Professional Documents

Culture Documents

Test 1 PFFL101 8 April 2019 PDF

Uploaded by

Anele HadebeOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Test 1 PFFL101 8 April 2019 PDF

Uploaded by

Anele HadebeCopyright:

Available Formats

Chemical

Engineering DUT Lecturer: Dr M Chetty

Process Fluid Flow: BEngTech

Test 1 Date: 08 April 2019

Time: 60 minutes Total marks: 40

Moderator: Dr Y. Isa Venue: BS2104

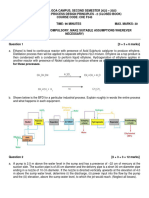

Question 1

Define the following terms with respect to a fluid flowing in a pipe:

1.1.Laminar flow (2)

1.2.Turbulent flow (2)

Question 2

2.1. Use the law of conservation of mass to prove the following for a fluid flowing from point 1

to point 2 in a pipeline where d1>d2:

(6)

2.2. Water at 320 K is pumped at a rate of 2.16 m3/h through a 40 mm ID pipe. It goes through a

length of 185 m horizontal pipe. There are a number of control valves and fittings online that

have a total equivalent length equal to 180 times the internal diameter. The head loss due to a

condenser online is1.8 m. Given the pipe roughness of 0.0002 m:

2.2.1 calculate the total head loss in the system and

2.2.2. determine the actual power required if the pump is 54 % efficient.

The density of water is 1000 kg/m3 and the viscosity of water is 0.65 mN.s/m2

(15)

Question 3

A non-Newtonian fluid flows from a tank to a distillation column along a 10 m pipe with an internal

diameter of 0.2 m. The fluid flows with an average velocity of 2 m.s-1, the pipe flow consistency

index k, has a value of 2.3 Pa.s0.3 and n value of 0.3. As the resident engineer you have been

requested to calculate the apparent viscosity, the Reynolds number and the pressure drop in the

pipeline for a new pumping system. The fluid density is 930 kg.m-3.

(15)

Total marks = 40

You might also like

- Angeles - Momentum TransferDocument16 pagesAngeles - Momentum TransferJaden BrownNo ratings yet

- Written Test 1 24 June 2021Document5 pagesWritten Test 1 24 June 2021Enabewhkom OhpmNo ratings yet

- Momentum TransferDocument2 pagesMomentum TransferrahulNo ratings yet

- Instructor: Prof. Dr. Behiç Mert 2018-2019 Fall TA: Res - Asst. Kübra ERTANDocument2 pagesInstructor: Prof. Dr. Behiç Mert 2018-2019 Fall TA: Res - Asst. Kübra ERTANGG MMNo ratings yet

- Final Exam-5th YearDocument2 pagesFinal Exam-5th YearNarasimha RaoNo ratings yet

- Rr210801 Fluid MechanicsDocument6 pagesRr210801 Fluid MechanicsSrinivasa Rao GNo ratings yet

- NR-220301 - Mechanics of FluidsDocument8 pagesNR-220301 - Mechanics of FluidsSrinivasa Rao GNo ratings yet

- KC22802 - FM 2 - BK18110065 - Fitri Nurulfazira HalimDocument13 pagesKC22802 - FM 2 - BK18110065 - Fitri Nurulfazira HalimnurulfaziraNo ratings yet

- 9A23303 Fluid Flow in BioprocessesDocument4 pages9A23303 Fluid Flow in BioprocessessivabharathamurthyNo ratings yet

- Solution To HW5Document23 pagesSolution To HW5minervini markNo ratings yet

- r050212102 Mechanics of FluidsDocument8 pagesr050212102 Mechanics of FluidsSrinivasa Rao GNo ratings yet

- Exercises - Ii 13-12-2022Document5 pagesExercises - Ii 13-12-2022Gãlväñ FôxNo ratings yet

- Rr210801 Fluid MechanicsDocument4 pagesRr210801 Fluid MechanicsSrinivasa Rao GNo ratings yet

- Class Test 1 15 JULY 2021: Process Fluid FlowDocument6 pagesClass Test 1 15 JULY 2021: Process Fluid FlowEnabewhkom OhpmNo ratings yet

- 3 - Fluid Kinemetics PDFDocument3 pages3 - Fluid Kinemetics PDFPrabhat PiyushNo ratings yet

- Fluid Mechanics Assignment 4Document2 pagesFluid Mechanics Assignment 4Rojan PradhanNo ratings yet

- Tim1 KelasADocument5 pagesTim1 KelasARiatus SNo ratings yet

- Mid-Term Test (2022-2023) CHE F343Document2 pagesMid-Term Test (2022-2023) CHE F343Vehaan HandaNo ratings yet

- 9A23303 Fluid Flow in BioprocessesDocument4 pages9A23303 Fluid Flow in BioprocessessivabharathamurthyNo ratings yet

- r-13 Supply June 15Document54 pagesr-13 Supply June 15Sony RamaNo ratings yet

- Tutorial 1 - Conservation of MassDocument2 pagesTutorial 1 - Conservation of MassAmir Akmal0% (1)

- VR 17 FM and HM HA Questions - Part 1Document5 pagesVR 17 FM and HM HA Questions - Part 1bhanu tejaNo ratings yet

- Tutorial 11Document7 pagesTutorial 11yash sononeNo ratings yet

- 7636fluid Mechanics and Hydralics MachinesDocument8 pages7636fluid Mechanics and Hydralics MachinesNitin GuptaNo ratings yet

- Fluid Mechanics and Hydraulic MachineryDocument8 pagesFluid Mechanics and Hydraulic MachineryDhanush RagavNo ratings yet

- Code No: 43011/43012Document7 pagesCode No: 43011/43012SRINIVASA RAO GANTANo ratings yet

- 9A21404 Mechanics of FluidsDocument4 pages9A21404 Mechanics of FluidssivabharathamurthyNo ratings yet

- Workbook TO1 FinalDocument9 pagesWorkbook TO1 FinalVivek Gupta0% (1)

- Assignment 2012 2nd Year Mechanical EngineeringDocument17 pagesAssignment 2012 2nd Year Mechanical EngineeringFiseha Bogale KibNo ratings yet

- ME Con-2Document8 pagesME Con-2Divyanshu YadavNo ratings yet

- STRENGTHENING OF DETERIORATED SMALLl-DIAMETER - SEWAGDocument10 pagesSTRENGTHENING OF DETERIORATED SMALLl-DIAMETER - SEWAGING. EUCLIDES POCLIN TUESTANo ratings yet

- SP 1 Assignment 30 March 2022Document2 pagesSP 1 Assignment 30 March 2022ONKAR ARORA0% (1)

- Final Fe Fluid Practice ProblemsDocument7 pagesFinal Fe Fluid Practice ProblemsHasen BebbaNo ratings yet

- Ffo AssignmentsDocument13 pagesFfo AssignmentsHarsh Subodh KhanvilkarNo ratings yet

- Rr212101 Mechanics of FluidDocument8 pagesRr212101 Mechanics of FluidSrinivasa Rao GNo ratings yet

- 9A23303 Fluid Flow in Bio ProcessesDocument4 pages9A23303 Fluid Flow in Bio ProcessessivabharathamurthyNo ratings yet

- Fluid Mechanics - Unit 6 - Week 5 - APPLICATIONS OF FLUID STATICS AND DYNAMICSDocument4 pagesFluid Mechanics - Unit 6 - Week 5 - APPLICATIONS OF FLUID STATICS AND DYNAMICShemaruthrra.rNo ratings yet

- Fluid Mechanics Question Bank @Document6 pagesFluid Mechanics Question Bank @AnujNo ratings yet

- Ndejje University Main Campus AssignmentDocument2 pagesNdejje University Main Campus AssignmentBitekateko Abel100% (1)

- Mechanics of Fluids May2004 RR 220301Document8 pagesMechanics of Fluids May2004 RR 220301Nizam Institute of Engineering and Technology LibraryNo ratings yet

- Topic 4 - (II)Document2 pagesTopic 4 - (II)daabgchiNo ratings yet

- Code No: 3220304 II B. Tech II Semester Regular Examinations April/May 2009 (Mechanical Engineering) Time: 3 Hours Max. Marks: 80 Answer Any FIVE Questions. All Questions Carry Equal MarksDocument7 pagesCode No: 3220304 II B. Tech II Semester Regular Examinations April/May 2009 (Mechanical Engineering) Time: 3 Hours Max. Marks: 80 Answer Any FIVE Questions. All Questions Carry Equal MarksKrishna BhaskarNo ratings yet

- R5102306 Process Engineering PrinciplesDocument1 pageR5102306 Process Engineering PrinciplessivabharathamurthyNo ratings yet

- FM - Assignment 2Document2 pagesFM - Assignment 2Swagata SharmaNo ratings yet

- III B.Tech I Semester Regular Examinations, Industrial Instrumentation (Electronics & Instrumentation Engineering)Document1 pageIII B.Tech I Semester Regular Examinations, Industrial Instrumentation (Electronics & Instrumentation Engineering)Sridhar Koneru VenkkatNo ratings yet

- Tutorial 7Document5 pagesTutorial 7KaliDasNo ratings yet

- r050212102 Mechanics of FluidsDocument8 pagesr050212102 Mechanics of FluidsSrinivasa Rao GNo ratings yet

- Advanced Fluid Mechanics (AFM) : Pakistan Navy Engineering College, PNEC, NUST KarachiDocument8 pagesAdvanced Fluid Mechanics (AFM) : Pakistan Navy Engineering College, PNEC, NUST KarachiHammad PervezNo ratings yet

- Isro Scientist Me 2020 Paper 80c39244Document20 pagesIsro Scientist Me 2020 Paper 80c39244Elsa PoirotNo ratings yet

- Mechanics of Fluids Nov2004 RR 212101Document7 pagesMechanics of Fluids Nov2004 RR 212101Nizam Institute of Engineering and Technology LibraryNo ratings yet

- Flow MwassurementDocument2 pagesFlow MwassurementAditi SharmaNo ratings yet

- One-Dimensional Compressible Flow: Thermodynamics and Fluid Mechanics SeriesFrom EverandOne-Dimensional Compressible Flow: Thermodynamics and Fluid Mechanics SeriesNo ratings yet

- Modern Devices: The Simple Physics of Sophisticated TechnologyFrom EverandModern Devices: The Simple Physics of Sophisticated TechnologyNo ratings yet

- Oscillometry and Conductometry: International Series of Monographs on Analytical ChemistryFrom EverandOscillometry and Conductometry: International Series of Monographs on Analytical ChemistryNo ratings yet

- Lecture 1 - MSOP - Absorption - 2023Document34 pagesLecture 1 - MSOP - Absorption - 2023Anele HadebeNo ratings yet

- Project 1 Technical and Economic Feasibility Study 2023 1Document12 pagesProject 1 Technical and Economic Feasibility Study 2023 1Anele HadebeNo ratings yet

- Oral PresentationDocument4 pagesOral PresentationAnele HadebeNo ratings yet

- Lecture 1 - MSOP - Absorption - Added InfoDocument40 pagesLecture 1 - MSOP - Absorption - Added InfoAnele HadebeNo ratings yet

- Feasibility Study For An Investment of An Industrial Plant Evaluating Red Mud by An Innovating Method. A Case StudyDocument8 pagesFeasibility Study For An Investment of An Industrial Plant Evaluating Red Mud by An Innovating Method. A Case StudyAnele HadebeNo ratings yet

- Lecture Notes Pumps 2022Document15 pagesLecture Notes Pumps 2022Anele HadebeNo ratings yet

- Lecture Notes Mixing PFFL101 For 2020 MCDocument20 pagesLecture Notes Mixing PFFL101 For 2020 MCAnele HadebeNo ratings yet

- Boiling Heat Transfer Prac Report 21909068 K RamabulanaDocument16 pagesBoiling Heat Transfer Prac Report 21909068 K RamabulanaAnele HadebeNo ratings yet

- Lecture Notes Compressible Flow 2022Document7 pagesLecture Notes Compressible Flow 2022Anele HadebeNo ratings yet

- Centrifual Pump Group Technical ReportDocument16 pagesCentrifual Pump Group Technical ReportAnele HadebeNo ratings yet

- Rotameter DoneDocument10 pagesRotameter DoneAnele HadebeNo ratings yet

- Rotameter Prac TestDocument5 pagesRotameter Prac TestAnele HadebeNo ratings yet

- Individual ReportDocument17 pagesIndividual ReportAnele HadebeNo ratings yet