Professional Documents

Culture Documents

IMG - 0173 PSME Code 2008 163

Uploaded by

let ramOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

IMG - 0173 PSME Code 2008 163

Uploaded by

let ramCopyright:

Available Formats

CHAPTERS.

HEATING,VENTILATING,REFRIGERATIONANDAIRCONDITIONING

shall be connected of the refrigerant at 46'11oC' ln no case

13.3 Pressure limiting devices pressure be less than 206'7

valve on shall the test

between the compressor and the top kPa by gauge.

the discharge sid6.

14.7 Posting of Tests

Section 14.0 Test of Refrigerant

Containing Vessels a. A dated declaration of test' signed by the

installer, shall be mounted in a frame'

the shells of posted in the

'14.1 Refrigerant containing vessels' frotected by glass, a.nd is present

which have been previously tested under machinery room-' lf an inspector

hydrostatic pressure of not less than one and at the tests he shall also sign the

one-half times the Design Working Pressure declaration-

pressure at

may Oe finally tested with pneumatic

one and one-half times the Design Working Section 15.0 lnstructions

Pressure, instead of hydrostatic pressure'

in a

15.1 All Refrigerating System shall be maintained oily

14.2 Gauges cleanly manner, fiee from accumulation

of

iirt, *.t", and other debris and shall be kept

a. Liquid level gauge glasses' except those.of readilY accessible at alltimes'

the bull's eie type, sha[ have automatic

glasses

closing shut-off valves' and such of

15.2 It shall be the duty of the person in chargesystel

the

shall be adequately protected against injury' premises on wnicn a refrigerating

containing more than 9'09 kg of refrigerant

is

in"trlt"O,-to place a card conspicuously as

nea-r

14.3 Motor Protection

unit

,. pir"ti"roie to the refrigerant of the system'

condensing

a. Motors of Refrigerating System shall be girilg Oit""tions for the operation

adequately protected against hazardous including precautions to be observed in

case of

overheating under normal or abnormal breakdown or leak as follows:

oPerating conditions'

in

a. lnstructions for shutting down the system

14.4 Tests case of emergency.

a. n"trig"rrnt containing part of every system b. The name, address and day and night

shall be tested and proved tight by the tetephone numbers for obtaining service'

manufacturel'at not less than the minim test

Pressure shown in Table

8'7' and telephone number

c. - name, address

The

department

of the municipal inspection

b. Every refrigerant containing part of every naring jurisdiction and instruction to notify

system tha]t is erected on the premises'

-department immediately incase of

said

except compressors, safety devices' emergency.

pressure gauges, and control mechanism'

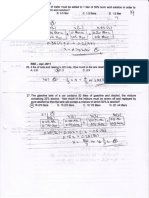

that are fictory tested, shall be tested and ' Table 8'7

proved tight after complete installation and Test Pressures

before Jperation at not less than the

minimum pressures shown in Table 8'7' Minimum Test

Refrigerant Pressure

14.5 Test Medium. No oxygen or any cornbustible

gas or combustible mixture of gases shall be Low

ChemicalHigh Pres. Pres.

fused for testing' Name Formula Side Side

14.6 Refrigerant not Listed

Ammonia NHg 2067 1 003.5

a. For refrigerants not listed in Table B'7' the Butane CaHr 620.1 344.5

Test PrJssure for the high pressure side Carbon dioxide Coz 10 355 6 890

shall be not less than the saturated vapor Dichlorodifluoromethane

pressure of the refrigerant at 57"C' The test (Freon-12) CCCI?F2 1619.15 999.05

pressure for the low pressure side shall be 551.2 344.5

Dicirlorometl'rane (Carre neC2Cl2F a

not less than the saturated vapor pressure

166

You might also like

- IMG - 0171 PSME Code 2008 162bDocument1 pageIMG - 0171 PSME Code 2008 162blet ramNo ratings yet

- IMG - 0160 PSME Code 2008 152Document1 pageIMG - 0160 PSME Code 2008 152bnqr584bNo ratings yet

- Bedienungsanleitung CC4E CC5 Und CC8 012003 97143C EnglDocument10 pagesBedienungsanleitung CC4E CC5 Und CC8 012003 97143C EnglAlanNo ratings yet

- Ve Yamaha p-220Document12 pagesVe Yamaha p-220VladislavNo ratings yet

- Protect Plants Against OverpressureDocument8 pagesProtect Plants Against OverpressureAmir BehrouzifarNo ratings yet

- Pipeline and Hazardous Materials Safety Administration, DOT Pt. 178, App. DDocument2 pagesPipeline and Hazardous Materials Safety Administration, DOT Pt. 178, App. Dروشان فاطمة روشانNo ratings yet

- Manual Compresor CopelandDocument40 pagesManual Compresor CopelandAntonio MazaNo ratings yet

- Refrigerator: Service ManualDocument42 pagesRefrigerator: Service ManualLuisAlhodaSilvaNo ratings yet

- CPB Partlist 13.02.13LDocument18 pagesCPB Partlist 13.02.13LRamraj EnterprisesNo ratings yet

- 1968 ASME III Article 9Document7 pages1968 ASME III Article 9Luis OrtizNo ratings yet

- #Ysystem: PanduanDocument9 pages#Ysystem: PanduanTechbhushanNo ratings yet

- Chicago Pneumatic Air CompressorDocument32 pagesChicago Pneumatic Air CompressorNeeraj gurung100% (1)

- D-Approved Instaliiation ProcedureDocument8 pagesD-Approved Instaliiation Procedurevin ssNo ratings yet

- Chapter 3 System Practices For AmmoniaDocument27 pagesChapter 3 System Practices For AmmoniaArib RahhimNo ratings yet

- Relocation and RepairsDocument5 pagesRelocation and Repairssky blueNo ratings yet

- Installation ManualDocument5 pagesInstallation ManualUhudhu AhmedNo ratings yet

- B022926 IM OM ICE INVERTER R410 Issue B PDFDocument23 pagesB022926 IM OM ICE INVERTER R410 Issue B PDFOblo OtrneNo ratings yet

- IMG - 0144 PSME Code 2008 136Document1 pageIMG - 0144 PSME Code 2008 136Arwyn BermasNo ratings yet

- CFR 2011 Title49 Vol3 Part178 SubpartIDocument1 pageCFR 2011 Title49 Vol3 Part178 SubpartIRenato BarretoNo ratings yet

- CFR 2011 Title49 Vol3 Part178 SubpartJDocument58 pagesCFR 2011 Title49 Vol3 Part178 SubpartJRenato BarretoNo ratings yet

- Centrifuge 7Document1 pageCentrifuge 7admin ptkmiNo ratings yet

- GN-234SQA Service Manual PDFDocument42 pagesGN-234SQA Service Manual PDFSergio ReyesNo ratings yet

- BAC MaintenanceVL MVLv10EN PDFDocument16 pagesBAC MaintenanceVL MVLv10EN PDFWissam JarmakNo ratings yet

- Denon 625R / 425R Receiver User Guide Owners ManualDocument20 pagesDenon 625R / 425R Receiver User Guide Owners ManualGreg JohnsonNo ratings yet

- 3750 Pulpress Pressurisation Unit: Installation and Operating InstructionsDocument14 pages3750 Pulpress Pressurisation Unit: Installation and Operating InstructionsRonNo ratings yet

- CPM Part ListDocument16 pagesCPM Part ListNeeraj gurungNo ratings yet

- Refrigerator: Service ManualDocument38 pagesRefrigerator: Service ManualCesar Calderon GrNo ratings yet

- Grs 642Document46 pagesGrs 642mrafi18No ratings yet

- Atlas Copco Stationary Air Compressors Ga 30-Instruction BookDocument49 pagesAtlas Copco Stationary Air Compressors Ga 30-Instruction Bookphoenix a703100% (1)

- Omega Air - Pressure VesselsDocument4 pagesOmega Air - Pressure VesselsOMEGA AIR d.o.o. LjubljanaNo ratings yet

- 48T 6SI ManualDocument82 pages48T 6SI ManualGene Williams Jr.No ratings yet

- O. Appendix O: Pressure Testing References: O.1. Hydrostatic Test ProcedureDocument13 pagesO. Appendix O: Pressure Testing References: O.1. Hydrostatic Test ProcedureCharlie Dela RosaNo ratings yet

- Atlas Copco Stationary Air CompressorsDocument2 pagesAtlas Copco Stationary Air CompressorsRE musicNo ratings yet

- Refrigerator: Service ManualDocument38 pagesRefrigerator: Service ManualCesar Calderon GrNo ratings yet

- CPB 20-40 Instruction BookDocument34 pagesCPB 20-40 Instruction BookgiridharNo ratings yet

- General Procedures: Refrigerant System Filtering Following Air Conditioning (A/C) Compressor InstallationDocument2 pagesGeneral Procedures: Refrigerant System Filtering Following Air Conditioning (A/C) Compressor InstallationJuan MonNo ratings yet

- 49 CFR Ch. I (10-1-11 Edition) 178.337-10: Chlorine Cargo Tanks. Angle ValvesDocument2 pages49 CFR Ch. I (10-1-11 Edition) 178.337-10: Chlorine Cargo Tanks. Angle ValvesAssemNo ratings yet

- User Manual Beko BP209H (English - 312 Pages)Document2 pagesUser Manual Beko BP209H (English - 312 Pages)Nina KinaNo ratings yet

- RT Svx21f en (3 10 Ton Iom)Document56 pagesRT Svx21f en (3 10 Ton Iom)jfisher54100% (1)

- SafetyPrec EN 20137703 PDFDocument2 pagesSafetyPrec EN 20137703 PDFandri julianNo ratings yet

- VX2T 50NPDocument36 pagesVX2T 50NPNishant AnandNo ratings yet

- 92 23577 122 00 - RheemDocument36 pages92 23577 122 00 - RheemIshfaqAhmedMayoNo ratings yet

- RecoverX - CAR Operating Manual 1Document8 pagesRecoverX - CAR Operating Manual 1coolguy19895No ratings yet

- Grs 552Document34 pagesGrs 552newid idNo ratings yet

- CFR 2011 Title49 Vol3 Part178 AppeDocument3 pagesCFR 2011 Title49 Vol3 Part178 AppeAssemNo ratings yet

- Portable Screw Compressor: Instruction Book and Part ListDocument33 pagesPortable Screw Compressor: Instruction Book and Part ListAbhishek GauravNo ratings yet

- Api 510Document1 pageApi 510Hashem AliNo ratings yet

- 1903 9323 95-VX 75 NPDocument34 pages1903 9323 95-VX 75 NPNishant AnandNo ratings yet

- Designing For Pressure Releases-Part 1Document3 pagesDesigning For Pressure Releases-Part 1john VilladaNo ratings yet

- SF 6Document1 pageSF 6Meet Kumar KataraNo ratings yet

- Centrifuge 6Document1 pageCentrifuge 6admin ptkmiNo ratings yet

- Hpet 4 Hpet 6 Hpet 7.5 Hpet 10Document16 pagesHpet 4 Hpet 6 Hpet 7.5 Hpet 10BASEM NOMAN ALI MOHAMMEDNo ratings yet

- Installation Manual ULC EngDocument5 pagesInstallation Manual ULC Engziad nabilNo ratings yet

- Carver CT-3 Owner ManualDocument25 pagesCarver CT-3 Owner Manualkhawar mukhtarNo ratings yet

- Zeks Compressed Air SolutionsDocument39 pagesZeks Compressed Air SolutionsChristian MabayaNo ratings yet

- THG (DF) C 0712 ManDocument16 pagesTHG (DF) C 0712 Mancesar luis gonzalez rodriguezNo ratings yet

- Chapter 2 System Practices For HalocarbonDocument30 pagesChapter 2 System Practices For HalocarbonArib RahhimNo ratings yet

- Installation Guide York YCJFDocument16 pagesInstallation Guide York YCJFGian Carlos Gonzales ChaconNo ratings yet

- Anti-Ice, de - Ice, Heater MatsDocument7 pagesAnti-Ice, de - Ice, Heater MatsTushar MantriNo ratings yet

- IMG - 0099 College Admission Test 82Document1 pageIMG - 0099 College Admission Test 82let ramNo ratings yet

- IMG - 0097 College Admission Test 80Document1 pageIMG - 0097 College Admission Test 80let ramNo ratings yet

- IMG - 0185 PSME Code 2008 174Document1 pageIMG - 0185 PSME Code 2008 174let ramNo ratings yet

- IMG - 0187 PSME Code 2008 176Document1 pageIMG - 0187 PSME Code 2008 176let ramNo ratings yet

- IMG - 0189 PSME Code 2008 178Document1 pageIMG - 0189 PSME Code 2008 178let ramNo ratings yet

- IMG - 0181 PSME Code 2008 170aDocument1 pageIMG - 0181 PSME Code 2008 170alet ramNo ratings yet

- IMG - 0096 College Admission Test 79Document1 pageIMG - 0096 College Admission Test 79let ramNo ratings yet

- IMG - 0093 College Admission Test 76Document1 pageIMG - 0093 College Admission Test 76let ramNo ratings yet

- IMG - 0095 College Admission Test 78Document1 pageIMG - 0095 College Admission Test 78let ramNo ratings yet

- IMG - 0100 College Admission Test 83Document1 pageIMG - 0100 College Admission Test 83let ramNo ratings yet

- IMG - 0540 EE PreBoard Exam 18Document1 pageIMG - 0540 EE PreBoard Exam 18let ramNo ratings yet

- IMG - 0534 EE PreBoard Exam 12eDocument1 pageIMG - 0534 EE PreBoard Exam 12elet ramNo ratings yet

- IMG - 0537 EE PreBoard Exam 15Document1 pageIMG - 0537 EE PreBoard Exam 15let ramNo ratings yet

- IMG - 0536 EE PreBoard Exam 14Document1 pageIMG - 0536 EE PreBoard Exam 14let ramNo ratings yet

- IMG - 0539 EE PreBoard Exam 17Document1 pageIMG - 0539 EE PreBoard Exam 17let ramNo ratings yet

- IMG - 0094 College Admission Test 77Document1 pageIMG - 0094 College Admission Test 77let ramNo ratings yet

- IMG - 0091 College Admission Test 74Document1 pageIMG - 0091 College Admission Test 74let ramNo ratings yet

- IMG - 0533 EE PreBoard Exam 12dDocument1 pageIMG - 0533 EE PreBoard Exam 12dlet ramNo ratings yet

- IMG - 0538 EE PreBoard Exam 16Document1 pageIMG - 0538 EE PreBoard Exam 16let ramNo ratings yet

- IMG - 0531 EE PreBoard Exam 12bDocument1 pageIMG - 0531 EE PreBoard Exam 12blet ramNo ratings yet

- IMG - 0532 EE PreBoard Exam 12cDocument1 pageIMG - 0532 EE PreBoard Exam 12clet ramNo ratings yet

- IMG - 0535 EE PreBoard Exam 13Document1 pageIMG - 0535 EE PreBoard Exam 13let ramNo ratings yet

- IMG - 0079 Algebra Lecture MRC 15Document1 pageIMG - 0079 Algebra Lecture MRC 15let ramNo ratings yet

- IMG - 0076 Algebra Lecture MRC 12sDocument1 pageIMG - 0076 Algebra Lecture MRC 12slet ramNo ratings yet

- IMG - 0080 Algebra Lecture MRC 16Document1 pageIMG - 0080 Algebra Lecture MRC 16let ramNo ratings yet

- IMG - 0081 Algebra Lecture MRC 17endDocument1 pageIMG - 0081 Algebra Lecture MRC 17endlet ramNo ratings yet

- IMG - 0083 Algebra Lecture MRC 19Document1 pageIMG - 0083 Algebra Lecture MRC 19let ramNo ratings yet

- IMG - 0084 Algebra Lecture MRC 20Document1 pageIMG - 0084 Algebra Lecture MRC 20let ramNo ratings yet

- IMG - 0090 Algebra Lecture MRC 26Document1 pageIMG - 0090 Algebra Lecture MRC 26let ramNo ratings yet

- IMG - 0082 Algebra Lecture MRC 18 PDFDocument1 pageIMG - 0082 Algebra Lecture MRC 18 PDFlet ramNo ratings yet

- Technical Reference Guide On Steam DistributionDocument66 pagesTechnical Reference Guide On Steam DistributionDainycious KibiwottNo ratings yet

- wp109 Optimizing Inj Quill PerfDocument8 pageswp109 Optimizing Inj Quill PerfMichael MedinaNo ratings yet

- Centrifugal Pump 2020Document21 pagesCentrifugal Pump 2020Justin VargheseNo ratings yet

- Ata 36 Pneumatic SystemDocument14 pagesAta 36 Pneumatic SystemNunes FreitasNo ratings yet

- Agam Sastrowibowo-Tugas Analisa Pencemaran Lingkungan PDFDocument12 pagesAgam Sastrowibowo-Tugas Analisa Pencemaran Lingkungan PDFagam sastrowibowoNo ratings yet

- PD 037 PDFDocument32 pagesPD 037 PDFSergio GuimarãesNo ratings yet

- Vaccuperm VGS - 141, - 143, - 145: Gas Dosing SystemDocument32 pagesVaccuperm VGS - 141, - 143, - 145: Gas Dosing SystemNorbert MeyerNo ratings yet

- Start-Up & Commissioning Manual 2 To 3Document6 pagesStart-Up & Commissioning Manual 2 To 3S.KNo ratings yet

- Megasan-Catalog CompressedDocument16 pagesMegasan-Catalog CompressedCasamed ServiceNo ratings yet

- SNO-I-DS-001 - 0 Instrument Data Sheet For Shutdown and Blowdown ValvesDocument174 pagesSNO-I-DS-001 - 0 Instrument Data Sheet For Shutdown and Blowdown Valvesono_czeNo ratings yet

- Flow Measurement Lecture 1Document37 pagesFlow Measurement Lecture 1Rahul KalraNo ratings yet

- Crowngas Detection System Profile - Doha, QatarDocument8 pagesCrowngas Detection System Profile - Doha, QatarCrowngas Detection System - Doha, QatarNo ratings yet

- Reusable Laryngeal Mask: Ambu Aura 40™ Standard Laryngeal MasksDocument4 pagesReusable Laryngeal Mask: Ambu Aura 40™ Standard Laryngeal MasksHany ElbarougyNo ratings yet

- SAB 120 and SAB 151 A-Frame Screw Compressor Units With OHU 04123 Oil SeparatorDocument42 pagesSAB 120 and SAB 151 A-Frame Screw Compressor Units With OHU 04123 Oil SeparatorEugen ButucNo ratings yet

- Hydraulic MachineryDocument2 pagesHydraulic MachineryEnriv YasiladNo ratings yet

- Design and Calculation Methods For Uniflow Cyclones Mar19 - SP PDFDocument11 pagesDesign and Calculation Methods For Uniflow Cyclones Mar19 - SP PDFSteve Wan100% (1)

- Combined Cycle Power PlantDocument9 pagesCombined Cycle Power PlantAbinCBabuNo ratings yet

- Course ContentDocument2 pagesCourse ContentBerkay ÇakırNo ratings yet

- F1-26 Series Parallel PumpsDocument1 pageF1-26 Series Parallel PumpsDaniel MabengoNo ratings yet

- Aceites TraneDocument12 pagesAceites TraneHomero Polanco100% (1)

- PFI ES-4-1985 (R1997) Hydrostatic Testing of Fabricated PipingDocument4 pagesPFI ES-4-1985 (R1997) Hydrostatic Testing of Fabricated PipingRodrigo Chambilla VernazaNo ratings yet

- Turbochargers - Hugh MaclnnesDocument193 pagesTurbochargers - Hugh MaclnnesRicardo VargasNo ratings yet

- Exhaust Carbon FilterDocument16 pagesExhaust Carbon FilterCj HealyNo ratings yet

- Rotary Evaporators RE300 SeriesDocument6 pagesRotary Evaporators RE300 Seriesanita shindeNo ratings yet

- Pressure and Fluid Flow - PPT - RevW10Document29 pagesPressure and Fluid Flow - PPT - RevW10RidiculouslySweet100% (1)

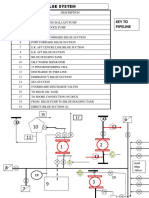

- Key To Pipeline: Bilge SystemDocument23 pagesKey To Pipeline: Bilge SystemvivekNo ratings yet

- Assignment 2Document2 pagesAssignment 2Kunal YadavNo ratings yet

- High DP Orifice FlowDocument2 pagesHigh DP Orifice FlowtibitomicNo ratings yet

- J Fluids Engineering 2009 Vol 131 N5Document124 pagesJ Fluids Engineering 2009 Vol 131 N5Нильва АлександрNo ratings yet

- 12 MGDP I 1045 0 (Spec For WHCP)Document26 pages12 MGDP I 1045 0 (Spec For WHCP)Ricardo NapitupuluNo ratings yet