Professional Documents

Culture Documents

F-Final: 870310-S-1247064-CST-H03-0001 Quality Control Plan Endorsement For Piping Prefab & Erection 04 A. Accepted

Uploaded by

ismariadiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

F-Final: 870310-S-1247064-CST-H03-0001 Quality Control Plan Endorsement For Piping Prefab & Erection 04 A. Accepted

Uploaded by

ismariadiCopyright:

Available Formats

TANGGUH EXPANSION PROJECT

LNG EPC – PT. Meindo – 1247064

COMMENT RESOLUTION SHEET

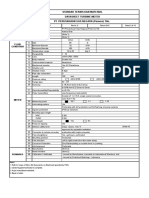

DOCUMENT NUMBER DOCUMENT TITLE REV. CODE ISSUE STATUS DOCUMENT STATUS

870310-S-1247064-CST-H03-0001 Quality Control Plan Endorsement For Piping Prefab & Erection 04 F- FINAL A. ACCEPTED

NO COMMENTS ORIGINATOR SUPPLIER RESPONSE REASONS NAME &TITLE SECTION AFFECTED COMMENT STATUS

Additional some Project Specification refer to TEP- A. Agreed, Comment will

930-SPE-QA-BP4-0021_B06_Quality Control Plan For MADE WISNAWA PUTRA Comment has been done YUNIARTO Section 2.1.2 Agreed - Closed

1

Piping Work be implemented

Additional attachment ITP list and forms list refer to A. Agreed, Comment will

2 TEP-930-SPE-QA-BP4-0021_B06_Quality Control MADE WISNAWA PUTRA Comment has been done YUNIARTO Section 5 Agreed - Closed

be implemented

Plan For Piping Work

© BP p.l.c. Page 1 of 1 Project Internal

Digitally signed by

Made W Putra

DN: cn=Made W Putra,

o=TEP, ou=CSTS QAQC,

email=madewisnawa.p

utra@csts-tep.com,

c=US

Date: 2019.09.24

15:00:01 +09'00'

Tangguh Expansion Project – LNG EPC

PT. Meindo – Quality Control Plan Endorsement For Piping Prefab & Erection

Revision History

Amendment Revision Amender Name Amendment

Date Number

31/JAN/2019 01 Yodhi R-Submit For Review

28/MAR/2019 02 Yodhi R-Submit For Review

11/JUL/2019 03 Mangojaktua F-Final

23/SEP/2019 04 Yuniarto F-Final

Related documents

Document Document name Description of Content

number

TEP-1247064- H03-0001 Page 2 of 56 Rev:04

870310-S-1247064-CST-H03-0001 BP Internal

Tangguh Expansion Project – LNG EPC

PT. Meindo – Quality Control Plan Endorsement For Piping Prefab & Erection

TABLE OF CONTENTS

1. Introduction ........................................................................................................ 4

1.1 PROJECT OVERVIEW .................................................................................................................. 4

1.2 SCOPE & OBJECTIVE ................................................................................................................... 4

1.3 DEFINITION AND ABBREVIATIONS............................................................................................. 5

2. REFERENCE DOCUMENTATION ...................................................................... 7

2.1 CODES AND STANDARDS ........................................................................................................... 7

2.1.1 Contract specifications ................................................................................................................... 7

2.1.2 Project Specifications& Study......................................................................................................... 7

2.1.3 Codes and Standards ..................................................................................................................... 8

2.1.4 Sub Contractor Reference ............................................................................................................ 10

2.2 APPLICABLE REVISION ............................................................................................................. 11

2.3 TECHNICAL REQUIREMENTS ................................................................................................... 11

2.4 LOCAL REGULATIONS ............................................................................................................... 11

3. QUALITY CONTROL PLANNING ..................................................................... 11

3.1 GENERAL ..................................................................................................................................... 11

3.2 DESCRIPTION OF QC CODE ..................................................................................................... 12

4. SYMBOLS, ABBREVIATIONS AND DEFINITIONS ......................................... 12

4.1 DESCRIPTION OF INVOLVEMENT CODE ................................................................................. 12

5. ATTACHMENTS ................................................................................................ 14

5.1 ITP LIST........................................................................................................................................ 14

5.1.1 General ITP for Initial Inspection: ................................................................................................. 14

5.1.2 Specific ITP for Construction: ....................................................................................................... 14

5.2 FORMS LIST ................................................................................................................................ 14

5.2.1 Inspection and Test Report Forms: .............................................................................................. 14

TEP-1247064- H03-0001 Page 3 of 56 Rev:04

870310-S-1247064-CST-H03-0001 BP Internal

Tangguh Expansion Project – LNG EPC

PT. Meindo – Quality Control Plan Endorsement For Piping Prefab & Erection

1. Introduction

1.1 PROJECT OVERVIEW

BP Berau Ltd, hereafter know as COMPANY, is the operator as TANGGUH LNG, a two train natural

gas (NG) liquefaction facility in Bintuni Bay, Papua Indonesia. The facility includes associated onshore

infrastructure, two onshore platforms, pipelines and twelve wells. These facilities as are the Train 1 and

2 developments at Tangguh.

COMPANY has initiated the Tangguh Expansion Project to commercialize the incremental resource

into high margin gas markets based on a single LNG (liquefied natural gas) train expansion (Train 3).

Tangguh Expansion Project will consist of new offshore facilities, including wellhead platforms and

pipelines, and onshore development on the exisiting Tangguh brownfield site. The new onshore

facilities will include one additional natural gas liquefaction train of a similar desighn and capacity to the

existing trains, an onshore receiving facility (ORF), New LNG and condensate loading berth, additional

boil of gas (BOG) recovery, utilities, flares and the infrastructure to support logistics and the associated

increase in the temporary and permanent workforce.

The Tangguh Expansion project comproses of the following new facilities :

[New] Onshore Receiving Facility (ORF)

[New] LNG Train 3

[New] Condensate Stabilization Train 3

[New/Inter Connection] Plant Utility Facilities

[New] LNG Loading System

[New] Condensate Loading System

[Expansion] Integrated Control and Safety System (ICSS)

[Expansion] Telecommunication System

[New] Trestle Jetty Structure

[Expansion] Onshore Infrastructure

Hazardous and Non-hazardous Waste Management System

1.2 SCOPE & OBJECTIVE

This document contain the details of quantity control quantity activities to be done during the execution

of the welding works as following :

Welding Qualification procedure and welding personnel qualification activities.

Welding at Site for pipe-supporting elements and miscellaneous steel structures of electrical /

instrumentations & others.

The quality control plan for welding activities associates with equipment manufacturing or material

supply at vendor or supplier shop premise are not covered by this document. The quality control plan

for that scope should be covered by IDS as written in the Vendor or Supplier Requisition.

TEP-1247064- H03-0001 Page 4 of 56 Rev:04

870310-S-1247064-CST-H03-0001 BP Internal

Tangguh Expansion Project – LNG EPC

PT. Meindo – Quality Control Plan Endorsement For Piping Prefab & Erection

This document shall be considered as contractual quality control plan to be implemented by

SUBCONTRACTOR.

The document is issued, at Project Level, as Quality Control Plan complete with project information’s,

Project requirements and contractual obligations.

1.3 DEFINITION AND ABBREVIATIONS

AFC : Approved For Construction

Certificate : Record of the inspection results, kept on the applicable predefined form

and signed by all parties as per involvement code (see 3.3)

Construction

Organization : Organization Performing the installation and/or fabrication and/or

construction

Contractor : Organization appointed by OWNER to perform the Works

Discipline : A certain branch of knowledge, an area of activity

DWG : Drawing

EPC : Engineering, Procurement and Construction

IDS : Inspection Data Sheet

INSPECTION : Critical appraisal involving examination, measurement, testing, gauging,

and comparison of materials or items, in order to determine if the material

or item is in proper condition and quantity, and if it conforms to the

applicable or specified requirements.

ITR : (Inspection and Test Report); a formal written record detailing the results

of an inspection organized in a narrative, graphic, or tabular form,

dentified for each QC Code (see § 3.2). Once signed by the involved

parties it becomes a Certificate. It includes also the traceability versus the

inspected Item.

ITP : (Inspection and test Plan); Specific Section(s) of QCP that identify and

define Inspection sequences. It is prepared in accordance with all the

applicable contractual, engineering and Supplier’s provisions and

requirements. The ITP(s) provide references to applicable

procedures,acceptance criteria, documentation, quality records and

inspection attendance to be performed, in chronological order, from initial

inspection, throughout final inspections and mechanical completion. The

ITP(s) provide reference for the Inspection Forms to be used.

Organization : Group of people and facilities with an arrangement of responsibilities,

authorities and relationship

OWNER : External entity to CONTRACTOR defining product requirements and

paying for it

TEP-1247064- H03-0001 Page 5 of 56 Rev:04

870310-S-1247064-CST-H03-0001 BP Internal

Tangguh Expansion Project – LNG EPC

PT. Meindo – Quality Control Plan Endorsement For Piping Prefab & Erection

PROCESS : Sequence of interdependent and linked activities which, at every stage,

consume one or more resources (employee time, energy, finance,

machines, facilities, equipment, techniques, and methods) to convert

inputs (data, material, parts, etc.) into outputs. These outputs then serve

as inputs for the next stage until a known goal or end result is reached.

PRODUCT : Result of a process. Any good, idea, method, information, object or

service created as a result of a process and serves a need or satisfies a

want. It has combination of tangible and intangible attributes (benefits,

features, functions, uses) that a seller offers a buyer for purchase.

QC : (Quality Control); process to verify that the product complies with

requirements. It is ensured by an organization not directly involved in

Product realization.

QCP : (Quality Control Plan); CONTRACTOR’s document to manage inspection

activities, incorporating all quality control requirements and complemented

with specific firm’s owned procedures as applicable.

RFI/IN : (Inspection Notification); written communication issued by the

Construction Organization to allow the involved parties to carry out their

own inspection or attend, as planned in the applicable ITP.

SUBCONTRACTOR : Is PT. MEINDO ELANG INDAH, Organization to whom any part of the

construction, fabrication of Piping and Structural item for Modularization

Work Project including Precommissioning (Hydrotest) Activity, Painting

and Pickling Passivation for Duplex Material, has been subcontracted by

CONTRACTOR.

TPI : (Third Party Inspection); any organization, authority, person or persons, to

which part of work has been subcontracted for the execution of inspection

and/or laboratory testing with related activities.

WORK : Means the permanent, new, revamped and refurbished facilities

constituting the Project, including all the construction / fabrication /

installation services, materials and equipment to be provided by

CONTRACTOR to satisfy its obligations pursuant to the Contract

undertaken with the OWNER

Any other terms related to quality and not listed above conform to section 3 “Terms and Definitions” of

ISO 9000:2005 “Quality Management System – Fundamentals and vocabulary”.

TEP-1247064- H03-0001 Page 6 of 56 Rev:04

870310-S-1247064-CST-H03-0001 BP Internal

Tangguh Expansion Project – LNG EPC

PT. Meindo – Quality Control Plan Endorsement For Piping Prefab & Erection

2. REFERENCE DOCUMENTATION

2.1 CODES AND STANDARDS

2.1.1 Contract specifications

930-PLA-PM-1001 Tangguh Expansion Project Quality Management Plan

930-PRC-QA-0001 Quality Assurance Audit Procedure

930-PRC-QA-0003 Non Conformance Reporting Procedure

------------------------- Contract Document No. 4420000942 Section V-Quality

and Integrity Management

2.1.2 Project Specifications& Study

TEP-900-SPE-PP-BP4-0006 Project Specification for Hot Insulation

TEP-900-SPE-PP-BP4-0007 Project Specification for Cold Insulation

TEP-900-SPE-PP-BP4-1009 Project Specification for Protective Coating

TEP-900-SPE-PP-BP4-1040 Project Specification for Internal Coating

TEP-900-SPE-PP-BP4-0001 Project Specification for Piping Design

TEP-900-SPE-PP-BP4-0003 Project Specification for Pipe Flexibility Analysis

TEP-900-SPE-PP-BP4-0004 Project Specification for Piping Vibration Analysis

TEP-900-SPE-PP-BP4-1001 Project Specification for Piping Material Class.

TEP-900-SPE-PP-BP4-1004 Project Specification for Metallic Pipe, Fittings,

Flanges and Gaskets(Amendment to GPO-EN-

SPE-42104& GPO-EN-SPE-42301)

TEP-900-SPE-PP-BP4-1005 Project Specification for Bolting(Amendment

GPO-EN-SPE-42300).

TEP-900-SPE-PP-BP4-1011 Project Specification for FRP Pipes and Components

TEP-900-SPE-PP-BP4-1012 Project Specification for CPVC Pipes &Components

TEP-900-SPE-PP-BP4-1013 Project Specification for HDPE Pipes &Components

TEP-900-SPE-PP-BP4-1015 Project Specification for Piping Material Identification

and Marking.

TEP-900-SPE-PP-BP4-0002 Project Specification for Piping Material Colour Coding

TEP-900-SPE-PP-BP4-0005 Project Specification for Wedge Gate(API600)

Globe(BS1873) ands wing and Wafer Check

(API594),Expanding &Gate(API6D).

TEP-900-SPE-PP-BP4-0011 Project Specification for Ball (API608),Ball (API6D)

Valves (Amendment toGPO-EN-SPE-62015).

TEP-900-SPE-PP-BP4-0012 Project Specification for Butterfly Valves

Amendment to GPO-EN-SPE-62014).

TEP-900-SPE-PP-BP4-0008 Project Specification for Globe, Gate &Check

TEP-1247064- H03-0001 Page 7 of 56 Rev:04

870310-S-1247064-CST-H03-0001 BP Internal

Tangguh Expansion Project – LNG EPC

PT. Meindo – Quality Control Plan Endorsement For Piping Prefab & Erection

(API602) Valves (Amendment toGPO-EN-SPE-

62021).

TEP-900-SPE-PP-BP4-0009 Project Specification for EEMUA 182Integral

Block & Bleed Valves(Amendment to GPO-EN-SPE-

62021).

TEP-900-SPE-PP-BP4-0010 Project Specification for Quarter Turn &Rising

Stem Valve Common Requirements (Amendment to

GPO-EN-SPE-62016 & Amendment to GPO-EN-

SPE-62017).

TEP-900-SPE-PP-BP4-1017 Valve Specification

TEP-900-SPE-PP-BP4-2001 Project Specification for Plot Plan Design.

TEP-900-SPE-MM-BP4-0003 Specification for Fabrication, Assembly, Erection and

inspection of pipe work(ASME B31.3) (Amendment to

GPO-EN-SPE-42103)

TEP-930-PRC-HS-BP4-0037 Pressure Testing Procedure

TEP-930-PRC-QA-BP4-0011 Control of Inspection Tools and Test Equipment at site

TEP-TBA-PLL-PP-BP4-0100 Piping Line List unit TBA

TEP-900-SPE-PP-BP4-2001 Project Specification for Plot Plan Design

TEP-930-PLA-QA-BP4-0007 Project Quality Plan for Site Construction

TEP-900-PRC-OP-BP4-0007 General Cleaning Procedure

TEP-900-SPE-QA-BP4-0023 QCP for Welding

TEP-900-SPE-QA-BP4-0031 QCP for Instrument

TEP-900-SPE-QA-BP4-0037 QCP for Lining & Refractory works at site

TEP-900-STD-PP-BP4-0002 Piping Standard Drawing Support

TEP-930-PRC-QA-BP4-0015 MIGAS Qualification Procedure for WPS and Welding

Operators

2.1.3 Codes and Standards

API 5L Specification for Line Pipe

API 5B Specification for Threading, Gauging, and Thread Inspection of

Casing, Tubing, and Line Pipe Threads

API 520 Sizing, Selection, and Installation of Pressure Relieving Devices in

Refineries – Part 1 & 2

API 521 Guide for Pressure-relieving and DE pressuring Systems

API 526 Flanges Steel Pressure Relief Valves.

API 551 Process Measurement Instrumentation.

API 594 Check Valve: Flanged wafer, Lug, and Butt-welding

API 598 Valve Inspection and Testing

API 599 Metal Plug Valves – Flanges, Threaded and Welding ends.

TEP-1247064- H03-0001 Page 8 of 56 Rev:04

870310-S-1247064-CST-H03-0001 BP Internal

Tangguh Expansion Project – LNG EPC

PT. Meindo – Quality Control Plan Endorsement For Piping Prefab & Erection

API 600 Steel Gate Valves – Flanged and Butt-welding Ends, Bolted Bonnet

API 602 Steel Gate, Globe and Check Valves for Sizes DN100 and Smaller for

the Petroleum and Natural Gas Industries.

API 607 Fire Test for Quarter-turn Valves and Valves Equipped with Non-

metallic Seats

API 608 Metal Ball Valves-Flanged, Threaded and Welding Ends

API 609 Butterfly Valves: Double Flanged, Lug-and Wafer-Type.

API Spec 6D Specification for Pipeline Valves.

API Spec 6FA Fire Test for Valves

API 941 Steels for Hydrogen Service at Elevated Temperatures and Pressures

in Petroleum Refineries

ASME BPVC Sect. 1 Section 1 Rules for Construction of Power Boiler.

ASME BPVC Sect. 2 Material Specification.

ASME B1.1 Unified Inch Screw Threaded (UN and UNR Thread Form)

ASME B1.20.1 Pipe Threads, General Purpose (Inch)

ASME B16.5 Pipe Flanges and Flanged Fittings NPS ½ Through NPS 24

ASME B16.9 Factory Made Wrought Steel Butt Welding Fittings

ASME B16.11 Forged Fittings, Socked Welding and Threaded

ASME B16.20 Metallic Gaskets for Pipe Flanges-Ring Joint Spiral Wound and

Jacketed

ASME B16.21 Non Metallic Flat Gaskets for Pipe Flanges

ASME B16.25 Butt-welding Ends

ASME B16.47 Large Diameter Steel Flanges NPS 26 Through NPS 60

ASME B16.48 Steel Line Blanks

ASME B31.1 Power Piping

ASME B31.8 Gas Transmission & Distribution Piping System

ASME B36.10M Welded and Seamless Wrought Steel Pipe

C205 Cement-Mortar Protective Lining and Coating for Steel Water Pipe

and Larger-Shop Applied.

C602 Cement-Mortar Lining of Water Pipeline in Place 4in. and Larger.

ASTM A105 Standard Specification for Carbon Steel Forgings for Piping

Application

ASTM A350 Standard Specification for Carbon and Low-Alloy Steel Forgings,

Requiring Notch Toughness Testing for Piping Components

ASTM B466 Standard Specification for Seamless Copper-Nickel Pipe and Tube

ASME B16.47 Large Diameter Steel Flanges. NPS 26 Through NPS 60.

ASME B16.20 Metallic Gaskets for Pipe Flanges. Ring-Joint, Spiral-Wound, and

Jacketed

ASTM A333 Standard Specification for Seamless and Welded Steel Pipe for Low

Temperature Service

ASME B16.42 Ductile Iron Pipe Flanges and Flanged Fittings: Classes 150 and 300

TEP-1247064- H03-0001 Page 9 of 56 Rev:04

870310-S-1247064-CST-H03-0001 BP Internal

Tangguh Expansion Project – LNG EPC

PT. Meindo – Quality Control Plan Endorsement For Piping Prefab & Erection

ASTM F1120 Standard Specification for Circular Metallic Bellows Type Expansion

Joints for Piping Applications

BS ISO 10497 Testing of Valves: Fire Type– Testing Requirements.

EEMUA No. 153 EEMUA Supplement to ASME B31.3

EEMUA No 182 Specification for Integral Block & Bleed Valve manifolds for Direct

Connection to pipework.

EEMUA Guide to the Specification, Installation and Maintenance of Spring

Publication 200 Supports for Piping.

ISO 13703 Petroleum and natural gas industries – Design and installation of

piping systems on offshore production platforms

ISO 14692 Petroleum and natural gas industries-Glass-reinforced plastic (GRP)

piping

ISO 15649 Petroleum and natural gas industries – Piping

ISO 17925 General Requirements for the Competence of Testing and

Calibrations Laboratories

SP-44 Steel Pipeline Flanges

SP-45 Bypass and Drain Connections

SP-58 Pipe Hangers and Supports

Norsok L-CR-003 Piping Details

PCIFL000 Flow Measurement Installation details.

PNF0200 Vents, Drains, and Instrument Connection Details.

PNFJ8000 Jacketed Piping Fabrication and Installation Details.

PNSC0035 Steam Tracing Details.

PNSC0036 Installation of High Density Polyethylene (HDPE)Piping.

UKOOA EHS15 Guidelines for the Management of Integrity of Bolted Pipe Joints

UKOOA EHS16 Installation guidelines for the Management, Design, and Maintenance

of Small Bore Tubing Systems.

2.1.4 Sub Contractor Reference

870310-S-1247064-CST-H02-0001 Project Quality Plan

870310-S-1247064-CST-H99-0006 Welding Control Procedure

870310-S-1247064-CST-P01-0001 Welding Book For Piping

870310-S-1247064-CST-H99-0009 NDT Personnel & Equipment List

870310-S-1247064-CST-P02-0001 NDT Procedure

870310-S-1247064-CST-H99-0005 Material Control Procedure

870310-S-1247064-CST-H99-0007 Welding Consumable, Handling, Storage, & Issue Control

Procedure

870310-S-1239022-CST-A99-0011 Fabrication Procedure for Piping

TEP-1247064- H03-0001 Page 10 of 56 Rev:04

870310-S-1247064-CST-H03-0001 BP Internal

Tangguh Expansion Project – LNG EPC

PT. Meindo – Quality Control Plan Endorsement For Piping Prefab & Erection

2.2 APPLICABLE REVISION

Unless otherwise specified in the contract documents, the applicable revision or edition of applicable

specifications and standards is the last valid at the time when the contract or agreement are made to

enter into effective date.

2.3 TECHNICAL REQUIREMENTS

Technical requirements are indicated in applicable drawings, specifications and Standards referenced

in the contract

2.4 LOCAL REGULATIONS

Inspections and tests required by local regulations are out from the scope of this specification.

However, they shall be strictly adhered to and documented by SUBCONTRACTOR. Copy of such

records shall be submitted to CONTRACTOR.

The order of precedence of the codes and standards quoted in the specifications shall be:

1. International and local statutory regulations.

2. Project data sheets.

3. Project specifications.

4. This Specification.

5. Referenced Company documents.

6. Referenced national and international code

SUBCONTRACTOR shall negotiate the matter with the Authorities concerned and keep

CONTRACTOR informed of any resulting deviation from design requirements.There shall be no

deviation to Project specification requirements without prior written CONTRACTOR’s approval.

3. QUALITY CONTROL PLANNING

3.1 GENERAL

The inspections, tests and certification to be implemented in performing Piping Prefabrication and

Erection works are detailed in the ITPs and the attendant Inspection Forms listed in Chapter 5.2

The ITPs can be separated into the two following main groups:

General ITPs include the initial necessary checks and verification to be performed, when required,

prior to perform the inspections and tests specified in the dedicated ITP(s) for works QC. The

frequency of the addressed inspections and tests are defined by the applicable Specifications,

Standards and/or Codes.

Specific ITPs include inspection and tests which are or can be directly related to specific items

and/or part of the works that can be identified and traceable by means of the engineering drawings.

TEP-1247064- H03-0001 Page 11 of 56 Rev:04

870310-S-1247064-CST-H03-0001 BP Internal

Tangguh Expansion Project – LNG EPC

PT. Meindo – Quality Control Plan Endorsement For Piping Prefab & Erection

3.2 DESCRIPTION OF QC CODE

Each inspection activity recalled in the ITP(s) is identified by a univocal QC Code. The QC Code is

split in three columns as follows:

LLL nnnn nnL Example: PIP010309M

QC Code: Activity sequential number (alpha numerical)

ITP number

Discipline code

First and second columns contain the split of the ITP ID number as identified in the ITP Title box, third

column contains the progressive number of the inspection phase which includes also the suffix for the

connection with the relevant works phase as to :

“Construction Completion” = M; “Precommissioning” = P; “Commissioning” = C

4. SYMBOLS, ABBREVIATIONS AND DEFINITIONS

4.1 DESCRIPTION OF INVOLVEMENT CODE

Hold Point (H) : A point which mandatory requires the presence of the involved

parties (CONTRACTOR/COMPANY/Third party/Migas) for the

inspection when the activity is performed and before that any

further processing is permitted.

A written notification (RFI) is issued by the Construction

Subcontractorand addressed to the involved parties in due time.

The Construction Subcontractorshall not process the activity/item

beyond a Hold Point in the absence of any of the involved

parties, unless prior written permission to proceed is obtained by

them

Witness Point (W) : A point which requires attendance/inspection/verification by the

involved parties (CONTRACTOR/COMPANY/Third party/Migas)

when the activity is performed.

TEP-1247064- H03-0001 Page 12 of 56 Rev:04

870310-S-1247064-CST-H03-0001 BP Internal

Tangguh Expansion Project – LNG EPC

PT. Meindo – Quality Control Plan Endorsement For Piping Prefab & Erection

A written notification (RFI) is issued by the Construction

Subcontractor and addressed to the involved parties in due

time.In case that any of the involved parties does not attend the

inspection at the scheduled time or does not provide comments

before the date notified, the Construction Subcontractor is not

obliged to hold further processing and the inspection can be

performed.

Surveillance Point (S) : Involvement for monitoring a phase of work activities. A written

notification (RFI) is not requested by the Construction

Organization. Periodic review by the CONTRACTOR and or

COMPANY representative on an activity, operation , process of

documentation by Construction Subcontractor

Review (R) : Review of documentation/reports. A written notification (RFI) is

not requested by the Construction Organization.

CONTRACTOR/COMPANY/ Third party/Migas representative

Perform/Submit (P) : Perform works and when requested by W/H points for other

parties prepare inspection and submit RFI.

Request for inspection (RFI) : The notification of inspection is a formal written request to be

issued by CONTRACTOR in order to allow all parties involved to

participate to the inspection and test as they are planned in the

applicable ITP(s). The Subcontractor QC shall notify COMPANY

through QC of Contractor to perform an in process inspection at

least 48 hours in advance of any HOLD point or 24 hours for

Witness inspections as soon as a representative portion of the

particular feature of work has been accomplished. In process

inspections include, but are not limited to,

- Handling of materials including welding consumables

- Fit-up inspection;

- Visual inspection;

- Dimensional Control inspection;

- NDE such as PT, MT, UT & RT including PMI for exotic

- material;

- E&I inspection;

TEP-1247064- H03-0001 Page 13 of 56 Rev:04

870310-S-1247064-CST-H03-0001 BP Internal

Tangguh Expansion Project – LNG EPC

PT. Meindo – Quality Control Plan Endorsement For Piping Prefab & Erection

- Pressure Test inspection;

- Blasting & Surface Preparation Inspection;

- Painting, Coating and Insulation Inspection.

5. ATTACHMENTS

5.1 ITP LIST

5.1.1 General ITP for Initial Inspection:

ITP No. PIP-0001 : Document Review and preliminary Activities.

5.1.2 Specific ITP for Construction:

ITP No. PIP-0101 : Pipe-Supporting Elements Fabrication – Fixtures and Structural

Attachments.

ITP No. PIP-0102 : Shop Fabrication of Metallic Piping.

ITP No. PIP-0103 : Aboveground and Underground Metallic Piping Erection.

ITP No. PIP-0104 : Fiberglass/Plastic pressure piping erection

ITP No. PIP-0105 : Underground Piping Work - HDPE

5.2 FORMS LIST

5.2.1 Inspection and Test Report Forms:

TEP-ITR-RFI-001 : RFI Request for Inspection

TEP-ITR-PIP-101 : Prefabricated Piping Structural Steel Components Inspection

Report.

TEP-ITR-PIP-102 : Prefabricated Piping Structural Steel Components Release

Report.

TEP-ITR-PIP-104 : Prefabricated Piping Spool / Subassembly Inspection Report.

TEP-ITR-PIP-105 : Prefabricated Piping Spool / Subassembly Release Report.

TEP-ITR-PIP-106 : Pipe-Supporting Elements Installation Inspection Report.

TEP-ITR-PIP-107 : Laid Piping Inspection Report.

TEP-1247064- H03-0001 Page 14 of 56 Rev:04

870310-S-1247064-CST-H03-0001 BP Internal

Tangguh Expansion Project – LNG EPC

PT. Meindo – Quality Control Plan Endorsement For Piping Prefab & Erection

TEP-ITR-PIP-108 : Valves / In Line Equipment Installation Inspection Report.

TEP-ITR-PIP-109 : Bolted Flange Joints Inspection Report.

TEP-ITR-PIP-110 : Screwed Pipework Installation Inspection Report.

TEP-ITR-PIP-111 : Orifice Flanges Installation Visual Inspection Report.

TEP-ITR-PIP-112 : Piping Release for Pressure Test Report.

TEP-ITR-PIP-113 : Pressure Test Report.

TEP-ITR-PIP-114 : Substantial Completion of post pressure test piping reinstatement

Report.

TEP-ITR-PIP-115 : Piping reinstatement & Mechanical Completion Inspection Report.

TEP-ITR-PIP-119 : Material receiving and inspection report (MRIR)

TEP-ITR-PIP-120 : Spring-Loaded Supports Installation Inspection Report – Variable

and Constant Load Type.

TEP-ITR-PIP-121 : Shock Absorber Installation Inspection Report.

TEP-ITR-PIP-122 : Expansion Joints Installation Inspection Report.

TEP-ITR-PIP-123 : RTR/Thermoplastic Joints preparation and Assembly.

TEP-ITR-PIP-124 : Checking of Heating Blanket Application and Curing Time.

TEP-ITR-PIP-125 : P&ID’s Conformity checks report for process Subsystem Report

TEP-ITR-PIP-126 : Blowing/Flushing of Piping Report

TEP-ITR-PIP-127 : Instrument Lines Blowing Report

TEP-ITR-PIP-128 : Joint Preparation and Pre-Assembly Report of Underground Piping

Work – HDPE Pipe

TEP-ITR-PIP-129 : Butt Fusion Welding Report of Underground Piping Work – HDPE

Pipe

TEP-ITR-PIP-130 : As Built & Cover Inspection Report of Underground Piping Work –

HDPE-Pipe

TEP-1247064- H03-0001 Page 15 of 56 Rev:04

870310-S-1247064-CST-H03-0001 BP Internal

Tangguh Expansion Project – LNG EPC

PT. Meindo – Quality Control Plan Endorsement For Piping Prefab & Erection

ITP No.: PIP-0001 DISCIPLINE

Title: DOCUMENT REVIEW AND PRELIMINARY ACTIVITIES. PIPING WORKS

Reference Documents Verifying Involvement Notes

QC CODE Inspection Phase Description Acceptance Criteria Documents CC QC JO CL CO

Availability latest version and approval status

PIP 0001 01M of Construction Drawings and any other AFC DWGs. P R R R

AFC DWGs.

applicable documentation check.

Review of applicable procedures:

PIP 0001 02M AFC drawings of AFC drawings of P R R R

Piping Material Traceability

Topographic survey Topographic survey

Piping Fabrication and Erection

and/or grading plans and/or grading plans

Flange Joint- Gasket Verification

and Flange Bolt tightening TEP-930-PRC-HS-BP4- TEP-930-PRC-HS-BP4-

0037 0037

Piping Internal Cleaning

Pressure Testing of Piping TEP-900-SPE-MM-BP4- TEP-900-SPE-MM-BP4-

0003

Valve Testing and Traceability 0003

Tagging TEP-900-SPE-PP-BP4-

TEP-900-SPE-PP-BP4-

0005

Subcontractor Method 0005

Statement Including Subcontractor

Etc method statements

Pressure Testing equipment adequacy List of Equipment Test Calibration register Site register to

PIP 0001 04M verification Check Test Manifold, Pressure Pack Folder Valid calibration P R R R be maintained

Gauges, Psv, Hoses & Couplings, etc. ISO 17025 certificate / label by CC-QC at

TEP-930-PRC-QA-BP4-0011

Site offices.

List of Equipment Calibration register Site register to

PIP 0001 05M Calibration status of inspection and test ISO 17025 Valid calibration P R R R be maintained

Instrumentation and devices. TEP-930-PRC-QA-BP4-0011 certificate / label by CC-QC at

Site offices.

ORGANIZATION CODE INVOLVEMENT CODE

CC – Construction Organization CO –CONTRACTOR Commissioning P – Perform/Submit W – Witness (Minimum 20% Inspection rate)

QC – QC Construction organization TP – PJIT/DGMIGAS S – Surveillance H – Hold Point (100% Inspection rate)

JO – CSTS Joint Operation/CONTRACTOR CL – COMPANY R – Review

TEP-1247064- H03-0001 Page 16 of 56 Rev:02

870310-S-1247064-CST-H03-0001 BP Internal

MEINDO will use

this ITP as per

Scope of work of

PO 1247064 ?

Tangguh Expansion Project – LNG EPC

PT. Meindo – Quality Control Plan Endorsement For Piping Prefab & Erection

ITP No.: PIP-0101 DISCIPLINE

Title: PIPE-SUPPORTING ELEMENTS FABRICATION-FIXTURES PIPING WORKS

AND STRUCTURAL ATTACHMENTS.

Reference Documents Verifying Involvement Notes

QC COD`E Inspection Phase Description Acceptance Criteria Documents CC QC JO CL CO

___ ___ ___ Joint fit-up Inspection, Welding Process ___ ___ Refer to QCP No. TEP-930-

implementation, Visual Inspection & NDE of SPE-QA-BP4-0023 for Welding

weldment

Piping bulk material receiving Material manag.nt OSDR Warehouse

___ ___ ___ procedure, packing Log Book

List,certification

PIP 0101 01M a. Physical verification of incoming

Project standard TEP-ITR-PIP--119* P H W W *(Phase to be included only when

materials: verification of identification TEP-900-SPE-PP-BP4-0002 Project material is provided

marks, tags, colour coding, thickness, without Material Release report)

TEP-900-SPE-PP-BP4-1015

dimensions, distortions, shape, any

evidence of damage

Final Inspection of Fabricated Item: TEP-ITR-PIP-101

PIP 0101 02M AFC DWGs.- P H W W

Completeness of the assembly check

Welding-induced distortion or TEP-900-SPE-MM-BP4-

deformation or warping check 0003

Related geometries, dimensions and TEP-900-STD-PP-BP4-

tolerances check 0002

Surfaces free from damages, rust &

scale, and cleaned

Erection marks for identification

Release of Pipe–Supporting Elements for TEP-ITR-PIP-102 Verify with respect to QC

PIP 0101 03M further activities or shipping: AFC DWGs P H W W

Code -01M.

Visual & Dimensional checks TEP-900-SPE-MM-BP4-

Welding and NDE 0003 Refer to Welding Data

PWHT (if required), Hardness test Base as per QCP No. TEP-

TEP-900-STD-PP-BP4-

930-SPE-QA-BP4-0023 for

0002

Cleanliness Welding

Preservation

ORGANIZATION CODE INVOLVEMENT CODE

CC – Construction Organization CO –CONTRACTOR Commissioning P – Perform/Submit W – Witness (Minimum 20% Inspection rate)

QC – QC Construction organization TP – PJIT/DGMIGAS S – Surveillance H – Hold Point (100% Inspection rate)

JO – CSTS Joint Operation/CONTRACTOR CL – COMPANY R – Review

TEP-1247064- H03-0001 Page 17 of 56 Rev:02

870310-S-1247064-CST-H03-0001 BP Internal

MEINDO will use

this ITP as per

Scope of work of

Tangguh Expansion Project – LNG EPCPO 1247064 ?

PT. Meindo – Quality Control Plan Endorsement For Piping Prefab & Erection

ITP No.: PIP-0102 DISCIPLINE

Title: SHOP FABRICATION OF METALLIC PIPING PIPING WORKS

Reference Involvement Notes

Documents Verifying

QC CODE Inspection Phase Description Acceptance Documents CC QC JO CL CO

Criteria

---- ---- ---- Piping bulk material receiving Material Over Short Activity as per “Material

management Damage Report Management” Procedure

procedure – Warehouse

packing List – Log Book

certification-

PIP 0102 01M Physical verification of incoming materials: Project standard TEP-ITR-PIP--119* P H W W *(Phase to be included only when

Project material is provided

a. verification of identification marks, tags, TEP-900-SPE-PP-BP4- without Material Release report)

colour coding, identification and 0002

traceability TEP-900-SPE-PP-BP4-

b. thickness, dimensions, distortions, 1015

shape, any evidence of damage

c. material certificates review

---- ---- ---- PMI testing (if required) Project PMI report/record (PMI report and Record to be

included in the specific procedure)

Specs/procedure

---- ---- ---- Piping materials protection and Project Specs Warehouse Activity as per “Material

preservation Log book Management” Procedure

ORGANIZATION CODE INVOLVEMENT CODE

CC – Construction Organization CO –CONTRACTOR Commissioning P – Perform/Submit W – Witness (Minimum 20% Inspection rate)

QC – QC Construction organization TP – PJIT/DGMIGAS S – Surveillance H – Hold Point (100% Inspection rate)

JO – CSTS Joint Operation/CONTRACTOR CL – COMPANY R – Review

TEP-1247064- H03-0001 Page 18 of 56 Rev:02

870310-S-1247064-CST-H03-0001 BP Internal

MEINDO will use this

ITP as per Scope of

work of PO 1247064 ?

Tangguh Expansion Project – LNG EPC

PT. Meindo – Quality Control Plan Endorsement For Piping Prefab & Erection

ITP No.: PIP-0102 DISCIPLINE

Title: SHOP FABRICATION OF METALLIC PIPING PIPING WORKS

Reference Involvement Notes

Verifying

Documents

QC CODE Inspection Phase Description Documents CC QC JO CL CO

Acceptance Criteria

Joint fit-up Inspection, Welding Process Refer to QCP No. TEP-

___ ___ ___ ___ ___ 930-SPE-QA-BP4-0023 for

implementation, Visual Inspection & NDE of

weldment Welding

PIP 0102 02M Visual inspection of completed pipe spools or: AFC DWGs.- TEP-ITR-PIP-104 P H W S

Geometric configuration and TEP-900-SPE-MM-BP4-

0003

completeness of assembly

Appropriate fit of components

Reinforcement of Welded Branch

Connections

Dimensional check including thickness

Measurement by UT as specified

Surface condition check including the

after temporary attachment

removal/NDT

Markings and identification

PIP 0102 03M Piping Pressure Test TEP-ITR-PIP-113 If prescribed.

AFC DWGs P H H W

Verification of test manifold TEP-930-PRC-HS-BP4-

Verification of test instrumentation 0037

Verification of test medium

Filling & Pressurization

Visual Inspection at Test Pressure

Verification of NDT Summary

ORGANIZATION CODE INVOLVEMENT CODE

CC – Construction Organization CO –CONTRACTOR Commissioning P – Perform/Submit W – Witness (Minimum 20% Inspection rate)

QC – QC Construction organization TP – PJIT/DGMIGAS S – Surveillance H – Hold Point (100% Inspection rate)

JO – CSTS Joint Operation/CONTRACTOR CL – COMPANY R – Review

TEP-1247064- H03-0001 Page 19 of 56 Rev:02

870310-S-1247064-CST-H03-0001 BP Internal

MEINDO will use

this ITP as per

Tangguh Expansion Project – LNG EPC Scope of work of

PO 1247064

PT. Meindo – Quality Control Plan Endorsement For Piping? Prefab & Erection

ITP No.: PIP-0102 DISCIPLINE

Title: SHOP FABRICATION OF METALLIC PIPING PIPING WORKS

Reference Involvement Notes

Verifying

Documents

QC CODE Inspection Phase Description Documents CC QC JO CL CO

Acceptance Criteria

PIP 0102 04M Release inspection of piping prefabricated AFC DWGs.- TEP-ITR-PIP-105 P H W W Verify with respect to QC

TEP-900-SPE-MM-BP4- Codes -02.

spools to Blasting/Painting: 0003

Visual & Dimensional checks Refer to Welding

Welding and NDE Data Base as per QCP No.

TEP-930-SPE-QA-BP4-0023

PWHT (if required), Hardness test for Welding

Internal Cleanliness If required

Lay-up & Preservation

ORGANIZATION CODE INVOLVEMENT CODE

CC – Construction Organization CO –CONTRACTOR Commissioning P – Perform/Submit W – Witness (Minimum 20% Inspection rate)

QC – QC Construction organization TP – PJIT/DGMIGAS S – Surveillance H – Hold Point (100% Inspection rate)

JO – CSTS Joint Operation/CONTRACTOR CL – COMPANY R – Review

TEP-1247064- H03-0001 Page 20 of 56 Rev:02

870310-S-1247064-CST-H03-0001 BP Internal

Tangguh Expansion Project – LNG EPC

PT. Meindo – Quality Control Plan Endorsement For Piping Prefab & Erection

ITP No.: PIP-0103 DISCIPLINE

Title: ABOVEGROUND AND UNDERGROUND METALLIC PIPING PIPING WORKS

ERECTION Reference

Verifying Involvement Notes

Documents

QC CODE Inspection Phase Description Documents CC QC JO CL CO

Acceptance Criteria

PIP 0103 01M Pipe Static Supporting Elements and Dynamic TEP-ITR-PIP-106

AFC DWGs P H W S Concrete curing and test

Components installation check: reports are acceptable prior to

Pipeway Location (Layout, Elevation & Spacing) TEP-900-SPE-MM-BP4-

loading

check 0003

Steel assemblies erection in racks

completeness

Concrete reinforced steel pedestals and thrust

blocks for sleeperways and trenches installation

completeness

PIP 0103 02M Pipe laying, Pipe Spool erection and assembly TEP-ITR-PIP-107

check (complete Line): AFC DWGs P H W S

Spool Release document Review TEP-900-SPE-MM-BP4-

Material Identification 0003

Ensure the Internal Cleaning of pipes for TEP-TBA-PLL-PP-BP4-

absence of debris prior to erection or placement. 0100

Strain-free installation of piping in compliance

with AFC Dwgs.

Pipework alignment, straightness, TOP, BOP,

BOF, etc.

Open ends protection of erected piping.

PIP 0103 03M Pipe Dynamic Supporting Elements and AFC DWGs TEP-ITR-PIP-106 P H W S If applicable .

Component installation check: TEP-900-SPE-MM-BP4- Plus any of the follow. as

0003 applicable

Spring Loaded Supports installation check AFC DWGs TEP-ITR-PIP-120

Shock Absorbers Installation check TEP-900-STD-PP-BP4- TEP-ITR-PIP-121

0002

Expansion Joints installation check TEP-900-SPE-MM-BP4-

TEP-ITR-PIP-122

0003

ORGANIZATION CODE INVOLVEMENT CODE

CC – Construction Organization CO –CONTRACTOR Commissioning P – Perform/Submit W – Witness (Minimum 20% Inspection rate)

QC – QC Construction organization TP – PJIT/DGMIGAS S – Surveillance H – Hold Point (100% Inspection rate)

JO – CSTS Joint Operation/CONTRACTOR CL – COMPANY R – Review

TEP-1247064- H03-0001 Page 21 of 56 Rev:02

870310-S-1247064-CST-H03-0001 BP Internal

Tangguh Expansion Project – LNG EPC

PT. Meindo – Quality Control Plan Endorsement For Piping Prefab & Erection

ITP No.: PIP-0103 DISCIPLINE

Title: ABOVEGROUND AND UNDERGROUND METALLIC PIPING PIPING WORKS

ERECTION Reference Involvement Notes

Documents Verifying

QC CODE Inspection Phase Description Acceptance Documents CC QC JO CL CO

Criteria

___ ___ ___ Joint fit-up inspection, Welding process ___ ___ Refer to QCP No. TEP-930-

implementation, Visual inspection & NDE of SPE-QA-BP4-0023 for Welding

weldment.

PIP 0103 04M Valves, quill and other Line-Equipment AFC Dwgs. TEP-ITR-PIP-108 P H S S

installation: TEP-900-SPE-MM-BP4-

0003

-Ensure the correct location and positioning as

per AFC Dwgs. and Stds.

PIP 0103 05M Bolted Flange Joints inspection (pipe to pipe AFC Dwgs. TEP-ITR-PIP-109 P H W S

and pipe to strain sensitive equipment): TEP-900-SPE-MM-BP4-

0003

- Joint assembly members condition.

TEP-900-SPE-PP-BP4-

- Cleaning and examination for condition of 1005

flange and fastener contact surfaces.

- Alignment of Flanges.

- Installation of Gasket.

- Installation and Tightening of Bolts.

ORGANIZATION CODE INVOLVEMENT CODE

CC – Construction Organization CO –CONTRACTOR Commissioning P – Perform/Submit W – Witness (Minimum 20% Inspection rate)

QC – QC Construction organization TP – PJIT/DGMIGAS S – Surveillance H – Hold Point (100% Inspection rate)

JO – CSTS Joint Operation/CONTRACTOR CL – COMPANY R – Review

TEP-1247064- H03-0001 Page 22 of 56 Rev:02

870310-S-1247064-CST-H03-0001 BP Internal

Tangguh Expansion Project – LNG EPC

PT. Meindo – Quality Control Plan Endorsement For Piping Prefab & Erection

ITP No.: PIP-0103 DISCIPLINE

Title: ABOVEGROUND AND UNDERGROUND METALLIC PIPING WORKS

PIPING ERECTION Reference Involvement Notes

Documents Verifying

QC CODE Inspection Phase Description Acceptance Documents CC QC JO CL CO

Criteria

PIP 0103 06M Screwed Pipework inspection: AFC Dwgs. TEP-ITR-PIP- P H S S Care of Welding Inspector

TEP-900-SPE-MM-

110

- Minimum threads engagement and

BP4-0003

maximum exposed pipe threads in TEP-ITR-PIP-

threaded connections check. 109

- Seal welds check.

PIP 0103 07M Orifice Flanges installation inspection AFC Dwgs. TEP-ITR-PIP- P H W W For inspection of flow orifice plate, refer to

111 QCP No. TEP-930-SPE-QA-BP4-0031for

- Visual Inspection of weld root profile TEP-900-SPE-MM-

Instrumentat..

BP4-0003

- Pressure Taps orientation Care of Welding inspector

ORGANIZATION CODE INVOLVEMENT CODE

CC – Construction Organization CO –CONTRACTOR Commissioning P – Perform/Submit W – Witness (Minimum 20% Inspection rate)

QC – QC Construction organization TP – PJIT/DGMIGAS S – Surveillance H – Hold Point (100% Inspection rate)

JO – CSTS Joint Operation/CONTRACTOR CL – COMPANY R – Review

TEP-1247064- H03-0001 Page 23 of 56 Rev:02

870310-S-1247064-CST-H03-0001 BP Internal

Tangguh Expansion Project – LNG EPC

PT. Meindo – Quality Control Plan Endorsement For Piping Prefab & Erection

ITP No.: PIP-0103 DISCIPLINE

Title: ABOVEGROUND AND UNDERGROUND METALLIC PIPING PIPING WORKS

ERECTION Reference Involvement Notes

Documents Verifying

QC CODE Inspection Phase Description Acceptance Documents CC QC JO CL CO

Criteria

Piping mechanical completion inspection of

PIP 0103 08M installed piping prior to release for pressure AFC Dwgs. TEP-ITR-PIP-112 P H W W W Limited to the

test: TEP-900-SPE-MM-BP4-

parts pertaining

- Mechanical completion and conformity of 0003 to QC.

lines to AFC Dwgs. Including Slope TEP-930-PRC-HS-BP4- For welding,

check, pipe supports and hangers. 0037 PWHT and NDE

- Location of permanent gaskets TEP-900-SPE-PP-BP4- works, refer to

- Test Pack folder preparation , 1001 Welding Data Base

- Pre-test Punch Listing (YES/NO items) as per QCP No.

- Installation/removal of TEP-930-SPE-QA-

permanent/temporary items BP4-0023 for

- Any valves installed in the circuit are kept Welding

in open position (Ball valves in the half-

open position)

- Verification of piping internal cleanliness

- External surface condition check including

temporary attachment removal/NDT

- Thickness Measurement as specified for

Baseline survey requirement

Piping Pressure Test

PIP 0103 09M - Verification of test manifold AFC Dwgs. TEP-ITR-PIP-113 P H H W W Either Hydrostatic

- Verification of test instrumentation TEP-930-PRC-HS-BP4-

or Pneumatic

- Verification of test medium 0037 missing TEP-

- Filling & Pressurization

- Verification of water certificate

ITR-PIP-114

- Visual Inspection at Test Pressure

ORGANIZATION CODE INVOLVEMENT CODE

CC – Construction Organization CO –CONTRACTOR Commissioning P – Perform/Submit W – Witness (Minimum 20% Inspection rate)

QC – QC Construction organization TP – PJIT/DGMIGAS S – Surveillance H – Hold Point (100% Inspection rate)

TEP-1247064- H03-0001 Page 24 of 56 Rev:02

870310-S-1247064-CST-H03-0001 BP Internal

Tangguh Expansion Project – LNG EPC

PT. Meindo – Quality Control Plan Endorsement For Piping Prefab & Erection

JO – CSTS Joint Operation/CONTRACTOR CL – COMPANY R – Review

ITP No.: PIP-0103 DISCIPLINE

Title: ABOVEGROUND AND UNDERGROUND METALLIC PIPING PIPING WORKS

ERECTION

Reference Documents Verifying Involvement Notes

QC CODE Inspection Phase Description Acceptance Criteria Documents CC QC JO CL CO

PIP 0103 10M De-Pressurization and Water Disposal AFC Dwgs.

___ P H W S

- Draining, drying with air TEP-930-PRC-HS-BP4-

0037 115

PIP 0103 11M Reinstatement of Piping:

AFC Dwgs. TEP-ITR-PIP-114 P H W W

Removal of test spades/blinds ,etc.

Installation of in-line components excluded TEP-900-SPE-MM-BP4- TEP-ITR-PIP-109

0003

from pressure test.

Clearing of Punch-list “NO” items TEP-930-PRC-HS-BP4-

0037

Setting spring pipe supports.

TEP-900-SPE-PP-BP4-

1001

Refer to QCP

___ ___ ___ Pipe external wrapping for UG piping (Tape ___ ___

No. TEP-930-SPE-

wrapping). if applicable QA-BP4-0037for

Lining & Refractory

Works at Site.

P&ID’s Conformity checks report for process AFC Dwgs. P H H* H H *The activity is supervised

PIP 0103 12P TEP-ITR-PIP-125 and controlled by CSTS

Subsystem

CO

TEP-900-PRC-OP-BP4- P H H* H H *The activity is supervised

PIP 0103 13P Blowing/Flushing of Piping TEP-ITR-PIP-126 and controlled by CSTS

0007

CO

TEP-900-PRC-OP-BP4- P H H H H *The activity is supervised

PIP 0103 14P Instrument Lines Blowing TEP-ITR-PIP-127 and controlled by CSTS

0007

CO

missing **Applicable for Non

Critical Lines where

Boroscope is negative

and for Critical Lines.

ORGANIZATION CODE INVOLVEMENT CODE

CC – Construction Organization CO –CONTRACTOR Commissioning P – Perform/Submit W – Witness (Minimum 20% Inspection rate)

QC – QC Construction organization TP – PJIT/DGMIGAS S – Surveillance H – Hold Point (100% Inspection rate)

JO – CSTS Joint Operation/CONTRACTOR CL – COMPANY R – Review

TEP-1247064- H03-0001 Page 25 of 56 Rev:02

870310-S-1247064-CST-H03-0001 BP Internal

Tangguh Expansion Project – LNG EPC

PT. Meindo – Quality Control Plan Endorsement For Piping Prefab & Erection

MEINDO will use

this ITP as per

ITP No.: PIP-0104 Scope of work of DISCIPLINE

PO 1247064

Title: FIBERGLASS/PLASTICPRESSURE ?

PIPINGERECTION PIPING WORKS

Reference Documents Verifying Involvement Notes

QC CODE Inspection Phase Description Acceptance Criteria Documents CC QC JO CL CO

Pre-installation inspection: AFC Drawings AFC Drawings P R R R Document review

PIP 0104 01M Verification of isometric, piping arrangement Control Sheets and material receiving

applicable inspection

drawings, components and spools shall be completed as

Preparation of isometric control sheets per ITP No. PIP-0001

and ITP No. PIP-0002

Check joints and assembly preparation: Manufacturer Assembly P W W S

PIP 0104 02M

squareness of cut spigot end Instructions TEP-ITR-PIP-123

insert depth

nose thickness

spigot diameter

adhesive application

Check heating blanket application and curing Manufacturer Assembly TEP-ITR-PIP-124 P W W S

PIP 0104 03M time Instructions

Inspection before pressure test: P&IDs TEP-ITR-PIP- P H H H Piping test-pack

PIP 0104 04M Pre-test punch listing TEP-900-SPE-MM-BP4-0003 preparation (TP-Folder)

TEP-930-PRC-HS-BP4-0037 112

Release for pressure test TEP-900-SPE-PP-BP4-1001

Piping pressure testing AFC Dwgs. TEP-ITR-PIP-113 P H H H

PIP 0104 05M TEP-930-PRC-HS-BP4-0037

P&ID’s Conformity checks report for AFC Drawings. TEP-ITR-PIP-125 P H H* H H *The activity is

IP 0104 06P supervised and controlled

process Subsystem by CSTS CO

TEP-900-PRC-OP-BP4-0007 *The activity is

PIP 0104 07P Blowing/Flushing of Piping TEP-ITR-PIP-126 P H H* H H

supervised and controlled

by CSTS CO

ORGANIZATION CODE INVOLVEMENT CODE

CC – Construction Organization CO –CONTRACTOR Commissioning P – Perform/Submit W – Witness (Minimum 20% Inspection rate)

QC – QC Construction organization TP – PJIT/DGMIGAS S – Surveillance H – Hold Point (100% Inspection rate)

JO – CSTS Joint Operation/CONTRACTOR CL – COMPANY R – Review

TEP-1247064- H03-0001 Page 26 of 56 Rev:02

870310-S-1247064-CST-H03-0001 BP Internal

MEINDO will use

Tangguh Expansion Project – LNG EPC

this ITPFor

PT. Meindo – Quality Control Plan Endorsement as Piping

per Prefab & Erection

Scope of work of

PO 1247064 ?

ITP No.: PIP-0105 DISCIPLINE

Title: UNDERGROUND PIPING WORK – HDPE PIPE PIPING WORKS

Reference Documents Verifying Involvement Notes

QC CODE Inspection Phase Description Acceptance Criteria Documents CC QC JO CL CO

PIP 0105 01M Approved MOCK P W W W

Mock up Test for UG Piping work - HDPE DVS 2202-1 UP report

pipe TEP-1221351-H99-0007

Check joints and assembly preparation: Manufacturer Assembly TEP-ITR-PIP-128 P W W S

PIP 0105 02M Instruction

Cut Length

Squareness check of cut and bevel DVS 2202-1

Surface Cleanliness TEP-900-SPE-PP-BP4-

Alignment check 1013

Temperature of heating plate

Jointing pressure

Holding time of fusion

Manufacturer Assembly TEP-ITR-PIP-129 P W W W

PIP 0105 03M Instruction

DVS 2207

Visual Inspection of Butt Fusion Welding

TEP-900-SPE-PP-BP4-

1013

Manufacturer Assembly TEP-ITR-PIP-130 P W W W

PIP 0105 04M Instruction

As Built and Cover Inspection

TEP-1175184-R06-0001

TEP-900-SPE-PP-BP4- TEP-ITR-PIP-113 P H H H

PIP 0105 05M Piping Pressure testing 1013

ORGANIZATION CODE INVOLVEMENT CODE

CC – Construction Organization CO –CONTRACTOR Commissioning P – Perform/Submit W – Witness (Minimum 20% Inspection rate)

QC – QC Construction organization TP – PJIT/DGMIGAS S – Surveillance H – Hold Point (100% Inspection rate)

JO – CSTS Joint Operation/CONTRACTOR CL – COMPANY R – Review

TEP-1247064- H03-0001 Page 27 of 56 Rev:02

870310-S-1247064-CST-H03-0001 BP Internal

Tangguh Expansion Project – LNG EPC

PT. Meindo – Quality Control Plan Endorsement For Piping Prefab & Erection

IN/RFI – INSPECTION NOTIFICATION

MONTH DAY

JAN FEB MAR APR MAY JUN 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

1

JUL AUG SEP OCT NOV DEC 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31

Document ref.:

DISCIPLINE : CIVIL ELECTRICAL MECHANICAL INSTR/AUT PIPING PIPELINE TELECOM

PACKAGE

INSPECTION

ITEM/TAG EXPECTED

No QC CODE ITEM/TAG DESCRIPTION AREA/LOCATION EXECUTION

NUMBER TIME

RESULT

SIGNATURE FOR NOTIFICATION / ACKNOWLEDGEMENT

Construction Subcontractor CONTRACTOR COMPANY PJIT/DGMIGAS/TPI

NAME NAME NAME NAME

SIGNATURE SIGNATURE SIGNATURE SIGNATURE

Date Date Date Date

LEGEND: INSPECTION EXECUTION RESULT

ACCEPTED ; REJECTED ; POSTPONED ; CANCELLED

Comment/Remarks:

INSPECTION PRESENCE: Construction Subcontractor. CONTRACTOR COMPANY OTHER

SIGNATURE FOR INSPECTION EXECUTED

Construction Subcontractor CONTRACTOR COMPANY PJIT/DGMIGAS/TPI

NAME NAME NAME NAME

SIGNATURE SIGNATURE

SIGNATURE SIGNATURE

Date Date Date Date

Form code: TEP-ITR-RFI-001

TEP-1247064- H03-0001 Page 28 of 56 Rev:02

870310-S-1247064-CST-H03-0001 BP Internal

Tangguh Expansion Project – LNG EPC

PT. Meindo – Quality Control Plan Endorsement For Piping Prefab & Erection

OWNER: BP Berau Ltd JOB UNIT

PLANT LOCATION: 1247064

BINTUNI BAY,PAPUA - INDONESIA QC CODE ITP REFERENCE

PIP-0101-01M PIP-0101

PROJECT TITLE: TANGGUH EXPANSION PROJECT

REPORT No. Sh. of.

SUBCONTRACTOR:

PREFABRICATED PIPING STRUCTURAL STEEL COMPONENTS INSPECTION REPORT

DRAWING / SPECIFICATION No. & Rev.:

ASSEMBLY LAYOUT AND COMPLETENESS AS PER AFC DRAWINGS

WORKMANSHIP – ABSENCE OF UNACCEPTABLE TWISTS,

BENDS, KINKS, WARPING, CAMBER OR SWEEP IN FINISHED

MEMBERS

APPROPRIATE FIT OF COMPONENTS

DRAWING RELATED GEOMETRIES

TAG ITEM / ELEMENT

DIMENSIONS AND

TOLERANCES

HOLING

UNIT ID

MARKS

No. Rev. C NC C NC C NC C NC C NC C NC

C= CONFORMING NC= NOT CONFORMING

NOTES: INSPECTION NOTIFICATION

REFERENCE

RFI No.:

____________________

Subcontractor QC CONTRACTOR COMPANY TPI

NAME NAME NAME NAME

SIGNATURE SIGNATURE SIGNATURE SIGNATURE

DATE DATE DATE DATE

Form Code:TEP-ITR-PIP-101

TEP-1247064- H03-0001 Page 29 of 56 Rev:02

870310-S-1247064-CST-H03-0001 BP Internal

Tangguh Expansion Project – LNG EPC

PT. Meindo – Quality Control Plan Endorsement For Piping Prefab & Erection

OWNER: BP Berau Ltd JOB UNIT

PLANT LOCATION: 1247064

BINTUNI BAY,PAPUA - INDONESIA QC CODE ITP REFERENCE

PROJECT TITLE: PIP-0101-02M PIP-0101

TANGGUH EXPANSION PROJECT REPORT No. Sh. of

SUBCONTRACTOR:

PREFABRICATED PIPING STRUCTURAL STEEL COMPONENTS RELEASE REPORT

DRAWING / SPECIFICATION No. & Rev.:

FABRICATION COMPLETED AND ACCEPTED AS PER ITR-PIP-101

HEAT TREATMENT

NON DESTRUCTIVE TESTING

DRAWING

FREE OF RUST, OR

CONTAMINANTS

TAG ITEM / ELEMENT

ITEM

RELEASED

Rev.

PAsS

FAIL

PASS

FAIL

NA

PASS

FAIL

NA

PASS

FAIL

YES

NO

No.

NOTES: INSPECTION NOTIFICATION

REFERENCE

RFI No.: ____________________

Subcontractor QC CONTRACTOR COMPANY TPI

NAME NAME NAME NAME

SIGNATURE SIGNATURE SIGNATURE SIGNATURE

DATE DATE DATE DATE

Form Code:TEP-ITR-PIP-102

TEP-1247064- H03-0001 Page 30 of 56 Rev:02

870310-S-1247064-CST-H03-0001 BP Internal

Tangguh Expansion Project – LNG EPC

PT. Meindo – Quality Control Plan Endorsement For Piping Prefab & Erection

OWNER: BP Berau Ltd JOB UNIT

PLANT LOCATION: 1247064

BINTUNI BAY,PAPUA - INDONESIA QC CODE ITP REFERENCE

PIP-0102-01M PIP-0102

PROJECT TITLE:

TANGGUH EXPANSION PROJECT REPORT No. Sh of

SUBCONTRACTOR:

PREFABRICATED PIPING SPOOL / SUBASSEMBLY INSPECTION REPORT

DRAWING / SPECIFICATION No. & Rev.:

PIPING ASSEMBLY LAYOUT AND COMPLETENESS AS PER AFC

DRAWINGS

LINEAR AND ANGULARITY & ROTATION

TOLERANCES

REINFORCEMENT OF WELDED

DRAWING BRANCH CONNECTIONS

TAG ITEM / ELEMENT WORKMANSHIP – NO

KINKS, SCRATCHES,

Etc.

MARKINGS

& COLOR

CODING

No. Rev. C NC C NC C NC NA C NC C NC

C= CONFORMING NC= NOT CONFORMING NA=NOT APPLICABLE

NOTES: INSPECTION NOTIFICATION

REFERENCE

Measuring devices S.N.:

RFI No.: ____________________

QC CONSTRUCTION ORGANIZATION CONTRACTOR COMPANY TPI

NAME NAME NAME NAME

SIGNATURE SIGNATURE SIGNATURE SIGNATURE

DATE DATE DATE DATE

Form Code:TEP- ITR-PIP-104

TEP-1247064- H03-0001 Page 31 of 56 Rev:02

870310-S-1247064-CST-H03-0001 BP Internal

Tangguh Expansion Project – LNG EPC

PT. Meindo – Quality Control Plan Endorsement For Piping Prefab & Erection

OWNER: BP Berau Ltd JOB UNIT

PLANT LOCATION: 1247064

BINTUNI BAY,PAPUA - INDONESIA QC CODE ITP REFERENCE

PROJECT TITLE: PIP-0102-03M PIP-0102

TANGGUH EXPANSION PROJECT REPORT No. Sh. of

SUBCONTRACTOR:

PREFABRICATED PIPING SPOOL / SUBASSEMBLY RELEASE REPORT

DRAWING / SPECIFICATION No. & Rev.:

FABRICATION COMPLETED AND ACCEPTED AS PER ITP-PIP-102

HEAT TREATMENT

NON DESTRUCTIVE TESTING

DRAWING

FREE OF RUST, OR

CONTAMINANTS

TAG ITEM / ELEMENT

ITEM

Rev. RELEASED

PASS

FAIL

PASS

FAIL

NA

PASS

FAIL

NA

PASS

FAIL

YES

NO

No.

NOTES: INSPECTION NOTIFICATION

REFERENCE

RFI No.: ____________________

Subcontractor QC CONTRACTOR COMPANY TPI

NAME NAME NAME NAME

SIGNATURE SIGNATURE SIGNATURE SIGNATURE

DATE DATE DATE DATE

Form Code:TEP-ITR-PIP-105

TEP-1247064- H03-0001 Page 32 of 56 Rev:02

870310-S-1247064-CST-H03-0001 BP Internal

Tangguh Expansion Project – LNG EPC

PT. Meindo – Quality Control Plan Endorsement For Piping Prefab & Erection

OWNER: BP Berau Ltd JOB UNIT

PLANT LOCATION: 870310

BINTUNI BAY,PAPUA - INDONESIA QC CODE ITP REFERENCE

PROJECT TITLE: PIP-0103-01M PIP-0103

TANGGUH EXPANSION PROJECT REPORT No. Sh of

SUBCONTRACTOR:

PIPE-SUPPORTING ELEMENTS INSTALLATION INSPECTION REPORT

APPLICABLE SPEC. /

LINE No. REF. P&ID No. & Rev.

PROCEDURE No. & Rev.

ITEM LOCATION IN PLAN RELATIVE TO THE POSITION POINT OF REFERENCE

(PR)

LOCATION OF THE CENTRELINE OF THE ITEM RELATIVE TO

THE ESTABLISHED SUPPORT LINE

ISO DRAWING

TAG ITEM / ELEMENT DISTANCE BETWEEN CENTRES OF ADJACENT

ITEMS

DEVIATION OF BOP LEVELS

SLOPE

No. Rev. C NC C NC C NC C NC C NC NA

C= CONFORMING NC= NOT CONFORMING NA=NOT APPLICABLE

NOTES: INSPECTION NOTIFICATION

REFERENCE

Measuring devices S.N.:

RFI No.: ____________________

Subcontractor QC CONTRACTOR COMPANY TPI

NAME NAME NAME NAME

SIGNATURE SIGNATURE SIGNATURE SIGNATURE

DATE DATE DATE DATE

Form Code: TEP-ITR-PIP-106

TEP-1247064- H03-0001 Page 33 of 56 Rev:02

870310-S-1247064-CST-H03-0001 BP Internal

Tangguh Expansion Project – LNG EPC

PT. Meindo – Quality Control Plan Endorsement For Piping Prefab & Erection

OWNER: BP Berau Ltd JOB UNIT

PLANT LOCATION: 1247064

BINTUNI BAY,PAPUA - INDONESIA QC CODE ITP REFERENCE

PROJECT TITLE: PIP-0103-02M PIP-0103

TANGGUH EXPANSION PROJECT REPORT No. Sh of

SUBCONTRACTOR:

LAID PIPING INSPECTION REPORT

APPLICABLE SPEC. /

LINE No. REF. P&ID No. & Rev.

PROCEDURE No. & Rev.

LOCATION

VERTICAL & HORIZONTAL ALIGNMENT

STRAIGHTNESS

ISO DRAWING ELEVATION & LEVEL / BOP / TOP

TAG ITEM / SPOOL OR ELEMENT

SLOPE

SUPPORT

SEATING

No. Rev. C NC C NC C NC C NC C NC NA C NC NA

C= CONFORMING NC= NOT CONFORMING NA=NOT APPLICABLE

NOTES: INSPECTION NOTIFICATION

REFERENCE

Measuring devices S.N.:

RFI No.: ____________________

Subcontractor QC CONTRACTOR COMPANY TPI

NAME NAME NAME NAME

SIGNATURE SIGNATURE SIGNATURE SIGNATURE

DATE DATE DATE DATE

Form Code:TEP- ITR-PIP-107

TEP-1247064- H03-0001 Page 34 of 56 Rev:02

870310-S-1247064-CST-H03-0001 BP Internal

Tangguh Expansion Project – LNG EPC

PT. Meindo – Quality Control Plan Endorsement For Piping Prefab & Erection

OWNER: BP Berau Ltd JOB UNIT

PLANT LOCATION: 870310

BINTUNI BAY,PAPUA - INDONESIA QC CODE ITP REFERENCE

PROJECT TITLE: PIP-0103-04M PIP-0103

TANGGUH EXPANSION PROJECT REPORT No. Sh of

SUBCONTRACTOR:

VALVES / IN-LINE EQUIPMENT INSTALLATION INSPECTION REPORT

APPLICABLE SPEC. /

LINE No. REF. P&ID No. & Rev.

PROCEDURE No. & Rev.

TYPE, SIZE, RATING DESIGNATION, END CONNECTIONS,

MATERIAL

ITEM DESCRIPTION ISOMETRIC DRAWING No. Rev. LOCATION FLOW DIRECTION

STEM ORIENTATION

C NC C NC C NC NA REMARKS

C= CONFORMING NC= NOT CONFORMING NA=NOT APPLICABLE

NOTES: INSPECTION NOTIFICATION

REFERENCE

RFI No.: ____________________

Subcontractor QC CONTRACTOR COMPANY TPI

NAME NAME NAME NAME

SIGNATURE SIGNATURE SIGNATURE SIGNATURE

DATE DATE DATE DATE

Form Code: TEP-ITR-PIP-108

TEP-1247064- H03-0001 Page 35 of 56 Rev:02

870310-S-1247064-CST-H03-0001 BP Internal

Tangguh Expansion Project – LNG EPC

PT. Meindo – Quality Control Plan Endorsement For Piping Prefab & Erection

OWNER: BP Berau Ltd JOB UNIT

PLANT LOCATION: 870310

BINTUNI BAY,PAPUA - INDONESIA QC CODE ITP

REFERENCE

PROJECT TITLE: PIP-0103- PIP-0103

TANGGUH EXPANSION PROJECT 05M No. Sh

REPORT of

SUBCONTRACTOR:

BOLTED FLANGE JOINTS INSPECTION REPORT

APPLICABLE SPEC. /

LINE No. REF. P&ID No. & Rev.

PROC. No. & Rev.

DRAWING FLANGE

JOINT No.

No. Rev. SPEC. SIZE TYPE FACING FINISH MATERIAL

GASKET

SPEC. TYPE (see note 1) SIZE RATING MATERIAL

OUTER INNER FILLE

WINDING

RING RING R

Note 1: In case of RTJ indicate number for Ring Gasket

BOLTING ASSEMBLY BOLT / STUD NUT WASHER

SPECIFICATION

SIZE

MATERIAL

LUBRICANT TYPE AND BRAND NAME :

CHECK PASS FAIL CHECK PASS FAIL

ROTATIONAL

FLANGE FACINGS FINISH

TWO-HOLE

JOINT ASSEMBLY CONDITION AND CENTERLINE HIGH/LOW SPACING / GAP

ALIGNMENT

FREE OF RUST

PARALLELISM AND

CONTAMINATS

Have Joints previously been hydrotested

BOLTS TIGHTENING

TIGHTENING WITH TENSIONING

TIGHTENING WITH HAND-OPERATED OR AUXILIARY POWERED TOOLS WITH TORQUE

TOOLS APPLYING LOAD-CONTROL

MEASUREMENT

TECHNIQUE

REQ.’D TORQUE VALUE: RESIDUAL BOLT LOAD / STRESS REQUIRED:

PRESSURE

No. OF PASS ACTUAL TORQUE VALUE TENSIONING STAGE

READING

30% of Req.’d. Torque Pressure A

60% of Req.’d. Torque Pressure B

100% of Req.’d. Torque Break Loose Pressure

FINAL RESULT: ACCEPTED REJECTED

INSPECTION NOTIFICATION

REFERENCE

NOTES:

Measuring devices S.N.:

RFI No.: ____________________

Subcontractor QC CONTRACTOR COMPANY TPI

NAME NAME NAME NAME

SIGNATURE SIGNATURE SIGNATURE SIGNATURE

DATE DATE DATE DATE

Form Code: TEP-.ITR-PIP-109

TEP-1247064- H03-0001 Page 36 of 56 Rev:02

870310-S-1247064-CST-H03-0001 BP Internal

Tangguh Expansion Project – LNG EPC

PT. Meindo – Quality Control Plan Endorsement For Piping Prefab & Erection

OWNER: BP Berau Ltd JOB UNIT

PLANT LOCATION: 870310

BINTUNI BAY,PAPUA - INDONESIA QC CODE ITP REFERENCE

PROJECT TITLE: PIP-0103-06M PIP-0103

TANGGUH EXPANSION PROJECT REPORT No. Sh of

SUBCONTRACTOR:

SCREWED PIPEWORK ERECTION INSPECTION REPORT

APPLICABLE SPEC. /

LINE No. REF. P&ID No. & Rev.

PROCEDURE No. & Rev.

MINIMUM ENGAGED THREADS

MAXIMUM EXPOSED THREADS

ISOMETRIC DRAWING No. Rev. JOINT ID No.

SEAL WELD

C NC C NC C NC NA REMARKS

C= CONFORMING NC= NOT CONFORMING NA=NOT APPLICABLE

NOTES: INSPECTION NOTIFICATION

REFERENCE

RFI No.: ____________________

Subcontractor QC CONTRACTOR COMPANY TPI

NAME NAME NAME NAME

SIGNATURE SIGNATURE SIGNATURE SIGNATURE

DATE DATE DATE DATE

Form Code:TEP-ITR-PIP-110

TEP-1247064- H03-0001 Page 37 of 56 Rev:02

870310-S-1247064-CST-H03-0001 BP Internal

Tangguh Expansion Project – LNG EPC

PT. Meindo – Quality Control Plan Endorsement For Piping Prefab & Erection

OWNER: BP Berau Ltd JOB UNIT

PLANT LOCATION: 870310

BINTUNI BAY,PAPUA - INDONESIA QC CODE ITP REFERENCE

PROJECT TITLE: PIP-0103-07M PIP-0103

TANGGUH EXPANSION PROJECT REPORT No. Sh of

SUBCONTRACTOR:

ORIFICE FLANGES INSTALLATION VISUAL INSPECTION REPORT

APPLICABLE SPEC. / PROCEDURE

LINE No. REF. P&ID No. & Rev.

No. & Rev.

PRESSURE TAPS ORIENTATION

INTERNAL GRINDING OF WELD ROOT

ORIFICE FLANGE ID

ISOMETRIC DRAWING No. Rev.

No.

SEAL WELD OF THREADED JOINTS

C NC C NC C NC NA REMARKS

C= CONFORMING NC= NOT CONFORMING NA=NOT APPLICABLE

NOTES: INSPECTION NOTIFICATION

REFERENCE

RFI No.: ____________________

Subcontractor QC CONTRACTOR COMPANY TPI

NAME NAME NAME NAME

SIGNATURE SIGNATURE SIGNATURE SIGNATURE

DATE DATE DATE DATE

Form Code: TEP-ITR-PIP-111

TEP-1247064- H03-0001 Page 38 of 56 Rev:02

870310-S-1247064-CST-H03-0001 BP Internal

Tangguh Expansion Project – LNG EPC

PT. Meindo – Quality Control Plan Endorsement For Piping Prefab & Erection

OWNER: BP Berau Ltd JOB UNIT

PLANT LOCATION: 870310

BINTUNI BAY,PAPUA - INDONESIA QC CODE ITP REFERENCE

PROJECT TITLE: PIP010308M PIP-0103

PIP010405M

TANGGUH EXPANSION PROJECT

SUBCONTRACTOR: REPORT No. Sh1 Of2

PIPING RELEASE FOR PRESSURE TEST REPORT

APPLICABLE SPEC. / PROCEDURE No. &

LINE No. / SECTION No. TEST PACKAGE No. & Rev.

Rev.

POS. FIELD WALKDOWN INSPECTION ITEMS DESCRIPTION YES NO NA REMARKS

1 TEST PACK VERIFICATION:

TEST DIAGRAM AVAILABILITY SHOWING THE FOLLOWING AS A MINIMUM:

A. LIMITS OF PIPING TO BE TESTED INCLUDING TEST MANIFOLD AND

EQUIPMENT INCLUDED IN THE TEST.

1.1 B. TEST PRESSURE OF THE SYSTEM

C. RELIEF VALVE SETTING D. SAFETY INSTRUCTION SHEET

D. PRESSURE TESTING PROCEDURE APPROVED

VERIFICATION OF WELD SUMMARY RECORD TO INDICATE COMPLETION OF ALL

1.2 WELD JOINTS.

APPLICABLE WELD INSPECTION (VISUAL AND NDE), POST WELD HEAT

1.3 TREATMENT, HARDNESS TEST COMPLETED.

TEST PRESSURE SENSITIVE PIPING COMPONENTS REMOVAL /

1.4 REINSTATEMENT LIST AVAILABLE

PRE-TEST PUNCH LISTING OF ON-PLOT PIPING AVAILABLE

1.5

TEMPORARY SPADES, PADDLES & BLINDS INSTALLATION LIST AVAILABLE

1.6

THE PRESSURE TESTING MANIFOLD IS SEPARATELY PRESSURE TESTED TO AT

LEAST 1.2 TIMES THE SYSTEM TEST PRESSURE BUT NOT LESS THAN THE

1.7 DISCHARGE PRESSURE OF THE PUMP USED FOR THE PRESSURE TESTING.

2 PIPING LINE WALKTHROUGH:

ON-PLOT PIPING LINE COMPLETELY ERECTED

2.1

PIPE RACK AND SLEEPERWAY SUPPORTS HAVE BEEN COMPLETELY ERECTED. SURVEYS

AND CHECKS BY INSPECTION ARE ACCEPTABLE. ADDITIONAL TEMPORARY SUPPORT MAY

2.2 BE INSTALLED AS REQUIRED

EXPANSION JOINTS AND SPRING HANGERS OR SPRING SUPPORTS ARE

2.3 PROVIDED WITH TEMPORARY RESTRAINTS.

BURIED PIPELINE ARE ADEQUATELY BERMED OR COVERED TO ANCHOR THE

2.4 LINE DURING PRESSURE TEST

ALL JOINTS (FLANGE, THREADED, WELDED OR MECHANICAL SEALS) ARE LEFT

EXPOSED FOR VISUAL LEAK DETECTION DURING THE PRESSURE TEST.

A) EXTERNAL COATING & PRIMING OF JOINTS IS ALLOWED ONLY IF

APPROVED BY INSP. DEPT. MGR & PROPONENT ORGANIZATION

2.5 REPRESENTATIVE.

B) THE PIPE ITSELF CAN BE EXTERNALLY PRIMED & COATED TO A FINAL

COAT.

2.6 DRAINS ARE PROVIDED AT ALL LOW POINTS OF THE PIPING SYSTEM

DRAINS ARE PROVIDED IMMEDIATELY ABOVE CHECK VALVES (VERTICAL

2.7 LINES)

VENTS AND DRAIN VALVES, BOTH TEMPORARY AND PERMANENT, CONFORMS

2.8 WITH THE PIPING CLASS OR RATING

ISOLATION VALVES ARE VERIFIED TO HAVE BEEN BODY AND/OR SEAT TESTED

2.9 PRIOR TO INSTALLATION THROUGH VERIFICATION OF FIELD TEST

CERTIFICATES

Form Code: ITR-PIP-112 ½

TEP-1247064- H03-0001 Page 39 of 56 Rev:02

870310-S-1247064-CST-H03-0001 BP Internal

Tangguh Expansion Project – LNG EPC

PT. Meindo – Quality Control Plan Endorsement For Piping Prefab & Erection

OWNER: BP Berau Ltd JOB UNIT

PLANT LOCATION: 870310

BINTUNI BAY,PAPUA - INDONESIA QC CODE ITP REFERENCE

PROJECT TITLE: PIP010308M PIP-0103

PIP010405M

TANGGUH EXPANSION PROJECT

REPORT No. Of2

SUBCONTRACTOR: Sh2

PIPING RELEASE FOR PRESSURE TEST REPORT

POS. FIELD WALKDOWN INSPECTION ITEMS DESCRIPTION YES NO NA REMARKS

ALL IN LINE VALVES THAT ARE NOT USED AS TEST ISOLATION

2.10 VALVES ARE IN OPEN POSITION (BALL VALVES IN HALF-OPEN

POSITION)

PERMANENT VENT AND DRAIN VALVES ARE IN OPEN POSITION

2.11

AFTER WATER FILLING AND AIR VENTING, AND PLUGGED.

FLAPPER/DISC OF CHECK VALVES IS REMOVED, UNLESS IT IS

2.12

FASTENED IN OPEN POSITION OR CHECK VALVE HAS BY-PASS

ALL PERMANENT FLANGE JOINTS ARE INSPECTED, GASKET MAT'L

VERIFIED & PROPERLY TIGHTENED

2.13

(VERIFICATION MADE THROUGH REVIEW OF FLANGE JOINT

INSPECTION REPORTS ITR-PIP-111).

2.14 PERMANENT GASKET COLOR CODE APPLIED

INSTALLED PROCESS INSTRUMENTS AND EQUIPMENT THAT MAY BE

2.15

DAMAGED BY THE STRENGTH TEST PRESSURE ARE DISCONNECTED

ARC STRIKES, GOUGES, AND OTHER INDICATIONS OF CARELESS

WORKMANSHIP (SUCH AS SURFACE POROSITY, UNEVEN WELD

2.16 PROFILES, AND UNDERCUT) SHALL BE REMOVED BY GRINDING AND

INSPECTED BY MAGNETIC PARTICLE OR LIQUID PENETRANT

METHOD.

TEMPORARY WELDED ATTACHMENTS TO THE PIPE WERE GROUND

2.17 OFF AND INSPECTED BY MAGNETIC PARTICLE OR LIQUID

PENETRANT METHOD.

PIPING SYSTEMS FLUSHED CLEAN OF LOOSE SCALE AND DEBRIS OR

2.18

SCRAPED PRIOR TO COMMENCEMENT OF PRESSURE TESTING.

NA=NOT APPLICABLE

PIPING RELEASED: YES NO

NOTES: INSPECTION NOTIFICATION

REFERENCE

Measuring devices S.N.:

RFI No.: ____________________

Subcontractor QC CONTRACTOR COMPANY TPI

NAME NAME NAME NAME

SIGNATURE SIGNATURE SIGNATURE SIGNATURE

DATE DATE DATE DATE

Form Code:TEP-ITR-PIP-112 2/2

TEP-1247064- H03-0001 Page 40 of 56 Rev:02

870310-S-1247064-CST-H03-0001 BP Internal

Tangguh Expansion Project – LNG EPC

PT. Meindo – Quality Control Plan Endorsement For Piping Prefab & Erection

OWNER: BP Berau Ltd JOB UNIT

PLANT LOCATION: 870310

BINTUNI BAY,PAPUA - INDONESIA QC CODE ITP REFERENCE

PIP010202M PIP-0103

PROJECT TITLE: PIP010309M

TANGGUH EXPANSION PROJECT PIP010405M

SUBCONTRACTOR: REPORT Sh of

No.

PRESSURE TEST REPORT

APPLICABLE SPEC. / PROCEDURE

LINE No. / SECTION No. TEST PACKAGE No. & Rev.

No. & Rev.

IDENTIFICATION OF TEST EQUIPMENT / INSTRUMENT USED

MODEL /

TEST EQUIPMENT / INSTRUMENT DESCRIPTION MAKE S/N

TYPE

PRESSURE TEST CHECK LIST

No. DESCRIPTION PASS FAIL N/A No. DESCRIPTION PASS FAIL N/A

TEST WATER

CONSTRUCTION JOINTS IN SYSTEM ARE

LABORATORY

EXPOSED INCLUDING ALL WELDS,

1 6 CHEMICAL ANALYSIS

FLANGES, THREADS

DONE.

APPROVAL OBTAINED

DISCS AND FLAPPERS REMOVED OR AND SAFETY

FASTENED IN OPEN POSITION ON CHECK PRECAUTIONS

2 VALVES 7 ENFORCED FOR

AIR/GAS TESTS

AN APPROVED

VENTS AND DRAINS INSTALLED BUBBLING SOLUTION

3 8 IS AVAILABLE

TEMPERATURE

EQUILIBRIUM

BLEED VALVE INSTALLED ESTABLISHED

4 9 BETWEEN TEST FLUID

AND SYSTEM

PRESSURE-TEMPERATURE RECORDER

5 INSTALLED

TYPE OF TEST

HYDROSTATIC PNEUMATIC

CATEGORY OF TEST

STRENGTH TEST TIGHTNESS TEST SERVICE TEST LEAK TEST

TEST PARAMETERS

SYSTEM DESIGN PRESSURE:

TYPE OF TEST FLUID: ____________________________

______________________

REQ.’D TEST PRESSURE:

TEST FLUID TEMPERATURE: ______________________

_________________________

TEST START: _____________ TEST FINISH:

AMBIENT TEMPERATURE: ________________________

_____________

SYSTEM DESIGN TEMPERATURE: _________________ ACTUAL HOLDING TIME: ________________

RESULTS

PRESSURE TEST: ACCEPTED REJECTED

NOTES: INSP. NOTIFICATION

REFERENCE

RFI No.:

____________________

Subcontractor QC CONTRACTOR COMPANY TPI

NAME NAME NAME NAME

SIGNATURE SIGNATURE SIGNATURE SIGNATURE

DATE DATE DATE DATE

Form Code: TEP-ITR-PIP-113

TEP-1247064- H03-0001 Page 41 of 56 Rev:02