Professional Documents

Culture Documents

SB 24-4034

Uploaded by

ravi k singhOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SB 24-4034

Uploaded by

ravi k singhCopyright:

Available Formats

MANDATORY

SERVICE BULLETIN

TITLE: ELECTRICAL POWER - INSPECTION/REWORK OF ZL PANEL DIODES WITH FLEXIBLE

BRAIDED LEADS

1. Planning Information

A. Effectivity

(1) Airplanes

Hawker 800XP and Hawker 850XP, Serials 258709 through 258819, 258821 through 258823,

258825 through 258838, 258840, 258841, 258844, 258845, 258847, 258848, 258852, 258855,

258856, 258858, 258859, 258861, 258872, 258874, 258876, 258891, 258893, 258895, 258900,

258901, 258904, 258907, 258909, 258912, 258915, 258921, 258959, 258961, 258963, 258977,

and 258982 through 258984;

Hawker 900XP, Serials HA-0001 through HA-0095, HA-0097 through HA-0108, HA-0110, HA-0112

through HA-0114, HA-0117, HA-0120, HA-0121, HA-0140, HA-0143, and HA-0146 through

HA-0164;

Hawker 750, Serials HB-1 through HB-35, HB-41, HB-43, HB-62, HB-63, HB-65 and HB-67.

If you are no longer in possession of the airplane, please forward this information to the present

owner.

(2) Spares

Any airplanes that have installed P/N SW06HHN400SU-U9096 diodes with flexible braided leads

purchased from Hawker Beechcraft Parts & Distribution (HBP&D) from January 1, 2005 through

June 18, 2010.

B. Reason

This Service Bulletin is being issued to address a production quality escape in which certain airplanes had

been delivered with four (4) diodes with flexible braided leads (hereafter referred to as diodes) that have a

greater length than is permitted by specification. The function of these diodes is to feed electrical power to

the essential power (PE) bus. The extra length of the diodes makes it possible for inadvertent contact to

occur. If contact occurs, it may result in reverse current from the PE bus to either PS1 or PS2. This may

lead to inoperative emergency contactors and/or reduced main battery duration in the event of loss of both

generators.

The export of these commodities, technology or software are subject to the U.S. Export Both classes are available on the web at http://pubs.hawkerbeechcraft.com and mailed to:

Administration Regulations. Diversion contrary to U.S. law is prohibited. For guidance on (a) Owners of record on the FAA Aircraft Registration Branch List and the HBC

export control requirements, contact the Commerce Department's Bureau of Export Safety of Flight Information (SOFI) List.

Administration at http://www.bis.doc.gov.

(b) Those having a publications subscription.

Hawker Beechcraft Corporation (HBC) issues Service Information for the benefit of owners Information on Safety of Flight Information (SOFI) or subscription can be obtained through

and fixed base operators in the form of two classes of Service Bulletins. The first class, the Hawker Beechcraft Corporation Technical Manual Distribution Center (TMDC). As

Mandatory Service Bulletins (red border) includes changes, inspection and modifications that Mandatory Service Bulletins and Service Bulletins are issued, the Service Bulletin Master

could affect safety or crashworthiness. HBC also issues Service Bulletins with no red border Index will be updated and available online at http://pubs.hawkerbeechcraft.com. Warranty

which are designated as either recommended or optional in the compliance section within the will be allowed only when specifically defined in the Service Bulletin and in accordance with

bulletin. In the case of recommended Service Bulletins, HBC feels the changes, HBC Warranty Policy.

modifications, improvements or inspections will benefit the owner/operator and although

highly recommended, Recommended Service Bulletins are not considered mandatory at the Unless otherwise designated, HBC Mandatory Service Bulletins, Service Bulletins and HBC

time of issuance. In the case of Optional Service Bulletins, compliance with the changes, Kits are approved for installation on HBC airplanes in original or HBC modified configurations

modifications, improvements or inspections is at the owner/operator's discretion. only. HBC Mandatory Service Bulletins, Service Bulletins and Kits may not be compatible

with airplanes modified by STC installations or modifications other than HBC approved kits.

Issued: July, 2010 SB 24-4034

1 of 7

MANDATORY

SERVICE BULLETIN

C. Description

This Service Bulletin provides instructions to access the ZL panel, which is located between Frames 22

and 23 in the rear equipment bay. The P/N SW06HHN400SU-U9096 diodes, A, C, D, and E, along with

associated wires and components in the area, shall be inspected for signs of heat damage. If any heat

damage is found, these items shall be repaired or replaced in accordance with the Aircraft Maintenance

Manual (AMM). If no heat damage is found, diodes A, C, D, and E shall each be insulated in a new

heatshrink sleeve.

D. Compliance

An Airworthiness Directive will be requested on the matter covered by this Service Bulletin.

Hawker Beechcraft Corporation considers this to be a Mandatory Service Bulletin. It must be accomplished

no later than 300 flight hours or 12 months from receipt of this Service Bulletin, whichever occurs first.

E. Approval

The engineering data contained in this Service Bulletin is FAA approved.

This modification is classified Level 2 Major per FAA Order 8110.52.

Prior to accomplishment, owners/operators of airplanes registered in countries other than the United

States shall consult with their local Aviation Regulatory Authority.

F. Manpower

The following information is for planning purposes only:

Estimated man-hours: 12 hours

Suggested number of personnel: 1

The above is an estimate based on experienced, properly equipped personnel complying with this Service

Bulletin. Occasionally, after work has started, conditions may be found that could result in additional man-

hours.

G. Weight and Balance

Negligible.

H. Electrical Load Data

No change.

I. Software Accomplishment Summary

Not applicable.

J. References

Aircraft Maintenance Manual (AMM), Chapter 20 and Chapter 24.

Issued: July, 2010

SB 24-4034

2 of 7

MANDATORY

SERVICE BULLETIN

K. Publications Affected

None.

L. Interchangeability of Parts

Not applicable.

M. Warranty Credit

Warranty credit for labor and parts to the extent noted under MANPOWER and MATERIAL will be allowed

on all affected airplanes that are under standard warranty coverage or an active HBC maintenance

program covering labor and parts on the date of issue. Claims for compliance with this Service Bulletin are

to be filed as a W3-type claim against SB 24-4034.

Warranty coverage offered in this Service Bulletin will expire 12 months from the last day of the month this

Service Bulletin is issued. After this date, the owner/operator assumes the responsibility for compliance

cost. Hawker Beechcraft Corporation (HBC) reserves the right to void continued warranty coverage in the

area affected by this Service Bulletin until the date the Service Bulletin is accomplished by an HBC

Authorized Service Center (ASC).

The owner/operator should contact an HBC ASC to schedule the warranty work to be accomplished. The

HBC ASC must be rated to perform maintenance on the specific model of Hawker Beechcraft airplane.

The HBC ASC will submit the appropriate paperwork directly to the HBC Warranty Department for

warranty consideration. In the event that work cannot be accomplished at an HBC ASC, parts may be

purchased directly from Hawker Beechcraft Parts & Distribution (HBP&D) and a warranty claim for parts

ONLY should be submitted directly to the HBC Warranty Department.

After the Service Bulletin has been accomplished, a warranty claim must be submitted to HBC within 60

days of the Service Bulletin completion date.

2. Material Information

A. Materials - Price and Availability

On application to the following address:

Hawker Beechcraft Parts & Distribution (HBP&D)

10511 East Central Avenue

Wichita, KS 67206

USA

Phone: 316-676-3100 or 1-888-727-4344

Fax: 316-676-3222 or 316-676-3327

E-mail: HBC_Parts@hawkerbeechcraft.com

B. Industry Support

Not applicable.

Issued: July, 2010

SB 24-4034

3 of 7

MANDATORY

SERVICE BULLETIN

C. Airplanes

The following parts required for accomplishment of this Service Bulletin may be ordered through a Hawker

Beechcraft Authorized Service Center or HBP&D:

Part Number Description Quantity Per Airplane

M23053/16-005-0 Heatshrink Sleeve 48 inches

Hawker Beechcraft Corporation expressly reserves the right to supersede, cancel and/or declare obsolete,

without prior notice, any parts or publications that may be referenced in this Service Bulletin.

D. Spares

Not applicable.

E. Reidentified Parts

None.

F. Tooling - Price and Availability

Not applicable.

3. Accomplishment Instructions

This Service Bulletin shall be accomplished as follows:

NOTE

Should any difficulty be encountered in accomplishing this Service Bulletin,

contact Hawker Beechcraft Corporation at 1-800-429-5372 or 316-676-3140.

Observe all Warnings and Cautions contained in the airplane manuals

referenced in this Service Bulletin.

Whenever any part of this system is dismantled, adjusted, repaired or

renewed, detailed investigation must be made on completion to make sure

that distortion, tools, rags or any other loose articles or foreign matter that

could impede the free movement and safe operation of the system are not

present, and that the systems and installations in the work area are clean.

Issued: July, 2010

SB 24-4034

4 of 7

MANDATORY

SERVICE BULLETIN

A. Airplane

(1) Remove all power from the airplane and disconnect the batteries. Display warning notices

prohibiting reconnection of airplane electrical power.

(2) Remove equipment as necessary in accordance with the applicable AMM chapter to gain access to

the ZL panel. Refer to Figure 1.

(3) Remove the ZL panel cover.

(4) Locate, at the upper end of the ZL panel, diodes A, C, D and E, which are in-line between the PE bus

and the #1 and #2 battery contactors and #1 and #2 emergency contactors. Refer to Figure 1, Detail

A.

(5) Accomplish the following inspection and modification at the defined area of the ZL panel:

(a) If evidence of heat damage exists to any of the associated wires and components in the area,

repair or replace these wires and components in accordance with AMM Chapter 20-10-50,

Standard Practices - Airframe.

(b) If evidence of heat damage does not exist, install heatshrink sleeve(s) P/N M23053/16-005-0

over diodes A, C, D, and E. Shrink the sleeve(s). Refer to Figure 2.

NOTE

Apply heatshrink sleeves to the braided area of the diode leads ONLY, being

careful to overlap a portion of the terminal lug and the crimped ferrule on the

diode. Do NOT include the body of the diode.

(6) Install the ZL panel cover.

(7) Install the equipment that was removed in Step (2) in accordance with the applicable AMM Chapter.

(8) Reconnect the airplane batteries, remove warning notices, and restore power.

(9) Functionally test the DC Generation System in accordance with AMM Chapter 24-30-01-501.

(10) Ensure all work areas are clean and clear of tools and miscellaneous items of equipment.

(11) Return airplane to service.

B. Spares

For spare unit P/N SW06HHN400SU-U9096 diodes purchased from HBP&D from January 1, 2005 to June

18, 2010, if the diode assembly exceeds six and three quarters (6.75) inches in length, return the diode to

HBP&D for replacement or credit.

C. Record of Compliance

Upon completion of this Service Bulletin, make an appropriate maintenance record entry.

Issued: July, 2010

SB 24-4034

5 of 7

MANDATORY

SERVICE BULLETIN

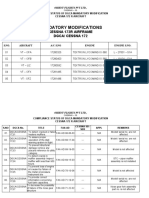

Inspection of ZL Panel

Figure 1

Issued: July, 2010

SB 24-4034

6 of 7

MANDATORY

SERVICE BULLETIN

Heatshrink Sleeve Installation on P/N SW06HHN400SU-U9096 Diodes

Figure 2

Issued: July, 2010

SB 24-4034

7 of 7

You might also like

- Aviation Weather Services Handbook: FAA AC 00-45HFrom EverandAviation Weather Services Handbook: FAA AC 00-45HRating: 3 out of 5 stars3/5 (5)

- SB-4100 - Pitch Trim Actuator Hawker 400Document7 pagesSB-4100 - Pitch Trim Actuator Hawker 400reginaldo11No ratings yet

- SB 27-3928Document13 pagesSB 27-3928412 BellNo ratings yet

- Service Bulletin: OptionalDocument7 pagesService Bulletin: OptionalFrancisco AriasNo ratings yet

- Get Beech or Hawker AttachmentDocument6 pagesGet Beech or Hawker AttachmentJorge CastroNo ratings yet

- Wings - Aileron Drain Hole Inspection SBDocument8 pagesWings - Aileron Drain Hole Inspection SBstiveNo ratings yet

- PK-ANQ - Related SB Sundowner C23 - TPU 13Document3 pagesPK-ANQ - Related SB Sundowner C23 - TPU 13Rivaldo Alfaridzki AviadiNo ratings yet

- SB 34-3379Document6 pagesSB 34-3379Francisco AriasNo ratings yet

- 407ASB407ASB21125Document8 pages407ASB407ASB21125e.a.m.v.9.8.1.2No ratings yet

- Bell 407 PSL 1701Document6 pagesBell 407 PSL 1701MahmudNo ratings yet

- SB 30-3143 Engine Inlet Anti-Ice Line InspectionDocument6 pagesSB 30-3143 Engine Inlet Anti-Ice Line InspectionGarrett ReeveNo ratings yet

- Afi 32 1062Document25 pagesAfi 32 1062José SánchezNo ratings yet

- IntroduccionDocument648 pagesIntroduccionAndres DE LA Cruz100% (1)

- Si 1185Document6 pagesSi 1185user10002No ratings yet

- CHAPTER 5 - TIME LIMITS and MAINTENANCE CHECKSDocument39 pagesCHAPTER 5 - TIME LIMITS and MAINTENANCE CHECKSAlvaro Lemos100% (1)

- Get Cessna AttachmentDocument6 pagesGet Cessna Attachmentmelvin ariel flores garciaNo ratings yet

- VD From1119 To 300619 181231 Final Vendor Directory PDFDocument160 pagesVD From1119 To 300619 181231 Final Vendor Directory PDFAnonymous jCIrzhhRNo ratings yet

- Chapter5 - General InspectionDocument2 pagesChapter5 - General InspectionElmer VillegasNo ratings yet

- Easa Ead Us-2024-05-51 1Document5 pagesEasa Ead Us-2024-05-51 1buracurexboNo ratings yet

- DownloadDocument9 pagesDownloadMohammadNo ratings yet

- 02.34 25635-220-3PS-MHCB-00001 Technical PDFDocument32 pages02.34 25635-220-3PS-MHCB-00001 Technical PDFEl_memitoNo ratings yet

- Pavement 33Document656 pagesPavement 33dinoNo ratings yet

- Easa Ead Us-2024-06-51 1Document5 pagesEasa Ead Us-2024-06-51 1vitalijusNo ratings yet

- Service BulletinDocument27 pagesService BulletinNegin ForozeshNo ratings yet

- 700 29 027 BasicDocument13 pages700 29 027 BasicHimanshu Pant100% (1)

- FAA 2017 0667 0006 - Attachment - 1Document5 pagesFAA 2017 0667 0006 - Attachment - 1pilot digitalNo ratings yet

- 549-00-0107 D Functional Ground Test PlanDocument11 pages549-00-0107 D Functional Ground Test PlanWong BennyNo ratings yet

- Maintenance Manual: Poplar Farm Prolley Moor Wentnor Bishops Castle Sy9 5ejDocument66 pagesMaintenance Manual: Poplar Farm Prolley Moor Wentnor Bishops Castle Sy9 5ejCristhian342100% (1)

- Airworthiness Directive Bombardier/Canadair 080523Document8 pagesAirworthiness Directive Bombardier/Canadair 080523bombardierwatchNo ratings yet

- Flight Standardization Board (FSB) ReportDocument65 pagesFlight Standardization Board (FSB) ReportJuaco Zamb100% (1)

- Project Specification: Motor-Control Centers For HvacDocument15 pagesProject Specification: Motor-Control Centers For HvacSoumojit SamantaNo ratings yet

- Service Bulletin Revision Transmittal Sheet: CL - 600 - 2B19 AircraftDocument38 pagesService Bulletin Revision Transmittal Sheet: CL - 600 - 2B19 AircraftJOSE ANTONIO MAGNE RODRIGUEZNo ratings yet

- ASTM B117: SD-11 Closeout Submittals Energy Efficient Equipment For Motors Reduce Volatile Organic Compounds (VOC)Document5 pagesASTM B117: SD-11 Closeout Submittals Energy Efficient Equipment For Motors Reduce Volatile Organic Compounds (VOC)JamesNo ratings yet

- Easa Ad CF-2020-45R1 1Document2 pagesEasa Ad CF-2020-45R1 1Silk BladeNo ratings yet

- 6-66 KV SF6 BKR R3 May12Document26 pages6-66 KV SF6 BKR R3 May12PB MehtaNo ratings yet

- 3.3 Technical Specifications of Prefabricated ContainerizedDocument81 pages3.3 Technical Specifications of Prefabricated Containerized021804No ratings yet

- 110 - Technical G-08 (B) 12.11.2009Document546 pages110 - Technical G-08 (B) 12.11.2009Sandeep Bharta100% (1)

- Aircraft Electrical CablesDocument20 pagesAircraft Electrical CablesMohd Shah100% (1)

- ASB 407-21-124 Page 1 of 6 Approved For Public ReleaseDocument6 pagesASB 407-21-124 Page 1 of 6 Approved For Public Releasemohammed kareemNo ratings yet

- Service Bulletin: TitleDocument12 pagesService Bulletin: TitleLuis EnriqueNo ratings yet

- Super King Air® Model B300 and B300C: Airworthiness Limitations ManualDocument5 pagesSuper King Air® Model B300 and B300C: Airworthiness Limitations ManualJorge CastroNo ratings yet

- McCauley Propeller ManualDocument133 pagesMcCauley Propeller Manualbmk5140100% (2)

- Vendor Directory From 1-1-2018 To 30-06-2018Document245 pagesVendor Directory From 1-1-2018 To 30-06-2018Santhosh V RaajendiranNo ratings yet

- Specification For 460 Volt MCCDocument4 pagesSpecification For 460 Volt MCCMrNo ratings yet

- Airworthiness Directive: Transport Transports Canada Canada CF-2007-20R2 6 February 2009Document3 pagesAirworthiness Directive: Transport Transports Canada Canada CF-2007-20R2 6 February 2009Karol KrzysztoszekNo ratings yet

- SB 60-78-9Document37 pagesSB 60-78-9Eliana Ayelen TruccoNo ratings yet

- Mandatory Service: BulletinDocument4 pagesMandatory Service: BulletinAlvaro AriasNo ratings yet

- Baron Annual Inspection ChecklistDocument20 pagesBaron Annual Inspection Checklistalorena.leon21No ratings yet

- BXT65XX IO Issue08 PDFDocument84 pagesBXT65XX IO Issue08 PDFJonatan BernalNo ratings yet

- ASBAS350760033ENR0Document17 pagesASBAS350760033ENR0tvsufi.comNo ratings yet

- 2018-19-04Document8 pages2018-19-04Juan Ruben GarciaNo ratings yet

- Control and Relay Panel - Technical SpecificationDocument57 pagesControl and Relay Panel - Technical SpecificationLourdhu Sagaya Jayakumar JNo ratings yet

- Easa Ad CF-2023-71 1Document2 pagesEasa Ad CF-2023-71 1RawiNo ratings yet

- Bundle Spacer: Engineering DepartmentDocument4 pagesBundle Spacer: Engineering DepartmentpvenkyNo ratings yet

- Boeing 737 NG M2 2023Document13 pagesBoeing 737 NG M2 2023przytul2007No ratings yet

- SB 11-642Document18 pagesSB 11-642clipper996No ratings yet

- TBO Hélice PDFDocument133 pagesTBO Hélice PDFCarlos Javier SilveraNo ratings yet

- Sae As 90328Document4 pagesSae As 90328fructoraNo ratings yet

- Service BulletinDocument13 pagesService BulletinBruno WilliansNo ratings yet

- Tech Spec of PTR 33 11 KVDocument34 pagesTech Spec of PTR 33 11 KVAnonymous sAmJfcVNo ratings yet

- Hawker 900XP MiscmodesDocument99 pagesHawker 900XP Miscmodesravi k singhNo ratings yet

- UntitledDocument17 pagesUntitledravi k singhNo ratings yet

- SL S185X501-25-03 (V00) INTEGRA ELTs Approvals - 0Document6 pagesSL S185X501-25-03 (V00) INTEGRA ELTs Approvals - 0ravi k singhNo ratings yet

- SL S185X501-25-02 (V00) COMPATIBILTY BETWEEN INTEGRA ELTs AND ALL KANNAD ELTs - 0Document10 pagesSL S185X501-25-02 (V00) COMPATIBILTY BETWEEN INTEGRA ELTs AND ALL KANNAD ELTs - 0ravi k singhNo ratings yet

- Service Letter: Packs Integra Elts / Retrofit Installation Kits Description / Installation 1. ReasonDocument2 pagesService Letter: Packs Integra Elts / Retrofit Installation Kits Description / Installation 1. Reasonravi k singhNo ratings yet

- Service Letter: Compact Elts Family / Integra Elts Family Guidelines For Periodic Inspection ReasonDocument14 pagesService Letter: Compact Elts Family / Integra Elts Family Guidelines For Periodic Inspection Reasonravi k singhNo ratings yet

- Dgca Mod C172Document8 pagesDgca Mod C172ravi k singhNo ratings yet

- Objective Type (OMR Valuation) (Please See Syllabus On The Last Page)Document2 pagesObjective Type (OMR Valuation) (Please See Syllabus On The Last Page)Ninson KMNo ratings yet

- 2017 Vol 3 CH 9 AnsDocument3 pages2017 Vol 3 CH 9 AnsDiola QuilingNo ratings yet

- Auditing Practice Problem 4Document4 pagesAuditing Practice Problem 4Jessa Gay Cartagena TorresNo ratings yet

- United States v. Wyman Taylor, 129 F.3d 131, 10th Cir. (1997)Document5 pagesUnited States v. Wyman Taylor, 129 F.3d 131, 10th Cir. (1997)Scribd Government DocsNo ratings yet

- Chapter 39 Corporate Formation and FinancingDocument12 pagesChapter 39 Corporate Formation and FinancingBao Thanh Nguyen LamNo ratings yet

- Prescription of Bir'S Right To Assess: (BDB Law'S "Tax Law For Business" BusinessmirrorDocument2 pagesPrescription of Bir'S Right To Assess: (BDB Law'S "Tax Law For Business" BusinessmirrorBobby Olavides SebastianNo ratings yet

- Alma Jose vs. JavellanaDocument1 pageAlma Jose vs. JavellanaMACNo ratings yet

- Banking Law Project TopicsDocument4 pagesBanking Law Project Topicsvkk_kvk83% (6)

- Classical Theory: Provision of A Criminal Policy Assumes RationalityDocument12 pagesClassical Theory: Provision of A Criminal Policy Assumes RationalityhargunNo ratings yet

- Jane Eyre ThemesDocument2 pagesJane Eyre ThemesphthysyllysmNo ratings yet

- Club vs. BautistaDocument7 pagesClub vs. Bautistadave_88opNo ratings yet

- Annotated BibliographyDocument5 pagesAnnotated BibliographyD_NorthNo ratings yet

- CA 3 Therapeutic Modalities F2 A Course Syllabus Lecture OnlyDocument13 pagesCA 3 Therapeutic Modalities F2 A Course Syllabus Lecture OnlyWestleyNo ratings yet

- The New StatesmanDocument19 pagesThe New StatesmanRaeanna ManasviNo ratings yet

- PA Juvenile Justice Task Force Report and Recommendations FINALDocument64 pagesPA Juvenile Justice Task Force Report and Recommendations FINALjmicekNo ratings yet

- Adjudication Order With Respect To M/s. Gajanand Infracon Private Limited and M/s. Yash Infra Realty Private Limited in The Matter of M/s. Shekhawati Poly-Yarn LTDDocument8 pagesAdjudication Order With Respect To M/s. Gajanand Infracon Private Limited and M/s. Yash Infra Realty Private Limited in The Matter of M/s. Shekhawati Poly-Yarn LTDShyam SunderNo ratings yet

- 2017 WCC Application FormDocument3 pages2017 WCC Application Formjamesernest266No ratings yet

- Adamson University Faculty and Employees Union. v. Adamson UniversityDocument2 pagesAdamson University Faculty and Employees Union. v. Adamson UniversityMark Anthony ReyesNo ratings yet

- Philosophy & Religious Studies IGCSE NotesDocument23 pagesPhilosophy & Religious Studies IGCSE Notesincognitowl50% (2)

- Unit 8, Chapter 19, Lesson 2Document3 pagesUnit 8, Chapter 19, Lesson 2hopscoNo ratings yet

- The Jungle Book Definitivo Con PDFDocument20 pagesThe Jungle Book Definitivo Con PDFMarcelo GalleguillosNo ratings yet

- Assessment #3 Analyzing Primary SourcesDocument2 pagesAssessment #3 Analyzing Primary SourcesGerald PerionNo ratings yet

- From Atty. Deanabeth C. Gonzales, Professor Rizal Technological University, CBETDocument6 pagesFrom Atty. Deanabeth C. Gonzales, Professor Rizal Technological University, CBETMarco Regunayan100% (1)

- Bharat Sanchar Nigam LTDDocument2 pagesBharat Sanchar Nigam LTDKrishna GNo ratings yet

- Rebuttals To ChristiansDocument200 pagesRebuttals To Christianssmashman793No ratings yet

- Content:: What Are The Human Rights Three Principles For WomenDocument9 pagesContent:: What Are The Human Rights Three Principles For WomenIlinca SimescuNo ratings yet

- Behave WellDocument3 pagesBehave WellXimenaNo ratings yet

- Lecture 07 Poverty and DemocaryDocument13 pagesLecture 07 Poverty and DemocaryNirob Rahman AzadNo ratings yet

- United States Court of Appeals, Third CircuitDocument1 pageUnited States Court of Appeals, Third CircuitScribd Government DocsNo ratings yet

- Report of Analysis: ROA - 1507211154BDocument1 pageReport of Analysis: ROA - 1507211154BAntonNo ratings yet