MANIT, BhopalNordiana IdrisNo ratings yet

- Welding ShopDocument4 pagesWelding ShopAmarjeet Singh (Assistant Professor- Mechanical Engineer)No ratings yet

- Metal Joining CH 1 GDocument20 pagesMetal Joining CH 1 Gወይኩን ፍቃድከNo ratings yet

- Basics in WeldingDocument63 pagesBasics in WeldingK JeevanNo ratings yet

- TVL SMAW11 Q2 M2 ModifiedDocument9 pagesTVL SMAW11 Q2 M2 ModifiedJennylynNo ratings yet

- Manual 2Document16 pagesManual 2Malik Umar KhakhNo ratings yet

- How To Do Arc WeldDocument17 pagesHow To Do Arc WeldLelli KurniaNo ratings yet

- Lec 3 - Part 1Document31 pagesLec 3 - Part 1May FadlNo ratings yet

- Lec 7Document28 pagesLec 7Omar AssalNo ratings yet

- Definition of Welding: Welding Is Defined As "A Joining Process That Produces Coalescence of Materials byDocument6 pagesDefinition of Welding: Welding Is Defined As "A Joining Process That Produces Coalescence of Materials bySaman SajadianNo ratings yet

- Report WeldingDocument16 pagesReport WeldingMuhamad AimanNo ratings yet

- Welding Juan DiazDocument12 pagesWelding Juan DiazJuan DiazNo ratings yet

- Electro Discharge Machining: Shivam JaiswalDocument9 pagesElectro Discharge Machining: Shivam JaiswalNabayan MarikNo ratings yet

- 00092021012MMDocument2 pages00092021012MMAMARENDRA SINo ratings yet

- Chapter 7Document24 pagesChapter 7abadittadesseNo ratings yet

- Friction Stir Welding ThesisDocument4 pagesFriction Stir Welding Thesisaflowlupyfcyye100% (2)

- Marc 2008 r1 Volume D: User Subroutines and Special RoutinesDocument658 pagesMarc 2008 r1 Volume D: User Subroutines and Special RoutinesKevinNo ratings yet

- PDMSDocument39 pagesPDMSprathikNo ratings yet

- Using Earths Resources Exam Practice GCSEDocument14 pagesUsing Earths Resources Exam Practice GCSEPaul GillNo ratings yet

- ASHRAE Journal - VAV Box Duct Design - TaylorDocument8 pagesASHRAE Journal - VAV Box Duct Design - TaylorsajuhereNo ratings yet

- FAFDocument3 pagesFAFHemant MunbodNo ratings yet

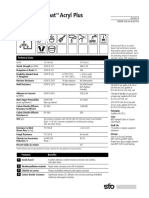

- Sto Acryl Plus crd+648+tbDocument2 pagesSto Acryl Plus crd+648+tbOgbedande Awo OrunmilaNo ratings yet

- Home Safety ChecklistDocument3 pagesHome Safety ChecklistJimmy AanderudNo ratings yet

- Class Xii PhysicsDocument4 pagesClass Xii PhysicsBiswajit BeheraNo ratings yet

- LRFD Compression Member DesignDocument248 pagesLRFD Compression Member DesignMukhlish Akhatar100% (1)

- Astm B 232MDocument16 pagesAstm B 232MRyan LasacaNo ratings yet

- KIVO-CSV 4.2mmDocument1 pageKIVO-CSV 4.2mmRinda ManuNo ratings yet

- Automatic Flow-Limiting Valve: Installation, Operation and Service InstructionsDocument2 pagesAutomatic Flow-Limiting Valve: Installation, Operation and Service InstructionsAnonymous 7xHNgoKE6eNo ratings yet

- Metal Matrix Composites: I. Kostikov A N D KilinDocument16 pagesMetal Matrix Composites: I. Kostikov A N D Kilinsupriyo1970No ratings yet

- 4 - Cutting Tool GeometryDocument21 pages4 - Cutting Tool GeometryFebry Risky Jr.No ratings yet

- A F E S: Process Piping 670.200Document17 pagesA F E S: Process Piping 670.200puwarin najaNo ratings yet

- NetCol5000-A042 In-Row Air Cooled Smart Cooling Product Quick GuideDocument32 pagesNetCol5000-A042 In-Row Air Cooled Smart Cooling Product Quick GuideWilson DominguezNo ratings yet

- DSSY-X Series: Diko Elektrikli Cihazlar San. Ve Tic. A.ŞDocument19 pagesDSSY-X Series: Diko Elektrikli Cihazlar San. Ve Tic. A.ŞEric LarrondoNo ratings yet

- NR-Air Conditioning and VentilationDocument4 pagesNR-Air Conditioning and VentilationKhate ÜüNo ratings yet