Professional Documents

Culture Documents

Ed M M M A GN 0001 01

Ed M M M A GN 0001 01

Uploaded by

721917114 470 ratings0% found this document useful (0 votes)

60 views39 pagesOriginal Title

ED-M-M-M-A-GN-0001-01

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

60 views39 pagesEd M M M A GN 0001 01

Ed M M M A GN 0001 01

Uploaded by

721917114 47Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 39

Project:

Doha Convention Center & Tower

DOHA, QATAR

(Client:

Qatari Diar

Real Estate Investment Company

P.O. Box 23175 - Doha - Qatar

Project Management:

Turner International

Terme osc 2420072 noundvou, Done ante

Te 974-441-4781-265

Architect:

Murphy/ Jahn

Architect of Record:

secon

Aton 14,0-70987 Span,

MAGNUSSON ‘Siractoral + Chil Eeginmers |ARCHITECTS:

EMeNCIC Beene re ENGINEERS

MESS Sea E

M.E.P Engineer: Local Engineer:

ARUP Hyder y en

RESUS BUS SAREE ease costang He

[Special Structure Engineers: Landscape Architect:

KING! RAINER SCHMIDT

WERNER SOBEK INGENIEURE LANDSCHAFTSARCHITEKTEN.

Klenzestratse £70, 89469 Munchen,

“Tek +49-(0)89-202835-0, Fax +49(0)89-202536-30

Sasi cane: General Contractor:

ix Construr

id 1 ‘SIX CONSTRUCT - MIDMAC JV

P.O. Box: 32263, Doha, Qatar

migmac | | Tels soreaaraec, Pox 10744470658

MEP Contractor:

ETA - DEBBAS JV

P.O. Box: 2373, Doha, Qatar

REP CONTRACTORS DOHA CONVENTION CENTER Tel ¥974-44886768, Fax: 197444665769

DOCUMENT TITLE:

Method Statement for Installation of HVAC Ducts and Accessories

ETA-DEBBAS

JOB NUMBER: DOCUMENT NUMBER: REVISION NUMBER:

0C2-536 weet GN-0001 of

PREPARED B

CHECKED BY: PPR BY:

WArAB 10 Kal BP.

YL

CSTCo

em no:

10/7/2011 23-3100 [Package no!

[Transmittal no:

; DOHA ==

FF succonstuc convention| E! = EE

fmldmMiac |" | CENTER &

: TOWER

PROJECT

Method Statement

For

Installation of HVAC Ducts and

Accessories

}

\une

10.7.2011 | 01 | WASSIME.N. PEDRO witson | JUN IGROS LAU E. RAIU cash RYAN

SALIM BASBOUS MUSTAFA S. iain Wane

TevIEWED Gv | PREPARED av: | PREPARED AY: | CHECKEDBY: | APPROVED BY:

pare | rev. | eva-peouasiv | ErA-DEBBAS HSE | ETADEBBASIV | ETA-DEOBASIV | ETA-DEBBAS.V

construction | DEPARTMENT anqc | ENGINEERING PROIECT

DEPARTMENT DEPARTMENT | DEPARTMENT | DIRECTORATE

‘Method Statement ~ Installation of HVAC Ducts and Accessories

DOCUMENT NUMBER: ED-M-M-M-A-GN-0001,

aged

DOHA

Fsixconstruct | convention

een HEP GONTHAGYOas "BUNA GONVENTTON BEATER

(iid(fiag \') | CENTER &

TOWER

PROJECT

Table of Contents

SN. DESCRIPTION PAGE

i. Front Page 1

ii. Table of Contents a

1. Purpose 3

2. Scope 3

a Definition 3

4. Reference Documents 4

5. Tools & Equipments 4

6. Manpower 5

7. Responsibilities 5

8 Material Inspection / Storage 6

9. Construction Sequence and Methodology 6

10. Inspection / Testing 8

11. Insulation 9

12. Health, Safety and Environment 11

13. QC Approval Report Requirements 12

14. Attachments

14.1 Risk Assessment

14.2 Inspection and Test Plan

14.3 Installation Check List

Method statement ~ Installation of HVAC Ducts and Accessories

DOCUMENT NUMBER: ED-M-M-M-A-GN-0001

Page2

Fisixconsteuct | convention)! ELE

iliac ||) | CENTER 8

1

DOHA KO) j bl Ww

MEP CONTRACTORS - DOHA CONVENTION CENTER

TOWER

PROJECT

1.0

2.0

3.0

Purpose

‘The purpose of this Method Statement is to describe the details used and controls to

be carried out for the installation of Ducts, fittings, insulation and accessories for

HVAC System to ensure that it complies with Project requirements, Project

Specifications (Section 23-3100 ) and standards.

Scope

This Method Statement is applicable to all Ducts, fittings, insulation and accessories

for HVAC System at Doha Convention Center & Tower Project.

Manpower and Equipments shall be organized to meet the schedule as per approved

Construction program.

Definition

3.1. “Abbreviation ”

@aac - — Quality Assurance Quality Control

Ms - Method Statement

MEP = - Mechanical, Electrical, Plumbing

RFIA = _—_—_-Request for Inspection & Approval

MIR = _—_Materials Inspection Request

iP - Inspection and Test Plan

TBT = _—_—_Tool Box Talk

3.2 “Approved” or “Approval”

Approved” or “Approvals means approved in writing by the applicable Engineers

Assistant acting within the scope of their delegate authority.

3.3 “Shop Drawings”

Shop Drawings means drawings produced where the contract designs drawings

require expressing in more basic form to facilitate construction.

3.4 “Final Inspection”

Final Inspection means the inspection of the records of works at completion or at

completion of pre-determined elements to ensure that all previous inspections and

tests have been satisfactorily carried out and properly recorded.

Method statement ~ Installation of HVAC Ducts and Accessories

DOCUMENT NUMBER: ED-M.N.M-A-GN-0001

Pages

1

DOHA = eee 1

Fsixconstruct CONVENTION HET © ||O debbas

cidiag ||| | CENTER &

MEP GONTRAGTORS - DOHA CONVENTION CENTER

TOWER

PROJECT

35

3.6

“Materials”

Materials means all items covering the materials or equipments delivered to site

‘that must be incorporated in the project.

“Method Statements”

Method Statements means a technical document to be read in conjunction with

the drawings, specification, standards and codes of practice, technical data sheets,

schedules, work instructions and any other technical document related to a

particular work.

4.0 Reference Documents ~ Specifications, Drawings. Etc.

4a

42

43

4a

45

Sixco Construct / Midmac Project Quality Plan

Project Specification ~ Section 23 3100

Approved Shop Drawings

Approved Material Submittal

Manufacturer's Instruction

5.0 Tools and Equipments:

5.1

5.2

53

54

55

5.6

57

5.8

5.9

Hack saw

Electric drill with bits and Grinder

Open and box type spanners

Chalk line / marking pen

Measuring Tape

Ball Hammer and cold chisel

Screw Driver set

Level Bar / Plum bob

Tin Snips / Scissors

5.10 Battery Drill Machine

5.11 Pop Riveter

5.12 Movable Scaffolding / Ladders

5.13 Handy Electric Air Blower( for cleaning removing dust /debris at internal ducts)

‘Method Statement ~Installation of HVAC Ducts and Accessories

DOCUMENT NUMBER: ED:M-M-M-A-GN-0001,

Page a

1

@Fsixconstruct SUE 8 ET@||@debbas.v

tiger 11 MEP CONTRACTORS - DOHA CONVENTION CENTER

miomac | | CENTER &

TOWER

PROJECT

6.0 Manpower

6.1 Staff:

Construction Manager

Site Engineers

Supervisors

QAQC Engineer / Inspector

Quantity Surveyor

Safety Officer

6.2

Foreman

‘Trade workers

Helpers / Labours

Drivers

7.0 Responsibilities

7.4 The Project Manager shall be responsible for the overall construction,

coordination site activities and implementation this method statement.

7.2 The Construction Manager, Site Engineers, Supervisors and Foremen shall

implement and execute this Method Statement.

7.3. The Material Controller shall be responsible for receiving all materials on site

warehouse.

7.4 Site Engineer / Supervisor shall check all the materials as per approved

material submittal & manufacturer's recommendation prior to installation

and shall be responsible for the execution as per approved shop drawings.

7.5 Safety Officer shall ensure that appropriate / necessary measures are in place

at work location to avoid any unexpected accidents / events.

7.6 — QAQC Engineer / Inspector shall be responsible for carrying out inspections

for the materials delivered on site, He shall document such inspections,

7.7 QAQC Engineer / Inspector shall monitor the installation activities

progressively and shall record all deviation from specification in a form of

snags list or non-conformance notification.

‘Method Statement ~Installation of HVAC Duets ancl Accessories

DOCUMENT NUMBER: ED-W-N-M-A-GN-0001,

Pages

@sixconstruct epee ig ETG||\Odebbas

midmia

8.0 Material

84

Note:

MEP GONTRAGTORS - DOHA CONVENTION CENTER

( ( | CENTER &

TOWER

PROJECT

Inspection / Storage

All materials and/or equipments received or purchased shall be inspected

and approved by Supervision Consultant before using on site. Materials shall

be stored in a safe, secured and tidy manner in appropriate condition to

prevent deterioration or damage. All major MEP equipments shall be

appropriately covered and protected from weathering ill effects, open

sunshine, sand storm, and other such vagaries peculiar to the region. Items

shall be stored for ease of access / handling / stock verification/ inspection/

checking by the main contractor / supervision consultant representative if

and when required,

Manufacturer's recommendation for storage criteria should be followed

where applicable to avoid damage to product quality. The storage areas

shall be laid out to ensure ease of handling, retrieval and to avoid damage to

materials which must be properly stacked in accordance with

manufacturer's recommendation. The storekeeper shall ensure that the

rotation of materials is maintained to ensure that the “first in, first out”

system is observed. Routine checks shall be carried out to ensure that this

rotation is maintained.

Insulation adhesive, sealant and other chemicals shall be stored in Air

Conditioned (ACU ) area as per manufacturer's recommendation.

9.0 Construction Sequence and Methodology.

94

Preparation before Installation

9.1.1 Ensure that all Drawings for Installation are latest approved and

properly coordinated with other services

9.1.2 Check if work location / area are ready for installation of HVAC Ducts,

fittings and accessories.

9.1.3 Before starting the work, check that all safety precautions are in place.

9.1.4 Ensure that all the provisions, openings, height levels required are

properly coordinated to Civil Construction which shall be checked by

Site Mechanical / HVAC Engineer and Supervisor.

Method Statement - Installation of HVAC Duets and Accessories

DOCUMENT NUMBER: ED-M-M-M-A-GN-0001,

Page 6

7 1

@ssixconstruct Sean is EG ||\Odebbas.v

| | MEP CONTRACTORS - DOHA CONVENTION CENTER

MIOMOC || | CENTER &

TOWER

PROJECT

9.2 Installation Procedure

9.2.1 All Ducts supports shall be done as per approved shop drawings

specified spacing, Material submittal approval and manufacturer's

recommendation.

9.2.2 Mark / lay out the ducts routings on the slab and riser shaft as per

approved shop drawings.

9.2.3 Install approved Anchor fasteners as per project specification,

materials submittal approval and shop drawings.

9.2.4 All Ducts shall be installed as shown in the approved shop drawings.

All Ducts will be supported from slabs or walls using anchor fasteners,

threaded rods and galvanized steel angles.

9.2.5. Sleeve of Ducts passing through partition walls and floors.

9.2.6 Installation should be as per manufacturer's instruction.

9.2.7. Flanged joints shall be tightened using nut, bolts and clamps.

9.2.8 Support of vertical Ducts at every floor. Support of Vertical Riser

independently of connected to horizontal ducts.

9.2.9 Approved Duct sealant ( by Foster or equal approved manufacturer)

shall be applied around all joints to avoid air leakages.

9.2.10 Permanent access doors to be provided as per approved shop

drawings and project specification.

9.2.11 All ducts open ends shall be cover properly with polyethylene plastics.

Ducts shall be protected during the remainder of construction period.

9.2.12 Minimum clearance between ducts and structural must be maintained

to all installed ducts and spacing as per approved shop drawings.

9,2.43 Fire Dampers will be provided at all ducts crossing fire walls as per

approved shop drawings and installed as per manufacturer's

instructions.

9.2.14 Fire Dampers, Volume control dampers, sound attenuators, flexible

connection and other accessories shall be installed as per approved

shop drawings.

9.2.15 The location of False ceiling access hatches required under the HVAC

ducts access door should be coordinated with the Architectural works,

9.2.16 Prior to False ceiling closure, all insulated and exposed ductwork

shall be identified as per approved by the consultant.

‘Method statement — Installation of HVAC Ducts and Accessories

DOCUMENT NUMBER: ED-M-M-M-A-GN-0001

Page7

]

PMsixconstruct ena & ETE ||\Odebbas.v

Ini | MEP CONTRACTORS - DOHA CONVENTION CENTER

MOMAC | | CENTER &

TOWER

PROJECT

10.0 Inspection and Testing (For Duct Installation)

10.1 After completion of the work, The Site Engineer & Supervisor who perform an

activity are required to raise an RFIA with complete attachment &

information regarding the scope of inspection, including necessary drawings

highlighted to show the scope of inspection. He shall systematically check

and inspect their work. The inspection shall be performed according to

typical checklist and approved Inspection and Test Plans (ITP) which shall also

be attached to the RFIA.

10.2 After Site Engineer & Supervisor completed thelr inspection and testing , RFIA

shall be submitted to QAQC Department who shall check and process the

documents to have completed work inspected by Supervision Consultant for

their approval.

10.3. Cleaning of installed ducts system use with Handy Air Blower high velocity

pressure to force out / remove accumulated dust and debris inside ducts.

10.4 Pneumatic / Air leak test for completed HVAC ductwork shall be carried out

as per SMACNA, HVAC Air Duct Leakage Test Manual. Refer to Section 4

Leakage Classification. ei »

10.5 Test reports : Indicates Pressure Test performed with date, Section/ line

tested, Pressure test and leakage ratings following SMACNA (HVAC Air Duct

leakage test Manual). Supply and Return ductworks Pressures Ratings as per

DW/144 appropriate pressure classification for the Ductworks. q

Note: RFIA must be processed and submitted to Supervision Consultant 24 hours

before the actual inspection and/or witnessing.

‘Method statement ~ Installation of HVAC Ducts and Accessories

DOCUMENT NUMBER: ED-M-M-M-A-GN-0001,

Page 8

@Asixconstruct

midmac ')

DOHA

CONVENTION

CENTER &

TOWER

PROJECT

MEP CONTRACTORS - DOHA CONVENTION CENTER

11.0

1.4

11.2

11.3

114

11.5

11.6

1.7

11.8

11.9

Insulation of Ducts:

All Ductwork insulation shall be as per Project specification Section 23

0713, approved Material submittal, approved shop drawings and

‘manufacturer's recommendation. The procedure instruction as per

Insulation Application Method as follows;

Determine the length of Duct Insulation plus board required to make a

Duct Insulation section of the Gl duct. This length is the sum of the

outside dimensions ( 2.x height + 2.x width) plus allowance for insulation

board thickness,

Cut along edge of Duct Insulation plus board to form the shiplap edge.

Remove scrap.

Start from edge of board and measure first outside duct dimension plus

add on allowance:

‘Add on allowance Thickness of insulation

1.75" r

2.625” 15”

73.5" 7"

Draw first corner groove center line.

From there, measure second outside duct dimension plus add on

allowance as per above. Draw second corner centreline.

From there, measure same

as first outside dimension plus add on

allowance as per table above. Draw third corner centreline.

From there, measure same as second outside dimension plus add on

allowance as per table below.

‘Add on allowance Thickness of insulation

1.375” i

2.0" 15”

275" 2"

Draw fourth corner groove centreline.

From there, measure as per table in 11.1.7 and draw line location edge of

closure flap. The board is ready to be grooved.

Cut along the first corner groove centreline and remove groove scrap.

This is easily done if insulation board is slightly lifted.

‘Method Statement ~Installation of HVAC Ducts and Accessories

DOCUMENT NUMBER: ED-M-V-M-A-GN-0001

Pages

= Sear]

Prsixconstuct |r ..| BET |@ debbas

CONVENTION ee

fidiriag |!) | CENTER &

; ; TOWER

PROJECT

11.10 Repeat this step for other corner groove centreline. Using straight knife,

cut along fourth corner break line through insulation only. Do not cut

through or score the facing.

11.11 Peel Insulation from flap. One line insulation plus board section is now

ready for assembly,

11.12 Two piece Duct Insulation Plus board section can be made in the same

manner as shown in the attached literature,

11.13 The length of duct insulation plus board section can be extended by

joining two sections one with female shiplaps and other with male

shiplaps.

11.14 Ensure surface of duct is dry and free from dust or grease. Apply

insulation adhesive to duct surface in strips approximately 15 cm wide.

Underside of duct of duct should be completely coated with adhesive to

prevent sagging.

11.45 Wrap Duct Insulation Plus board section prepared as above, while

keeping foil face up to the prepared duct surface one adhesive become

tacky, or as instructed by the manufacturer.

11,16 Make sure that all edge joints if any, are closely butted and ends are

flushed and sealed properly.

11.17 Using minimum 2.5” wide good quality tape (high temperature resistance

pressure sensitive aluminium tape or heat sensitive thermal aluminium

tape). Position the tape along the longitudinal edge of the flap in a

manner that allows 1” overlap on adjacent surface.

11.18 Rub tape with a plastic sealing tool until the facing shows through the

tape.

11.19 For Internal Lining (Ducts / Plenum), the following installation procedure:

11.20 Measure and cut to shape the duct liner allowing a 5 cm excess at

downstream transverse joints. Carefully remove insulation from 5 cm

excess leaving the surface tissue for overlapping to next section.

Longitudinal joints should be closed butted and sealed with a proper

sealant, tape or metal angle. Ensure that internal surface of duct is clean

and free from dust and grease,

11.21 Affix mechanical fastener in accordance with manufacturers instruction at

not more than 45 cm center. Fixing should start within 7.5 cm of joints

corners, ends, etc.

11.22 Where exposed ducts installed runs through occupied or public areas,

‘Aluminium Cladding shall be installed/ carried out with aluminium sheet,

0.9mm or thicker as per project specification - 23 0713 clause 2.7 (8). TAS

‘Method statement Installation of HVAC Ducts andl Accessories

DOCUMENT NUMBER: ED-M-M-M-A-GN-0001

Page 10

DOHA | iy genes

PFsixconstuct CONVENTION | = ET@||Odebbas

| | MEP CONTRACTORS - DONA CONVENTION CENTER

mideiac \] CENTER &

TOWER

PROJECT

11.23 After completion of insulation work, RFIA must be raised and submitted to

Supervision Consultant 24 hours before the actual inspection and final

approval.

12.0 Health, Safety and Environment

Safety of all personnel and equipment is the highest priority of ETA-Debbas JV during

the execution of the Works.

12.1 Personnel Protective Equipment

12.1.1 Safety Helmet

12.1.2 Safety Goggles (during drilling and use of grinders)

12.1.3 Face shield (during grinding)

12.1.4 Safety Footwear (steel toes)

12.1.5 Safety Gloves (for material handling)

12.1.6 Coverall (as protective clothing)

12.1.7 Ear plug protection

12.1.8 Full Body Harness

12.1.9 Respiratory Mask (if required )

12.2 Tool Box Talk (TBT)

12.2.1. Safety Tool Box Talk shall be given by the Site supervisor / Safety

officer every week and/or as deemed necessary.

12.2.2. Safety tool Box Talk shall brief the task / subject and shall be given in

languages understandable by multinational workforce.

12.2.3. Safety Tool Box Talk attendance shall be recorded on a sheet and

signed by attendees

12.3. Material Safety Data Sheet (MSDS)

12.3.1 All materials shall be identified and all MSDS should be read and

understood before use.

12.4 Housekeeping

12.4.1 Housekeeping shall be maintained by all personnel working at site.

Housekeeping for fabrication and installation shall be as per project

safety plan and ETA-Debbas Safety Manual.

‘Method statement ~ Installation of HVAC Ducts and Accessories

DOCUMENT NUMBER: ED:M-M-M-A-GN-0001,

Page 11

|

; DOHA .

PFsixconsiruct | coyyenrion| 2 = F &||\@debbas

ride \|j | ceNTER &

MEP GONTRAGTORS - DOHA CONVENTION CENTER

TOWER

PROJECT

12.5 Signage

12.5.1 All necessary safety warning and caution signs shall be displayed at

work locations.

12.6 Environment

12.6.1. MSDS for COSHH materials shall be kept by the storekeeper and a

copy given to HSE Dept. The MSDS shall be followed as per Qatar

labour law. Waste Disposal shall be segregated and disposed by a

Certified Subcontractor and send it to the municipality stockyard for

COSH material as per Qatar labour law.

13.0 QC Approval Report Requirements:

13.1. Material Inspection Report (MIR) - Form,

13.2. Request for Inspection and Approval - (RFIA)

Method statement ~ Installation of HVAC Ducts and Accessories

DOCUMENT NUMBER: ED-M.M-M-A-GN-0001,

Page 12

DOHA CONVENTION CENTER &

@Fsixconstwuct TOWER PROJECT midmac |!) elLoao

Package BP 02B

|

MATERIAL INSPECTION REPORT

|

Ref: ED -BPO2B- M DATE :

Discipline

DELIVERY NOTE NO. : (Clstructural civit

Dl Architectural

Cimep- "Feortoee

CSI Code:

‘SUPPLIER: "ADDRESS:

DATE OF INSPECTION : TIME:

MATERIAL DESCRIPTION :

‘The above materials have been checked by QAQC Department representative for completeness, accuracy

and ate confirmed to comply with internal submittal documents,

Date : Time :

SUPERVISION CONSULTANT COMMENTS :

(ETATDEBBASIV) TSIKCOTMIDMIAG JV) —

a [mo | oo © [raid

ans

suprson Cowan | oa

FRRTRE TEN, sme

Hoo! ders\MiR.doc Page 1 of 1

DOHA CONVENTION CENTER &

Posix ‘Construct TOWER PROJECT midmac {') vlloxo

Package-BP 02B

REQUEST FOR INSPECTION AND APPROVAL.

REQUESTIONER NAME: Ref:

DATES

RFIA-EDA

Discipiing ‘SUBMITTED TO: MURPHYWJAHN, HYDER

(2 Steucturalcivi =

Architectural DATE & TIME. OF INSPECTION: Dat Fie

iercM AREA: (Skatch attached)

‘SHOP DRAWINGIDESIGN DRAWING: Rov,

STATUS:

ITEM TO BE INSPECTED : LOCATION

Sector:

Level

Grids

INSTALLATION OF

GRIDS: SECTOR: LEVEL:

AS PER THE ATTACHED HIGHLIGHTED DRAWINGS.

The above works have been checked by QA/QC department representative for completeness, accuracy, coordinatfon and are

confirmed to comply withthe contractual cocum:

Time:

(PRINT NAME & SIGN)

1 ‘This document shail not bo used to specify aoceptance of the aspect of test ths can ony be achieved by sign off of

appropriate inspection report which shal be attached hereto.

‘Supervision Consultant Commonts:

‘A | Accepted B | Accepted with comments © | Rejected

REMARKS:

‘Supervision Consuitant. DATE:

TT EANTANESIGN— Time:

QC Dept. REP. Received: “To be Revises DATE:

PRINT AMEE SIGN)

Form F08 Rev.1Page I of

: I

7 DOHA

Fsixconstruct CONVENTION

(iliac |) CENTER &

TOWER

| PROJECT

Sree eee |

TG ||Mdebbas.\

MEP CONTRACTORS - DOHA CONVENTION CENTE!

HETG

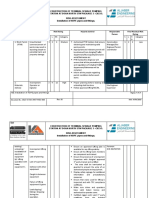

14.1 — Risk Assessment

For

Installation of HVAC Ducts

And Accessories

Method statement ~ Installation of HVAC Ducts and Accessories

DOCUMENT NUMBER: ED-M-M-M-A-GN-0001

03 1000NO-V-O-H-'Ga AESAAON INSHNDOT

SSUOSEOY PEERING QVAHJO HOBETESE—IONEAIS POST

SROPARSH TONSA TSS

peuzep pue pouieiuco suds ‘popeouieg oq snus eave eip eBerEds Jo ese ul

‘s10400 PUI Ut p20] Jo podsuER ay Suryy si ou uosrad eg SteLEp30cO

(0 Uosied Su inoddly “(oro BUREN “epenvny woes s==5y :

*

*

*

<

+

ax prnoxs sono pus pu S009 Aajes on susuudnbe mae ood

eA ALAR NAL LARS OPE

p03 1m sno wn woes eSuexo peau non ouds emayeusa @ *

S80 2 Sowansiens Arenpe Ka Aves Peal aa ©

peace Se cre on0 wag ag near sowLaR PINE

‘Gown sopneus

mm Be ee ee ae a uomsod (2°

siqeisun ‘pjoonoy Kien ‘peouzjequn “aiSexydueusyhong) pea SU SSESSY °

7g Buryy asoyog uno. 9g jonus poy] oq oHIUEIeM SL °

>

1004, 5'9) uo

zi/s/2|2/8

uopeunaryy

aug Aeauog

SpORDNRY puE Sng DVAHJP RODEIESST

(jes0u96) Buljpuey jenueyy

‘SHUNSVSN TOXLNOD

OSIM LPS Aq pessessy

ALNBIWISSASSV SIA SSH

majshy juomeSvunyy powsSapuy

| QooHrayint

~poddorp ronuids |

|} orenp siuio oy Af,

TAROT AOG TOD

peeks Antu 200

ortovono-v-c-re-as arzaWaN wNgHND0G

SSHOSHOY PUES DVAHJ® HOMIES HERESIES PORTA

“pepoo mojoo pure siseq Aporenb e uo paysodsur oq [[PYS SISPPET [VW : SON.

b«

“BAOGE B Wiz JO SHPDIOY UO Wow 9g oN SSoUTeY APOC TAT

(seno(6 9 S2}5808 ‘seoys Ayes ey pred) Lom 99 2Sns Bed JONG,

‘sieppe] \puh Supzom elym paunsua 9g ISM eC wWiod ¢

‘epperders

2 40 Buns do} tq s9A0 Ya! 2q JeAeU PINOUS SIO0Y @ II} [EWEPLCS

jueneud ©} pus su12e Buh} Ag pesn oq AUuo pinous $00} PUEL,

“papione eq smu: sappey wow Suyoesiseno

‘padewepun 2q jsnuu Suny

suogeunp

uo} 30 ssyOM Jo} pue Sqo! Anzey JO} PEsN q JOU pINOUS S1EDRET.

AAA

alels

*

“BnOgE ® WZ Jo SWyBIOY UO WOM eq ySnW Ssawley APOG

“est

‘51 210399 paypo) exe sueppel eunsuR “UoRIpUDS podB UI eq zSnw S07

JBPPEI

91g Supeid euwn peureyureu oq snl 7 :) 40 ones uSioy 0} 252q

wg0"L Jo JUIOd yo-days @iy pasoxe pue (LuOROG 40 doy aun 72 Buk

Aq) sug oug We 1123 3SureB= peunoes oq jsnui Sieppe} ‘Sse00e Se Pesn J}

Fond] pue way aq ysnw s1EpPeI JO aseq puns auL

JAA A A AA AAA

alerle

© ONINIVE,

| (xog joo, 60) THO

© (ver 8) wari

ninanas

{ GooHM=DAn

SuoRooy put Rong DVAHJO NORTEL

SIOPPe] UO 4JO/\\

SHYNSVSIN TONLNOD

ANAINSSSSSY MSI 3SH

assis juowabounyy paynsSaquy

“sr

© AuRIaNaS

» Gouin

i

i a |

2

o

sioppet |_Iyq

i woieu |)

40 Buy Bue

ubjeur

‘woy sjopojeu jo 231

wou suossed jo 24

| 8 |

a

0-100 NO-V---e- 0S USEWNAN INEANDOG

ssuosSeoy BaP SERC OVAL BOgELESE] TEES POI

“papoo mojoo pur siseq Aaurenb e uo parsadsut 99 TENS SPIOHIOS OLOW ITV : SION.

“BAGRE BU fo SHIR uO Cio 8G SHU HTUTOT IDO IAT = T

{senoj6 = sof6506 ‘sont Hoses ey pie) WOR aqisn sda seNEeE

oy uo sjavereu 10 wosved ius Janos oyens ayqow aupindysnd youog &

200p dea ong yaa

Agua pue samo} Jo apisur wos aq snus UOReId BupyOM PJOYEDS o} sse00y &

‘Uno

(2q 30 Pinoys sjeusyew pur ployeos ou umop Jo dn pedo: aq ysnu: sjevaleNN *

progeos og uo

egy ge Vere on a Des eines 0 chavs sorta Pee) .

une wus vo yeu wus pue pun up pun ORD} Bq ISM SPIOUEDS ©

‘suogonasu seinpesnuels sod se sie86iqn0 |

Foxe jaro papuawanooe: an spesare oper iuSis| 0} a5eq 1 "26n EURO

x|x|x |v] 6] os ve pueasn apsu.o yee pecs lousmMoge ssa uoouuru | zh |v | € x

“anOge = Wiz Jo Sbioy Uo aM aq jamin seoUIeY FDOT AS +

(sonoi6 » 5215606 ‘seous Kapes ey pueu) wom oqyenw Bad JEG +

Damonos 24

eye le qu uuoperd wo SupeolunUpU ai SUPE SONI SAOSIN ¢

yee ee ce eee fees anoovenone upmosndpousn even cameno + || "| x

Sea

3 gase| s| &

e|2 sopossooy posed OVAHIP NORRIE geze| 2) =

slzlZ| elf eine ela PE} s| a] |

elf \2), 182 SIIqQOU!) SIOMO} S]IGOW UO YOM, g\= 22) 2| 2 |

=\Zps|s|2/2/8 2\8/3 fee

z| 2/2/85 8/2/8 = 8 |

ote eee S3UNSVSINTONLNOD sry [euIBU

erp Aeauog — IeMpIsey,

SC’VZVH

wsamnce’ Oise ze ANSWISSESSV ¥STH SSH

masks uauasounyy paypsSaquy op, ae ose

e1000-NO-V-ErH-C"Ca RUSEDNON INGHENDOG

‘SHOSRIOY pot RNG OVAHJP SONEIESD]~ OSINS POS

ANSINSSASSV YSIE SSH

wmapsdy juomaSvunyy paywsSaguy

GEAOIS = SSIBEOD "SoOUs Hayes Wey pley) WOM aq Isnw Sad HMB <<

Auadosd papunesS

9q pinoys (Seue payemsul-siqnop ydaoxe) seumpew aun ity “e6eon Sugesedo

(oso 8 pos 9p Sapo amp 2 Pea Feo sada <

F

| 7| 1b 20; 101s cy powrne: pue paSSeyyo pououms oq pinoys swowdnbs anDajeG _ < wieris 4

T ‘GanowS @ SeSHOS ‘Sa0US Kayes FEY Pied) Wom oq |SNW Sad wNBsy <

“eoejdsyom uo pepinaud sseysinSunxe

‘90y pu veo oq yenusymed spoM.jo4 speds Saysam opsaMod 3] <

vil vib acess sree 509.90 uy pds eorpesd Una Ig AR en < oir) + xX

300r

| ‘eunjpew ayy jo uogergin / edus jo yaya Ip aig sonpas o; seno{6 puey es) <

pene

04g uo aio; paurbos 8 compas 6 deus x8 sone Suge oqamneus < |

‘uo pau S13 UOU S962 |

sumo an vo fugoe ssans enpin wanaid o ofue edad ouneLl aw Os <

‘9S00] 003 30u "yu

(00 jou - suRpew aug jo ajpUEY ain Ln PaYsAqeIsS 9q PROUS dub saddled <

4 ‘2uILDew ey} Un BunyoM alojaq pasnsus oq pinoys aunysod Apog sadold <_ zwiyi| se) x

SS Saw bao San oa W SSeS Te 1G WER Oa ETDS |

. ne e/ alee |

sepa seau Bupyiom ertua 12} Sy ywanasd o} ados 2 YM SiOO}/ SBURDEW YO SI < x

F Se. +

| £3 | 2E222 Ez

maemo pa nc OVAL SOREL | |2site (2

7 seuluoeul 5 z| | £822| 8

a ol & gise| 3

2 giqeyod pjey puey uM Bupyopa a) 2 e222) &

3 : 2|8|z BEES | 3

8 a| 3| 8 5

8 2/2) 8

yen s

Ss ‘SSUNSVSIN TONLNOD I SguvZvH

FFA Spl senesucowsae

00-1000 NO-W-e-st-a-aa “USEHEAN INEWADOG

ssuosSooy Pee HG OVAHIO SORETES — HEDIS PORTIA

‘Bajigp BUanp Wom 64 FSA PANS Saks 0 SeHSESH pus SSE 1ST

‘Gave 320m Ui pouleIMew og snus GurioeresTio4 sedate

><

<

<

CHROE G SBBOS SOUS NoRES TH pled) Wom oq NU sad MY <

(G06) uoaisod panrew 3 o}

‘arBue yu6u ye up pue eanysod yoauoo uy yosuy uoRised pinoys LeDELoSR OL <

‘uogipuco poob ui 2q sna

_y pu sje sausnsey o4oue ou Joy IMEYERE Og PINOUS YO TP selawIeIPDaLLD <

Peay sue Suda; Aquaé Aq Ary waAup siyeIng a aunsuy <

‘painsue oq SMil yang ou anu 2 10} Sumaspound wid Yauco joesN <

sampeynueu ty Aq pauoguaut

anjea oun uew ser2ei6 exe 24g spe0] o} Parpelans aq Jonau pINoUS suOURISe| |<

‘sroua}se} oyoue SuRDa}es a10}9q puNCGTe OM UNE} IMU PeO|axEjO GON <

‘sweumnoop/souynesp

ous penautide sed se papas oq yenuu ssousisey sieudauddy <

[ls

© (oa 1001.60) 10

(ver 6) warm

© qoourmasiri

ssposseoy par sand VAH JO HONEST

sugue}se} Joyoue Jo Hulxi

SaYNSVAW TOXLNOD

© goourasit

BBL ‘SCYVZVH

yng.

‘syuedinbo:

pejeisuy | |>¢

jo ones

ANaWSSaSS¥ USIY SSH

wmagsdy quaumasounyy payosSapuy

oo 100 NO-Vavee-03 RESSHAN LNDEDOG

‘SyoRooy Da Rand OVAHI COMETS ~IEIENS PON

TEAOGE Wz 30 SWyBIeY UO Wom aq ySAW Ssouey Apog INI <

(senoi6 9 S2i6808 ‘soous Aajes Yeu piel) wom eq isnui Sad semBoy <

uuogesd Sunyom ayy enoge sooy au papyasd aq c} uoRDa}oud peaweAD <

oss

‘aq 70u pinous sjeuaew pue proyens exp Lunop 20 dn podas oq ents SieuaeN <

x|x |x si s|b oisiy x

X|xX|x vi] yi b sped vosmiag ded auy pue painses pur ny 9q pinoys uNOReId WOM aL < wivis x

x] x]x ele|+ (sonc(S 2 soj8605 ‘sooys hayes ey pie) womaqismmscaendoy < | 6 |e | &

1 UODUINS JOU PUNos s} UOREMUSA fe9USH 31 PSAOIGWS 9g O} UOTEINUDA PEDIC < Xx.

1 1 Z SSE

t

zsis| | 32

2 E232) 2/2

z\é sees| 5) FF

eld a spss pe se80 VAHL SOREDESEL 2 B72] 2] fe

alSlzZ| [el2 sueys solales ul BupYOM\ 2|3 ga) El é

Z)zjz|_lz/@ gi8 ae] | =

alzlelslziglg algg| |) 23) 7] 3

#/6|2|/2/ 4/2/85 2) 3/8 3

ee SHUNSVAN TOSLNOD 3iSfa [eUIBLO, SCUYZVH

-_ on een | LNZINSS3SSV MSIY SSH

7 SoaeP = a

OlBLz § SEA SL:L assucoms

wmashy juowaSouny powssopuy

oo-to0gNo-v-asira-a ArSWAN LNaHEADOG

SHOR PH Nd OVAH JO SOGEIERE “HEREIN ORIN

(SaiEOS

-2 So0us "SEU 2035 ‘SOnCIS) BUILEA! OLY Ide Jodo TOM

“eare peysodde uljeveieuresodsiq + sd

‘2n saye Ajyerpounut AUER PESO} 2G PINOYS SIOUIETUOD eOWEUD °

vile suom 219304 peanbau Aquend ep ues shemy ° | ze| |e

“Symp Bupuey ueyan Wom aq jSnUI SeAO PUB © x

clels -arqissod senausym yuniq epew aq pincus sanpjosebpedeus © | 6 |e |e

T “PapINOId 8q OF SEIDBOS @ SEU 8Oe; “SOND eGEUNS >

| “senjue

| ue syoum uo o95613 UA 2 J9H0D BONS POOH LAN TRIEAED OFIESOEEI ©

“UBS tm JeUa}EU UOREINSUI J0 72eIUOD paveades 10 BuO LOY © |

| ‘1gISSod S212} Se |

ase paqejos; ue ut euop 2q pinoys sionp paresuge;-sid Jo uoREINsUL ©

| “Ksessaoou (AT) x

vopemuan jeuorppe apunosd ‘ease PaIeINUEA TOM e UL Past eq OL ©

| ‘igeyene 34

¢ | ¢ | + | pnoys (oom sseio B enscupy waisos)weus ee Khaesreueen | sr isle

i i = z E

g2| ¢9| 3g

3 | ag &| ge

g e2| 2| Be

z c ‘SSuOSSHOY oe SONG OVAHJO SOPTITSS] ia se =| 32

= ig 2 uoRejnsu] jong gla Ze *| 25

é}_isl= S\E se 55

$|z/2/8 2/2 |S 3 gz

2/2/2|8 BiR|8 2

uogeuoy = ysny 3st ——

ayy henuog — eMPISe Seo reurBug ce

ANSIISSESSV ¥SIN SSH

| masks juawaSounyy paynsSoquy

Bo2Ki4eM Page 1 of 6

(02-14-2008

MATERIAL SA\

‘TY DATA SHEET

REVISION DATE: 12-19-2007 SUPERSEDES: 12-29-2006

SECTION I: CHEMICAL PRODUCY AND COMPANY IDENTIFICATION,

‘COMPANY INFORMATION

Specialty Construction Brands, Ic.

‘AnH. Fuller Company

1105 §, Frontenae Street

‘Aurora TL 60504

Phone: 1-800-323-7407

‘Medical Emergency Phone Number (24 Hous): 1-888-853-1758

‘Transport Emergency Phone Number (CHEMTREC): 1-800-424-9300

PRODUCT INFORMATION

PRODUCT IDENTIFIER: soz414PM

PRODUCT NUMBE P8520

PRODUCT NAME: FOSTER 85.20

PRODUCT DESCRIPTION: Adhesive

SECTION 2: COMPOSITION/INFORMATION ON INGREDIENTS,

‘Unlisted ingredients ae not hszardous per the Occupational Safety and Trealth Administration Hazard

Conminiation Standard 29 CFR 1910.1200) and/or are not found on the Canadian Workplace Hazardous

“Materials Information System ingredient disclosure lis. See Section 8 for any additonal exposure lint guideline,

Cantante cas PERCENT josma ver.

tiene ide 5.007 50-70 FIWA 25am

SEL 25ppe0

crest aati arama 30 ete

ssi TWA Croat an TsNaRT

[TWA (kespable dsp SBEGI3

aca aS

Tloene Toe Ts TWA Totem

SEL Sopp

grater eras rs FrWA tooo;

Tastee racers ort PTW rad TONG

SECTION 3: HAZARDS IDENTIFICATION

EMERGENCY OVERVIEW

‘Moderate eye itritant.

Causes skin irvtation,

Severe respiratory tract titan

Harm ifswallowed.

BO2ALPM. Page 2 0f 6

02-14-2008

MATERIAL SAFETY DATA SHEET

Cancer hnzav.

HMIS RATING: HEALTH --2 FLAMMABILITY -- 0RBACTIVITY ~ 0

See SECTION &; EXPOSURE CONTROLS/PERSONAL PROTECTION for personal proteetive equipment

recommendations,

POTENTIAL HEALTH EFPECIS BY ROUTE OF ENTRY

EYE: Canenuse moderate ination, tearing and reddening, but not likely to permanently injure eye tissue.

SKIN: Can eause moderate skin iitation, defating, ad desmattis. Not likely to cause permanent damage.

Component) may be tbsorbed through intact ski, but it is unlikely that harmful effects will occur unless contact is

prolonged, repeated, and extensive,

INHALATION: Can eauso sovere respiratory invitation, nausea, and headache, Tubal

cutting, grinding or sading ofthis product may cause initation of the respiratory tract

Inhalation of high concenteations may result in cenral nervous system (CNS) effets such as dizziness, weakness,

fatigue, nansea, headache, and lek of coordination.

a of dusts produced daring

This product contains one oF more materials that may be hazardous when present as an airborne dust, During. normal

handling ofthe produc, the material is encapsulated within the product ai will not present an exposure isk, Ones

the prot has reached is final state and is abraded or disturbed, dusting and expostre may oceur.

INGESTION: Ingestion is not an anticipated route of exposure, Hermfil i swallowed, Severely initating to mouth,

‘throat, and stomach,

LONG-TERM (CHRONIC) HEALTH EPPECTS

REPRODUCTIVE: Contains a substance tht isa possible reproductive hazard based on animal

studies at doses that could be encountered inthe workplace

TARGET ORGANS): Heatt Liver Centeal nervous system Reproductive system Blood Lungs

REGULATED CARCINOGEN STATUS:

Unless noted below, this produet does not contain regulated levels of NTP, IARC, ACGIH, or OSHA listed

enreinogens

Methylene chloride

‘Titainm dioxide

EXISTING HEALTH CONDITIONS AFFECTED BY EXPOSURE: Liver disease; Overexpost

chloride may eause eardine effects (including the elevation of carboxyliemoglobin levels) which nny be si

smokers ot persons with anemia or heart disease nnd those exposed to carbon nionoxide; Blood disorders (ike

‘entia); Lung disease

{CTION 4: FIRST AID MEASURI

TP INEYES: Flush yes with plemy of water for at ‘often. Til the head to prevent

chemical from tansfearing tothe uncontaminated eye. Get inimediate medical attention,

IF ON SKIN: — Wash with soap and water. Remove contaminated clothing and launder. Get mestcal attention if

nitation develops or persist.

TE VAPORS INHALED: Remove to feesh air, Restore breathing, ifvecessary, Keep warm and quiet, Calla

pihysleian,

IF SWALLOWED: Severely ivtating. Do not induce vomiting, Scek medical attention immediately. Drink 2

glasses of water or milk to dilute. Do not give anything by mou to an unconscious person. Indused vomiting may

{ead to aspitation of the material into te lungs potentially causing chemical pneumonitis that may be fatal.

SECTION 5: FIRE FIGHTING MEASURES,

FLASH POINT: Non flammable

AUTOIGNITION TEMPERATURE: Not established

Bo2s140M Pago 3 0f6

02-14-2008,

MATERIAL SAFETY DATA SHEET

LOWER EXPLOSIVE LIMAT (% init): Notestablished

UPPER EXPLOSIVE LIMIT (% in alr Notestablished

EXTINGUISHING MEDL Use water spray, foam, dry chemical or eusbon dioxide.

UNUSUAL FIRE AND EXPLOSION HAZARDS: There is. possibilty of pressure buildup in closed containers

when heated, Water spray may be used to cool the containers.

[SPECIAL FIRE FIGHTING INSTRUCTIONS: Persons exposed to prods of combustion should were solf-

contained breathing apparatus and fal protective equipment.

HAZARDOUS COMBUSTION PRODUCTS: Carbon dioxide, Carbon monoxide Chlerine containing gases

SECTION 6: ACCIDENTAL RELEASE MEASURES.

‘SPECIAL PROTECTION: Exposure to the spilled material maybe iritating or harmful. Follow

personal protective equipment recommendations found in Section 8 of this

‘MSDS. Aalitioual precautions may be necessary based on pect

circustances ereated by the spill including; the material spied, the qua

‘of to pil the areain which the spill eceurred.

y

CLEAN-UP: Dike ifnecessery, contain spill with inert absorbent and transfer to containers

or disposal. Keep spilled product out ofsewers, watersheds, of water

systems.

rangpont Emergeney Phone Number (CHEMTREC): 1-800-424-9300

SECTION 7: MANDLING AND STORAG!

“Handling, Havmfl or irtning matetial. Avoid contecting and avord breathing the material. Use only in

a well ventilated aca. Avoid breathing vapors.

‘Use only with adequate ventilation

‘Avoid contact with eyes, skin ad clothing.

‘Wash thoroughly after handling.

Keep container closed.

Enyptied container retains vapor and product residue

Observe all labeled safeguards until container is cleaned.

DONOT CUT OR WELD ON OR NEAR THIS CONTAINER.

‘Aluminum isnot an acceptable material of construction for pumps, mixers, filings or storage

for this product

Storage: Store in cool, dry pace.

Consult the Technical Data Sheet for spectie storage istuctions.

SECTION 8: EXPOSURE CONTROLS/PERSONAL PROTECTION,

EYE PROTECTION: ‘Wear safey glasses wih side shields when handling this product

‘Wear additional eye protection such as chemical splash goggles

and/or face shield wien the possibility exists for eye contact with

ig oF spraying liquid, or airborne material, Have an eye wast

SKIN PROTECTION: ‘Avoid skin contact by wearing chemically resistant gloves and long

sleeved shit. An apron may be appropriate if splashing ean oceu.

‘Skin absorption may potentially coneibute to the overall exposure to

this mateial, Appropriate measures should be taken to prevent

‘bsomption so that the TLV is not invalidated.

GLOVES: Nitrile

RESPIRATORY PROTECTION: Regpitatory protestion wil be required when vewilation or other

‘engineering contrls can not redice the exposure to seceptable levels

Use supplied-ai respiratory equipment as required.

Respirators should be selecte! by and used following requirements

8o2414eM, Page 4 of 6

02-14-2008,

MATERIAL SAFETY DATA SHEET

found in OSHA's respirator standard (29 CFR 1910134).

VENTILATION: Local exhaust ventilation or other gineering contolsare nomnally

required wen handling or using this product to avoid overexposure.

[ACGNT EXPOSURE TINTS ta WHEE,

TWA Sopp Rot eater :

citar pati

eae Twa ToT erence

rae TWA ORR — pire

ETaarat—— FWA TOO oe cae 4

Pra aS TWATONGRE Wot biahed ~

SECTION 9: PHYSICAL AND CHEMICAL PROPERTIES

PRYSICAL STATE: Liquid

COLOR: Oftewiite

opor: Solvent

ODOR THRESHOLI Notestablished

WEIGHT PER GALLON (Ibs. 108

SPECIFIC GRAVITY: 129

SOLIDS (% by weight): 340

yl Not established

BOILING POINT (deg. C): ‘Not established

REBZING/MELTING POINT (deg, C): Not established

‘VAPOR PRESSURE (nnn Fig) Not established

VAPOR DENSITY Not established

EVAPORATION RATE: [Not established

OCTANOL/WATBR COEFFICIENT: Not established

SECTION 10: STABILITY AND REACTIVITY

STABILITY: Stable under normal conditions

CHEMICAL INCOMPATIBILITY: Alninam alloys

HAZARDOUS POLYMERIZATION: Will nt occur,

HAZARDOUS DECOMPOSITION PRODUCTS: Carbon monoxide, carbon dioxide Chlorine

so2414rM, Page 5 of

2-14-2008

MATERIAL SAFETY DATA SHEET

SECTION 11: TOXICOLOGICAL INFORMATION

[CHEMICAL NAME ——[EDSHECSO -

Inaton LES0 Monee I5049ppn8

chaise peta (TBSO Rar aTsouRNe

_____|bsmatosonabti> 10ateg - a

fameabonte Ont LDSD at = 6150nehg

faene on aso ra= ce

Intaon LCS Rat 45050mpe

[Demy LDsO Rabbi 14 EZ

[atest Ost L050 t= 1s0imareg

Intlation LCS0 Rae Fgh

[ion das Reena

“This product contains methylene eMoride, Compliance with

ayplicable pats of the Occupational Safety and Health

‘Aadministstion’s (OSHA) regulation 29 CFR 1910.1052,

METHYLENE CHLORIDE maybe required. Methylene chlor is

Tistod asa potential carcinogen by NTP, IARC, ACGIH aid OSHA.

‘SECTION 13: DISPOSAL. CONSIDERATIONS

“This produet contains greater than 10% chlorinated solvent. Spent chlorinated solvents are considered hazardous

‘waste; however, as a component of a mixture, chlorinated golvents do not meet the RCRA definition of hazardous

waste

wer 40 CER 261. Consult state, local, or provi

al authorities for more restrictive requirements,

LAND DISPOSAL RESTRICTIONS: Methylone chloride Toluene

SECTION {4: TRANSPORTATION INFORMATION

‘Consult Bill of Lading for ansportation information.

DOT; UNIS93, DICHLOROMETHANE MIXTURE, 6.1, ll. IN CONTAINERS 1679 POUNDS OR MORE:

‘UNI593, DICHLOROMETHANE MIXTURE, 6.1, Il, RQ

IATA; UNI593, DICHLOROMETHANE MIXTURE, 6.1, II. IN CONTAINERS 1679 POUNDS OR MORE:

‘UNI593, DICHLOROMETHANE MIXTURE, 6.1, 11, RQ

SECTION 15: REGULATORY INFORMATION.

INVENTORY STATUS

‘US. BPA TSCA: ‘This producti in compliance with the Toxic Substances Conttol Act's

Inventory requirements

CANADIAN CEPA DSL: This product isin compliance with the Canadian Domestic Substance List

requitements.

BUROPEAN BINECS: This products in compliance with the Furopesn Inventory of Notified and

Existing Chemie Substances requirements

AUSTRALIA AICS: This products in compliance with the Aust

Suibstauces requirements.

JAPAN ENCS: ‘This produet is in compliance withthe Japanese Bxisting and New Chemical

Inventory of Chemical

s024140M, Page 6 of 6

(2-14-2008

MATERIAL SAFETY DATA SHEET

Substances requirements

KOREAN TCCL: his product isin compliance withthe Korean Bxisting Chemicals List

requirements.

about the inventory stats ofthis product call 651

16-5858,

you need more inform

‘This product may contain chemical substances that are regulsted for export by various government agencies (such as

the Environmental Protection Ageney, the Bureau of industry and Seowity, or the Drug Enforcement

Administration, among oles). Before exporting this product from the USA or Canada, we recommend you contact

sat 651-236-5858 (USA) ot 450-655-1306 x227 (Canada) to request an export review.

FEDERAL REPORTING

EPA SARA Tile II Section 313

Unless listed below, this product does not contain toxie chemical(s subject to the reporting requirements of section

313 of Tite II of the Superfund Amendments and Reauthorization Act of 1986 (SARA) and 40 CFR part 372, EPA.

has advised that when a percentage range is listed the anidpoint may be use to fulfill reposting obligations.

Chess Naz

rc a CZ

50-70

1

WHMIS STATUS: Unless listed below, this product is not controlled under the Canadian Workplace Hazardous

‘Materials Information System,

D2AD2B

STATE REPORTING

‘This MSDS isnot propaved for dsteibution in California,

SECTION 16: ADDITIONAL INFORMATION

‘This Material Safety Data Sheet i prepared to comply with the United States Occupational Safety and Health

‘Adininistation (OSHA) Hazard Communication Standard (29 CFR 1910.1200) aud the Canadian Workplace

Hazardous Materials Information System (WHMIS).

Prepared by: The Global Regulatory Department

Phone: 651-236-5842

The information and vecommendations set forth herein are believed fo be accurate, Because some ofthe information

{is derived ftom information provided to Specialty Consinction Brands, Ine. ftom its suppliers, and beeause

Specialty Construction Brands, Ine, hes no control ever the conditions of handling and use, Specialty Construction

Brands, Ine. makes no warranty, expressed or implied, regarding the accuracy of the data or the resis to be

obtained ftom the use thereof. The information is supplied solely for your information and consideration, and

Specialty Construction Brands, ne, assumes no vesponsibility or use or reliance thereon. It isthe responsibilty of

the user of Specialty Construction Brands, In. products to comply with all applicable federal, state and local laws

and regulations.

{\, Science Lab, coin

Chemicals & Laboratory Equipment

enctivity 0

tFsronal a]

Fesieaia& |

Material Safety Data Sheet

Glass wool MSDS

Section 1: Chemical Product and Company Identification |

Prodluot Namo: Glass wool Contact information:

Catalog Cocos: SLG1363, Solencolab.com, Ine.

+4025 Sih Rd

Asi: 7631-86-9 Houston, Texas 77306

RTECS: VV7328000 US Sale 800-901-7247

International Seles: 1-204-441-4400

Order Online: SclenceLab.com

CHEMTREG (2411R Emergency Telephone), eal

‘TSCA: TSCA 6(b) Inventory: Class woo!

Ci Not applicable.

‘Synonym: Sand; Silla gel 4-800-424-9300

Chemical Name: Silicon dioxide Intornattlonal CHEMTREG, call: 1-703-527-3887

Chemical Formula: SiOz For non-emergency assistanco, call: 1-281-447-4400

Soction 2: Composition and Information on Ingredients

Composition:

Name CAS ‘by Welght

Glass wool 7631-86-9 400

‘Toxicological Data on Ingracllonts: Glass wool: ORAL. (LDSO)}: Acute: 4160 mgikg (Rat.

Section 3: Hazards Identification

Potontial Acute Health Effects:

Hazardous in case of ingestion, of inhalation, Sightly hazardous in case of skin contact (iran), of eye contact (Initent)

Potential Chronic Health Effects:

Hazardous in oase of Ingostion, Slightly hazardous in case of skin contact (iitant), of eye contact (iritant, of inhalation

CARCINOGENIC EFFECTS: Classified A3 (Provon for animal.) by ACGIH, MUTAGENIC EFFECTS: Not avalable.

TERATOGENIC EFFECTS: Not evallablo. DEVELOPMENTAL TOXICITY: Not available. The substance Is toxlo to lungs,

mucous membranes, Repeated or prolongad exposure to the substance can produce terget organs damage.

Soction 4: First Ald Measures.

yo Contact: No known effect on aye contact, rinse with water for a few minutes.

Skin Contact:

pe

‘After contact with skin, wash immediately with plenty of water. Gently and thoroughly wash the contaminated skin with running

water and non-abrasive soap. Be parllcularly careful fo clean folds, crevices, creases ond groin. Cover the Inftated skin with an

‘emollient. Ifiitation peretsts, seek medical attention.

Sorlouts Skin Contact: Not available.

Inhalation: Allow the villm to rest in a well ventilated arva, Seek immediate medteal attention.

Sorious Inhalation: Not available.

Ingestion:

'Do not induce vomiting. Loosen tight clothing such as a collar, tle, belt or waistoand. If tho vielim Is not broathing, perform

‘mouth-to-mouth resuscitation, Seek immediate medical attention.

Sorious Ingestion: Not available.

Section 5: Fire and Explosion Data

Flammability of the Product: Non-fiammable,

Auto-Ignitlon Tomporaturo:

lot applicable,

Flash Potnts: Not applicable,

Flammable Limits: Not appltcable.

Products of Combustion: Not available.

Fire Hazards in Presence of Various Substances: Not applicablo.

Explosion Hazards In Prosonco of Varlous Substances:

Risks of explosion of the product in prosonce of mechanical Impact: Not avalablo. Risks of explosfon of the product in

presence of static discharge: Not available.

Flro Fighting Modia and Instructions: Not epplcable.

Spoclal Remarks on Fire Hazards: Keap container tight closed.

‘Spoctal Remarks on Explosion Hazards: Not avalable,

Section

ccidontal Release Measures

Small Spill:

Use appropriate tools to put the spilled solld in a convenient waste disposal container. Finish cleaning by spreading water on

the contaminated surface and dispose of according to local and reglonal authority requirements,

Large Spi:

Uso a shovel to put the materiel Into a convenient waste disposal container. Finish cleaning by spreading wator on tho

contaminated surface and allow to evacuato through the sanitary system. 8 careful that the product Is not present al a

concentration level above TLV. Check TLV on the MSDS and with local authoritios.

Section 7: Handling and Storage

Procautlons:

Keep locked up Do not ingest. Do not breathe dust. Wear suitable protective clothing In case of insufficient ventilation, wear

sultable respiratory equipment If ingested, eeek madical advice Immediately and show the container or the label.

Storage:

Gerclnogenlo tratogonte or mutagenic materials should be stored in separate locked safely storage cablnot or root.

Section 8: Exposure Gontrols/Personal Protection

Engineering Controls:

Use process onelosures, local exhaust venation, oF other angineering controls o Keep altborne levels below recommended

‘xposurolimts user oparafons generate dust, fume oF mist, use ventlallon to Keop oxpostre to alrborne contaminants

below the exposure lint.

Personal Protection: Safely glasses, Lab coat, Dust respirator, Be sure to use an approvedicortfied respirator or equivalent.

Gloves,

Porsonal Protection in Case of a Large Spill:

Splash goggles. Full sult, Dust resplrator. Boots, Gloves. A solf contained breathing apparatus should be used to avold

inhalation of the product, Suggested protective clothing might not be suffcent; consult @ spociaist BEFORE handling this,

product,

Exposure Limits:

‘TWIA: 10 (rgimm3) Consul local authoriles for acceptable exposure limits,

Soctlon 9: Physical and Chemical Properties

Physical stato and appearance: Solid. (Sold powder.)

Odor: Odortess.

‘Taste: Tastoloss,

Molecular Weight: 60.08 g/mol

Col

Bolling Point: 2290°C (4046°F)

Molting Polnt: 1710°C (3110"F)

Critical Temperature: Not avaliable,

Spooitic Gravity: 2.2 (Water= 1)

Vapor Prossuro: Not applicable.

‘Vapor Density: Not aveilablo,

Volatility: Not available,

Odlor Threshold: Not evalable.

Wator/Oll Dist. Coeff: Notavetlable,

lonitelty (in Water): Not available,

Dispersion Properties: Not avallable.

‘Solubility: Insoluble in cold water, hot water, methanol, dothil ether, n-octanol.

Sectton 10: Stability and Reactivity Data

Stability: The product Is stable.

Instability Temperature: Not availabe.

Conulitons of Instability: Not available.

Incompatibility with vartous substancs

Gorrosivity: Not considered to he corrosive for motals and glass.

pa

Spoclal Remarks on Reactivity: Incompatible with hydrogon fluoride,

Spoclal Romarks on Corrosivity: Not avaliable,

Polymerfzation: No.

Section 14: Toxtcological Information

Routes of Entry: Inhalation, Ingestion.

Toxlelty to Animals: Acute oral toxteity (LOSO): 3160 mglkg (Rat.

Chronfe Effects on Human:

CARCINOGENIC EFFECTS: Classified AS (Proven for animal.) by ACGIH, The substance Is toxic to lungs, mucous.

mombranos.

Other Toxle Effects on Humans:

Hazardous In ease of ingestion, of Inhalation. Slightly hazardous in case of skin contact (tant),

‘Spootal Romarks on Toxielly to Animals: Not avallable.

Special Remarks on Chronle Effects on Humans: Not available.

Spocial Remarks on other Toxle Effects on Humans: Matera is rating fo mucous membranes and upper rospiralory

tact

Section 12: Ecological Information

Eeotoxteity: Not available.

BODS and COD: Not avallablo,

Products of Blodegradation:

Possibly hazardous short term degradation products are not ikely. However, long term degradation products may arise.

Toxicity of the Products of Blodegraclation: The products of degradation are as toxlo as the orlginal product

‘Spacial Remarks on the Products of Blocegradatton: Not evaliablo,

Section 13: Disposal Considerations

Waste Disposal:

Section 14: Transport Information

DOT Clasaifleation: Not 2 DOT controlled material (United States).

Idontificatton: Not applicable.

Spoctal Provislons for Transport: Not applicable,

Section 15: Other Regulatory Information

Federal ancl State Regulations:

California prop. 66: This product contains the following ingredients for which tho State of Calfornia has found to cause cancer,

birth dofects or othar reproduclive harm, which would require a warning under the slalute: Glass wool California prop. 65: This

product contains the following ingredients for which the State of California has found to causa cancer which would require &

pea

Warning under the statute: Glass wool Pennsylvania RTK: Glass wool Massachusalts RTK: Glass wool TSCA 8(b) inventory:

Glass woo!

thar Regulatlons: OSHA: Hazardous by definition of Hazard Communication Standard (29 CFR 1910.1200),

Other Classifications:

WHMIS (Canada): GLASS D-2A: Material causing other toxle effects (VERY TOXIC),

DSCL. (EEC):

R40- Possible risks of reversible effects,

HMIs (U.S.A):

Health Hazard: 4

Fire Hazard: 0

Reactivity: 0

Porsonal Protection: &

Nationat Fire Protection Association (U.S.A):

Hoalth: 4

Flammability: 0

Reactivity: 0

‘Spooitie hazar

Protective Equipment:

Gloves, Lab coat. Dust respirator. Bo suro to use an approved/corified respirator or equivalent, Wear appropriate respirator

‘when ventilation is inadequato, Safely glasses.

Section 16: Other Information

References:

-Hawley, 6.G.. The Condensed Chemical Dictionary, ‘4 od., New York N.Y., Van Nostrand Relnold, 1987. ~SAX, NA.

Dangerous Properties of Indutrial Materials, Toronto, Van Nostrand Reinold, Ge ed. 1984, -The Sigma-Aldtich Library of

Chomleal Safety Data, Edition Il

thor Special Considerations: Not avaliable,

Created: 10/09/2006 05:37 PM

Last Updated: 11/01/2010 12:00 PM

The information above Is belleved to be accurate and reprosents the best information currently available to us. However, we

‘make no warranty of morchantabilty or any other warranty, express or Implied, vith respect fo such information, and we assume

1no lahilly resulting from its use. Users should make their own investigations to determina the sulfabiily ofthe information for

thelr pardcular purposes, In no event shell SclenceL.ab.com be lable for any claims, losses, or damages of any third party or for

lost proiits or any special, indirect, Incidental, consequential or oxomplary damages, howsaever arising, even if SclenceLab,com

has heen advised of the possibiliy of such damages.

pb

@Fsixconstruct pons ferays

ot CONVENTION J

MIOMOC |] | CenTER &@ TOWER | ames

PROJECT

14.2 - Inspection and Test Plan

For HVAC Ducts

And Accessories

Method Statement ~ Installation of HVAC Ducts and Accessories

DOCUMENT NUMBER: ED-M-M-M-A-GN-0001

z30 Teas

S19NG IVAH 4O NOLLVTIVISNI 3H HO4 NVId 1S3l GN NOLLD3dSNI

wees) eae modgwoloig] opeiprenaa | cease

v ¥ 2 oUOH |, cee pang] PeYBuMeIG) pueswsunoeg | “OOTESZ | seBueH/suoddnssiong |»

/3=1p R249 Jovolf? “PNP dous panouddy | quensjay AoA ones

nt asne

4 u 4 vant] teusen feawensiemen| suounooa | SOE? vorsossu)

Teorey 0 Av2nuaa Avon ponovdey| werojydquon | ‘SOTE St Aaanod siewaxew

lenmugns nee veep (v) 9Tasnep

v a 2 reusrew | rersmugns Alena (| pueswusuinop | ‘cove Ez | enosdey ennwans vores] z

pononidy werS4pe| Suen Aven | UORDeS

uonesyods| eye

y 2 doug ponosdey | PBMANS Arona pue sy | orate eee renal

suymeia suena] WEAPRLAMEA | uoRDES

shun 95086109

ween [ws | arcs ae

enoday Ty) ereqionuey | souonbosg ssw |oonosdsu jo sdhi|yeyuoneupeds| | unsexpuewowadsuy | ow

os Te) RAO POH an) rome “Ghuensyi| SUMMA soueidexoy | /pomenser | alee | jouondunseg)aseua nom | Aunmoy

wopnedsurjo ahi /seniea uonsedsu

suonenyioads / uaumyers pousan /2unpan01 2000.94 rouerpow :ouresa|

“[DifOWd WIMOL B IND NOLINSANOD VHOG

00 "oN x04 z000 ow apa, pene 820 49 :e;oeg peauon]

SaIOSS390V GNY

@

193f0ud

YSMOL 8 YSLNID NOILNJANOD VHOG

zy ceaes

Andy

3

“Sq yey

‘TOO0-NO-W-W-WW-WN-03 “ON auaUINDOG

souossaaoy pue 5]9NG DAH Jo HORE|/EIsUI - WoMDIeIS POLRAIN O} USUNDERY

ort dL 34n Ur aynaze 01 Sunsieved mainas quauunoog ‘morn

lenosdde say Aue anurqucs Aeus {ONY “ALoyepUEUL aun pusne 0 3m

aouepuaNe a\p 204M S!3ulOd PIOH "lod PIOH-H ue puone 03 9s vi Ue 8 sonsed payaut aay SI UIOd SSDUNYIA "UO SSOUNA- A,

spuEBAINS “Ar Seqgaq:vi3 Aq pajosiuo> pue paunoysod aq 01 AuNR>e ¥.0NN -3

:S9]0N

sauauinooa| (4) yz asnt iy

visu /Suymeig #7220°7| wenger tone] GY TESHED sumed]

¥ x H ing sy | UORSIESULITY ‘o0z0 €z ung-sy jo wona|duio9}

sBumeig dous-t ener] UOP2S pue uonsadsul jeu

s movariy | UOReIeIsut iy eee JEMsIA (G3) sme) | say year ay /anewnaud

= i 32018 Vis E avovan wnowns| | ‘gore €z 235 L287 aly / 28

aumeia] swansea] gtuo sz

H s H womsedsu} uonenersulily | gous panoiddyuensiey Aen) ones uoneinsuy syanq|

403 wsanboy “T

Bumerg Suuauinoog) FE ene

sauossazoy pue

H s H a uonerersut iy | douspanciddyfuensioy —Aguan| ‘OOTE EZ v Pi

it uonaas

193f0dd 1 5a

, ewe

YAMOL 8 Y3LN39 NOLLNJANOD VHOG ronnsueors

DOHA

@Pssixconstruct

if ! CONVENTION

MIGTOC |) | CENTER & TOWER

PROJECT

14.3 - Inspection Checklist for

HVAC Ducts

And Accessories

‘Method statement ~ Installation of HVAC Ducts and Accessories

DOCUMENT NUMBER: ED-M-M-M-A-GN-0001

icons | DOHA CONVENTION CENTER

rida AND TOWER PROJECT

QAQC INSPECTION CHECK LIST FOR HVAC DUCTS AND ACCESSORIES

Inspection Request No. Date:

Location / Area Time:

S/N | ACTIVITIES / TEMS TO BE INSPECTED

Superiion

epav | sway | SPerion Acceptance Criteria,

1__|inspection of Materials ‘As per approved MIR

|_2 |installation / routing ae ‘As per Shop Drawing

3. installation are coordinated with other services. As per Shop Drawing

Flanges and Joints are sealed prior for AllJoints properly completed with

4 appropriate/ approved material & as

Insulation i

per manufacturer instruction

5. |Support,Brackets & Hangers fixed properly ‘As per Shop Drawing

6 _|Ducts are levelled and aligned As per Shop Drawing

_7 |Preumatic /Air leak test ee | __ As per Method Statement

8. |Cover for the incomplete ducts installation tH ‘As per Method Statement

| Ductsis protected during the remainder of the

[construction period. ‘As per Method Statement

Comments / Remarks:

‘Attachemant to Method Statement - Installation of HVAC Duets and Accessories

Document No. ED-M-M-M-A-GN-0003,

sheet Lf

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- RISK ASSESSMENT For Installation of HDPE Pipes and Fittings...Document21 pagesRISK ASSESSMENT For Installation of HDPE Pipes and Fittings...721917114 4757% (7)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Purchase Order For MemDocument3 pagesPurchase Order For Mem721917114 47No ratings yet

- UntitledDocument33 pagesUntitled721917114 47No ratings yet

- Reply From HPP0100-MS-0004 Method Statement SubmittalDocument1 pageReply From HPP0100-MS-0004 Method Statement Submittal721917114 47No ratings yet

- Ra Eg C Oo Ecur' Yfachtties: Document Submitta!Document64 pagesRa Eg C Oo Ecur' Yfachtties: Document Submitta!721917114 47No ratings yet

- 383-To-NPP-17-0117 MS, ITP and RA For Geotechnical Investigation WorksDocument35 pages383-To-NPP-17-0117 MS, ITP and RA For Geotechnical Investigation Works721917114 47No ratings yet

- Responces To HPP Comments - Strategic Food Storage Facility - Al Jaber Engineering - 30 April 2018Document6 pagesResponces To HPP Comments - Strategic Food Storage Facility - Al Jaber Engineering - 30 April 2018721917114 47No ratings yet

- Enc:osu :: Od: ReceivingDocument40 pagesEnc:osu :: Od: Receiving721917114 47No ratings yet

- 383-NPP-0085-LT-0058 Reply From NPPDocument2 pages383-NPP-0085-LT-0058 Reply From NPP721917114 47No ratings yet

- Reply From HPP0100-MS-0005 Method Statement SubmittalDocument1 pageReply From HPP0100-MS-0005 Method Statement Submittal721917114 47No ratings yet

- 383-NPP-0085-LT-0108 Reply From NPPDocument3 pages383-NPP-0085-LT-0108 Reply From NPP721917114 47No ratings yet

- Reply From HPP0100-MS-0001 Method Statement SubmittalDocument1 pageReply From HPP0100-MS-0001 Method Statement Submittal721917114 47No ratings yet

- 383-NPP-0085-LT-0016 - Rev - 0 Reply From NPPDocument3 pages383-NPP-0085-LT-0016 - Rev - 0 Reply From NPP721917114 47No ratings yet

- C823 3 Doc MST Mec 009Document24 pagesC823 3 Doc MST Mec 009721917114 47No ratings yet

- 1.internal Concrete Pour Register Updated On 25-01-2023Document9 pages1.internal Concrete Pour Register Updated On 25-01-2023721917114 47No ratings yet

- C823 3 Mtin Civ 042Document2 pagesC823 3 Mtin Civ 042721917114 47No ratings yet

- New IndexDocument1 pageNew Index721917114 47No ratings yet

- New IndexDocument1 pageNew Index721917114 47No ratings yet

- Material Inspection Report (BP 02B)Document2 pagesMaterial Inspection Report (BP 02B)721917114 47No ratings yet

- Sequence of OperationDocument1 pageSequence of Operation721917114 47No ratings yet

- Qinph2 P08 Tes MST JTC Ele 00012 - R0Document34 pagesQinph2 P08 Tes MST JTC Ele 00012 - R0721917114 47No ratings yet

- Regarding INR LogDocument51 pagesRegarding INR Log721917114 47No ratings yet

- Installation Clean Agent SystemsDocument14 pagesInstallation Clean Agent Systems721917114 47No ratings yet

- Submittal Package No 3238.1Document1 pageSubmittal Package No 3238.1721917114 47No ratings yet

- RFIA Formrev00 (BP02B)Document2 pagesRFIA Formrev00 (BP02B)721917114 47No ratings yet

- RFI Formrev 01Document1 pageRFI Formrev 01721917114 47No ratings yet

- C823 3 Doc MST Mec 004Document23 pagesC823 3 Doc MST Mec 004721917114 47No ratings yet

- SUBMITTAL - Mussaimeer Pumping Station Surya ExhaustDocument134 pagesSUBMITTAL - Mussaimeer Pumping Station Surya Exhaust721917114 47No ratings yet

- HDPE Manufacturer RecommendationDocument3 pagesHDPE Manufacturer Recommendation721917114 47100% (1)

- 0304 Concrete Delivery ReportDocument8 pages0304 Concrete Delivery Report721917114 47No ratings yet