Professional Documents

Culture Documents

Untitled

Untitled

Uploaded by

721917114 470 ratings0% found this document useful (0 votes)

31 views33 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

31 views33 pagesUntitled

Untitled

Uploaded by

721917114 47Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 33

Mi ALJABER

M@™ ENGINEERING

NPPO085-LTR-JEC-NPP-0203 19 September 2017

Mis. New Port Project Steering Committee

P.O. Box: 28333

Doha, Qatar

Tel: 4406 4444

Fax: 4406 4420

Attention: The Engineer

Mr. Maisar Jamil E-Qutami

Project Executive Director

Project: New Port Project

Contract No. NPP/O085: Strategic Food Security Facilities

‘Subject: Method Statement for High Energy Impact Compaction Works

Dear Sir,

‘The Contractor hereby submits the method statement for the High Energy Impact Compaction works,

associated withthe relevant inspection and testing plan (ITP) and risk assessment (RA) forthe Engineer's

review and approval

The Contractor looks forward to receiving the Engineer's early approval on the submitted documents,

Enclosures:

2. Inspection Test Plan (ITP) (2 Pages)

1. Method Statement for High energy Impact Compaction (21 Pages)

Lf 3. Risk assessment (RA) (9 Pages)

NEW PORT PROJECT

Allaber Engineering Company

[NPP /0085: Strategic Food Storage Facilities

Method Statement

7 ALJABER

‘Ml ENGINEERING

om ee

Method Statement for High Energy Impact Compaction

NPP/0085

(NPPOO85-CIV-MS-00003_0)

; Preparedby | pougenon

Rev Date Modifications Content. (full name) Designatior

soaae | Cnstcbn

0 | s85en27 Fite tise | Coton |

:

2

3

Checked by Reviewed by Approved by

Tatnane: | MnDrw.TupANO | cusioN ctnee SimorALASHAe

Designation: Sr. QA/QC Engineer QA/QC MANAGER PROJECT DIRECTOR

Date: 18-Sep-17 Laser

Surat FS [Seer

2 c

Page 1 of 18

NEW PORT PROJECT ‘ML ALJABER

Aljaber Engineering Company Method Statement ‘i ENGINEERING

[NPP/OOBS: Strategic Food Storage Facites OM ee

[CONTENT

CONTENT, renee 2

1 INTRODUCTION sare 3

1 PurPost... 3

12 Score oF WorK, od

1.3 REQUIRED PeRMITs od

2 ROLES AND RESPONSIBILITIES... 4

2.1 MAINCONTRACTOR - : 4

3 DEFINITIONS / ABBREVIATION / REFERENCE: rarer

3.1 —_DeFINmoN:

3.2 ABBREVIATIONS...

3.3 ReFeReNces

4 RESOURCES wenn

4.1 Manpower...

4.2 PLANTAND EQUIPMENT.

43 MATERIALS,

5 HEALTH / SAFETY / ENVIRONMENTAL PROVISIONS...

5.1 HEALTHAND SAFETY

5.1.1 Emergency response

5.2 ENVIRONMENTAL ISSUES...

5.2.1. Aspect and Impact identification

5.2.2. Aspect Identification and Mitigation measure

6 SEQUENCE OF WORKS eee es

6.1 INTRODUCTION.

6.2 DETAILED METHODOLOGY. 16

7 APPENDICES sree

Page 2of 19

[NEW PORT PROJECT MB ALIABER

Aljaber Engineering Company Method Statement ‘Ml ENGINEERING

[NPP /OO8S: Strategie Food Storage Faclities MD 12) vba

[7 intropucrion

1.1 PURPOSE

The purpose of this document is to describe the general working methodology for High Energy Impact

Compaction to be followed in Strategic Food Security Facilities Project (NPPOOBS-SFSF) and to ensure that

during all work phases will be undertaken efficiently as possible and by adhering to all appropriate qu:

health, safety security and environmental requirements of the project.

The Contractor reserves his right to adapt the methods of execution as contained in this document from time

to time, aecording to specific site conditions, in agreement with the Engineer.

1.2 SCOPEOF WORK

‘This method statement identifies the general steps and arrangement which should be followed during High

Energy Impact Compaction in NPPOO8S-SFSF Infrastructure and Building and describes as follows:

A. Preparatory and Preliminary Works

B, High Energy Impact Compaction

C._ Testing & Reporting

This method statement is subject to the requirements as stated in the following regulatory & statutory

documents, applicable standards / specifications / building codes:

+ Project Specification

+ Approved shop drawings

+ Contract Drawings

+ Project Quality Plan

*+ Project HSE Plan

1.3. REQUIRED PERMITS

The following permits are required for the execution of this method statement:

+ MME Permit

+ Related statutory permits from government institutions.

Page 3 of 18

[NEW PoRT PROJECT 7 ALJABER

Aljaber Englnesring Company Method Statement ‘MB ENGINEERING

[NPP/OOBS: Strategic Food Storage Facities

[2 owes ano nesponsiouiTies

2 MAIN CONTRACTOR

Project Director

+ The Project Director is over all responsible for execution of this method statement and ensures that his

team of Engineers and the Sub-Contractor are aware of this method statement. All resources to include

personnel, required material and necessary equipment are available in order to carry out the work as,

planned and without delay.

+ Heis also in charge for the implementation ofall safety, health and environmental arrangements for JECand

its Sub-Contractor(s) and/or Sub-Consultant().

Project Manager

+ The Project Manager is responsible for managing the Construction activities and provide general interface

between Sub-contractors.

+ Monitor progress and site resources.

+ Review of the construction methodologies and ensuring the construction team and subcontractors abide

with agreed methodologies.

+ Implement agreed Quality procedures and ensure the Construction Inspection / Supervision Team

understands the requirements.

+ Adopt a leading role with respect to JEC Quality and SH&E procedures and provide assistance to the

team when required.

Construction Manager

+The Construction Manager is responsible for overseeing and coordinating the work has been carried out on

field as per the approved method statement, ITP, RA and drawings.

+ He co-ordinates with the Safety and Health Specialist and with the Environment Engineer.

+ He is also in charge to ensure that all necessary required equipment, tools and materials are in place prior

to commencement of the works.

Senior Site Engineer

+ The Senior Site Engineer is responsible for overseeing and coordinating the work has been carried out on

field as per the approved method statement.

+ He co-ordinates with the Safety and Health Specialist and with the Environment Engineer.

+ He is also in charge to ensure that all necessary required equipment, tools and materials are in place prior

to commencement of the works.

QA/QC Manager

= The QA/QC Manager is responsible to ensure that all the operational documents and procedures are

approved and available at site.

‘= He shall provide necessary information pertaining to inspection testing to Construction team and Quality

‘team, and shall ensure that all requirements are effectively implemented,

‘= He is responsible for follow up of the assigned tasks to the Quality team and working closely with related

Engineering and Construction team for compliance with project requirements.

QA/QC Engineer

‘+ The QA/QC Engineer is responsible to ensure work has been executed on field as per the specification and.

approved method statement.

Safety and Health Specialist

+ The Safety and Health Specialist is responsible to ensure that all safety precautions and procedures are in

place.

+ He may conduct audits or inspections to ensure said compliance.

Paget of 19

NEW PORT PROJECT 20 MB ALIABER

‘Aljaber Engineering Company Method Statement

[NPP/008S: Strategic Food Storage Facilities

Safety and Health Officer

+ The Safety and Health officer is responsible for monitoring and ensuring that all safety precautions are being

followed by the respective engineers, supervisory staff, In addition ensure that the supervisory staff have

confirmed checked that all personnel have undergone any necessary induction trainings and that all

personnel are equipped with (PPE) Personal Protective Equipment.

+The Safety officer shall ensure that all works have undergone the necessary pre commencement STARRT

talk provided by the works supervisor.

+The Safety officer shall periodically inspect all works ensuring adequate signage and permits are in place.

+ The Safety officer shall conduct inspections as and where necessary to ensure plant equipment is in full

compliance with the projects requirements. Where deemed appropriate issue corrective action notices and

or observation reports in line with JEC procedures.

First Aider

+ The First Aider ensures first aid kits are provisioned and are adequately available.

+ He communicates with Emergency Medical Services when necessary, reassures bystanders, and ensures

the wellbeing of work colleagues, undertakes record keeping and recording.

Fire Warden

+ The First Warden takes immediate action as per his training to fight the fire, evacuates the personnel, uses

the firefighting system.

Rigger

+ The riggers a 3rd party certified employee who assists in movement of heavy equipment and by calculating

the size and type of sling required for a particular lift, selecting the slings to lift the load, attaching the slings

to the load and assisting in controlling the load as its lifted by a crane.

+ He also checks and ensures lifting equipment are in good condition each day, loads are being lifted within

‘the lift capacity, barricading of the lifting zones are in place and pedestrians remain out of the lift zone.

Banksman

+The Vehicle Banksman is the person who isin charge of directing the movements of large vehicles on a work

site, particularly large cranes during loading and unloading,

Environment Manager

+ The Environment Manger is responsible to ensure that all environmental arrangements are in place, all

personnel have undergone any necessary induction training and that all personnel are trained and

complaint with all environmental regulations, legislation, policies and procedures.

+ He may conduct audits or inspections to ensure said compliance.

Environmental Engineer

+ The Environmental Engineer is responsible for monitoring all activities related to ground improvement to

‘ensure compliance with all environmental regulations and commitments and to lead mitigation and/or

response procedures in the event of a non-compliance with permit conditions or an environmental incident

(e.g. hydrocarbon spill, chemical release, etc.)

+ He will conduct inspections to ensure said compliance,

Page of 19

[NEW PORT PROJECT

0M ALJABER

Aljaber Engineering Company Method Statement ‘Mil ENGINEERING

/o0as: Strategic Food Storage Facilities Om ae

3__ DEFINITIONS / ABBREVIATION / REFERENCES

3.1_ DEFINITIONS

SESE Strategic Food Security Facilities,

CONTRACTOR | Ablaber Engineering Company (JEC)

sumoven |e Goverment ofthe Sef ty represented by he iow Por roa Seng

Committee

PMC Project Management Consultant (AECOM)

Laboratory | Al, hand others

3.2. ABBREVIATIONS

EC Environmental Consultant (COW!)

eC Engineering Design Consultant

TAR Improvement Action Report ~

TEC Independent Engineering Consultant

FA issued for Approval 7 J

TFC Issued for Construction

A issued for information

FR issued for Review

IR inspection Request

TTP Inspection Test Plan

KPI Key Performance Indicator 7

Ms Method of Statement

ee Employer Designated Pork Master Systems Integration Consultant

[110s ‘Material Safety Data Sheet -

NCR ‘Non Conformance Report

PMc Programme Management Consultant

Pap Project Quality Plan

“esas Qatar Sustainability Assessment System

a Employer Designated Security Sub-Contrator (Qatar Security Systems Co)

RA Risk Assessment - -

RF Request for Information - -

HEIC High Energy Impact Compaction 7

eae Safety, Health and Environment

SQOR Site Quality Observation Report

CEMP —__| Construction Environmental Management Plan -

Page 6 of 19

NEW PORT PROJECT 7M ALIABER

‘Aljaber Engineering Company Method Statement Mil ENGINEERING

INPP/008S: Strategic Food Storage Facilites CM oe

3.3 REFERENCES

Document Reference Document title

'NPPOGBS-CIV-ITP-00003 _| ITP for High Energy Impact Compaction

'NPPOO8S-CIV-RA-00003_| RA for High Energy Impact Compaction

1/383/NPP/SK/aa/17/0042 | Health and Safety Management Plan

1/383/NPP/Sk/aa/17/0046 | Traffic Management Plan

1/383/NPP/Sk/aa/17/0042 | Construction Environmental Management Plan

acs 2014 Qatar Construction Specification - 2014

Page 7 of 19

[NEw PORT PROJECT

Aljaber Engineering Company Method Statement

[NPP/008S: Strategic Food Storage Facities

RESOURCES

4.1 MANPOWER

+ Site Engineer

* Safety Officers

* Foreman

* Supervisors

* Charge Hands

* survey Team

* HEIC Drivers/Operators

* Labour

* Riggers

* Banksman

* Fire Warden

42 PLANTAND EQUIPMENT

‘The following equipment and materials shall be used for the works:

Bulldozers

Trailer Trucks

High Energy Impact Roller Compactors

Grader

Survey Instruments

Note: Safety officer will only check the availability and validity of registration, insurances and 3rd Party fitness

certificates of plant, operator and equipment and its physical condition. Mechanical maintenance team should

inspect thoroughly the plant or equipment before its use on site that all are operational as per manufacturer's

specification and standards.

4.3 MATERIALS

NA

Page 8 of19

NEW PORT PROJECT

Aljaber Engineering Company Method Statement

[NPP/OO8S: Strategic Food Storage Factities

[5 _ HEALTH / SAFETY / ENVIRONMENTAL PROVISIONS

5.1 HEALTH AND SAFETY

‘The health and safety activities are to be in accordance with the relevant Health, Safety and Environmental

requirements as described, but not limited to, within the guidelines for method statement.

The Sub-Contractor shall ensure that the JEC Health and Safety Management Plan is followed stringently; in

addition, Sub-Contractor shall ensure their internal health and safety procedures are followed by all crew

‘members which is prepared to sult. Where applicable particular site safety procedures shall be adhered to at

all times during site works.

Prior to commencement of any work activity crew members shall ensure all relevant third party certificates

for plant equipment to be in place.

Allssite employees to attend both QSS and JEC safety inductions.

‘A Daily tool box talk shall be given to all employees; this shall include a 360 Haz ID, findings of which shall be

discussed and where practical mitigated,

All employees shall hold on their possession of New Port Project identification ID cards along with JEC

training ID Cards

In the event of an emergency the Project Engineer / Foreman shall immediately inform the JEC Project

Director in addition the S&H Manager providing them with all relevant information regarding the emergency.

Unobstructed safe Access and Egress shall be provided and maintained during the course of all work

activities

During the works Contractor shall ensure adequate barricading in order to restrict access to authorized

personnel only.

Make sure all employees are Safety inducted before they can work on site.

Make sure employees take the right equipment with them on visits. Check they have been trained and know

how to use it

Keep available, records of hazards on particular sites. Make sure all relevant people are notified,

Make sure a supply of the right equipment is available.

Helmets, steel capped high angle shoes, Safety goggles, High visibility jackets, face masks, overalls should be

appropriate and in good condition.

‘Assess the risks of manual handling before going to the site and look at the materials being used or stored.

Lighting devices shall be set up at the work area and ensure the required Lux available as per QCS 2014 during

night shift

The lifting area should be barricaded and appropriate signs boards to be fixed to warn and avoid the

unauthorized entry.

Copies of driver’s/operator's license vehicle's registration and security passes to be submitted to Company

safety department before commencing the work.

All moving crane/equipment shall have reverse horn. All major equipment and crane shall be tested and

certified by Third Party prior to mobilization to site.

‘Ample and unobstructed passage shall be maintained at al times in and around the truck loading and lifting

space.

All equipment movement at job site must be controlled by third party certified rigger/banks man.

Trained, Competent and Authorized Supervision present at all times to ensure workers are safely working on

site

Page 9 of 18,

NEW PORT PROJECT ‘Mi ALJABER

[Aljaber Engineering Company Method Statement BE ENGINEERING

[NPP /0085: Strategic Food Storage Facities

Personal Protective Equipment Requirements

© Safety Helmet

Safety Goggles

Safety Boots

High Visibility Vest

Hand Gloves

Ear Plugs

Full Body Harness

Respiratory Protection

Provision of additional PPE required for the specified activities i.e. Hot work and working near or over,

water - Life jacket, Life buoy/ring with rope, welding apron, welding mask, welding gloves etc.

Information to personnel

Health and Safety knowledge shall be disseminated through;

© SH&E Site Safety Inductions

Ensure STARRT and/or RAMS are discussed with the work group prior to works commencing

Safety toolbox talks

Environmental toolbox talks

SHBE training records / Toolbox attendance register

Training courses (Internal and Third Party Training)

Group discussions of Method Statement and Job Hazard Analysis

SHBE Bulletin /SH&€E Site Notice Boards

‘SHE Personnel site instructions

Site Engineers, Site Supervisors and Site Foreman,

Site Traffic Management

‘As per Contractor's approved Site Traffic Management Plan

Site Emergency Procedures

‘As per contractor's approved Site / Office Emergency Response Plan

Summer and Ramadan working hours

In reference to the ministerial decision no.16 of the year 2007, determining working hours in bare sites in

summer, the following working hours shall be complied from the 15* of June till 31° of August that the works

shall not exceeding 11.30am and shall not start in the evening period before 3.00pm.

During Ramadan, the works shall comply with Qatar Labour Law Regulation Article 73 and 74 with regards to

Ramadan working hours (maximum 36 hours per week)

Site Night Works SH&E Procedure

‘Night Works and Activities beyond Normal Working Hours

‘* The project HSE procedures, standards and regulations must be integrated with this activity which

would include the prevention and protection measures necessary to perform the work in a safe

manner.

‘© Authorization from the Site Manager or his designee to work beyond normal working hours must be

obtained;

Page 100f 19

NEW PORT PROJECT

‘Ml ALJABER

‘Aljaber Engineering Company Method Statement ENGINEERING

[NPP /0O85: Strategic Food Storage Facilities

ME) aka

Al works to be performed by the Subcontractor outside the normal working hours must be pre-

approved by the main contractor.

Method Statement and Risk Assessment must be submitted in advance by site management or the

‘Sub-contractor and reviewed by HSE Department.

The Client's Representative must be properly no!

precautions to be taken.

ied of the work and must agree with the necessary

Coordination must be made with other activities such as Site Radiography, Concrete works, Demolition

works, etc. and ensure that signs, barriers, flashing lights and adequate lightings are provided.

‘Adequate medical coverage must be in place during work activities;

All necessary tools and equipment must be provided and that personnel access routes to the tools are

illuminated in accordance with this procedure;

Ensure regular inspection and maintenance of lighting equipment;

Ensure that cables and other material are located in a way that prevents trip hazards;

Public access to work areas must be restricted to the extent possible;

Ensure that employees are provided with suitable and sufficient personal protective equipment;

First Aid Attendant(s) must be present when working at night.

Lighting

Lighting is needed for safety, productivity and security

‘The color and nature of any artificial lightings must not adversely, affect or change the perception of

the color of any safety signs.

Where failure of the primary artificial lighting would create a risk to health or safety of the persons at

work, secondary lighting must be provided.

Suitable lightings and equipment must be provided and shall be checked in accordance with temporary

lightings procedures.

Lights provided for this purpose shall be sited to avoid glare and spaced to provide adequate light for

the areas covered.

‘Tower lightings shall be installed and maintained and used in accordance with the Manufacturer's

instructions in addition to ensuring that

© The equipment is Third party certified,

(© Ensure that the ground is firm and reasonably level.

(© Extend the outriggers fully and wind down the jacks to take the weight of the unit.

(© Ensure drip trays, firefighting equipment and barricades are provided,

‘© Is operated in well ventilated areas,

‘© Maintained by authorized and competent personnel. Daily checks carried out and checklist

‘maintained.

‘Tower lighting shall be sited in a manner that illuminates all parts of the area where the workis taking

place.

Lighting poles and other metal parts shall be earthed and the circuit fitted with residual current

devices.

Generators provided shall be checked prior to use to ensure they meet the requirements.

Page 11 of 19

[NEW PORT PROJECT 7 ALIABER

Aljaber Engineering Company Method Statement ENGINEERING

[NPP/0ORS: tratege Food Storage Facilities ME 2)

‘* Cables employed for the purpose of temporary lighting shall be routed to ensure that they do not

present a trip hazard or other obstruction.

Mlumination.

Levels of Illurination

Illumination is measured in units of lumens or lux which is the amount of light falling on one square meter. (See

Recommended Levels for Site Lighting below)

Recomment for Site Lighti

‘Applies to both indoor and outdoor activities and relates to the value on the ground, floor or horizontal working

plane. They may require adjustment according to district brightness.

Purpose Governing factors Design value

(Lux)

Security jepending on the degree of risk 530

‘Movement and handling [Movement of people, machines and vehicles, handling 20

terials, walkways and access routes

“Stores and stockyards _ [For stored goods 30

Site entrances sneral access, vehicle and pedestrian 30

General workarea _eneral rough work, ste clearance 50

Craft work Reinforcing concreting, shuttering erection, bricklaying, 100

: joinery, all work with power tools and circular saws, plastering

Fine craft work painting, electrical, plumbing, shop-fittng, brickwork ou

‘Special work Retouching paint, French polishing 500

Site huts Rest rooms, locker rooms, toilets 150

Site offices in desks and reference tables, general lighting of drawing office| 500

Drawing offices on site [On drawing boards 750

570

Emergency lighting For escape and standby purposes

Lights meters will be used to check levels of illumination. illumination should be measured at the

workplace, not at the light fitting.

‘© When the distance from the light source to the workplace is doubled the illumination level will be

reduced to one quarter (inverse square law).

Site Lighting — For Area lighting with floor lights or beam floodlights

Page 12 0f 18

NEW PORT PROJECT MB ALIABER

Aljaber Engineering Company Method Statement ‘il ENGINEERING

INPP/0O8S: Strategic Food Storage Facilities vm s

‘© Allareas should receive light from at least two directions.

+ Fittings should be mounted on poles; towers and high masts must be securely stayed.

‘© Fittings should usually be spaced at not more than two or three times the mounting height.

‘© 230 volts is generally accepted for fixed floodlighting, mounted well above ground,

‘© Additional lighting should be provided in hazardous area,

Permits and Certificates

SSH&E Work Permits and Certifications (as per activity requirements) ~ These should correlate with the activity

Risk Assessment.

© Lifting plan

‘+ Mobile plant operations ~ Third party certification (competence certificates) for workers, operators.

Equipment valid registration, insurance and fitness certifications, operator dally inspection checklists

available,

5.1.1 EMERGENCY RESPONSE

ies for emergency responses are to be in accordance with NPPOO8S-JEC-EMP-00001 (as well as

NPPOO8S-JEC-HSE-0001) as described, but not limited to, within the guidelines for method statement.

5.2 ENVIRONMENTAL ISSUES

All relevant Qatari Environmental Legislation will be adhered to prior to, and during construction. MoE

Permits will be applied for and granted prior to carrying out works where permits are required. The approved

CEMP shall be stringently adhered to. Environmental risks and mitigation Measures will be identified in order

to pre-empt potential environmental incidents and employ corrective measures where necessary.

5.2.1 ASPECT AND IMPACT IDENTIFICATION

‘The aspects and impacts relevant to the works described in the method statement are addressed through

the Aspect Impact Assessment and Mitigation table attached in this section.

5.2.2 ASPECT IDENTIFICATION AND MITIGATION MEASURES

The mitigation measures are to specifically address the identified environmental impacts, in addition to and

not limited to, the items as described within the guidelines for method statement.

Environmental | Source/Activity | Relevant permits | Relevant control | Additional mitigation

aspect procedure measures

Soil/groundwater | Fuel, oil or CEMP Use drip trays, | Maintain appropriate spill

contamination | hydraulic fluid bundingetc., | kits on site at all times. Train

from equipment during and | relevant staff for emergency

operation, spill response.

maintenance

Soil/groundwater | Chemicals and ‘CEMP Store chemicals in | Maintain appropriate spill

contamination hazardous approved facility, | kits on site at all times. Train

substances Follow chemical | relevant staff for emergency

transportation and spill response.

handling

procedures

Page 13 of 19

NEW PORT PROJECT

Al ALJABER

‘Aljaber Engineering Company Method Statement ‘Ml ENGINEERING

INPP/008S: Strategic Food Storage Facilities OM ue

Soil/groundwater | Cement/concrete EMP. Ensure no concrete | Ensure appropriate training

contamination spillage on exposed | via Toolbox Talk so that

earth. Mixon | labor are aware concrete

impermeable _| spillage constitutes pollution

surface. Wash out

shoot in designated

wash bay

Greenhouse gas_| Operation of CEM? Ensure all Keep equipment well

‘emissions fossil fuel equipment | maintained and monitor for

combustion (delivery trucks and | unusual behavior, .e..

engines pumps) have ‘excessive smoke

undergone

emissions test

Housekeeping | Dally activities, cEMP Promptly collect all | Implement the principles of

rubbish and | reduce, reuse and recycle to

dispose in limit the amount of waste

approved generated

receptacle

‘irqualityand | Storage and CEM? ‘Adhere to speed | Dampen roads using water

dust transportation of limits in orderto | truck fitted with sprinkler

concrete reduce dust | system should dust become

generation excessive

Page 14 of 19

NEW PORT PROJECT

‘Aljaber Engineering Company

INPP/0085: Strategic Food Storage Facilites

Method Statement

i ALJABER

‘Ml ENGINEERING

=

6 _ SEQUENCE OF WORKS

6.1 INTRODUCTION

Impact compaction is a form of dynamic compaction whereby high levels of energy are imparted into

the ground at low frequency. Special shaped (3-sided, 4-sided or 5-sided) drums are used.

High energy impact compaction involves the transfer of compaction energy into the soil by means of

the lifting and falling motion of non-circular rotating masses. The rotation of such masses to their

highest point results in an effective potential energy build up. Further rotation of these masses results

in the conversion of this potential energy into a falling kinetic energy, which is transferred to the soil

upon the impact of the lowest point of the masses with the surface of the soil. The amount of energy

transferred (compaction effort) is closely related to the amount of potential energy generated in the

lifting process.

LEN

Cae

Depth of NS

Influence 7 ON,

‘STATIC VIBRATORY IMPACT

Wes.cn static pressure low amplitude / igh amplitude /

ENSBY: and kneading high frequency low frequency

Figure 1: Comparison between vibratory rollers and high energy impact compactors

Depth of influence with this type of compactors in Figure 1 is between 2-4 meters, depending on compactor

weight, soil type and soil saturation,

‘The HEIC-unit(s) is towed along the fill by means of a challenger tractor — or equivalent — at a relatively high

speed of 10 to 15 km/h. The non-circular masses are forced to rotate and to generate a series of high impact

‘and high amplitude blows that are delivered to the surface of the soil at a relatively low frequency of 90 to

1130 blows per minute. Because the energy is transferred as a dynamic load, itis possible to generate very

high compaction forces. The pictures below represent the working principle of the HEIC technique.

Figure 2: Double HEIC pulled by a Dump Truck

Page 15 of 19

NEW PORT PROJECT ALJABER

‘Aljaber Engineering Company Method Statement il ENGINEERING

'NPP/0085: Strategic Food Storage Facilites -_

6.2 DETAILED METHODOLOGY

‘A. PREPARATORY AND PRELIMINARY WORKS

1. JEC Surveyor will stake out on site the areas to be compacted.

2, JEC will ensure that the area to be compacted are free from any unsuitable materials, graded

and levelled in order to ensure a proper working platform for the HEIC.

B._ HIGH ENERGY IMPACT COMPACTION (HEIC)

1. In order to further optimize the compaction pattern, tractors can be equipped with positioning

system allowing online monitoring of the number of tracks compacted.

2. The patterns will be monitored and the more efficient (compaction, time and cost) process will

be applied given the space availability.

3. The entire area has been divided into sub-areas as shown in the attached sketch in Appendix A,

‘The number of passes for each Sub-area shall be of 20.

4. Prior and in between passes, the area will be levelled by graders in order to improve the

maneuverability of the tractor.

5. The drawings below illustrate two different cases. The first sketch shows a “corkscrew” pattern,

which is generally used for the compaction of vast areas, while the second shows a “fix & oval”

pattern which is commonly used for narrow areas and longer rectangular strips.

|

|

Figure 3: Typical driving pattern

Adjacent areas are compacted with a certain ‘overlapping’ pattern. This principle is illustrated in the drawing

below,

Figure 1: Overlapping pattern for adjacent areas

‘Typical compaction layout

Page 16 of 19|

[NEW PORT PROJECT ‘Mi ALJABER

‘Aljaber Engineering Company Method Statement ENGINEERING

[NP /0085: Strategic Food Storage Facilities —_ .

Figure 2: Double HEIC pulled by a tractor (Challenger)

Figure 3: Double HEIC pulled by a tractor (Challenger)

Page 17 of 19

NEW PORT PROJECT Mi ALJABER

Aljaber Engineering Company Method Statement Ml ENGINEERING

'NPP/0085: Strategic Food Storage Facilities —_

Figure 4: Double HEIC pulled by an articulated dumper

6. The area to compact with HEIC should be free of open excavation as the impact of the rollers on

the ground may cause the edges of excavation collapse.

7. The area to compact with HEIC should be free a structures as the vibration generated by the

impact of the rollers may cause the apparition of cracks or even displacement of the structure,

8. HEIC should be operated at a speed comprised between 10-15 km/hour to optimize the energy

transferred to the underground by the impact of the rollers.

9. The area should always be large enough to allow the HEIC to gain the right speed prior entering

the compaction field and to minimize the edging effect.

10. Overlapping the passes shall be done to surcharge the complete underground.

C._ TESTING & REPORTING

Testing shall be done as per the frequency, locations, CPT, SPT, etc. as mentioned in the Method

Statement for Geotechnical Investigation with Ref No. NPPOO8S-CIV-MS-00002. The reports shall be

submitted to the Designer for verification and conclusion.

Page 18 of 19,

‘NEw PoRT PROJECT Piney

Aljaber Engineering Company Method Statement Ml ENGINEERING

[NPP/008S: Strategic Food Storage Faces we

[7_appenvices

‘A | site Layout for HEIC NPPOOBS-JEC-SK-GN-

(00005

B | inspection Check Sheet for High Energy Impact Compaction NPPOO8S-JEC-QCF-

0001.0

c

D

E

F

6

H

Ete,

Page 19 0f 19

‘MM ALJABER

MM ENGINEERING

wap

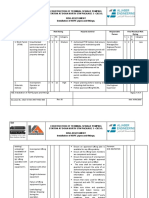

fen ron Pacer HIGH ENERGY IMPACT COMPACTION

‘Alber togioeeing Company INSPECTION CHECK SHEET

'NPP/0085:Strateri Food Storage Facity

Contract No: NPP-0085

IR Ref. No.

Inspection

[RA Ret. No. Date:

(COMPLIANCE

sr ITEM TO BE CHECKED REMARKS:

ves | no | NA

1. [Check instrument having valid calibration certificate

Check the area to be compacted are free from any unsuitable materials, graded and

levelled

23 | cheek the sting out ofthe works

4. | Check the compaction patterns and number of passes are done as per required

5 | Check the Finished Ground Level after compaction as per required

Inspection Comments:

TEC CONSTRUCTION / SUB-CON

(Cate Signatre over Pte Name) (Date & Sinatra ovr Pred Name (Gate & Signature oer Ped Nae)

‘NPPo08S-JEC-OCF-0001.0

19 August 2017

zuorstey

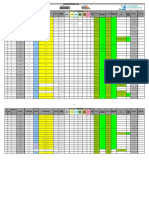

owas (000

o c ee sessed oz | powon parody «| 8 omabvonoeded pete toms wan |e

uoneayeds

‘pelaig |

ered b 295

suouoop #102590 «| . e

s ” ‘ange He 010 Sunonueo pu woke nowsas "| ¥! | voypedicois end swon sn feneunes | °

auseu um s5u618w09 | poop poncwey

voneoypeds

paloid «|

NoUDWaNOD IDVEALADHINBHOM |Z

aeons says et wea 1308

queumysul pu SRTaRAD SEEDED ‘LOZ SOD «| “SUOHEIqIED pUE

4 s Jauidinbs Buunsesus son: pus Aouetie Aad pina yeoyv90 voHDedsul juoWIdNDA . ur

woud Bumrseou hong | 048 ounbe fed pa verges son goodsu uous 23 ND

Zuea7 00s

oes woweynbas #102500 | evasnyoresontty |

4 4 ‘Aunnoe Weis 1 Oud, ypsfeud ijn soueyétuog vuoneoyoods | 8S? <4 pue vad sw jo jenoiddy | TT

er |

awsngo | +

2Wa | sonenven | hued nf s9pop ul

(onoraq pueda} sad se) fouanbasy js meee spuepuers / ujod jorqu09 jo uondunseq a

wouronjonu posinboy suey eoueideory | suoneayneds | us eal

(0 €0000-SW-AID-S800ddN PU SIN

NOILIWdINOD LVdINI ADYINA HOH Ate 60-ET | _ SAE TERIA.

0 €£0000-dLI-AID-SB00ddN 3R9Y B4OU LE

cory ie A A

ONISSSNION3 i

aaavely mar

uej}d 3S) UOIWadsuU]

sapeg Ayunoag poos aiarens : Suyaousius saqeliy

afd 104 MAN,

zyozateg

‘ayqeaqidde e1aym parsi| aq snus (S>1) ays 9B4> UORDadsUI oY dDuELa}04 ‘WUANIOD PUDDS

‘up unyayny “S¢9IA9z UALUNDOp J04 Pars] |2q 04 DYSD PUE AaIANDe auIS Jem9e OF padst| aq O2 WI “UUUN|OD PAIL 'Sa10N

(an220 4140)

‘Suyjpung vay Ajuo) uorsadsul aauE|anins =s /1UIOd PIOH = H / lod SsOUIIM = M / woNDedsUI ]eUI=NU = |

;pua8>)

eLved Loe.

‘Loz $00 «| : ,

L000-00-93r-sad0diN 10x SOI

™ 4 : ‘enoge sy arenes | agg anaes | a ravanda 7 $20)

uoneayoods

‘paloid |

eb ved 199

emma nome 102 $90 «|

ayonuoo pue noxe} a

008 ae wowores

as xa i couRHewod | powmoya panoxddy |

Uwone2yoads.

‘pated «|

200ddN 19% SOI)

57 puna USS

7 ypey Ayunaas poo 4 aBaxeNS :s800/adN

ONIS3NIDN3 A Avedon Suyaauriu3 seqely

agave wor uejd 3sa1 uoRDadsuy 103/0Ud 1d MAN

‘ameti|

0008 SHFAO-s800dN

‘Swomso vane

cea varno-se00aaN

uve toyoesog edu Hava WE

wane uaa]

Towdineg Banseuta eaery emi] _20meR009 Uea|

Sa aa

SNRISSNION ma

waevry war

quOUISsossy SIN AaJeg PUR URIEEH 8, JoENUOD

hsoueg Bueout3

send 1937044 10 NSH

erade taoua

90 jou ee kun sab BAO

awe

ayes wears arse! ae va Gunn ose

a sup Yoon em Buon Bue

wewerbe

puesontsedo

sie

conse vores oa at (en

| poseda Susan) eyo ue ps moon

samoes pve suena ano 2]

‘are omens

somwnd

wapede veoeaues ea sence 6 S4BLey LE

5106

“np woos nd 0 |

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5807)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (346)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- RISK ASSESSMENT For Installation of HDPE Pipes and Fittings...Document21 pagesRISK ASSESSMENT For Installation of HDPE Pipes and Fittings...721917114 4757% (7)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Enc:osu :: Od: ReceivingDocument40 pagesEnc:osu :: Od: Receiving721917114 47No ratings yet

- Ra Eg C Oo Ecur' Yfachtties: Document Submitta!Document64 pagesRa Eg C Oo Ecur' Yfachtties: Document Submitta!721917114 47No ratings yet

- C823 3 Doc MST Mec 009Document24 pagesC823 3 Doc MST Mec 009721917114 47No ratings yet

- Regarding INR LogDocument51 pagesRegarding INR Log721917114 47No ratings yet

- C823 3 Doc MST Mec 004Document23 pagesC823 3 Doc MST Mec 004721917114 47No ratings yet

- Reply From HPP0100-MS-0004 Method Statement SubmittalDocument1 pageReply From HPP0100-MS-0004 Method Statement Submittal721917114 47No ratings yet

- Reply From HPP0100-MS-0005 Method Statement SubmittalDocument1 pageReply From HPP0100-MS-0005 Method Statement Submittal721917114 47No ratings yet

- 383-NPP-0085-LT-0108 Reply From NPPDocument3 pages383-NPP-0085-LT-0108 Reply From NPP721917114 47No ratings yet

- Purchase Order For MemDocument3 pagesPurchase Order For Mem721917114 47No ratings yet

- Reply From HPP0100-MS-0001 Method Statement SubmittalDocument1 pageReply From HPP0100-MS-0001 Method Statement Submittal721917114 47No ratings yet

- 383-NPP-0085-LT-0016 - Rev - 0 Reply From NPPDocument3 pages383-NPP-0085-LT-0016 - Rev - 0 Reply From NPP721917114 47No ratings yet

- 383-To-NPP-17-0117 MS, ITP and RA For Geotechnical Investigation WorksDocument35 pages383-To-NPP-17-0117 MS, ITP and RA For Geotechnical Investigation Works721917114 47No ratings yet

- Responces To HPP Comments - Strategic Food Storage Facility - Al Jaber Engineering - 30 April 2018Document6 pagesResponces To HPP Comments - Strategic Food Storage Facility - Al Jaber Engineering - 30 April 2018721917114 47No ratings yet

- 1.internal Concrete Pour Register Updated On 25-01-2023Document9 pages1.internal Concrete Pour Register Updated On 25-01-2023721917114 47No ratings yet

- 383-NPP-0085-LT-0058 Reply From NPPDocument2 pages383-NPP-0085-LT-0058 Reply From NPP721917114 47No ratings yet

- Ed M M M A GN 0001 01Document39 pagesEd M M M A GN 0001 01721917114 47No ratings yet

- C823 3 Mtin Civ 042Document2 pagesC823 3 Mtin Civ 042721917114 47No ratings yet

- New IndexDocument1 pageNew Index721917114 47No ratings yet

- RFIA Formrev00 (BP02B)Document2 pagesRFIA Formrev00 (BP02B)721917114 47No ratings yet

- Qinph2 P08 Tes MST JTC Ele 00012 - R0Document34 pagesQinph2 P08 Tes MST JTC Ele 00012 - R0721917114 47No ratings yet

- New IndexDocument1 pageNew Index721917114 47No ratings yet

- SUBMITTAL - Mussaimeer Pumping Station Surya ExhaustDocument134 pagesSUBMITTAL - Mussaimeer Pumping Station Surya Exhaust721917114 47No ratings yet

- Sequence of OperationDocument1 pageSequence of Operation721917114 47No ratings yet

- 0304 Concrete Delivery ReportDocument8 pages0304 Concrete Delivery Report721917114 47No ratings yet

- Installation Clean Agent SystemsDocument14 pagesInstallation Clean Agent Systems721917114 47No ratings yet

- Submittal Package No 3238.1Document1 pageSubmittal Package No 3238.1721917114 47No ratings yet

- Material Inspection Report (BP 02B)Document2 pagesMaterial Inspection Report (BP 02B)721917114 47No ratings yet

- RFI Formrev 01Document1 pageRFI Formrev 01721917114 47No ratings yet

- HDPE Manufacturer RecommendationDocument3 pagesHDPE Manufacturer Recommendation721917114 47100% (1)