Professional Documents

Culture Documents

Maintenance Chart HDX

Uploaded by

George GOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Maintenance Chart HDX

Uploaded by

George GCopyright:

Available Formats

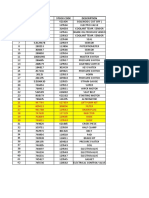

Plate Processor 85-125-150 T2657

Maintenance Chart

OPERATION SECTION Developer Wash Gum Dryer Cooler Cleaning Time

1. Check the replenisher container. Daily Daily ~ 2 min.

2. Check the waste container. Daily ~ 2 min.

3. Safety check of the mechanical components. Daily ~ 5 min.

4. Clean the transport rollers from residues. Daily ~ 5 min.

5. Change the filter (and reset the filter counter. See " -> Manual tasks"). 1) ~ 5 min.

6. Change the water and clean the section with the hand-shower (and reset the wash

Daily 2) ~ 10 min.

water counter. See " -> Manual tasks").

7. Run the gum clean program (Automatic function when switching the processor to

Daily ~ 10 min.

sleep mode if "Auto gum rinse" is set to "Yes").

8. Change the chemistry (and reset the developer counter. 1) ~ 30 min.

See " -> Manual tasks").

9. Main cleaning: Developer 3) 9)

a. Clean all rollers and guides.

b. Clean the tank with the "PROCESSOR CLEANER". By chemistry change ~ 1 hour

c. Clean the spray tubes with brush.

d. Clean the tubes and drain with backflush.

10. Main cleaning: Wash 3)

a. Clean the brush roller.

By chemistry change ~ 1 hour

b. Clean the tank with the "PROCESSOR CLEANER".

c. Clean the tubes and drain with backflush.

11. Main cleaning: Gum 4)

a. Flush the gum pumps and solenoid. 4)

By chemistry change ~ 1 hour

b. Clean the rollers.

c. Clean the tank with the "PROCESSOR CLEANER". 4)

12. Clean the circulation pumps. 5) Every 3 months ~ 1 - 2 hours

13. Clean the replenish, vacuum and gum pumps. 5) Every 3 months Every 3 months ~ 1 - 2 hours

14. Change brush. Every 25,000 m2 ~ 30 min. - 1 hour

15. Install Preventive Maintenance Kit Minor (bearings - O-ring - V-seal). 6) Every year or 1,500 hours ~ 30 min. - 1 hour

16. Install Preventive Maintenance Kit Medium (gears - worms - O-rings - V-seals - poppet

Every 2 years or 3,000 hours ~ 2 - 3 hours

valves - pump heads - bearings). 7)

17. Install Preventive Maintenance Kit Major (motors - bearings). 8) Every 4 years or 6,000 hours ~ 3 - 4 hours

18. Check the water level, fill up if necessary. Every 2 months ~ 5 min.

1) Change of chemistry/filter is based on the type of chemistry.

2) Machine with water circulation system built in. Chemistry type: ______________________

3) See the cleaning instructions in the User's Manual. Chemistry change: ______________________ m2

4) Use lukewarm water. Filter change: ______________________ m2

5) See the instructions in the processor Service Manual.

6) See the instruction of Preventive Maintenance Kit Minor.

7) See the instruction of Preventive Maintenance Kit Medium.

8) See the instruction of Preventive Maintenance Kit Major.

9) Make certain that tank section and filter housing have been drained completely of chemistry, fill up the section with "PROCESSOR CLEANER" (1:4) and let the circulation pump run for 5-10 min. Drain the section again (both the tank section and the filter housing), fill with water and let

the pump run again for 5-10 min. Drain the section and the filter housing again. Remove the filter and clean it. MAKE ABSOLUTELY CERTAIN THAT NO WATER REMAINS IN THE FILTER HOUSING! Install filter. Close filter bottom valve and section drain valve and fill up the section

with fresh chemistry.

Part Number 10060717-AB (GB)

You might also like

- Action Plans For Micro Issue Tracker - Sent Per ShiftDocument10 pagesAction Plans For Micro Issue Tracker - Sent Per ShiftDave GianganNo ratings yet

- Treating Wastewater from 50 HomesDocument2 pagesTreating Wastewater from 50 HomesM Azhar FirdausNo ratings yet

- Cleaning turbo depositorsDocument3 pagesCleaning turbo depositorsleila lolita leila lilasNo ratings yet

- (SIS3) Assignment2 MJPZ.02Document13 pages(SIS3) Assignment2 MJPZ.02rafaelferiaNo ratings yet

- Cleaning Procedures at Distribution CentersDocument8 pagesCleaning Procedures at Distribution CentersImran KarimNo ratings yet

- DIVISIO 2000 Series - SIMPLEX - Maintenance: Author: Thomas KeimDocument20 pagesDIVISIO 2000 Series - SIMPLEX - Maintenance: Author: Thomas KeimNader KortNo ratings yet

- Back Wash RecycleDocument2 pagesBack Wash RecycleMSAJJIMALNo ratings yet

- Sewage treatment plant membrane bioreactor flow sheetDocument13 pagesSewage treatment plant membrane bioreactor flow sheetyoucef tecNo ratings yet

- Frequency Cleaning / Inspection Points Lubricating Points Type of LubricantDocument3 pagesFrequency Cleaning / Inspection Points Lubricating Points Type of LubricantKrishnamurthy NatarajanNo ratings yet

- Basic RO machine operation and maintenanceDocument3 pagesBasic RO machine operation and maintenanceGemma t. BarteNo ratings yet

- Maintenance ProgramDocument3 pagesMaintenance ProgramEdgar Jr SuyatNo ratings yet

- eCL8000 Maintenance GuideDocument24 pageseCL8000 Maintenance Guidegerente soportecNo ratings yet

- BTR Greens Homes Scope of ServicesDocument3 pagesBTR Greens Homes Scope of ServicesV Narasimha RajuNo ratings yet

- Monthly Monitoring Report MayDocument8 pagesMonthly Monitoring Report MayBrainard ConcordiaNo ratings yet

- A. Standard Membrane Bioreactor Computations: 2.1. Design Flowrates and Maximum Monthly Loading RatesDocument7 pagesA. Standard Membrane Bioreactor Computations: 2.1. Design Flowrates and Maximum Monthly Loading RatesshekharshindeNo ratings yet

- Cage Wash ProceduresDocument7 pagesCage Wash ProceduresMalathi SathivelNo ratings yet

- Standard Membrane Bioreactor ComputationsDocument8 pagesStandard Membrane Bioreactor ComputationsSwaminathan ThayumanavanNo ratings yet

- PerhitunganDocument8 pagesPerhitungantsaniya.mardhiyahNo ratings yet

- Bak Equalisai / PengumpulDocument3 pagesBak Equalisai / PengumpulRegita ArdaniaNo ratings yet

- NHT Amine Degrease Procedure Rev2Document29 pagesNHT Amine Degrease Procedure Rev2raj kumarNo ratings yet

- Daily MainenanceDocument5 pagesDaily MainenanceChanthol RibeiroNo ratings yet

- Summary 2021 - Muhammad FadliDocument113 pagesSummary 2021 - Muhammad FadliFadliNo ratings yet

- Bag Filters Types, Working Principles & Daily Maintenance - INFINITY FOR CEMENT EQUIPMENT PDFDocument14 pagesBag Filters Types, Working Principles & Daily Maintenance - INFINITY FOR CEMENT EQUIPMENT PDFRICARDOALEXBORGES100% (2)

- Hydrocyclones Maintenance PDFDocument6 pagesHydrocyclones Maintenance PDFYOGESH GOPALNo ratings yet

- Partnerships For Modernizing The Grain Postproduction SectorDocument90 pagesPartnerships For Modernizing The Grain Postproduction SectorCPS_IRRINo ratings yet

- Washing Water Turbidity As Indicator To Fruit and Vegetable Washer EfficiencyDocument14 pagesWashing Water Turbidity As Indicator To Fruit and Vegetable Washer EfficiencyasasdNo ratings yet

- TSB - RF Drain CleaningDocument8 pagesTSB - RF Drain Cleaningpetej.publicscribdNo ratings yet

- METHOD STATEMENT FLUSHING - StampedDocument3 pagesMETHOD STATEMENT FLUSHING - StampedMohammad OsmanNo ratings yet

- R Y B Average Units/day/Machin e MC #1 3.78 3.12 2.76 3.220 52.70Document3 pagesR Y B Average Units/day/Machin e MC #1 3.78 3.12 2.76 3.220 52.70praveenchinnaNo ratings yet

- Ablandador Manual-Hankscraft-Runxin PDFDocument37 pagesAblandador Manual-Hankscraft-Runxin PDFgonzaloagustin84No ratings yet

- Periodic maintenance schedule and procedures for G-500 snowblowerDocument24 pagesPeriodic maintenance schedule and procedures for G-500 snowblowerØystein71% (7)

- Downloaded From Manuals Search EngineDocument24 pagesDownloaded From Manuals Search EnginekevenNo ratings yet

- Without Rebars-9m GantryDocument1 pageWithout Rebars-9m GantryShivsagar yadavNo ratings yet

- Performance Evaluation of 1 MLD MBBR Type Sewage Treatment PlantDocument4 pagesPerformance Evaluation of 1 MLD MBBR Type Sewage Treatment PlantRanadive AnanthNo ratings yet

- Annual Physical Report of OperationsDocument7 pagesAnnual Physical Report of OperationsKenneth ApgaoNo ratings yet

- Washing Machine BasicsDocument6 pagesWashing Machine BasicsSwagat PradhanNo ratings yet

- DIST-GAM-SOP-011-02 (Cleaning Operation at Distribution Centers)Document8 pagesDIST-GAM-SOP-011-02 (Cleaning Operation at Distribution Centers)Imran KarimNo ratings yet

- Pulse Jet Cleaning Collectors Preventative MaintenanceDocument2 pagesPulse Jet Cleaning Collectors Preventative Maintenanceehsan.aziziNo ratings yet

- MD1-0-T-060-05-00614-A Method Statement For Chemical Cleaning (Pre-Boiler Alkali Cleaning) PDFDocument60 pagesMD1-0-T-060-05-00614-A Method Statement For Chemical Cleaning (Pre-Boiler Alkali Cleaning) PDFNguyễn ĐứcNo ratings yet

- WTP Monitoring Report Provides Insights for Butuan City 30MLD ProjectDocument8 pagesWTP Monitoring Report Provides Insights for Butuan City 30MLD ProjectBrainard ConcordiaNo ratings yet

- Construction Pipelaying FlowchartDocument31 pagesConstruction Pipelaying FlowchartBernadette JoveroNo ratings yet

- CIP Cleaning MachineDocument13 pagesCIP Cleaning MachineCoteneanuIonutNo ratings yet

- INDESIT XWE-91282 ManualDocument36 pagesINDESIT XWE-91282 Manualrazib1271No ratings yet

- Chapter-6 (6 6 2 2-6 9 3)Document107 pagesChapter-6 (6 6 2 2-6 9 3)sagar khanalNo ratings yet

- Maintenance Schedule of Stenter Machine: ObjectsDocument14 pagesMaintenance Schedule of Stenter Machine: ObjectsAbel TayeNo ratings yet

- Ariston Hot Point Us Cat orDocument88 pagesAriston Hot Point Us Cat orMarius PopaNo ratings yet

- Deep Cleaning SopDocument3 pagesDeep Cleaning Sopjamil voraNo ratings yet

- Primary and Secondary TreatmentDocument8 pagesPrimary and Secondary TreatmentJohn Rhey Almojallas BenedictoNo ratings yet

- Procedure For Landscaping and Compound MaintenanceDocument14 pagesProcedure For Landscaping and Compound MaintenanceDamalieNo ratings yet

- Preventive Sheet 13-02-2023Document15 pagesPreventive Sheet 13-02-2023Vishal MehtreNo ratings yet

- Anaerobic Sludge Digestion - Review Checklist: GeneralDocument8 pagesAnaerobic Sludge Digestion - Review Checklist: GeneralMagin Idelfonso TorreblancaNo ratings yet

- Basic MaintenanceDocument23 pagesBasic MaintenancePedro Lucas Rodrigues QueirozNo ratings yet

- Sop WTP CombinedDocument17 pagesSop WTP CombinedsiccppNo ratings yet

- ProStream Series User Guide Level 1 Uptime OptimizationDocument19 pagesProStream Series User Guide Level 1 Uptime OptimizationthurboyNo ratings yet

- Instruction Booklet: Tumble DryerDocument16 pagesInstruction Booklet: Tumble DryerDuncan KingNo ratings yet

- مرفق رقم 8 - مواصفات وحدة معالجة الصرف الصناعي - مجزر الزقازيقDocument20 pagesمرفق رقم 8 - مواصفات وحدة معالجة الصرف الصناعي - مجزر الزقازيقHesham ElshazelyNo ratings yet

- Cavitation Cleaning - ValquaDocument4 pagesCavitation Cleaning - ValquaEurotech Tra TranNo ratings yet

- Descripción FunnelDocument9 pagesDescripción FunnelVeronika TerrazasNo ratings yet

- Sewage Disposal Works: Their Design and ConstructionFrom EverandSewage Disposal Works: Their Design and ConstructionNo ratings yet

- Service Manual Thermal 125Document96 pagesService Manual Thermal 125George GNo ratings yet

- CP 85 CP 120Document68 pagesCP 85 CP 120George GNo ratings yet

- Ip 85HDDocument144 pagesIp 85HDGeorge GNo ratings yet

- Ip 85HDX 2010Document114 pagesIp 85HDX 2010George GNo ratings yet

- Adara TH 2010 enDocument85 pagesAdara TH 2010 enGeorge GNo ratings yet

- Mizar TH - enDocument113 pagesMizar TH - enGeorge GNo ratings yet

- SAP PM Best PracticeDocument55 pagesSAP PM Best PracticesachinWebDNo ratings yet

- The Effect of Inrush Current On Transformer ProtectionDocument9 pagesThe Effect of Inrush Current On Transformer Protectionbigsteve9088No ratings yet

- Ceramic Tile TechniquesDocument13 pagesCeramic Tile TechniquesStefan Van CleemputNo ratings yet

- ASTM D747 Overview PDFDocument41 pagesASTM D747 Overview PDFtangogll11No ratings yet

- Critical Spare For Manitou MT X1840 New ManitouDocument3 pagesCritical Spare For Manitou MT X1840 New ManitouamonNo ratings yet

- Ball Drop ActivityDocument4 pagesBall Drop ActivityKogilan ChitranNo ratings yet

- Experiment #8 - Slender MemberDocument4 pagesExperiment #8 - Slender MemberLuís Alberto Tang YorisNo ratings yet

- 95 8576 9.2 - X3302 PDFDocument37 pages95 8576 9.2 - X3302 PDFSalik SiddiquiNo ratings yet

- Electrician job hazard analysisDocument1 pageElectrician job hazard analysisZaul tatingNo ratings yet

- Quartz Analogue Watches User Manual: Display and FunctionsDocument3 pagesQuartz Analogue Watches User Manual: Display and FunctionsFlorin MihaiNo ratings yet

- EAO MC 61 Main-Catalogue En-469531Document104 pagesEAO MC 61 Main-Catalogue En-469531Saheer AmbadanNo ratings yet

- TMP 727Document40 pagesTMP 727FrontiersNo ratings yet

- Estimating Power Demand Using Diversity FactorDocument31 pagesEstimating Power Demand Using Diversity FactorRamesh Ananthanarayanan0% (1)

- Tremie SealsDocument12 pagesTremie SealsWalid MghazliNo ratings yet

- For Drifting and Tunneling: Sandvik RT300-seriesDocument6 pagesFor Drifting and Tunneling: Sandvik RT300-seriesДамир НазиповNo ratings yet

- Stake Out Data Analysis and ComparisonDocument15 pagesStake Out Data Analysis and ComparisonDewy Widya ningsihNo ratings yet

- Carestation 650 Brochure PDFDocument12 pagesCarestation 650 Brochure PDFzulfiah100% (1)

- Check Valve VickersDocument15 pagesCheck Valve Vickersعلي عائشة100% (1)

- OOSE03 - Basing Software Development OnDocument48 pagesOOSE03 - Basing Software Development Onfaiz10march6456No ratings yet

- Physics Cambridge Igcse Year 10 Paper 1Document18 pagesPhysics Cambridge Igcse Year 10 Paper 1Adibah AliasNo ratings yet

- Propeller Tolerances and Inspection - John Carlton PDFDocument17 pagesPropeller Tolerances and Inspection - John Carlton PDFhenryNo ratings yet

- Aspect Security The Unfortunate Reality of Insecure LibrariesDocument20 pagesAspect Security The Unfortunate Reality of Insecure Libraries99patinoNo ratings yet

- Srs On Quora Com 364482795 Srs On Quora ComDocument13 pagesSrs On Quora Com 364482795 Srs On Quora Comayush dwivediNo ratings yet

- Jurnal ErielDocument5 pagesJurnal ErielPaste GigiNo ratings yet

- No. Description ApplicationDocument50 pagesNo. Description ApplicationMihes AdrianNo ratings yet

- Python3 Tutorial PDFDocument26 pagesPython3 Tutorial PDFferronatto11100% (1)

- CushmanDocument23 pagesCushmanChuck BristolNo ratings yet

- 2017+Module+1+Term+Test+ SolutionsDocument13 pages2017+Module+1+Term+Test+ Solutionszubair ahmedNo ratings yet

- AminesDocument21 pagesAminesDEVIKAA ARUNNo ratings yet

- Dam PluggingDocument104 pagesDam PluggingMpho Vince MatlouNo ratings yet