100% found this document useful (1 vote)

737 views3 pagesEccentric Footing and Strap Beam Design

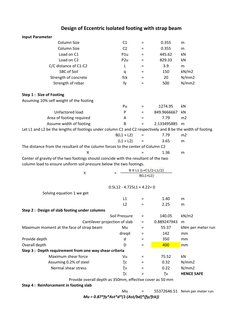

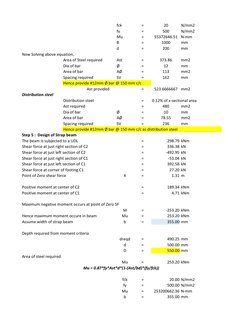

The document describes the design of an eccentric isolated footing with a strap beam to support two columns. Key steps include:

1) Sizing the footing to a width of 2.13m and lengths of 1.4m and 2.25m for each column area.

2) Designing the slab footing with a depth of 400mm and reinforcement of #12mm bars at 150mm spacing.

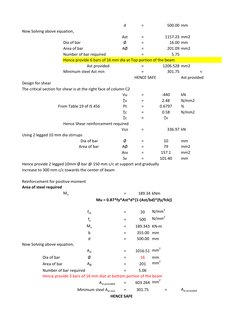

3) Designing the strap beam to resist bending and shear from the column loads, with a depth of 550mm and reinforcement of 6 #16mm bars at the top.

4) Detailing shear reinforcement of 2-legged 10mm stirrups at 150mm spacing at supports to 300mm at the center

Uploaded by

Bishal ShresthaCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

100% found this document useful (1 vote)

737 views3 pagesEccentric Footing and Strap Beam Design

The document describes the design of an eccentric isolated footing with a strap beam to support two columns. Key steps include:

1) Sizing the footing to a width of 2.13m and lengths of 1.4m and 2.25m for each column area.

2) Designing the slab footing with a depth of 400mm and reinforcement of #12mm bars at 150mm spacing.

3) Designing the strap beam to resist bending and shear from the column loads, with a depth of 550mm and reinforcement of 6 #16mm bars at the top.

4) Detailing shear reinforcement of 2-legged 10mm stirrups at 150mm spacing at supports to 300mm at the center

Uploaded by

Bishal ShresthaCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

- Step-by-Step Design Instructions

- Design Overview and Initial Parameters

- Advanced Structural Design Steps

- Final Design Checks and Conditions