Professional Documents

Culture Documents

Cycle Counting Work Instruction

Uploaded by

Fati MagalangCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cycle Counting Work Instruction

Uploaded by

Fati MagalangCopyright:

Available Formats

RN No.

REGISTRATION

NOTICE

Section 2.16 Date:

OPERATIONS

IMT-001 Revision No.

ISO 9001:2008 CYCLE COUNT

Distribution : Inventory Management Team

Registration Revision

Date Name Revision History Details

Notice No. No.

0 04/29/16 IM Supervisor Origination

No. of

Prepared by: Reviewed by: Reviewed by: Approved by: Noted by: Copy

Holders

(Form1/Rev.0)

Head of Logistics Document

IMT Supervisor IMT Manager QMR

Operations Controller

Date: Date: Date: Date: Date:

2GOLI-BPQ-002 (Form 1/Rev. 0)

Page No.

PROCEDURES AND WORK

1/3

INSTRUCTIONS MANUAL

Section 2.16 Date:

OPERATIONS

IMT-001 Revision No.

CYCLE COUNT

OBJECTIVE:

To provide procedural guidelines in conducting Cycle Counting.

SCOPE:

This procedure shall cover the daily cycle count activities up to stock adjustment in the

system.

RESPONSIBILITY:

IM Stock Control Assistant

Responsible in leading the Cycle Counting activity, preparing Count Sheets and

generating ending inventory in the system. Also ensures complete, accurate, and

timely submission of the results of the physical count, request for inventory

adjustment if needed and suggests Action Items to implement to address inventory

variance.

IM Counter

Responsible in conducting accurate physical counting of the items that are

scheduled for count.

IM Supervisor / IM Manager

Responsible in validating the Cycle Count Report, approving inventory adjustment

and providing action items to help minimize variances and improving inventory

accuracy.

REFERENCE:

Agreed blueprint & process flow with client

DEFINITION OF TERMS:

SKU or Stock Keeping Units

Inventory term or code serves as identifier for an item or material.

Count Sheets

Form used during cycle count.

SAF or System Adjustment Form

Form used as reference for request for Inventory Adjustment found during cycle

count.

Prepared by: Reviewed by: Approved by:

IMT Supervisor IMT Manager QMR Head of Logistics Operation

(Form2/Rev.2)

Page No.

PROCEDURES AND WORK

2/3

INSTRUCTIONS MANUAL

Section 2.16 Date:

OPERATIONS

IMT-001 Revision No.

CYCLE COUNT

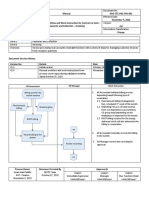

PROCEDURE:

Support

Responsible

Activity Documentation

Person

Used

1. Generates inventory balance in system for Operations Assistant Bin Check List

bin checking of lanes to be counted

2. Generates inventory balance in system for IM Stock Control Cycle count

scheduled SKU’s to be counted Assistant calendar

3. Prepares Count Sheets and performs actual IM Stock Control

Count Sheet

counting. Assistant

IM Stock Control

4. During count proper, counting is per Lane as Assistant &

Count Sheet

indicated in the count sheets Warehouse

Representative

5. Validates the physical count versus inventory

balance in the system;

5.1 In the event that there will be IM Stock Control

disparity (as to quantity) it will be Assistant

adjusted in the system and the

physical stocks will be segregated for

reconciliation;

6. Consolidate and prepares an Inventory

Record Accuracy / Count Result and sends it

IM Stock Control Cycle Count IRA

to concerned parties. Initial result must be

Assistant Report

sent not later than 5PM of the day of

counting.

Prepared by: Reviewed by: Approved by:

IMT Supervisor IMT Manager QMR Head of Logistics Operation

(Form2/Rev.2)

Page No.

PROCEDURES AND WORK

3/3

INSTRUCTIONS MANUAL

Section 2.16 Date:

OPERATIONS

IMT-001 Revision No.

CYCLE COUNT

PROCESS FLOW:

Prepared by: Reviewed by: Approved by:

IMT Supervisor IMT Manager QMR Head of Logistics Operation

(Form2/Rev.2)

You might also like

- The Sarbanes-Oxley Section 404 Implementation Toolkit: Practice Aids for Managers and AuditorsFrom EverandThe Sarbanes-Oxley Section 404 Implementation Toolkit: Practice Aids for Managers and AuditorsNo ratings yet

- Stage 2 Isolating A Mill Feeder 1. PurposeDocument3 pagesStage 2 Isolating A Mill Feeder 1. Purposejoseph kamwendoNo ratings yet

- Stage 1 Isolating Boiler Feed PumpDocument3 pagesStage 1 Isolating Boiler Feed Pumpjoseph kamwendoNo ratings yet

- Ujvnl PM Preventive Maintenance User ManualDocument21 pagesUjvnl PM Preventive Maintenance User ManualUCPL Training100% (1)

- IQA IATF ChecksheetDocument37 pagesIQA IATF ChecksheetSumeet Rathee100% (5)

- ISO ChecklistDocument36 pagesISO ChecklistDhinakaran100% (1)

- IMS M1 General ProceduresDocument345 pagesIMS M1 General ProceduresCarlo Mark Villarva LadaoNo ratings yet

- Manufacturing Process Audit Checklist1Document4 pagesManufacturing Process Audit Checklist1Sophie ThuyDinhNo ratings yet

- LGT - WHD - QP05-Physical Inventory Count ProcedureDocument9 pagesLGT - WHD - QP05-Physical Inventory Count ProcedureGregorNo ratings yet

- Ujvnl PM Calibration Maintenance User ManualDocument40 pagesUjvnl PM Calibration Maintenance User ManualSiva Thunga50% (2)

- Department: HOT SHOP Auditee: AuditorDocument52 pagesDepartment: HOT SHOP Auditee: AuditorSead ZejnilovicNo ratings yet

- 1IOTC IMS Manual - 2Document66 pages1IOTC IMS Manual - 2Alghezy AlghezyNo ratings yet

- Stage 1 Isolating Boiler Feed PumpDocument3 pagesStage 1 Isolating Boiler Feed Pumpjoseph kamwendoNo ratings yet

- GR Power Switchgear Limited: Quality System Management ISO 9001:2015Document5 pagesGR Power Switchgear Limited: Quality System Management ISO 9001:2015G RajasekharNo ratings yet

- FIN201 Fundamentals Finance Part 3 BookletDocument10 pagesFIN201 Fundamentals Finance Part 3 BookletThulani NdlovuNo ratings yet

- SOP - MT - 01 MaintenanceDocument2 pagesSOP - MT - 01 MaintenanceHarits As SiddiqNo ratings yet

- Stage 1 Isolating Boiler Feed Pump 1. PurposeDocument3 pagesStage 1 Isolating Boiler Feed Pump 1. Purposejoseph kamwendoNo ratings yet

- QMP-10 New Product DevelopmentDocument15 pagesQMP-10 New Product Developmentom cnc100% (1)

- WI-TL-091 Outstation IMTE and PMI ControlDocument7 pagesWI-TL-091 Outstation IMTE and PMI ControlAzizul HakimNo ratings yet

- Volume 3 - InventoryDocument35 pagesVolume 3 - Inventorysreekumar.chandranNo ratings yet

- SOP-PR-13 - Maintance SOPDocument3 pagesSOP-PR-13 - Maintance SOPkelvinalphonce97No ratings yet

- IATF ChecksheetDocument37 pagesIATF ChecksheetDhinakaran67% (3)

- CTC-Payments and Collection-Invoicing - v2.0Document3 pagesCTC-Payments and Collection-Invoicing - v2.0Jacklyn LadeslaNo ratings yet

- Maintenance Management System Guideline For Maintenance Operating Procedures Corrective MaintenanceDocument22 pagesMaintenance Management System Guideline For Maintenance Operating Procedures Corrective MaintenanceGlad BlazNo ratings yet

- Procurement of Excisable-Non Excisable Jobwork MaterialsDocument9 pagesProcurement of Excisable-Non Excisable Jobwork MaterialsBryant AdhitiaNo ratings yet

- Maintenance Management System Guideline For Maintenance Operating Procedures Modifications and ImprovementDocument19 pagesMaintenance Management System Guideline For Maintenance Operating Procedures Modifications and ImprovementGlad BlazNo ratings yet

- Perfomance Review FormDocument2 pagesPerfomance Review Formndayiragije JMVNo ratings yet

- QMP-01 - Control of DocumentDocument7 pagesQMP-01 - Control of Documentom cncNo ratings yet

- Department: CNC SHOP Auditee: AuditorDocument33 pagesDepartment: CNC SHOP Auditee: AuditormuthuselvanNo ratings yet

- Integrated Management System: Title: Internal AuditDocument4 pagesIntegrated Management System: Title: Internal AuditjeyaseelanaNo ratings yet

- F-1705 Internal Audit Check ListDocument73 pagesF-1705 Internal Audit Check ListAjay100% (1)

- Calibration and Maintenance of Measuring and Monitoring Devices SOPDocument3 pagesCalibration and Maintenance of Measuring and Monitoring Devices SOPBPG Service100% (1)

- (QSP MR 03) Internal AuditDocument3 pages(QSP MR 03) Internal AuditBASAVA ENGINEERINGNo ratings yet

- 16 Maintenance Report Sheet 2 - enDocument8 pages16 Maintenance Report Sheet 2 - enIsaac LopbenNo ratings yet

- Chapter 16 (GENERAL LEDGER AND REPORTING SYSTEM)Document7 pagesChapter 16 (GENERAL LEDGER AND REPORTING SYSTEM)Amara Prabasari100% (1)

- Information Sheet No. 1.3-3Document19 pagesInformation Sheet No. 1.3-3ggtxc7x2bkNo ratings yet

- Adequacy of Tools MaintenanceDocument1 pageAdequacy of Tools Maintenancepranay26No ratings yet

- Energy Manual Policy and ProcedureDocument41 pagesEnergy Manual Policy and ProcedureAKHIL SHARMANo ratings yet

- Mobis Isir ManualDocument17 pagesMobis Isir ManualGabriel MolinaNo ratings yet

- OPMAN-Part-2 - Joel Factoriza Misa - ID 21226220 - ETEEAP BSBADocument20 pagesOPMAN-Part-2 - Joel Factoriza Misa - ID 21226220 - ETEEAP BSBAOnice BallelosNo ratings yet

- TPI-MTN-SOP-004 Corrective Maintenance PLTUDocument18 pagesTPI-MTN-SOP-004 Corrective Maintenance PLTUsas13No ratings yet

- SPTR Audit CSDocument3 pagesSPTR Audit CSRakesh SNo ratings yet

- QMP-02 - Control of RecordDocument5 pagesQMP-02 - Control of Recordom cncNo ratings yet

- Nadiatul - HW Week 7Document4 pagesNadiatul - HW Week 7nadxco 1711No ratings yet

- Intermediate Accounting 19th Edition Stice Solutions ManualDocument35 pagesIntermediate Accounting 19th Edition Stice Solutions Manualpassagevoyagera5cnhd100% (24)

- Document NumberingDocument8 pagesDocument NumberingRaja RehaNo ratings yet

- FM-IPI-QA-16 - Rev.00 (CPAR) - 1HR - DraftDocument2 pagesFM-IPI-QA-16 - Rev.00 (CPAR) - 1HR - DraftdekengNo ratings yet

- Work Instruction For Perpetual Inventory Verification Steps Activity Responsibility 1Document2 pagesWork Instruction For Perpetual Inventory Verification Steps Activity Responsibility 1saikumar selaNo ratings yet

- Procedure For Process Control: Manager ManagerDocument2 pagesProcedure For Process Control: Manager ManagerBK SinhaNo ratings yet

- Training Manual For AMPSDocument40 pagesTraining Manual For AMPSShujauddin MohammedNo ratings yet

- SOP 08 Batch Process ControlDocument2 pagesSOP 08 Batch Process ControlKrishna Rameshrao Ambilwade0% (1)

- QM-F-7.1-15 Ver.2.0 - Annual Quality Audit of VendorsDocument5 pagesQM-F-7.1-15 Ver.2.0 - Annual Quality Audit of VendorssanjaydeNo ratings yet

- Procedure For Internal Audit: Input / Output DiagramDocument8 pagesProcedure For Internal Audit: Input / Output DiagrammuthuselvanNo ratings yet

- Sap For Utilities Release Notes Sap Is U 472Document118 pagesSap For Utilities Release Notes Sap Is U 472Hanif AbdurrahmanNo ratings yet

- Software Requirement Specification Document: ICBS - Reserve Management Module Royal Monetary AuthorityDocument167 pagesSoftware Requirement Specification Document: ICBS - Reserve Management Module Royal Monetary Authorityrudrapatel6808No ratings yet

- Audit PlanDocument6 pagesAudit Plansyedumarahmed52No ratings yet

- Cycle Counting: Configuration, Process Flow and ImplementationDocument7 pagesCycle Counting: Configuration, Process Flow and ImplementationPilla Satish KumarNo ratings yet

- NcManagement - SA1 - 2021Document13 pagesNcManagement - SA1 - 2021Nagarajan100% (1)

- FM 198 Q1 ISO 9001 Audit Report Form Revision 7 20210803Document17 pagesFM 198 Q1 ISO 9001 Audit Report Form Revision 7 20210803Supriya GothwalNo ratings yet

- Cycle Counting Configurations and FlowDocument5 pagesCycle Counting Configurations and FlowBalanathan VirupasanNo ratings yet

- Cargo Agent Presentation For GST March 2018Document13 pagesCargo Agent Presentation For GST March 2018rishi pandeyNo ratings yet

- Tirzok Software-Service ProfileDocument13 pagesTirzok Software-Service ProfileHasan Ibna AkbarNo ratings yet

- Analysis of Supply Chain in Siddhi Engineers: Interim Report ONDocument6 pagesAnalysis of Supply Chain in Siddhi Engineers: Interim Report ONantrikshaagrawalNo ratings yet

- Sticky Branding Work BookDocument38 pagesSticky Branding Work BookChjk PinkNo ratings yet

- GM StudentDocument16 pagesGM StudentShuvranil SahaNo ratings yet

- FijiTimes - April 13 2012 PDFDocument48 pagesFijiTimes - April 13 2012 PDFfijitimescanadaNo ratings yet

- EXEMPTIONDocument15 pagesEXEMPTIONAndrey PavlovskiyNo ratings yet

- Special Event Banner PolicyDocument4 pagesSpecial Event Banner PolicySam DunneNo ratings yet

- Chapter IVDocument47 pagesChapter IVselomonbrhane17171No ratings yet

- Dunkin' Donuts: The History of The Phenomenal BrandDocument9 pagesDunkin' Donuts: The History of The Phenomenal BrandMacMac DañasNo ratings yet

- Matrix FAQDocument5 pagesMatrix FAQSafix YazidNo ratings yet

- Module 9Document12 pagesModule 9Johanna RullanNo ratings yet

- Extern Inspect200703Document4 pagesExtern Inspect200703John D. BalyaNo ratings yet

- InteretrustDocument21 pagesInteretrustConstantin WellsNo ratings yet

- Kelvin Lau MWI +RRDocument18 pagesKelvin Lau MWI +RRUniversityJCNo ratings yet

- Chapter 3 Case Part 2Document3 pagesChapter 3 Case Part 2graceNo ratings yet

- Chaoter 4 AnswersDocument45 pagesChaoter 4 Answersmorgan.bertone100% (2)

- Information Security Awareness PDFDocument4 pagesInformation Security Awareness PDFHemkeshNo ratings yet

- Sitrans: Speed SensorsDocument24 pagesSitrans: Speed SensorsJaime ViloriaNo ratings yet

- Pan-Os 7.1 Admin GuideDocument932 pagesPan-Os 7.1 Admin GuideneoaltNo ratings yet

- Fat Test (Jawaban)Document19 pagesFat Test (Jawaban)Carat ForeverNo ratings yet

- WhatsApp Payment Kumar Simplilearn CBAP PROJECT PDFDocument18 pagesWhatsApp Payment Kumar Simplilearn CBAP PROJECT PDFPriyanka Shrivastava100% (1)

- How To Earn Money Blogging? (Top 10 Ways To Easily Earn $1k+ Per Month)Document34 pagesHow To Earn Money Blogging? (Top 10 Ways To Easily Earn $1k+ Per Month)Raginee Summoogum100% (1)

- AUE Guide To Outsourcing Governance Procedures PDFDocument20 pagesAUE Guide To Outsourcing Governance Procedures PDFLingua IntlNo ratings yet

- Employment Registration Form of Foreign Employees in China PDFDocument1 pageEmployment Registration Form of Foreign Employees in China PDFFabio SerranoNo ratings yet

- Q2, Module 2, Lesson 2Document9 pagesQ2, Module 2, Lesson 2Jerome A. Gomez67% (3)

- Buying Sales Leads - Is It Right For Your Company?Document2 pagesBuying Sales Leads - Is It Right For Your Company?MikhailNo ratings yet

- Welcome Pack ULIP PDFDocument16 pagesWelcome Pack ULIP PDFRyan Putra GushendraNo ratings yet

- Pre-Feasibility Study-Guava Pulping & Squash Making UnitDocument16 pagesPre-Feasibility Study-Guava Pulping & Squash Making Unitnishi@sainiNo ratings yet

- Reading Data Science The Sexiest Job in The 21st CenturyDocument2 pagesReading Data Science The Sexiest Job in The 21st CenturyAtiq ur RehmanNo ratings yet