Professional Documents

Culture Documents

383-To-NPP-17-0117 MS, ITP and RA For Geotechnical Investigation Works

383-To-NPP-17-0117 MS, ITP and RA For Geotechnical Investigation Works

Uploaded by

721917114 470 ratings0% found this document useful (0 votes)

95 views35 pagesOriginal Title

383-To-NPP-17-0117 MS, ITP and RA for Geotechnical Investigation Works

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

95 views35 pages383-To-NPP-17-0117 MS, ITP and RA For Geotechnical Investigation Works

383-To-NPP-17-0117 MS, ITP and RA For Geotechnical Investigation Works

Uploaded by

721917114 47Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 35

4 ALJABER

4@@™ ENGINEERING

va»

US83INPP/SK/aa/17/0117 10 August 2017

Mis. New Port Project Steering Committee

P.O, Box: 28333

Doha, Gatar

Tel: 4406 4444

Fax: 4406 4420

Attention: The Engineer

Mr. Maisar Jamil El-Qutami

Project Executive Director

Project: New Port Project

Contract No. NPP/0085: Strategic Food Security Facilities

Subject __; Method Statement for Geotechnical Investigation Works

Dear Sir,

The Contractor hereby submits the method statement for the geotechnical investigation works, associated

‘with the relevant inspection and testing plan (ITP) and risk assessment (RA), for the Engineer's review and

approval

‘The Contractor looks forward to receiving the Engineers early approval on the submitted documents.

fe faithfully,

a

Encldeures:

4. Method Statement for geotechnical investigation works

2. Inspection Test Plan (ITP)

3. Risk assessment (RA)

F Paid-Up Capital worwjeca weUgs)

New PORT PROJECT ALJABER

Aljber Engineering Company Method Statement ‘All ENGINEERING

NPP/0O8S: Strategic Food Storage Facies, v—_

Method Statement for Geotechnical Investigation

Strategic Food Storage Facilities

NPP/o085

(NPP0O85-CIVIL-MS-00002_0)

Prepared by »

rev) vate Modifications Content emer | basen

0 | 05-Aug-17, First issue ‘Abdala Barghouti Comstnietion;

Manger

a

2

3

Propared by Reviewed by Approved by

Full Name: ABDALA BARGHOUT ‘ANIMA AL ALAWNEH SHADIALKHASHAB

Designation CONSTRUCTION MANGER PROJECT MANGER PROJECT DIRECTOR

Date | 05-Aug-17 o5-Aea7 _Asyuett

Signature 4 :

, /

wis

Revision 0-05 Aug 2017

NeW PORT PROJECT i ALIABER:

‘Ajaber Engineering Company Method Statement “il ENGINEERING

'NPP/0085; States: Food Storage Facilities OM as

1a PuRPOse

1.2 Score or wom

1.3 REQUIRED PERKATS

2 ROLES AND RESPONSIBILITIES

2a JC

2.2 SUB-CONTRACTOR

3. DEFINITIONS / ABBREVIATION / REFERENCES...

3.1 DerINmions.

3.2 Asoreviations

33 REFERENCES en

4 RESOURCES.

42 Mawwower 7

4.2 PANTANDEQUIPMENT....

43° Marais

5 HEALTH / SAFETY / ENVIRONMENTAL PROVISIONS

5.1 HEALTH AND SAFETY, .

5.11 Emergency response...

5.2. ENVIRONMENTAL SSUES.

5.21 Aspect and Impact Identification. hci caret

5.2.2 Aspect Idemification and Mitigation measures 7 10

5.23 Emergency Response...

6 SEQUENCE OF WorKS.

6.1 AREAOF THE Wonks. Se ote eee te a 14

6.2. PROGRAMME / TIMELINE OFTHE WORKS 7 14

63 SETTING OUT SURVEY... aemenens li dtueasnestet

6A BoReHouss 4

65 InSmu Testing 12

6.6 INSTRUMENTATION. 212,

6.7 LaBoRAToRY TESTS 12

68 REPORTING... 13

6.9 DEMOBIUSATION OF CREW AND PLANT. : : 13

7 APPENDICES

[Ac FIGURE-1: ACKER AD? Lority MOUNTED ROTARY DRILUNG RIS

28

Revision 0-5 Aogst 2017

New poRT PROJECT

Alber Engineering Company Method Statement

[NPP/OO8S: Strategic Food Storage Facilities,

INTRODUCTION _]

1.1 Purpose

‘The purpose ofthis method statement is to serve asthe details, sequence and quality for the Geotechnical Investigation

‘works, which will be conducted in order to obtain and determine detailed information about the surface and subsurface

sol stratification along with geological conditions, physical, mechanical and chemical properties of the ground materials in

the investigated site in order to provide sufficient information to asist design and construction purposes ofthe proposed

structure, in addition to provide recommendation for ground and ste preparation works.

1.2 Scope of work

This method statement describes the necessary in-situ and laboratory works/tests for the foundation design of the building

as below:

+ Drilling of fifty boreholes,

+ Carrying out of in-situ testing and laboratory testing,

+ Submission of Factual Geotechnical Report in accordance with the project specifi requirements.

The boreholes were determined according to topographic survey provided of the site area and matching with Design

Consultant requirements

‘This method statement is subject to the requirements as stated in the following regulatory & statutory documents,

applicable standards / specications / building codes:

+ Qatar Construx

+ SiS cP 2012

+ QS, 8s 1377, Bs 8004:1986

n Specification (ACS) 2010

1.3. Required permits

For the execution of this methad statement work no permits shall be required from government bodies, municipalities

‘and/or authorities.

ss

Revision 0-5 August 2017

NeW PORT PROJECT Ml ALJABER:

‘Ajaber Engineering Company Method Statement ‘MBL ENGINEERING

'NPP/0085: Strategie Food Storage Facies wm sie

2__ ROLES AND RESPONSIBILITIES

21 JEC

Project Director

*+ The Project Director is over all responsible for execution of this method statement and ensures that his team of

Engineers and the Sub-Contractor are aware of this method statement. All resources to include personnel, required

‘material and necessary equipment are avallable in order to carry out the work as planned and without delay.

‘+ Heis also in charge for the implementation of all safety, health and environmental arrangements for JEC and its Sub-

Contractor(s) and/or Sub-Consultant(s)

Construction Manager

+ The Construction Manager is responsible for overseeing and co-ordinating the work has been carried out on field as per

the approved method statement.

+ He.co-ordinates with the Safety and Health Specialist and with the Environment Engineer.

‘+ Hels also in charge to ensure that all necessary required equipment, tools and materials are in place prior to,

‘commencement of the works

QA/aC Engineer

+ The QA/AC Engineer is responsible to ensure work has been executed on field as per the specification and approved

‘method statement.

Safety and Health Specialist,

+ The Safety and Health Specialist is responsible to ensure that al safety precautions and procedures are in place.

+ Hemay conduct audits or inspections to ensure said compliance.

Safety and Health Officer

‘+The Safety and Health Specialist i responsible to ensure that all safety precautions are in place, all personnel have

undergone any necessary induction trainings and that all personnel are equipped with (PPE) Personal Protective

Equipment.

Environment Manager

‘+The Environment Manger is responsible to ensure that all environmental arrangements are in place, all personnel have

undergone any necessary induction training and that all personnel are trained and complaint with all environmental

regulations, legislation, policies and procedures.

‘+ He may conduct auaits or inspections to ensure said compliance.

2.2. Sub-Contractor

Branch Manager

‘+ The Branch Manager is over all responsible for execution of this method statement and ensures that his team of

Engineers, Technicians, Manager and Supervisor are aware of this method statement. All resources to include

personnel, required material and necessary equipment are available in order to carry out the work as planned and

without delay,

+ The ultimate responsibility for determining the Sub-Contractor’s company policy environment matters lies with the

Branch Manager.

+ He checks each report to be issued by Sub-Contractor for the accuracy and completion of all date and results and a final

inspection form is issued.

ans

Revision 0-5 August 2017

NEW PORT PRO.ECT 7M ALJABER

‘Aljaber Engineering Company Method Statement ENGINEERING

'NPP/00KS: strates Food Storage Facilities 1

Project Engineer

+The Project Engineer is responsible for overall management of field works and laboratory testing,

‘+ He issues the reports in compliance with the regulatory & statutory documents, applicable standards / specifications /

building codes and project specific requirements.

‘+ He also co-ordinates with the Safety and Health Specialist and with the Environment Engineer of JE.

Foreman (Chief Driller)

+The Foreman is responsible forthe supervision of all field works.

‘+ Hei in charge for implementation of Health and Safety throughout the execution of the field works. He ensures that

personnel use the proper work procedures.

+ He is also responsible for the Environmental awareness, in order to achieve maximum commitment and therefore

‘effectiveness, compliance with their company polices, project specific & Employer's environmental regulations and

statutory environmental requirements.

sis

Fevsion 0-5 August 2017

NEW PORT PROLECT

Aber Engineering Company Method Statement

[NPP/OO8S: Strategic Food Storage Facilities

3.1. Definitions

3 _ DEFINITIONS / ABBREVIATION / REFERENCES

‘SFSF ‘Strategic Food Storage Facies

CONTRACTOR | Ajaber Engineering Company

ENGINEER ‘Mr Maiser Jamil ELQutami, Acing Project Executive Director, New Port Project

EMPLOYER ‘The Government of the State of Qatar, represented by the New Port Project Steering

Commitee

‘SUB ‘Qatar Industial Laboratories/ Arab Centre for Engineering Studies

CONTRACTOR

2 Abbreviations

BEGL Below Existing Ground Level

BH Boreholes

EC Environmental Consultant (COW)

De Engineering Design Consultant (Worley Parsons)

TAR Improvement Action Report

ec Independent Engineering Consultant

IFA Issued for Approval

Fe Issued for Construction

FI Issued for Information

FR Issued for Review

R Inepection Request

ISRM International Society for Rock Mechanics.

me Inspection Test Pian

KPI Key Performance Indicator

Ms “Method of Statement

MSIC Employer Designated Port Master Systems integration Consultant

MSDS Material Safety Data Sheet

NCR 'Non Conformance Report

PMC Programme Management Consultant

POP: Project Quality Plan’

sas: Qatar Sustainability Assessment System

ass) Employer Designated Securty Sub-Contractor (Qatar Security Systems Co.)

RA Risk Assessment

RFI Request for Information|

RI Request for Inspection

SHEE Safety, Health and Environment

sis Site Inspection Schedule

‘SOR Site Quality Observation Report

Revision 0-5 August 2017

ons

NeW Poar PRO.ECT

Aliaber Engineering Company

Method Statement

[NPP/0085: Strategic Food Storage Facies

Ml ALJABER

ENGINEERING

‘Standard Penetration Test

Tal Pit

Work Breakdown Structure

3 References

Document

slegencs Document title

NPPOOBS-JEC-ITP- | TTP Inspection and Test Plan for Geotechnical Works

(00020

INPPOOBS-JEC-RA- | RA~ Risk Assessment for Geotechnical Works

‘00020

'NPPOOBS-JECHSE- | Health and Safety Management Plan

001_0

NPPOOBSJECTMP- | Traffic Management Plan

001_0

NPPOOBSJECDMP- | Disaster Management Plan

001_0

Fevsion 0-5 August 2017

78

NEW PORT PROJECT 27M ALJABER

Aljaber Engineering Company Method Statement ENGINEERING

NPP/OO85: Strategic Food Storage Facilities: wi Wh Aaa.

4 __ RESOURCES

4.1 Manpower

Safety and Health Offcer— 01 No.

Foreman (Chief Driller) 01 No.

Chief Oriller-01 No.

Assistant Driller 08 Nos.

Back hoe excavator Operator—01 No.

* Trial pit Technician ~02 Nos.

4.2. Plant and equipment

‘The following equipments and materials shall be used for the works:

* Lorry mounted driling rigs ~ up to 02 Nos.

* Backhoe excavator JCB type or similar—01 No.

‘Note: All equipments should have accurate certificates for use, and should be checked before starting works by trained

safety officer for ood concition.

4.3 Materials

+ Piezometer.

+ pvCpipe2”

* Pea gravel

Portland cement.

Cast iron flush cover 300mm x 300mm.

Revson 0-5 August 2017

NeW PORT PROJECT af ALJABER

‘Alber Engineering Company Method Statement ENGINEERING

NPP/OO8S: Strategic Food Storage Facilities: Cm is

JS_HEALTH / SAFETY / ENVIRONMENTAL PROVISIONS

5.1 Health and Safety

The health and safety activities are to be in accordance with the relevant Health, Safety and Environmental requirements as

described, but not limited to, within the guidelines for method statement.

‘The Sub-Contractor shall ensure that the JEC’s Health and Safety Management Plan is followed stringently; in adlition Sub-

Contractor shall ensure their internal health and safety procedures are followed by all crew members which Is prepared to

sult. Where applicable particular site safety procedures shall be adhered to at all times during site works.

Prior to commencement of any work activity crew members shall ensure all relevant third party certificates for plant

equipment to be in place.

All site employees to attend both QSS and JEC safety inductions.

A Dally tool box talk shall be given to all employees; this shall include a 360 Har ID, findings of which shall be discussed and

where practical mitigated.

Allemployees shall hold on their possession of New Port Project identification ID cards along with JEC training 1D Cards.

In the event of an emergency the Project Engineer / Foreman shall Immediately inform the JEC Project Director (Mr. Shadi

‘Alkhashab 3339-9740) in addition the S&H Specialist (Mr Zafar Khan 5030-1309) providing them with all relevant

Information regarding the emergency.

During the works Sub-Contractor shal ensure adequate barricading in order to restrict access to authorised personnel only

‘The roles and responsibilities of safety staf is to be listed under chapter 2 of this MS.

5.1.1 Emergency response

‘The activities for emergency responses are to be in accordance with the (NPPOO8S-JEC-HSE-0001_0 and NPPOO8S-JEC-

DMP-0001_0) as described, but not limited to, within the guidelines for method statement.

5.2 Environmental issues

‘The activities for environmental preservation through mitigation are to be in accordance with the Qatari Environmental

Legislation, MoE permits, environmental contract conditions and CEMP.

Compliance to Qatari Environmental Legislation, MoE permits, environmental contract conditions and CEMP isto be listed

and ensured prior to commencing the works.

Specific environmental risks and mitigations related to the activities of the method statement are addressed through the

Aspect Impact Assessment and Mitigation Measures table attached to this section.

JEC and their Sub-Contractor ensures that the preservation of the environment is achieved via no damage is caused to the

environment as a result of the execution of this method statement

‘The roles and responsibilities of environmental staff is to be listed under chapter 2 of this MS.

oy18

Revision 0-5 August 2017

[NEW PORT PROJECT

Alber Engineering Company

[NP /0O8S: Strategic Food Storane Facies,

Method Statement

5.2.1 Aspect and Impact Identification

‘The aspeets and impact relevant to the works described in the method statement are addressed through the Aspect Impact

‘Assessment and Mitigation Measures table attached in this section,

5.2.2. Aspect Identification and Mitigation measures

2M ALJABER

‘Mil ENGINEERING

Environmental Sourceimctivity | Relevant permits | Relevant control} _Adiltional mitigation measures

‘aspect procedure

(Contamination Fut, ot or nyarauie | CEMP Use ap trays during | Maintan appropri spl ks on

‘ui irom equipment ‘any manienarce, MOB | sie a all mes and traning for

teak DeEMOB. emergency sil response

‘Groundwater Boring for coe ‘cEMP Use ony fresh water as | i any potential for contamination of

contamination samp lubreant curing boring | groundwater occurs, all activins

Wil be ceased and investigation wil

be undertaken

Greenhouse gas Operation of fossil fuel | CEMP Ensureall equipment | Monitor equipment for any abnormal

emissions combustion engines has undergone condition and replacamaintain

Inspection of emissions | equipment as required

‘within the fst 8 monte

Litering Daly actives cEMP Prompt collec lt_—_| implament the principe of duce,

rubbish and dspose in| reuse and rece tot the

approved receptacle | amount of rubbish generated

5.2.3 Emergency Response

All reasonably practicable precautions shall be taken to eliminate the potential for hydrocartion or chemical spills. All

equipment (10 Ton truck and diesel operated drill rig) will be maintained according to manufacturer's specifications and

dlivered to the project site in a clean condition free of leaks, drips, etc. A drip tray (or similarly suitable containment) and

spill kit wil be avallable for each truck/dfil rig to be used in the event of a spill, The spi kit wil contain hydrocarbon

absorbent, durable receptacle, PPE and Emergency Response Instructions.

In the event of an environmental issue or incident, JEC’s Environmental Manager and the PMC will be immediately notified

and it will be entered into the InfoExchange system.

Revision 0-5 August 2017

sy 18

NeW PORT PROJECT 41M ALJABER

Alaber Engineering Company Method Statement ENGINEERING

[NPP/0085: Strategic Food Storage Facilities, WR pA sitacia

6 _ SEQUENCE OF WORKS

6.1 Area of the works

‘The Geotechnical Investigation will ke conducted on the field at NPP/O085 Strategic Food Security Facilities construction

site, and the samples willbe tested at the laboratory by Sub-Contractor. Site access, whether vehicular or foot, shall be

through designated routes and passages approved in advance by al parties and will be in compliance with the Traffic

‘Management Plan NPFOO8S-JEC-TMP-0001_0

6.2. Programme / Timeline of the works

The submitted Subsurface Investigation program, as detailed in sections 6.4 through 6.9 ofthis method statement, is

developed for the planned buildings, roads and parking areas. Based on the outcomes ofthis investigation program, the

Contractor's designer (APG) will advise on the necessity of further extending the scope of the SI program, in particular ifthe

subsurface conditions revealed to be heterogeneous and/or necessitating ground improvement.

The Geotechnical investigation Works shall be executed within thirty (30) working days in line with the programme. This is

based on six (6) day working weeks, between 6:00 to 17:00.

AA detailed programme is also provided at the Appendix C.

6.3 Setting out Survey

‘The accurate location and ground level of boreholes and trial pts shall be set by JEC prior to the commencement of

Geotechnical Investigation.

6.4 Boreholes

Fifty (50) boreholes will be sunk to a nominal depth ranging between 10m and 20m below existing ground level (BEGL| or

refusal. Acker ADII lorry mounted rotary din rig (see Figure 1) will be used in the execution of the boreholes.

The borehole will be advanced from ground surface using 125mm (S") diameter casing up to rock head. Large disturbed

bulk sample shall be taken from the inspection pit. Disturbed samples willbe taken at ground surface and in cohesions soil

at 1.0m intervals from SPT split spoon. Undisturbed samples will be taken in cohesive materia, if encountered, at 1.0m

intervals andor at change of strata using Shelby tube. In-situ standard penetration test, SPT, will be carried out at 0.5m

BEGL and at 1.0m interval for the top $.0m and at 1.5m interval thereafter.

Upon reaching rock head coring will commence using double tube core barrel with diamond core bits capable of producing

cores of the specified diameter. The hole diameter will be 101mm (2"). Water will be used as a flush media a all time

during driling.

Bulk samples willbe taken from surface and preserved in polythene bags and properly labeled.

‘The SPT split spoon samples will be kept in airtight jars and labelled

Cohesive undisturbed samples will be preserved inside the sampling Shelby tube and sealed from both ends using multi

layers of wax. The tube will be properly labelled.

Core samples will be kept in special wooden boxes and labelled,

Groundwater level shall be measured at the beginning and end of each day shift

Borehole to receive standpipe piezometer will be flushed clean from debris and residual water before installing the

standpipe and pea gravel backfill. Boreholes with no instruments to be installed will be backfilled with arising.

aya8

Revision 0-5 August 2017

NeW PORT PROJECT 1 ALJABER

‘Ajaber Engineering Company Method Statement ENGINEERING

'NPP/0085; Strategic Food Storage Facilities MW ON

{At the end of each borehole all samples will be transported to Sub-Contractor’s laboratories in Doha for further

‘examination logging and eventually testing.

6.5 In-Situ Testing

Standard Penetration Test in Borehole, SPT

SPT, will be carried out at 0.5m BEG and at 1.0m interval for the top 5.0m and at 1.5m interval thereafter, as specified and

In accordance with Clause 25.2, BS 5930.

‘The drive assembly of SPT consists of 63.5 kg weight, a driving head and a guide permitting a free fall of 76cm. The sampler,

consisting ofa split spoon sampler, is driven 450mm into the soll for each test or refusal. The number of blows for every

150mm penetration will be recorded as standard penetration resistance. The samples recovered from the split spoon

sampler will be inspected visualy, properly identified and preserved in airtight containers. The sarmples will later be

transported to Sub-Contractors laboratory in Doha for further testing.

Constant Head Permeability Test

Three (3) constant head permeability tests will be carried out in boreholes at pre-specified depth.

Fresh water shall be used at alltime during testing, The test will be carried out in accordance with Clause 25.4.4 of BS5930.

Packer ity T

‘Three (3) double packer permeability tests will be carried out in boreholes at pre-specified depth zone.

Fresh water shall be used at alltime during testing. The test will be carried out in accordance with Clause 25.5 of 8S5930,

6.6 Instrumentation

PVC Samm diameter standpipe piezometer will be installed in selected boreholes (3 Nos). Installation details including

borehole purging, well development, protective cover, etc, shall bein full compliance with Specification,

Water level within the standpipe piezometer will be monitored dally during fieldwork period only

6.7 Laboratory Tests

All samples sent tothe laboratory will be thoroughly examined and described andthe findings incorporated inthe final

borehole and trial pit logs. Selected samples will be destined for testing for classification, compaction related, strength and

chemical properties

‘The Table below lists all specified tests and their tentative quantities:

Item | Test Description No.

1 __| Sieve analysis inc Mc) 90

2 __| Extra over 1 above by hydrometer (inc Mc) 90

3__| Dryandbutk densities of cemented and cohesive sol 0

4 | Plasticity indices |

5__| Specific gravity 10

6 __| Unconfined compression tests on cohesive soils 10

7 | WUTsI compression tests on cohesive soils 3

ny

Revision 05 August 2087

NEW PORT PROJECT MM ALJABER

Aljaber Engineering Company Method Statement ENGINEERING

'NPP/0085: Strategic Food Storage Facilites poi dau

‘CU Tal compression tests on cohesive soils, :

Direct shear test i 3

10 _ | One dimensional consolidation tests on cohesive soils 3

11_| One dimensional swell or collapse potential tests on cohesive soils 3

12 _| Determination of the dry density/ moisture content relationship of soil, 25

13 | CBR (4 day soaked) # 25

14 _| UcStests on rack cores inc bulk density and Me 50

15 _| UcS tests on rock cores inc bulk density, Me + E 7

16 _| Point load index of rock samples q 50

17__| Sulphate Content fi 10

18 | Chloride Content 10

19_| pH Value 10

20 _| Calcium carbonate content of soll or rock a 10

6.8 Reporting

‘The Geotechnical investigation and factual report giving a full description of subsurface conditions and result of in-situ and

laboratory testing. Detalled description of the surface condition and features within the site shall be provided.

Site Description.

* Geology of the Area

* Seismicity and Tectonic of the area

+ Prevailing weather conditions

* Field and Laboratory Testing

* Material Properties; physical and mechanical

+ The choice of foundations type

Conclusions and Recommendations:

= Foundation Depth and Type

= Allowable bearing pressure for shallow foundations

= Deep Foundation (Deep)

= Foundations settlement

- Earth Pressure

= Excavation Side Slope

= Excavation Method

+ Ground Improvement Method

+ Backfill Material and Compaction Criteria

= Protection from Soll

= Depth Shallow Foundation Excavation

6.9 Demobilisation of Crew and Plant

Upon completion of each task the related personnel, equipment and plant will demobilize from site efter ensuring that

‘work site is re-instated to its original condition. For instance the tral pitting when completed the back hoe will be

demobilized immediately outside the site area waiting for low loader to be transported away. The drilling rigs however are

lorry mounted that will be driven out of site immediately after completion of their tasks. Appendix D shows demobilization

plan as part of the work program.

3/18

Revislon 0-5 August 2017,

ALJABER.

NeW PORT PROJECT

‘Ajaber Engineering Company Method Statement ENGINEERING

'NPP/0085: Strategic Food Storage Facies OMe

7_ APPENDICES

[ovens Ee joe

A | Figure-t

8 | Layout Drawing

| Programme

1D | Design Consultant's Subsurface investigation Specification, MOM, and 80

ups

Revision 0-5 August 2017

Ml ALJABER

New PORT PRONECT

‘Aljaber Engineering Company Method Statement ‘Mil ENGINEERING

'NPF/0085: Sates Food Storage Facts __

Appendix A

ACKER AD2 Lorry Mounted Rotary Drilling Ri

15/18

Revision

[New PORT PROJECT 4 ALJABER

‘labor Engineering Company Method Statement ‘MM ENGINEERING

[NPP/0085: Strategic Food Storage Facies wm ics

‘Appendix B

16/8

RevsionO—5 August 2017

ASABER

ENGINEERING

UMD Holts

}

i ss seman

ee ea Se [See aaa pS ee ee

eee See SS ——— Sees

eee Patmos Ea-Heere eee aan ae 2a es

eee efeeetaaees aes See nee =

oe Aes es 2 eeu pain eae ogi teed

ee Hee SS aes stanatues

ees Fe een SEES | SSeS 2a

i 2 eee SBS See a sees

Se SSeS ae a anos

ee [efi le SSeS | Boast Sele

pes (Steet See pa Pee aaa

rs | sess [re 75 [eas | ate 96 fesse] vs “borne or “e_| soem su or common

eee vedi tee Sane ee : ee Pines oor

a ae ae ee

eee Spee SE - ee ee

ee ees 2 Sees f eo a fape ines

ee ee ee - Hee — Soe

ves age eee ee tenet —t Eats

Sess ee ten eee ee ieeeee

eee eee: ear pe ee Pees ae

ates Desks eee eee

: Eee Es ae arteatae

ELSES eee bee oie ice. rung Pov Srey Fay SSF)

2 = a = SSE =

: See ee ol aeateest — | fags ar

é See ee Rees ee ar

: oe Sn See a eeiapeer a

: eee hee Sees ae Ome sltuais

: SEES ae =e a

i ae ee ae Seen ee

z a Ee teeel eee 2 ee 2 ete ==

: - SUES Sea oe = sox. esronnon

2 eee Ss Pees a corceanons

s ee aes = = {eae ———

if Pe aE sieetea— = E==|— =

# SEES ea we een =

= r : ; = : : et —

[NEW PORT PROJECT ALJABER

Alber Engineering Company Method Statement ENGINEERING

[NPP/0085: Strategc Food Storage Facies wm iow

|

Appendix ¢

Programme |

|

w/18

Revision 0-5 August 2017

NEW PORT PROUECT ‘ALJABER

Alber Engineering Compeny Method Statement ENGINEERING

NPP/0085: Strategic Food Storage Faces wm siews

Appendix D

nsultant’s Subsurface Investigation Specification and Sco,

ays

Revision 0-5 August 2017

Lagbaiallg djLacll ac gare

ARCHITECTURE & PLANNING GROUP

Sao).

PROJECT NO. 346.6

‘ate: FEBRUARY 2017

Ref: NPP0dss_Gta2

SCOPE OF

SERVICES FOR

GEOTECHNICAL SERVICES

PURPOSE.

Geotechnical Consultant services in the areas of geotechnical

investigation, analysis and design are required by the Department in

support of preliminary engineering and construction-related efforts.

In the execution of its services, the geotechnical Consultant will work

principally with and coordinate its activities with the main contractor /

consultant.

‘The Report shall consist of site description, investigation procedures,

description of subsurface conditions, borehole log sheets and shall present

discussion and recommendations for design.

SERVICES TO BE PERFORMED.

This section describes various work items which may be required of the

geotechnical Consultant. All of the work items will not necessarily be

required in a single assignment. The geotechnical consultant shail be

prepared to perform all work included in the work areas covered by the

contract. When work items are referenced to existing specifications and/or

standards, all work must strictly adhere to those specifications and/or

standards unless alternate methods are approved in advance by the main

contractor / consultant.

All works performed by the Geotechnical Consultant shall be in accordance

with the Department's current Soils and Foundations Procedure Manual, the

Qatar Construction Specifications QCS 2014 and Guidelines for Review of

Geotechnical Reports and Preliminary Plans and Specifications, related

directives, and referenced standards and specifications.

‘The Consultant's services shall include, but not be limited to the following:

B01

A Data Collection

Data collection shall be a combined effort of the geotechnical Consultant and

the Main Contractor/Consultant and shall include the appropriate activities

listed or any other activity deemed necessary by the Department's Project

Manager. and shall be considered incidental to data collection. Obtain all

existing geotechnical data from:

1. Topographic maps

2. Aerial photographs

3. Ground water resources

4. Construction plans

5. Geological bulletins

6. Pile driving and construction records

7. Existing plans

8. Other sources

EO]

B, Geotechnical Seismic Desi wwirement

1 Foundation Stiffness matrices including individual pile stiffness’s, pile group

stiffness's and footing stiffness’s will be developed using the procedures

outlined in Geotechnical Earthquake Engineering Design Specifications.

2 Selsmic Site Classification and corresponding recommended response spectra

for both period and displacement.

3+ Liquefaction Potential (where required) will be assessed per the current LRFD

Design Specifications or equivalents.

4 A preliminary lateral pile analysis and the corresponding lateral load vs.

deflection curve isto be included in the final geotechnical report

5+ Special dynamic analysis beyond that required by codes such as ground-

foundation response.

6 Special physical soil model analysis.

7- Horizontal Earthquake Coeff,(c) in Earth Pressure due to Earthquake according

‘to Mononape Okabe method.

C.Field Reconnaissance

Field reconnaissance shall be a combined effort of the geotechnical Consultant

and the Main Contractor / Consultant and shall include the appropriate activities

listed or any other activity deemed necessary by the Department's Project

Manager. and shall be considered incidental to field reconnaissance. Perform a

site reconnaissance and note the following:

1. Location with detailed land description

2. Horizontal and vertical survey control

3. Geologic formations

4, Seismicity and tectonic of the area

5. Surface soils

6. Surface water (if applicable)

7. General site condition

8 Presence of rock outcrop and rock type

9. Conditions for detours

10, Foundation type, condition and location

11. Type, condition, and location of nearby structures

12, Visual evidence of scour at bridges or culverts

13. Site conditions relative to boring plan including site access, private

property, and checking all field testing locations for existing

utilities/obstructions and revising locations where necessary

14. Presence of Hazardous Materials and Waste

15, Prevailing weather conditions including temperature and pressure,

relative humidity, rainfall and wind

16. Other pertinent data

17. Based on information from Section Il, A, B and C, develop a plan

for geotechnical investigation

DField Investigation - Soil

10.

LL

12;

‘The field investigation for structures may include, but is not limited to:

Bore holes shall be drilled at specified locations to obtain information

about the sub-soil profile, its nature, strength and to collect soil samples

for strata identification and conducting laboratory tests. The minimum.

diameter of the bore hole shall be 150 mm and boring shall be carried

‘out in accordance with the provisions of QCS 2014 and as per

specification Thin-walled tube samples per ASTM D 1587

‘Standard Penetration Test (SPT) borings per ASTM D 1586 including

water table readings. Extra samples are taken in areas where continuous,

sampling is desired or at every change in strata.

Cone Penetrometer Test (CPT) borings per ASTM D 3441 including

water table readings

Field Vane Shear Tests (Drained Condition) as per ASTM D 2573 (soil

shear strength)

Soil Lateral Stiffness

Engineering support required in conjunction with determination of

piezometric head of artesian aquifers if encountered.

Obtain environmental corrosion samples of soil and water for testing

Obtain samples to determine D50 grain size

Monitor well installation and data acquisition

Permits for test borings or other work items,

Miscellaneous drilling services not covered elsewhere,

Provide survey services to locate and determine elevations of field

testing locations.

13. Water Flow through soils under the effect of head different

between the sea level and SFSF level.

E.Laboratory Testing (Structures)

The laboratory testing for structures may include, but is not limited to:

1

1.

12,

Grain-size analyses and shape (Sieve analysis) conducted according to BS

1377: Part 2:1990 and related standards (Complete Hydrometer Analysis)

used to further classify the shape of the grains.

(Determination of the proportions of soil constituents)

Atterberg limits conducted according to ASTM D 4318 and ASTM D 4318

and related standards (shrinkage, Plastic and liquid limit) we can define the soil

if swelling or Collapse soil and we can identiy the liquefaction.

Moisture content test conducted according to ASTM (American Society for

Testing and Materials) or related standards including the optimum moisture

content & the corresponding max dry density)

Organic content by wet combustion tests or by loss on ignition tests

conducted according to ASTM STP479 and related standards

Specific gravity test conducted according to FM. 1-T100 and related

standards

Consolidation tests conducted according to Terzaghi and directions from the

Department's Project Manager (soil decrease in volume - decrease in water,

content of saturated soil without replacement of water by air.) - to determine

the soil settlement and corresponding time.

‘Triaxial compression tests conducted according to ASTM D 7012-2010 and

directions from the Department's Project Manager (to identify the Angle of

Intemal Friction and soil Cohesion C)

Point load test conducted according to ASTM D 5731: 1995

Unconfined compression tests conducted according to ASTM D 2166 and

directions from the Department's Project Manager

Corrosion tests for environmental classification conducted according to

Department directives and the following:

a pH tests conducted according to ASTM D 1293 (water) and ASTM.

G51 (soil)

b. Resistivity tests conducted according to ASTM D 1125 (water) and

ASTM G 57 (soil)

©. Chloride content tests conducted according to BS 1377 Part 3:1990

4, Sulfate content tests conducted according to BS 1377: Part 3:1990

pH tests conducted according to ISO 4316

Splitting Tension tests ASTM D-3967 with variations noted

inary Report (Structures}

‘The Preliminary Report shall include, but not be limited to:

13

4.

15,

16,

11,

‘Summary of background data

Analysis of foundation alternatives, to include:

&

Spread footings

Steel H-piles of various sizes and capacities

Steel pipe piles of various sizes and capacities

Other feasible foundation types

Basis of recommended selection

Evaluation of retained earth walls for external and internal stability

(ifapplicable)

Evaluation of other wall systems for external stability (if applicable)

Analysis of design soil resistance, including:

©

Plots of design and ultimate compression and tension, safe bearing

capacity and soil resistance versus elevation for all feasible foundation

sizes and alternatives

Calculation of lateral soil resistance and allowable lateral load for

all feasible foundation alternatives.

Plots of allowable lateral loads.

‘A detailed boring/sounding standard sheet for inclusion in the construction

plans ase

scted by the Department's Project Manager, to include Specialized

construction requirements,

‘A summary of all pertinent soil parameters used in analysis calculations,

‘The source of all parameters shall be clearly indicated as deriving from tests,

correlations with tests, or standard references. The summary shall include,

but is not limited to:

a.

Pre mee

Unit weight

Specific gravity, SG

Existing ground water (dated) and seasonal high groundwater

elevations

Consol

Cohes

Strain @ 50% stress level

‘Modulus of subgrade reaction

Other parameters as required by the Department's Project Manager

18, a Construction information report. As a minimum, the report should

address:

a. Estimated hammer requirements and maximum driving

resistance anticipated

Provisions for footing or shaft construction, as applicable

Recommendations on test pile/shaft plans, as applicable

4. Recommended Special Provisions for soils-related construction

considerations

© Plan sheets for special treatments, as necessary

19. Anappendix, to include as a minimum:

SPT boring logs

CPT sounding logs

Data from specialized field tests

Laboratory test data sheets

Engineering analysis notes,

20. Recommendation for Soil stabilization in case When no good material is

available for filling

F. Construction

The Consultant shall perform activities during the pre-construction and/or

construction phases as requested by the Department's Project Manager.

1, Analysis of pile driving dynamics based on data supplied by the

Contractor employing the wave equation analysis. The computer

program used shall be approved in advance by the District Geotechnical

Engineer. The geotechnical Consultant shall provide graphs of the

following: 1) ultimate soil resistance as a function of the number of

blows per foot and 2) maximum pile tensile and compression stresses as

a function of blows per foot

2. Conduct pile/drilled shat load tests by standard methods, quick-load

methods as approved by the District Geotechnical Engineer

3. Perform pile driving analysis utilizing dynamic measurement devices

as approved by the District Geotechnical Engineer

4, Perform drilled shaft inspections and construction monitoring as

approved by the District Geotechnical Engineer

5. Analysis and reporting of load test data.

6 Monitoring of settlement platform installation

7. Monitoring, performing analysis, and reporting settlement platform data

8. Pile Integrity Tester

9, Installation of piezometers |

10. Monitoring, analyzing, and reporting of piezometer data

11, Installation of slope inclinometer casing (Lateral Soil movement)

12. Monitoring, analyzing, and reporting of slope inclinometer data

13. Monitoring of other specialized geotechnical methods and/or

equipment during construction phase including PIT testing of piles and

shafts |

14, Serve as technical expert in the investigation and analysis of

unforeseen geotechnical problems during the construction phase

15, Providing the labor necessary to perform all Section

16. Perform building condition surveys before construction begins and

afier work is complete. Monitor vibrations during construction to

determine potential for structural or cosmetic damage

G.Emergency Subsurface Investigations

The geotechnical Consultant may be requested to investigate roadway,

drainage or structural problems to determine if the cause is a geotechnical issue.

Investigations may occur on existing facilities or on-going construction

projects. All activities shall be coordinated with the District Geotechnical

Engineer, the main Contractor and Main Consultant or their representative.

Conditions that potentially endanger the public, facilities or the environment

may require immediate response (i.e., after normal working hours, at night,

‘weekends or holidays). Activities may include, but are not limited to any field

and laboratory services previously listed in this Scope, and preparation of

plans and/or specifications to remediate unsuitable soil conditions.

10)

retey

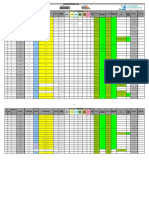

sores ve- 0084

aurtocrouest¥-00r00eeN

wining yoipeueg fq ‘mained wuauwnodp 10) paisl 8q 01 JUSD puE AiAlRde Bis jemiDe 04 parsi| aq 01 W -UUIN}OD PANY S310N

saBueW O0-VO peUubis {UlOg PIOH = H / tulog SSaURIM = mM / UORDadsUI ;eWI=IUI = | ~puaiay

ot

6

8

“

9

s

OuBUILIOS euoRoeg

ke

a H H Woda 01 0U woenoy =| Siopenn | ul jwes sjoysiog |

@OUBLULUOD €-uOHIeS

Mw H H Buyjdwes 0} Jog Aoeinooy -p1oz-so0 | {ous uo) Buyip ejoyerog |

for e-uonDeS ~ Buywesg nO

H H H 20UALUUIOD 0} JOU einooy | SES | 9480 | sumog ud wilt waeeen | 2

payuans €-UOROES

H H H 20UBLLUIOD 0} Joe sueuncog — | - prozeso | 04S quouierers pouren | |

Wd | sowenuos | Aued né sprepuers | wl

(mojaq pueda sed se) fouanboss see 5 / aujod jonuos jo uondi2saq isi

quauranjonuy pauinbay eye souederry | uoreaypads | _ous> eu

0 Z0000-SW-TIAID-LO00ddN {Pus

(uopesisanul je2}U4293035) 102-86 | ‘atep rennwans |

0 20000-dLI-IIAID-S800ddN ‘AUB 4PU dL

ere (peat

‘ONIMSSNISNA

uaavely aa

uejd 384 uoWIadsul

-sapupey Aaunoas poo

fuedwog Buyaou

oysone

41931044 1NOd MAN

syorases

_svoeiedo Oupionpuco pus “e038 120m

siqeise uoue201 Cuseg we Bu mp des,

ens Boy 07pue oes

So SL OPSsOy _peRiog ans

NaF 2000-%E-ID-S800dEN PUVA _uOqeBAsORU| POUN_!ED —_“SponyouoyseseG veciog Swsseuus egeiy = 0%eAU0D Ue

fe bows a0 ones -nbcn 25H amy Wow sa panera

wanes = q ‘anmong smn venano-aoNbieg Hepay — Haseeu

eae ae juowssessy

ONREZANIONS Ba Misi Gajes @ uicanmaaenias eng Aunoes pooa 9690s: 00/4

49arOwd LUOd MEN

‘Aueduwop Buuseui6ua Jeqelhy

eyozateg t07 WoreV1 #2 OuDssy

‘WUHS-TOET-WO¥-0OTODAN

seqiaroy nou me) Hus ABN)

pq es Bupeowea| v0 ay vonerweW09 YOs ‘suew BUND ha

‘NaF 2000'SHEIAD-SBO00dAN WUSH aS uoHoNEuCO seODAEN "390m VOWED TO RSa0y — vIKeMOG-aNs

o-n0F 2o00-va-TUALO-S8DOdEN WUYE — uoneBysanu| jeouYDeIceD —-SyoMJouDNdREEG

‘Auzouog Cuseu6u3 eqeliy -so;MUOD HEM

eyo caaeg

249 dooy 0} pue nok ams 00

us ouypew sanaue ue 63n 49 oU0ud ott

‘weopea

0} sopeus efo.0 sping Moree ‘SUELO

tehuaa ns]

enn npnsnroiaiata

‘ep ou Suunp ses pue deo venous ene ot ans

0" Z000-SH-WWo-SB00ddN 2M SWI—_ ays uogonasveo ge00EN "10m 0 UOI=207| WO RS30¥ _oReMIOg-ang

(o'r Z000-¥eI-AID-S800dKN "RUE uoyeBysanul jeouYsI00q Sy. jo UoNGHOESO ‘usdwop Euusouu3 Rely se}2e09 WEN

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5807)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (346)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- RISK ASSESSMENT For Installation of HDPE Pipes and Fittings...Document21 pagesRISK ASSESSMENT For Installation of HDPE Pipes and Fittings...721917114 4757% (7)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Enc:osu :: Od: ReceivingDocument40 pagesEnc:osu :: Od: Receiving721917114 47No ratings yet

- Ra Eg C Oo Ecur' Yfachtties: Document Submitta!Document64 pagesRa Eg C Oo Ecur' Yfachtties: Document Submitta!721917114 47No ratings yet

- C823 3 Doc MST Mec 009Document24 pagesC823 3 Doc MST Mec 009721917114 47No ratings yet

- Regarding INR LogDocument51 pagesRegarding INR Log721917114 47No ratings yet

- C823 3 Doc MST Mec 004Document23 pagesC823 3 Doc MST Mec 004721917114 47No ratings yet

- 383-NPP-0085-LT-0058 Reply From NPPDocument2 pages383-NPP-0085-LT-0058 Reply From NPP721917114 47No ratings yet

- Purchase Order For MemDocument3 pagesPurchase Order For Mem721917114 47No ratings yet

- Reply From HPP0100-MS-0004 Method Statement SubmittalDocument1 pageReply From HPP0100-MS-0004 Method Statement Submittal721917114 47No ratings yet

- 1.internal Concrete Pour Register Updated On 25-01-2023Document9 pages1.internal Concrete Pour Register Updated On 25-01-2023721917114 47No ratings yet

- 383-NPP-0085-LT-0108 Reply From NPPDocument3 pages383-NPP-0085-LT-0108 Reply From NPP721917114 47No ratings yet

- UntitledDocument33 pagesUntitled721917114 47No ratings yet

- Reply From HPP0100-MS-0005 Method Statement SubmittalDocument1 pageReply From HPP0100-MS-0005 Method Statement Submittal721917114 47No ratings yet

- Responces To HPP Comments - Strategic Food Storage Facility - Al Jaber Engineering - 30 April 2018Document6 pagesResponces To HPP Comments - Strategic Food Storage Facility - Al Jaber Engineering - 30 April 2018721917114 47No ratings yet

- 383-NPP-0085-LT-0016 - Rev - 0 Reply From NPPDocument3 pages383-NPP-0085-LT-0016 - Rev - 0 Reply From NPP721917114 47No ratings yet

- Reply From HPP0100-MS-0001 Method Statement SubmittalDocument1 pageReply From HPP0100-MS-0001 Method Statement Submittal721917114 47No ratings yet

- C823 3 Mtin Civ 042Document2 pagesC823 3 Mtin Civ 042721917114 47No ratings yet

- Sequence of OperationDocument1 pageSequence of Operation721917114 47No ratings yet

- Qinph2 P08 Tes MST JTC Ele 00012 - R0Document34 pagesQinph2 P08 Tes MST JTC Ele 00012 - R0721917114 47No ratings yet

- New IndexDocument1 pageNew Index721917114 47No ratings yet

- New IndexDocument1 pageNew Index721917114 47No ratings yet

- RFI Formrev 01Document1 pageRFI Formrev 01721917114 47No ratings yet

- Installation Clean Agent SystemsDocument14 pagesInstallation Clean Agent Systems721917114 47No ratings yet

- RFIA Formrev00 (BP02B)Document2 pagesRFIA Formrev00 (BP02B)721917114 47No ratings yet

- Ed M M M A GN 0001 01Document39 pagesEd M M M A GN 0001 01721917114 47No ratings yet

- 0304 Concrete Delivery ReportDocument8 pages0304 Concrete Delivery Report721917114 47No ratings yet

- Submittal Package No 3238.1Document1 pageSubmittal Package No 3238.1721917114 47No ratings yet

- HDPE Manufacturer RecommendationDocument3 pagesHDPE Manufacturer Recommendation721917114 47100% (1)

- Material Inspection Report (BP 02B)Document2 pagesMaterial Inspection Report (BP 02B)721917114 47No ratings yet

- SUBMITTAL - Mussaimeer Pumping Station Surya ExhaustDocument134 pagesSUBMITTAL - Mussaimeer Pumping Station Surya Exhaust721917114 47No ratings yet