Professional Documents

Culture Documents

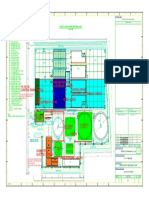

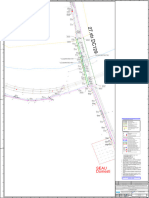

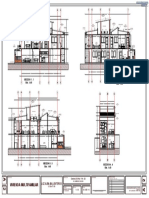

Connstruction Detail PDF

Uploaded by

Pham Thanh PhongOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Connstruction Detail PDF

Uploaded by

Pham Thanh PhongCopyright:

Available Formats

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24

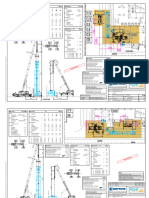

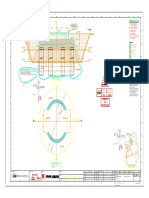

TYPE 1 TYPE 2 TYPE 3 TYPE 4 DETAIL TYPICAL WEBFRAME CONNECTION DETAIL CONNECTION STEMPIPE / TRIPLATE

A WEBFRAME BRACKET WEBFRAME BRACKET TANK/ SUPPORT BRACKET FLANGED BRACKET All plate thickness acc.General

Egg Box Construction

n=15, Tmin=t (General construction plan) Construction Plan

To be applied on connection

Hmin= h of the webframes and the girders

H,L=1.5 x (greater of h1, h2) 4 T<6 T<10 H= greatest of H1 of H2

Lmin=1.5 x h Hmin=2 x h Hmax, Lmax=240

Hmin=2 x h Hmax=400 mm

150 CROSS SECTION CL

4

200 240

H

R - see doc.1449211

B

h1

L

Pipe 219.1x8.2 (Alu)

n

R 5 R H4

n -T-

L

Aluminium

Webframe

R B B

R

-T- H5 -T- H5 n

34

Main deck

H

H

n

C Triplate

L h2

H

h

h

-t- -t-

00

Triplate disc

R1

Bent flange

4

15

H

Triplate

Pipe 219.1x8.8 (Steel)

H2

D

Bottom Girder

GIRDER TRANSITION TYPE 5 TYPE 6 TYPE 7 H SECTION B-B

TANK / SUPPORT BRACKET N=40 mm OVERLAPING BRACKET GIRDER+FLANGED BRACKET

Xmax=1000 mm Triplate strip 16x34

Hmin=2xh

FRAME VIEW

Steel

Triplate disc t=34

16

FB

E

-t- -t- Bend flange

h

H4

h

L L H4

t

N

T

125

H1

n

h

-T- -T-

H

F

X

125

-t-

-T-

n

WEBFRAME PENETRATION

G

WEBFRAME SIDE-DECK CONNETION TYPICAL LONG. GIRDER WITH LONG.

CONNECTION ER GIRDER+ FRAME SECTION A-A CONNECTION ER GIRDER+ FRAME

PROFILE TRANSITION

FR 13&14 FR 9..12

Deck

Tripping bracket

-5- Tripping bracket

H

h2

A

End radius

Min.100

Shell

R=

h ig

he FB50X5

J st -5- FB50X5

ofe Girder FB50X5 Girder

ith -20- -20-(-15-)

er

End radius h1

or

Min.100

h2

NOTE:

Shell

x

2 -For plate bending radius see drawing 1449211

h1 -5-

-All thicknessed accordign General Construction plan 1970680

Welding has to -For welding table see 1848686

K

compensate for

beveled bulb area Bracket Bracket

150x150 A 150x150

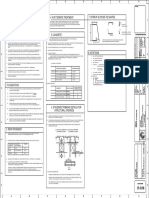

H1 H2 H3 H4 H5

Typical section weld hole. Typical profile drain hole Typical profile drain hole Typical Scallop Fr.

Typical Snipe

B=min 50mm, R=A-5mm,A=25 for HP 100 for HP<100 Steel only, R = 35, R min = 25 Alu/Steel

for HP<100 and/or under In brackets with arms min = 150mm

L

brackets it is to be sealed shut

with closing plate

20

20

A

B

25

R

ISO 5457 - ISO 7200 A1-1

R10

R

80

6

M 6

25

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24

You might also like

- Classics meet Jazz: 10 jazz fantasies on classical themes for flute and pianoFrom EverandClassics meet Jazz: 10 jazz fantasies on classical themes for flute and pianoRating: 3.5 out of 5 stars3.5/5 (14)

- Specifications For Repair of Concrete in Buildings (ACI 563-18)Document44 pagesSpecifications For Repair of Concrete in Buildings (ACI 563-18)yasser fouad100% (1)

- Responsibility Matrix For Shop & Site WorksDocument3 pagesResponsibility Matrix For Shop & Site WorksRenny DevassyNo ratings yet

- Din 1048Document8 pagesDin 1048Mostafa Hussein AbdouNo ratings yet

- CNN008311 Diagrams and DrawingsDocument40 pagesCNN008311 Diagrams and DrawingsandraNo ratings yet

- Bhatinda R 2 SLDDocument1 pageBhatinda R 2 SLDvineets058No ratings yet

- SPI HSE FR 02 Tower Erection ChecklistDocument1 pageSPI HSE FR 02 Tower Erection ChecklistChandan KumarNo ratings yet

- Nokia XL Dual SIM RM-1030 RM-1042 Service Schematics v1.0Document19 pagesNokia XL Dual SIM RM-1030 RM-1042 Service Schematics v1.0MarcinDryjaNo ratings yet

- MEP 1st Fix Clearance For Ceiling WorkDocument3 pagesMEP 1st Fix Clearance For Ceiling WorklaraibNo ratings yet

- MCMRA Roofing Cladding Manufacturing TolerancesDocument8 pagesMCMRA Roofing Cladding Manufacturing TolerancesPham Thanh PhongNo ratings yet

- Air Conditional & Mechanical Ventilation (ACMV)Document2 pagesAir Conditional & Mechanical Ventilation (ACMV)naraNo ratings yet

- Sample Test Questions Bricklayer - Ita WebsiteDocument7 pagesSample Test Questions Bricklayer - Ita WebsiteTri Oke MahendraNo ratings yet

- CDM Bucket Elevators: Centrifugal ContinuousDocument2 pagesCDM Bucket Elevators: Centrifugal ContinuousOcta IrawanNo ratings yet

- Main Structure List: No. Item Name Main Size or Building Area QuantityDocument3 pagesMain Structure List: No. Item Name Main Size or Building Area QuantityAlhaz Uddin100% (1)

- Building ContractorsDocument56 pagesBuilding ContractorsAashish PardeshiNo ratings yet

- Lower Ground Floor Plan: Property LineDocument4 pagesLower Ground Floor Plan: Property LineLiving OvercomersNo ratings yet

- Dokumen - Tips Tetrapod-3Document5 pagesDokumen - Tips Tetrapod-3Kali Sadar AbiprayaNo ratings yet

- Wiring Diagram - 2012 DS450 EnglishDocument1 pageWiring Diagram - 2012 DS450 EnglishWences Cortez0% (1)

- DS450 2009 Wiring DiagramDocument1 pageDS450 2009 Wiring Diagrambobby brownNo ratings yet

- S-18-13306 - DR7050 - A - V-169AB-01 Stack (Max.31t)Document3 pagesS-18-13306 - DR7050 - A - V-169AB-01 Stack (Max.31t)Hanif Nur Fauzi MargonoNo ratings yet

- Closer 2022-09-16 - ViolaDocument2 pagesCloser 2022-09-16 - Violanikita nikitaNo ratings yet

- HCD-GTZ4 - GTZ5 Diagrama-20135Document11 pagesHCD-GTZ4 - GTZ5 Diagrama-20135vivian elizabeth hurtadoNo ratings yet

- A-19 - Electrical General Synoptics (Complete Motor List) - Layout1Document1 pageA-19 - Electrical General Synoptics (Complete Motor List) - Layout1Moez BorchaniNo ratings yet

- Planilla de Aceros: Proyecto: Conjunto Residencial SantoriniDocument1 pagePlanilla de Aceros: Proyecto: Conjunto Residencial SantoriniMesias CheNo ratings yet

- Ed 0900 PRS Pid 000 09021HDocument1 pageEd 0900 PRS Pid 000 09021HMohamed ArafaNo ratings yet

- Ogura Clutch Inc - Fire Protection - Jul-26-2022Document4 pagesOgura Clutch Inc - Fire Protection - Jul-26-2022Christian DaganzoNo ratings yet

- Screenshot 2023-07-31 at 9.55.52 AMDocument1 pageScreenshot 2023-07-31 at 9.55.52 AMQais AldananiNo ratings yet

- LHD 110 DRW 501592 3 Jyn 85Document1 pageLHD 110 DRW 501592 3 Jyn 85Tajana TovarovićNo ratings yet

- MHP-23-DEC-CEB-0218 From DEICDocument2 pagesMHP-23-DEC-CEB-0218 From DEICPasan RajasingheNo ratings yet

- NorthPoint Variance Application Package 2021-07-08Document31 pagesNorthPoint Variance Application Package 2021-07-08Jessica A. BotelhoNo ratings yet

- Reference Drawing Bill of Material For This Drawing General Notes Topographic Symbols Pipeline Symbols Soil SymbolsDocument26 pagesReference Drawing Bill of Material For This Drawing General Notes Topographic Symbols Pipeline Symbols Soil SymbolssubudhiprasannaNo ratings yet

- MCB Toilet ElevationspdfDocument1 pageMCB Toilet Elevationspdfjuy rose cunananNo ratings yet

- P3 2 Storey Res 7 20 23Document1 pageP3 2 Storey Res 7 20 23Jehrome CruzNo ratings yet

- Calculo de Columnas SiiDocument1 pageCalculo de Columnas SiidanielNo ratings yet

- Hanger System - Heating Surfaces 1.48760/00 213-0009: Zugehörige Zeichnungen / Relevant DrawingsDocument1 pageHanger System - Heating Surfaces 1.48760/00 213-0009: Zugehörige Zeichnungen / Relevant DrawingsDenkaNo ratings yet

- Ratrace GuitarDocument7 pagesRatrace GuitarneotaogeoNo ratings yet

- Brewery Ganzberg - Architectural design (thiết kế kiến trúc) - 18 June 2018- R6-TN-LAYOUT OF WWTPDocument1 pageBrewery Ganzberg - Architectural design (thiết kế kiến trúc) - 18 June 2018- R6-TN-LAYOUT OF WWTPsong1088No ratings yet

- J-DMS: Project HarmonyDocument1 pageJ-DMS: Project HarmonyMary DenizeNo ratings yet

- Measurements Recorded Area: Ground LevelDocument1 pageMeasurements Recorded Area: Ground LevelHytech Pvt. Ltd.No ratings yet

- Tumi Kamon Kore Gaan 1 PDFDocument5 pagesTumi Kamon Kore Gaan 1 PDFBal ArunavaNo ratings yet

- Tumi Kamon Kore Gaan 1Document5 pagesTumi Kamon Kore Gaan 1Bal ArunavaNo ratings yet

- QFD - FinalDocument1 pageQFD - FinalAngie Katherin MartínNo ratings yet

- 10187286-00A MMC 4l45 r4 AssyDocument1 page10187286-00A MMC 4l45 r4 AssymmNo ratings yet

- R6 (TYP) : Stub Axle-Rh (For RHD Vehicle)Document1 pageR6 (TYP) : Stub Axle-Rh (For RHD Vehicle)Sujay AvatiNo ratings yet

- Projet PompesDocument44 pagesProjet Pompesrocceli nzoulouNo ratings yet

- 1 1 XX048256 1 2 2 2 XX048256 1 1: Key Product Characteristics Safety/Compliance Fit/Function F/F CheckpointsDocument1 page1 1 XX048256 1 2 2 2 XX048256 1 1: Key Product Characteristics Safety/Compliance Fit/Function F/F CheckpointsRichard CruzNo ratings yet

- 011 012 MergedDocument12 pages011 012 MergedAli HusseinNo ratings yet

- 14 Temporal Señales (3) - ModelDocument1 page14 Temporal Señales (3) - ModelsoporteabacotecnologiaNo ratings yet

- TSL AcmvDocument11 pagesTSL AcmvTrần ChâuNo ratings yet

- JFN01 05 032 C.Document1 pageJFN01 05 032 C.luca.laniNo ratings yet

- Planuri Generale Si de Situatie Dumesti - rev.8-PS - 18 - Dumesti - A0Document1 pagePlanuri Generale Si de Situatie Dumesti - rev.8-PS - 18 - Dumesti - A0tebreanlNo ratings yet

- Spanish Tube Map1 PDFDocument2 pagesSpanish Tube Map1 PDFRaquel SaizNo ratings yet

- Activity Center Front Elevation: Esj and Sons Construction and Construction Supply, IncDocument1 pageActivity Center Front Elevation: Esj and Sons Construction and Construction Supply, IncGerard Paul CusiNo ratings yet

- Diagram KelistrikanDocument2 pagesDiagram KelistrikanDwidodo SantosoNo ratings yet

- Screenshot 2024-04-03 at 11.31.56 AMDocument7 pagesScreenshot 2024-04-03 at 11.31.56 AMAnticlockNo ratings yet

- Em-2006-Mep-Eom-Mt-Sd-Plb-109-2 (Rev-1)Document1 pageEm-2006-Mep-Eom-Mt-Sd-Plb-109-2 (Rev-1)shreeNo ratings yet

- 1-ModelDocument1 page1-Modeljoselito navarroNo ratings yet

- 481 - TrumpetDocument1 page481 - TrumpetIsaque PinheiroNo ratings yet

- 1-ModelDocument1 page1-Modeljoselito navarroNo ratings yet

- Notes:: Typ. Butt Welds (Not To Scale)Document1 pageNotes:: Typ. Butt Welds (Not To Scale)Cesar Eugenio Sanhueza ValdebenitoNo ratings yet

- Dilermando Reis Noite de Lua3Document15 pagesDilermando Reis Noite de Lua3daniel nogaraNo ratings yet

- Cxa VVVF 220Document1 pageCxa VVVF 220Mohamed ArefNo ratings yet

- PE1007 00GAC10 XJ00 446301 Piping Isometrics Rev 1Document1 pagePE1007 00GAC10 XJ00 446301 Piping Isometrics Rev 1JOSUE FERNANDO FERNANDEZNo ratings yet

- RC Pile Port-Layout3 PDFDocument1 pageRC Pile Port-Layout3 PDFKirk Gecosala FuertesNo ratings yet

- Combined PDFDocument40 pagesCombined PDFyilkal kassahunNo ratings yet

- Detail Buttress (4X) Section 4 - 4 Detail Buttress (4X) Section 5 - 5Document1 pageDetail Buttress (4X) Section 4 - 4 Detail Buttress (4X) Section 5 - 5joselito navarroNo ratings yet

- Queen SoloDocument1 pageQueen SoloLeandro PortelaNo ratings yet

- Water Intake Plant SLDDocument1 pageWater Intake Plant SLDali mohammedNo ratings yet

- Vivienda Multifamiliar: Luz Alba BallesterosDocument1 pageVivienda Multifamiliar: Luz Alba Ballesterosm4guipeNo ratings yet

- Internal & External ThreadDocument7 pagesInternal & External ThreadPham Thanh PhongNo ratings yet

- PC Color Chart-Under Development-6 Apr 2019Document1 pagePC Color Chart-Under Development-6 Apr 2019Pham Thanh PhongNo ratings yet

- Shipment 18-VTDocument4 pagesShipment 18-VTPham Thanh PhongNo ratings yet

- Atad-22022-Vt-19Document4 pagesAtad-22022-Vt-19Pham Thanh PhongNo ratings yet

- Atad-22022-Đn-19Document2 pagesAtad-22022-Đn-19Pham Thanh PhongNo ratings yet

- Welding Connections PDFDocument1 pageWelding Connections PDFPham Thanh PhongNo ratings yet

- TIÊU CHUẨN XI MẠ (TCVN 5026 2007, ISO 2081 1986)Document13 pagesTIÊU CHUẨN XI MẠ (TCVN 5026 2007, ISO 2081 1986)Pham Thanh PhongNo ratings yet

- En 12517-1 2006 Acceptance Criteria PDFDocument4 pagesEn 12517-1 2006 Acceptance Criteria PDFPham Thanh PhongNo ratings yet

- TCVN 1916-1995 Bulong - Vit - Vit Cay Va Dai OcDocument44 pagesTCVN 1916-1995 Bulong - Vit - Vit Cay Va Dai OcPham Thanh PhongNo ratings yet

- NANTE Cranes Components - Crane Components - Crane RailDocument2 pagesNANTE Cranes Components - Crane Components - Crane RailPham Thanh PhongNo ratings yet

- Adjustable Weldable Double Rail Clip WDM16R: 2. Pad Mounted Rail 1. Rail Without PadDocument1 pageAdjustable Weldable Double Rail Clip WDM16R: 2. Pad Mounted Rail 1. Rail Without PadPham Thanh PhongNo ratings yet

- Samboan FSDocument6 pagesSamboan FSalvic rodaNo ratings yet

- Research Article: Research On Visual Management Technology of Tunnel Construction Process Based On BIM TechnologyDocument9 pagesResearch Article: Research On Visual Management Technology of Tunnel Construction Process Based On BIM TechnologyjohnNo ratings yet

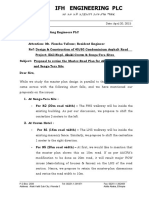

- Proposal To Revise The Master-Road PlanDocument2 pagesProposal To Revise The Master-Road PlanEngineeri TadiyosNo ratings yet

- Uae Fire Code-2010 PDFDocument652 pagesUae Fire Code-2010 PDFselva.uae8207No ratings yet

- Literature Review On Bridge ConstructionDocument6 pagesLiterature Review On Bridge Constructionm1dyhuh1jud2100% (1)

- Continuous Assessment Test II: March 2018 Reg. No.Document2 pagesContinuous Assessment Test II: March 2018 Reg. No.Venkatram PrabhuNo ratings yet

- Involved in All Stages of The Design of Structures, From Concept To ConstructionDocument2 pagesInvolved in All Stages of The Design of Structures, From Concept To ConstructionSanjeev V KumbharNo ratings yet

- ASCE Hydrocompression Settlement of Deep FillsDocument13 pagesASCE Hydrocompression Settlement of Deep FillsHoNo ratings yet

- Waterproof Boxes, Cover, Lampholder and Lighting FixtureDocument30 pagesWaterproof Boxes, Cover, Lampholder and Lighting FixtureMuhamad PriyatnaNo ratings yet

- 01 Boq 220KV - Gis - Karanjde - Price Schedule (Consolidated)Document4 pages01 Boq 220KV - Gis - Karanjde - Price Schedule (Consolidated)Akd DeshmukhNo ratings yet

- 08 Landscape Work - NIMDocument38 pages08 Landscape Work - NIMjennyNo ratings yet

- EMPM5103-PQMP Assignment - Part BDocument60 pagesEMPM5103-PQMP Assignment - Part Bnorizam32100% (2)

- Lakeview Tower - Case History of Foundation FailureDocument8 pagesLakeview Tower - Case History of Foundation FailureJorge Andres Arias PerdomoNo ratings yet

- SSC Cat Spirax Sarco Vacuum BreakersDocument1 pageSSC Cat Spirax Sarco Vacuum BreakersEb RahimNo ratings yet

- Tank Datasheet - CS-8000KL - RADocument1 pageTank Datasheet - CS-8000KL - RASumantrra ChattopadhyayNo ratings yet

- 008 - 6060 - RH340B - Attachment Functions FS - CATDocument62 pages008 - 6060 - RH340B - Attachment Functions FS - CAThectorNo ratings yet

- Notice - RFP ImmigrationDocument4 pagesNotice - RFP ImmigrationVeenoyNo ratings yet

- BOQ - External Development WorksDocument5 pagesBOQ - External Development WorksAmit RuhilNo ratings yet

- IS2527-1984 Gutter and Ds PDFDocument21 pagesIS2527-1984 Gutter and Ds PDFmaheshbandhamNo ratings yet

- AR8703 SPECIFICATION, ESTIMATION AND VALUATION - Notes - 5 UnitsDocument77 pagesAR8703 SPECIFICATION, ESTIMATION AND VALUATION - Notes - 5 UnitsBhuvana50% (2)

- 002-History of ArchitectureDocument9 pages002-History of ArchitectureCj ColarinaNo ratings yet