Professional Documents

Culture Documents

7560 Deaerator Roof

Uploaded by

Bala MuruganOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

7560 Deaerator Roof

Uploaded by

Bala MuruganCopyright:

Available Formats

BILFAL HEAVY INDUSTRIES LTD.

P.O. BOX 10138

JUBAIL INDUSTRIAL CITY – 31961

KINGDOM OF SAUDI ARABIA

Email: Tec@bilfal.com

Website: www.bilfal.com

SWCC - YANBU 20 MIGD

MSF EVAPORATOR

Client: DOOSAN HEAVY INDUSTRIES &

CONSTRUCTION Co. Ltd.

METHOD STATEMENT FOR DEAERATOR ROOF PANEL

ERECTION

0 13-4-2015 JACOB T. S.L. SANTOSH ISSUED FOR INFORMATION

Rev. Date Prepared Verified Approved Modifications

REVISION

SCOPE OF WORKS

This document is describing detailed methods and sequence to be followed for the

erection of DEAERATOR Roof Panel for Evaporator Unit 75 & 76

REFERENCE DOCUMENTS AND STANDARDS

• 70-GDG-MTC-001 : Evaporator General Assembly

• 70-GDG-MTC-151 : Deaerator General Assembly

• 70-GDG-MTC-152 : Deaerator Tolerance Drawing

• 70-GDG-MTC-153 : Deaerator Roof Drawing

PRE CHECKLIST

• Deflection check:

Installation of 2 Nos additional stiffener beam longitudinally placed at top of Roof

Panel to avoid Deflection during lifting

• Temporary Lifting lug:

Installation of Temporary Lifting Lug: Each lug shall be of Minimum thickness of

plate: 20 thk. A-36 Material

Minimum Fillet Weld size 16mm and 200 mm Length for each Lug

• Checking of shackles slings

• Checking of access clearance throughout the way

• Checking of Ground stability

• Assembly of lifting gear

TECHNICAL INFORMATION

Item Description : Deaerator Roof Panel

Weight : 27000 Kg. (Maximum weight for lifting)

Lifting crane : 100 Ton 2 nos, 60 Ton 1 Nos (Crawler Crane)

Weight of crane HOOK : Av. 2000 Kg For Each Crane

TRANSPORTATION AND UNLOADING OF ROOF PANEL

• Roof panel to be transported from Factory to erection area and positioned on the

Concrete block which placed on Erection area.

• Ensure the orientation of Roof panel and all lifting lugs are securely fitted for

lifting

• Confirm all internal components need to be erected before the Deaerator is

closed

• Ensure all lifting gears are available at location

Unloading and Erection Positioning of ROOF PANEL

ERECTION OF ROOF PANEL (First Step)

Two steps of installation need to be performed for Roof panel erection. The first step

involves lifting of roof panel from ground and place over the roof panel of Evaporator

STAGE 26, using with pre-installed Rails and Trolleys. See below sketch for rail and

trolley arrangement.

Positioning of Cranes Rails and trolleys for 1 stage Installation

LIFTING OF ROOF PANEL

• After placing of Roof Panel at lifting area, Locate 2 Nos. 100 ton capacity cranes

(Crane No. 1 & 2) on both side of roof panel and 1 No. 50 Ton capacity Tailing

crane (Crawler Crane No. 3) at end side, as shown in above sketch

• Install Lifting tools like shackle, Lifting slings directly to the temporary lifting lugs

welded on roof panel.

• Securely connect all slings to cranes and ensure all slings and shackles are

properly fitted.

• Lift up the Roof panel up to 1 meter height; check the levelness of roof panel. In

case, the roof panel found tilted, load down and adjust the sling to keep levelness

• After Roof panel is lifted until higher level of the trolley, which was placed over

the roof of stage 26.

• Slowly down the Crane 1 and 2 in order to seat the Roof Panel distillate side onto

the TROLLEY No. 2

• Once the roof panel distillate side completely seated on trolley No. 2, then the

Crane No. 1 & 2 can be released. (See below sketch)

1 stage Installation of ROOF PANEL

• After releasing Crane No. 1 and 2, Push the panel slowly towards the distillate

side using with tailing Crawler crane – No. 3.

• Once the roof panel reaches nearly up to the distillate side, Release the tailing

Crawler crane No 3

Pushing the panel through rails

ERECTION OF ROOF PANEL (2nd Step Erection)

• After placing of Roof Panel over the roof of stage 26, All lifting gears shall be

installed on Roof panel at Brine side and Distillate side

• Perform Re positioning of Cranes; such as Crane No. 2 at Brine side and Crane

No 3 at Distillate side.

• Securely connect all slings to cranes and ensure all slings and shackles are

properly fitted.

• Lift up the Roof panel up to the top level of Deaerator side panel

• Align the roof panel with all side panels and carry out temporary tack weld in

order to release lifting cranes

Final Erection positioning

TOOLS AND EQUIPMENTS TO BE USED

Cranes: Mobile Hydraulic Cranes- 150Ton Capacity

Crawler Crane 60 Metric Ton Capacity- 1 No

Mobile Crane 100 Metric Ton Capacity- 2 Nos

Shackles: 30 Ton (Quantity as per requirement)

Spreader Beam: 40 Ton Capacity x 19 Meter Lg. 1 no.

Pneumatic Winch: 5 Ton Pulling Capacity (If Required)

Trolley Special made 2 Nos

Trailer: 1 Nos. 50 Ton Long Ttrailer

---------

You might also like

- Method Statement For PILINGDocument7 pagesMethod Statement For PILINGcworld86% (7)

- Three-Phase HV / LV Transformers: Instructions For Installation, Commissioning and MaintenanceDocument27 pagesThree-Phase HV / LV Transformers: Instructions For Installation, Commissioning and MaintenancelcatelaniNo ratings yet

- Benwil Lift Manual Fp14ka CDocument27 pagesBenwil Lift Manual Fp14ka Coldtrukluvr100% (2)

- Turbine ErectionDocument131 pagesTurbine ErectionSam92% (12)

- Erection Procedure - MosDocument13 pagesErection Procedure - MosBaisel Rahuman67% (3)

- Design DrawingDocument1 pageDesign Drawingkeith11221100% (2)

- 3 - Presentacion WhipstockDocument40 pages3 - Presentacion WhipstockIsaac Almeida100% (2)

- Switch Gear Commissioning ChecklistDocument27 pagesSwitch Gear Commissioning ChecklistRAM SHANMUGAMNo ratings yet

- Planning & Building RegulationsDocument64 pagesPlanning & Building RegulationsJayamal Induruwa86% (28)

- Erection ProcedureDocument2 pagesErection ProcedureDebu Das100% (1)

- Boiler Drum Erection ProcedureDocument6 pagesBoiler Drum Erection Procedureer_sanjaypatel100% (1)

- Introduction To Rigging EngineeringDocument139 pagesIntroduction To Rigging EngineeringAdel ChelbaNo ratings yet

- Erection of BoilerDocument40 pagesErection of BoilerSam100% (1)

- Tower Crane Course 2013Document98 pagesTower Crane Course 2013Rizwan AhmedNo ratings yet

- TRN-0203 Approval-BDocument8 pagesTRN-0203 Approval-BrayNo ratings yet

- Concrete Finishing and CuringDocument13 pagesConcrete Finishing and CuringrayNo ratings yet

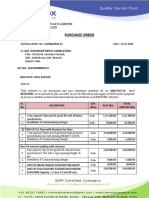

- Purchase Order: Chemox Pharma Private Limited GST NO: 24AAICC4574G1ZN Pan No: Aaicc4574GDocument7 pagesPurchase Order: Chemox Pharma Private Limited GST NO: 24AAICC4574G1ZN Pan No: Aaicc4574GVipul RathodNo ratings yet

- Example Method Statement Jack in-PPCDocument4 pagesExample Method Statement Jack in-PPCLatifi AmirNo ratings yet

- Bundle Lifting Procedure 1 PDFDocument14 pagesBundle Lifting Procedure 1 PDFBala MuruganNo ratings yet

- Tower CraneDocument16 pagesTower Cranekarthika18maniNo ratings yet

- Used Power Plant Equipment For SaleDocument54 pagesUsed Power Plant Equipment For SaleR. Baker and Son All Industrial ServicesNo ratings yet

- Dock Lifts: Heavy DutyDocument2 pagesDock Lifts: Heavy DutyAja YlNo ratings yet

- 6.a.g Power - Senaat Substation - TC1 Wolff 6031.8 - Dismantling Method Statement Rev 0Document70 pages6.a.g Power - Senaat Substation - TC1 Wolff 6031.8 - Dismantling Method Statement Rev 0renjuNo ratings yet

- 02 Construction Guide For TankDocument16 pages02 Construction Guide For TankARABONo ratings yet

- Tankage Erection - Procedure - CPCL SiteDocument10 pagesTankage Erection - Procedure - CPCL SiteAnantha Narayanan100% (1)

- Method Statement of Jack-In Pile PDFDocument3 pagesMethod Statement of Jack-In Pile PDFAMIR ASYRAF ZAINUDIN100% (1)

- Preparation For Platform FabricationDocument6 pagesPreparation For Platform FabricationMOHANNo ratings yet

- High Mast LightDocument41 pagesHigh Mast LightShaik's PeerNo ratings yet

- Boiler Erection Persentation Rev-2Document21 pagesBoiler Erection Persentation Rev-2juarsa r100% (3)

- Dokumen - Tips - Lighting High Mast Installation ProcedureDocument41 pagesDokumen - Tips - Lighting High Mast Installation Procedurekatiki216No ratings yet

- Method Statement - Manifold StructuresDocument5 pagesMethod Statement - Manifold StructuresAdagharaNo ratings yet

- White and Green Clean Construction PresentationDocument25 pagesWhite and Green Clean Construction PresentationramNo ratings yet

- N-20AA Installation ManualDocument15 pagesN-20AA Installation Manualxin xanNo ratings yet

- Machine Room NotesDocument2 pagesMachine Room NotesSayed NagyNo ratings yet

- Construction Method Statement FOR RCC Boundry Wall With Precast Panel & ColumnDocument8 pagesConstruction Method Statement FOR RCC Boundry Wall With Precast Panel & Columnkhurshidoman123No ratings yet

- Diaphargm Wall Construction DetailsDocument48 pagesDiaphargm Wall Construction DetailsAkshay Joshi100% (1)

- Method Statement For Lift WorksDocument29 pagesMethod Statement For Lift WorksMuhammad AdamNo ratings yet

- White and Green Clean Construction PresentationDocument25 pagesWhite and Green Clean Construction PresentationramNo ratings yet

- ScaffoldDocument17 pagesScaffoldAnwar ShaikNo ratings yet

- Pren81 31cDocument49 pagesPren81 31cbrunoagandraNo ratings yet

- PANORAMA Specifications Feb FINALDocument13 pagesPANORAMA Specifications Feb FINALagmibrahim5055No ratings yet

- Quotation For Paf Base Nurkhan 1 T Crane 4 M Span - 29-06-2019Document4 pagesQuotation For Paf Base Nurkhan 1 T Crane 4 M Span - 29-06-2019AdeebNo ratings yet

- Piling Works Mos RevisedDocument4 pagesPiling Works Mos RevisedPrince Car-chang50% (2)

- Method Statement PVD (Wick Drain)Document9 pagesMethod Statement PVD (Wick Drain)Arq Mario Josue Lopez BasañezNo ratings yet

- BSL Method Statememt For Lifting Thermal Tank - 1Document4 pagesBSL Method Statememt For Lifting Thermal Tank - 1Abhay BaisNo ratings yet

- Electromechanical Work at 132kv SiteDocument14 pagesElectromechanical Work at 132kv SitePius Odaba100% (1)

- Method Statement Rectification of Insufficient Lapping Length 45 Dia. For Column Starter BarDocument2 pagesMethod Statement Rectification of Insufficient Lapping Length 45 Dia. For Column Starter BarMohd Hafizul Hj Tanalol100% (1)

- Exhibit A - Plans Specifications FinalDocument2 pagesExhibit A - Plans Specifications Finalpedro guzmanNo ratings yet

- Guniting Slope, Ed.1, Rev.0Document8 pagesGuniting Slope, Ed.1, Rev.0Andrei Radu100% (2)

- Rig Building ReportDocument22 pagesRig Building ReportAditya SumanNo ratings yet

- Scope of Work To Supply and Install Warehouse, Trailers, Latrine Trailers, and Utilities at Tent City Air Base, KuwaitDocument41 pagesScope of Work To Supply and Install Warehouse, Trailers, Latrine Trailers, and Utilities at Tent City Air Base, KuwaitAzharudin ZoechnyNo ratings yet

- External DismantlingDocument11 pagesExternal DismantlingNavdeep Singh GrewalNo ratings yet

- I&M Manual - WGZ-1Document72 pagesI&M Manual - WGZ-1cesar luis gonzalez rodriguezNo ratings yet

- Robotics Solution For Truck LoadingDocument21 pagesRobotics Solution For Truck Loadingkarnail singh dhimanNo ratings yet

- Stinger 3470: Boom Truck CraneDocument4 pagesStinger 3470: Boom Truck CraneKatherinne ChicaNo ratings yet

- DEMAG - I-Beam Slewing Jib Crane RangeDocument72 pagesDEMAG - I-Beam Slewing Jib Crane Rangeaiyubi2No ratings yet

- MV Switchgear 11 KV VCB Rev-0Document16 pagesMV Switchgear 11 KV VCB Rev-0ISHA SINGHNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Machines, Tools and Methods of Automobile ManufactureFrom EverandMachines, Tools and Methods of Automobile ManufactureRating: 4 out of 5 stars4/5 (1)

- 7560 MSF Method S-1 - Rev. 1Document41 pages7560 MSF Method S-1 - Rev. 1Bala MuruganNo ratings yet

- 7560-Hydro Test - Sequence 1Document9 pages7560-Hydro Test - Sequence 1Bala MuruganNo ratings yet

- 7560-Hydro Test - Sequence 3Document10 pages7560-Hydro Test - Sequence 3Bala MuruganNo ratings yet

- Fall From Height Drill: Dammam Crude & Gas Development ProjectDocument17 pagesFall From Height Drill: Dammam Crude & Gas Development ProjectBala MuruganNo ratings yet

- INFRA-TES-MST-CCC-CIV-00023 Rev. 0 - Excavation and BackfillingDocument25 pagesINFRA-TES-MST-CCC-CIV-00023 Rev. 0 - Excavation and BackfillingTaiwo OshinNo ratings yet

- The Potential Application of Ibs Modular System in The Construction of Housing Scheme in MalaysiaDocument8 pagesThe Potential Application of Ibs Modular System in The Construction of Housing Scheme in Malaysiaarif fadilahNo ratings yet

- Carport UniversalDocument19 pagesCarport UniversalRobert BNo ratings yet

- 3.5xRC 21.5'X46.5' - Structural Drawing - R00Document31 pages3.5xRC 21.5'X46.5' - Structural Drawing - R00Moe Oo HtunNo ratings yet

- Alver AaltoDocument5 pagesAlver AaltoJayant RajNo ratings yet

- Series 4000 - Bituminous Layers and SealsDocument52 pagesSeries 4000 - Bituminous Layers and SealsBatenda Felix0% (1)

- Ram Internship ReportDocument65 pagesRam Internship Report20135A0120 PINNIKA RAMESHNo ratings yet

- Nfpa 5000Document7 pagesNfpa 5000Sreenath S KallaaraNo ratings yet

- Precast BrochureDocument12 pagesPrecast BrochureNicholasOmodingNo ratings yet

- Counterweight Rigging ManualDocument34 pagesCounterweight Rigging ManualGustavo ArancibiaNo ratings yet

- CEO Secret LoverDocument33 pagesCEO Secret LoverViviana J. Willamson100% (1)

- Taper Threaded Rebar Splicing SystemsDocument20 pagesTaper Threaded Rebar Splicing SystemsHao LuoNo ratings yet

- Conmix SP4Document2 pagesConmix SP4albarajeel forwarding001No ratings yet

- DMDave - Dungeons & Lairs 41 - Water Weird Ruins - Full VersionDocument16 pagesDMDave - Dungeons & Lairs 41 - Water Weird Ruins - Full VersionSam BrownNo ratings yet

- Solving Construction Estimating Puzzle - Guide 1Document12 pagesSolving Construction Estimating Puzzle - Guide 11983dgNo ratings yet

- PRICELISTDocument112 pagesPRICELISTCatherine AbarabarNo ratings yet

- Contract Doc AnalysisDocument47 pagesContract Doc AnalysisHazirah ZieraNo ratings yet

- Fas-11 Typical Device Equipment Installation PDFDocument1 pageFas-11 Typical Device Equipment Installation PDFMØhãmmed ØwięsNo ratings yet

- Design of Steel Tied Arch BridgesDocument98 pagesDesign of Steel Tied Arch BridgesZin Ko LinnNo ratings yet

- Example 3Document12 pagesExample 3iknowvictoriassecret49No ratings yet

- Block Rotation: The Key Is Understanding TorqueDocument2 pagesBlock Rotation: The Key Is Understanding TorqueMuhammed ShamseerNo ratings yet

- Foundation Plan Roof Beam Plan 1 2: A B A BDocument1 pageFoundation Plan Roof Beam Plan 1 2: A B A Bjay-ar barangayNo ratings yet

- Building Construction IDocument57 pagesBuilding Construction IChinedu Godfrey100% (1)

- NRC Full-Scale Test Steel Pole FoundationsDocument24 pagesNRC Full-Scale Test Steel Pole FoundationsChahreddine KOUMENJINo ratings yet

- Introduction of The Site:: Form Work & ScaffoldingDocument43 pagesIntroduction of The Site:: Form Work & ScaffoldingAV ChavdaNo ratings yet

- Sieve Analysis #1Document19 pagesSieve Analysis #1Zhir nawzadNo ratings yet

- Quebec Bridge Collapse Case Study Case Study: BackgroundDocument28 pagesQuebec Bridge Collapse Case Study Case Study: BackgroundMoonNo ratings yet

- 8491-Article Text-32930-1-10-20151225 PDFDocument7 pages8491-Article Text-32930-1-10-20151225 PDFChetali SinghNo ratings yet

- Brick CalculationsDocument13 pagesBrick CalculationsMirza Mustansir BaigNo ratings yet