Professional Documents

Culture Documents

Paving Edge (Curb) : CCCC Water Transportation Consultants Co - LTD

Uploaded by

Joel MontoyaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Paving Edge (Curb) : CCCC Water Transportation Consultants Co - LTD

Uploaded by

Joel MontoyaCopyright:

Available Formats

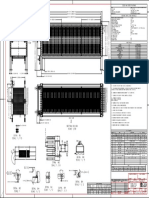

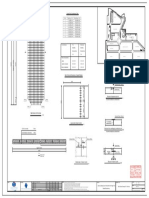

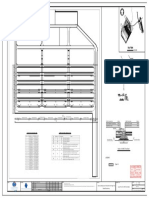

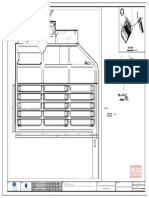

PAVING EDGE (CURB)

INSTRUCTION:

1. Quality standard of interlocking block pavement

1.1. The quality standards and allowable deviations of precast concrete interlocking blocks shall conform to

ASTM C936, BS 1338, BS 6717 and associated testing standards, and are listed as follows:

10

No. Item Quality standards and allowable deviations

10

Compressive Average ≥55

37.5

1 cube strength

(MPa) Minimum of single block ≥50

Average ≤5

2 Water absorption

(%) Minimum of single block ≤7

3 Thickness (mm) ±2

37.5

±1.6

112.5

4 Length and width (mm)

thickness loss≤3mm,

5 Average abrasion resistance 3 2

volume loss≤15cm/50cm

Penetration Not allowed

6 Crack(mm)

No penetration Not allowed

37.5

7 Layered Not allowed

8 Sticky surface(cm2) Not allowed

10

9 Tensile splitting strength(MPa) ≥3.6

10

10 Mean slip/skid resistance value(C scale units) ≥45

1.2. Bedding sand is medium-coarse sand and its gradation should conform to ASTM C33

10 10 10 10 with modification as shown in the following table

Sieve size (mm) 9.50 4.75 2.36 1.18 0.60 0.30 0.15 0.075

37.5 37.5 75 37.5 37.5

Percentage passing (%) 100 95~100 80~100 50~85 25~60 5~30 0~10 0~1

225

1.3. Joint sand is medium-fine sand and its gradation should conform to ASTM C144 with modification

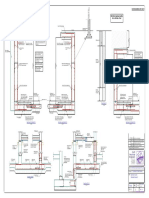

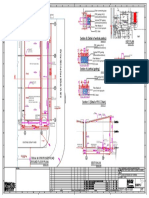

PLAN VIEW as shown in the following table

SKETCH PLAN OF PAVEMENT Sieve size(mm) 4.75 2.36 1.18 0.60 0.30 0.15 0.075

Percentage passing (%) 100 95~100 70~100 40~75 10~35 2~15 0~5

1.4. Construction quality control standard for interlocking block surface layer should conform with ICPI

Tech Specs 15

No. Item Allowable deviation (mm)

1 Elevation ≤6

2 Surface tolerance ±10mm over 3m

Chamfer 3 Elevation difference of adjacent block ±3

Chamfer 75 4 Straightness of joints ±15mm from a 15m straight line

5 Maximum joint width ≤5

3

3

2.Notes:

2.1. Construction of concrete paving blocks shall be in accordance with BS 7533.

2.2. Four concrete block samples will be tested per each 500m² of blocks.

2.3. After leveling according to the requirements of slope, interlocking blocks are paved on the sand cushion

80

80

which paved on the top of base and do not allowed to drive or stand on. Loose layering depth in the

77

77

construction should be determined by the test to ensure that the thickness of the interlocking block layer is

consistent with design value after vibrating compaction.

2.4. Interlocking block layer should be paved by sections from slope toe to slope ridge. The control line should

be drawn when laying, and the section length of the road and the border of the storage yard is appropriate for

5m.

2.5. After interlocking block is paved, the strong flat vibrator is applied to vibrate 2~3 times on the top surface,

but it is not allowed to vibrate in the 1m wide range of free side of pavement construction.

2.6. After compaction, the joints of interlocking block should be filled with medium-fine sand of which the water

content is less than 2%. During the construction, the sand sweep and the vibrating compaction should be arried

10 225 10

out 2~3 times alternately until the joints are filled with sand, and the remaining sand should be cleaned.

10 112.5 10 2.7. Testing for bedding sand and joint sand should also include primary properties and secondary properties as

listed in Table 4 of 2003 ICPI Tech Spec No.15.

2.8. Factory production control shall conform to BS EN 1338:2003 clause 6.3.

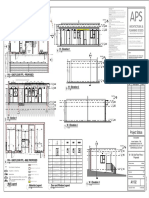

VERTICAL VIEW SIDE VIEW

0 ISSUED FOR CONSTRUCTION 2021-05-10 Zhang Yong Chang Zhanwei Wu Zhefeng NOTES: PROGECT: DRAWING TITLE: SCALE :

CLIENT: DESIGNER : A1: 1:1

F For Revision 2020-10-20 Zhang Yong Chang Zhanwei Wu Zhefeng 1.The dimensions are in millimeter. A3: 1:2

E For Revision 2020-09-21 Zhang Yong Chang Zhanwei Wu Zhefeng

D For Revision 2020-08-18 Zhang Yong Chang Zhanwei Wu Zhefeng Chancay Multipurpose Terminal New First Stage, Peru DATE :

C For Revision 2020-04-09 Zhang Yong Chang Zhanwei Wu Zhefeng Interlocking Block Structure Drawing 2021-05-10

中远海运港口秘鲁钱凯公司 2020-03-20 Zhang Yong Chang Zhanwei Wu Zhefeng Detailed Engineering

CCCC Water Transportation Consultants Co.Ltd B For Revision CODE : REVISION:

Rev. DESCRIPTION DATE BY. CKD. APD. AUD.

The Ports for ALL P114143-E-000-RY-DWG-025-R0 R0

REVISIONES

You might also like

- Instant Assessments for Data Tracking, Grade 5: Language ArtsFrom EverandInstant Assessments for Data Tracking, Grade 5: Language ArtsNo ratings yet

- P843 GEM Poster - JK CiDocument1 pageP843 GEM Poster - JK CiTsubasa OozoraNo ratings yet

- VS3120 Hardness Comparison Chart 12 2018Document1 pageVS3120 Hardness Comparison Chart 12 2018Emmanuel BonillaNo ratings yet

- Projeto CPD Splice - Rev 2Document1 pageProjeto CPD Splice - Rev 2GLOBAL SERVIÇOS ELÉTRICOSNo ratings yet

- RW Tew 22Document1 pageRW Tew 22Yong TonghannNo ratings yet

- WEG CFW500 Installation Guide Parameter Reference 10007479673 en Es PT ZHDocument12 pagesWEG CFW500 Installation Guide Parameter Reference 10007479673 en Es PT ZHRicardo LeiteNo ratings yet

- Torque-Tension Reference GuideDocument1 pageTorque-Tension Reference GuideJacob Sánchez67% (3)

- Brinell en Iso 6506 Vickers en Iso 6507 Rockwell en Iso 6508 Knoop en Iso 4545Document1 pageBrinell en Iso 6506 Vickers en Iso 6507 Rockwell en Iso 6508 Knoop en Iso 4545Son NguyenNo ratings yet

- Hse PlanDocument1 pageHse PlanClassic MatroNo ratings yet

- 2220-PW-6"-C1E2A-21269: Diametro Largo Total (M) ItemDocument1 page2220-PW-6"-C1E2A-21269: Diametro Largo Total (M) ItemAlonso FarfanNo ratings yet

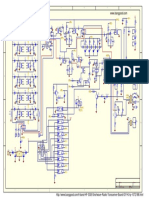

- SSB6 1-SchematicDocument1 pageSSB6 1-Schematicfox787867% (3)

- PE1007-00GAD10-XJ00-446302 Piping Isometrics - Rev 1Document1 pagePE1007-00GAD10-XJ00-446302 Piping Isometrics - Rev 1JOSUE FERNANDO FERNANDEZNo ratings yet

- Drawing - BasementDocument1 pageDrawing - BasementCanny EngineerNo ratings yet

- Installation & Owner'S Manual: EnglishDocument8 pagesInstallation & Owner'S Manual: EnglishAdilen A. NadlorNo ratings yet

- Carvin C-1644 4 Bussmaster Audio 2002 SCHDocument1 pageCarvin C-1644 4 Bussmaster Audio 2002 SCHAndres GuerreroNo ratings yet

- S001Document1 pageS001Yong Hui OngNo ratings yet

- Sec Aa: Staircase Details: 16 Ø at 180 C/C Starter BarsDocument1 pageSec Aa: Staircase Details: 16 Ø at 180 C/C Starter Barsnimish.aquamarineNo ratings yet

- PSK1-E0000-0000-DDI - Single Line Diagram-Rev-ADocument1 pagePSK1-E0000-0000-DDI - Single Line Diagram-Rev-AAsep SaepudinNo ratings yet

- Construction Material Testing Manual-1 PDFDocument112 pagesConstruction Material Testing Manual-1 PDFLalkiran Vadde100% (1)

- Ab-H-16 - Level 4 WestDocument1 pageAb-H-16 - Level 4 Westicas2017secaNo ratings yet

- BB BB: Code and SpecificationsDocument1 pageBB BB: Code and SpecificationsandersonNo ratings yet

- Detail-D RCC Cladding Wall CH-100+460-100+520: Produced by An Autodesk Student VersionDocument1 pageDetail-D RCC Cladding Wall CH-100+460-100+520: Produced by An Autodesk Student Versionrao shoaibNo ratings yet

- Digital HV 5KV Insulation Tester HTC 6250INDocument1 pageDigital HV 5KV Insulation Tester HTC 6250INindustrialindiaNo ratings yet

- RCC Slab Bridge Reconstruction 1X8.0 at 14+495-GADDocument1 pageRCC Slab Bridge Reconstruction 1X8.0 at 14+495-GADShivam SharmaNo ratings yet

- Sgebste1 21Document3 pagesSgebste1 21Ronnie1478No ratings yet

- Column Cleaning and Storage: Together, We Can Do MoreDocument1 pageColumn Cleaning and Storage: Together, We Can Do MoreAdjieDarmawanNo ratings yet

- LooooooooooooooouiDocument1 pageLooooooooooooooouirim deNo ratings yet

- Final Network DesignDocument1 pageFinal Network DesignAdam ThursbyNo ratings yet

- SPR3 en Tcd210147ad 20220704 Inst WDocument2 pagesSPR3 en Tcd210147ad 20220704 Inst WManel CoelloNo ratings yet

- Bdstde01 16 PDFDocument1 pageBdstde01 16 PDFAhmed HadeeNo ratings yet

- FX 400-2000 460V UL Electrical Diagram Montecchio 2205044709 Ed02Document1 pageFX 400-2000 460V UL Electrical Diagram Montecchio 2205044709 Ed02francisco jose arruda de sousaNo ratings yet

- Transformer /175W Line Safety Line: MotorDocument1 pageTransformer /175W Line Safety Line: Motororo plataNo ratings yet

- Darlington: Silicon PNP Epitaxial Planar Transistor (Complement To Type 2SD2439)Document1 pageDarlington: Silicon PNP Epitaxial Planar Transistor (Complement To Type 2SD2439)Elcio BrembattiNo ratings yet

- Bridge No.121Document1 pageBridge No.121RajeshNo ratings yet

- Truss - 1 Detail 2: A B C D E FDocument1 pageTruss - 1 Detail 2: A B C D E FPinunO kamoNo ratings yet

- Dimensions: (MM) Recommended Land Pattern: (MM) Electrical PropertiesDocument10 pagesDimensions: (MM) Recommended Land Pattern: (MM) Electrical PropertiesasadsadsadsaNo ratings yet

- Antipolo WaterlineDocument1 pageAntipolo WaterlineDang-dang Siggaoat-CopiacoNo ratings yet

- Canalización y AlimentadoresDocument9 pagesCanalización y AlimentadoresLEONEL VILCANo ratings yet

- Parts and Assemblies Simpson and Shipton Short Stroke Steam EngineDocument2 pagesParts and Assemblies Simpson and Shipton Short Stroke Steam EngineThanh VuNo ratings yet

- VFD-ED Quick Start EngDocument2 pagesVFD-ED Quick Start Engaba alzahraaNo ratings yet

- 1K2 PotDocument1 page1K2 PotcbsomtecladosNo ratings yet

- 60019gb8 PDFDocument6 pages60019gb8 PDFbnNo ratings yet

- 2sd2560 Ds enDocument1 page2sd2560 Ds enMarius IggyNo ratings yet

- Dicoat Punches: Products DataDocument1 pageDicoat Punches: Products Dataluis ortaNo ratings yet

- Rehabilitation and Expansion of Puntales Feeder Port: 10mmø Bars at 250Mm O.C.B.W. Serrated StepDocument1 pageRehabilitation and Expansion of Puntales Feeder Port: 10mmø Bars at 250Mm O.C.B.W. Serrated Stepalezandro del rossiNo ratings yet

- Eltek FP2 схемаDocument1 pageEltek FP2 схемаDmiNo ratings yet

- Report Akreditasi Batch MBT in Branch Batch 124 2024-04-04 08 48 26Document2 pagesReport Akreditasi Batch MBT in Branch Batch 124 2024-04-04 08 48 26Muhammad Agung PratamaNo ratings yet

- AS15001CDocument3 pagesAS15001Cjeniful jenifulNo ratings yet

- Darlington: Silicon PNP Epitaxial Planar Transistor (Complement To Type 2SD2642)Document1 pageDarlington: Silicon PNP Epitaxial Planar Transistor (Complement To Type 2SD2642)Migue Rodriguez RamirezNo ratings yet

- X8DAH+-F-LR-F-LR Quick Reference GuideDocument1 pageX8DAH+-F-LR-F-LR Quick Reference GuidenwortelNo ratings yet

- AB A1 001 R1 Ground FLoor Plan& SectionsDocument1 pageAB A1 001 R1 Ground FLoor Plan& Sectionsrohit guptaNo ratings yet

- 2sc4140 Ds enDocument1 page2sc4140 Ds enAdah BumboneNo ratings yet

- PE1007-00GAD10-XJ00-446303 Piping Isometrics - Rev 1Document1 pagePE1007-00GAD10-XJ00-446303 Piping Isometrics - Rev 1JOSUE FERNANDO FERNANDEZNo ratings yet

- S1Document1 pageS1Hailley DensonNo ratings yet

- 2SC3263 en 10044835Document2 pages2SC3263 en 10044835Janos NagyNo ratings yet

- Mitutoyo Hardness Tester-Symbols and ChartDocument1 pageMitutoyo Hardness Tester-Symbols and ChartAdithya PrabhasNo ratings yet

- Detail-D RCC Cladding Wall CH-100+460-100+520: Produced by An Autodesk Student VersionDocument1 pageDetail-D RCC Cladding Wall CH-100+460-100+520: Produced by An Autodesk Student Versionrao shoaibNo ratings yet

- 12.15.1 Plano de Red de Distribucion-Ap-01Document1 page12.15.1 Plano de Red de Distribucion-Ap-01Dick GuiliansNo ratings yet

- As Built - CP Drawing For Well Head AreaDocument1 pageAs Built - CP Drawing For Well Head AreaMohammed HijaziNo ratings yet

- Ec 00000 31346 010 - 1Document1 pageEc 00000 31346 010 - 1wilsonNo ratings yet

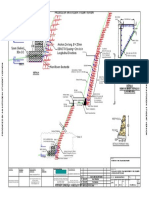

- Slab Division Drawing For For Extension Road Extension RoadDocument1 pageSlab Division Drawing For For Extension Road Extension RoadJoel MontoyaNo ratings yet

- CCCC Water Transportation Consultants Co - LTD: Steel Railing Structure DrawingDocument1 pageCCCC Water Transportation Consultants Co - LTD: Steel Railing Structure DrawingJoel MontoyaNo ratings yet

- Key Plan: Chancay Multipurpose Terminal New First Stage, Peru Detailed Engineering Layout Plan For Curb of ZOP AreaDocument1 pageKey Plan: Chancay Multipurpose Terminal New First Stage, Peru Detailed Engineering Layout Plan For Curb of ZOP AreaJoel MontoyaNo ratings yet

- Package Number 1: No. Specification Unit Observation Steel Plate QuantityDocument1 pagePackage Number 1: No. Specification Unit Observation Steel Plate QuantityJoel MontoyaNo ratings yet

- Key Plan: Control Point Coordinates TableDocument1 pageKey Plan: Control Point Coordinates TableJoel MontoyaNo ratings yet

- Trans-Isand To Tunnel Road: CCCC Water Transportation Consultants Co - LTDDocument1 pageTrans-Isand To Tunnel Road: CCCC Water Transportation Consultants Co - LTDJoel MontoyaNo ratings yet

- CCCC Water Transportation Consultants Co - LTD: Designer: Project: Drawing Title: Scale: Client: NotesDocument1 pageCCCC Water Transportation Consultants Co - LTD: Designer: Project: Drawing Title: Scale: Client: NotesJoel MontoyaNo ratings yet

- Control Point Coordinates Table: CCCC Water Transportation Consultants Co - LTDDocument1 pageControl Point Coordinates Table: CCCC Water Transportation Consultants Co - LTDJoel MontoyaNo ratings yet

- CCCC Water Transportation Consultants Co - LTD: Designer: Project: Drawing Title: Scale: Client: NotesDocument1 pageCCCC Water Transportation Consultants Co - LTD: Designer: Project: Drawing Title: Scale: Client: NotesJoel MontoyaNo ratings yet

- Contenedor Vacío / Pesado y OGG: CCCC Water Transportation Consultants Co - LTDDocument1 pageContenedor Vacío / Pesado y OGG: CCCC Water Transportation Consultants Co - LTDJoel MontoyaNo ratings yet

- Plano Clave: Chancay Multipurpose Terminal New First Stage, Peru Detailed Engineering Layout Plan For Curb of CI AreaDocument1 pagePlano Clave: Chancay Multipurpose Terminal New First Stage, Peru Detailed Engineering Layout Plan For Curb of CI AreaJoel MontoyaNo ratings yet

- Key Plan: Section of A-RMG Track BeamDocument1 pageKey Plan: Section of A-RMG Track BeamJoel MontoyaNo ratings yet

- Key Plan: LegendDocument1 pageKey Plan: LegendJoel MontoyaNo ratings yet

- Elevation: CCCC Water Transportation Consultants Co - LTDDocument1 pageElevation: CCCC Water Transportation Consultants Co - LTDJoel MontoyaNo ratings yet

- Índice Área de Mantenimiento de Patio de Contenedores: Horizonte 1: 100Document1 pageÍndice Área de Mantenimiento de Patio de Contenedores: Horizonte 1: 100Joel MontoyaNo ratings yet

- CCCC Water Transportation Consultants Co - LTD: Designer: Project: Drawing Title: Scale: Client: NotesDocument1 pageCCCC Water Transportation Consultants Co - LTD: Designer: Project: Drawing Title: Scale: Client: NotesJoel MontoyaNo ratings yet

- Elevation: CCCC Water Transportation Consultants Co - LTDDocument1 pageElevation: CCCC Water Transportation Consultants Co - LTDJoel MontoyaNo ratings yet

- Key Plan: LegendDocument1 pageKey Plan: LegendJoel MontoyaNo ratings yet

- Elevation: CCCC Water Transportation Consultants Co - LTDDocument1 pageElevation: CCCC Water Transportation Consultants Co - LTDJoel MontoyaNo ratings yet

- Type 1 Type 2 Type 3: Pavement AreasDocument1 pageType 1 Type 2 Type 3: Pavement AreasJoel MontoyaNo ratings yet

- Key Plan: LegendDocument1 pageKey Plan: LegendJoel MontoyaNo ratings yet

- Key Plan: CB1 CB2 CB1 CB1 CB2 CB1 CB1 CB2 CB1Document1 pageKey Plan: CB1 CB2 CB1 CB1 CB2 CB1 CB1 CB2 CB1Joel MontoyaNo ratings yet

- CCCC Water Transportation Consultants Co - LTD: Designer: Project: Drawing Title: Scale: Client: NotesDocument1 pageCCCC Water Transportation Consultants Co - LTD: Designer: Project: Drawing Title: Scale: Client: NotesJoel MontoyaNo ratings yet

- Cable Slot Through TrenchlokDocument1 pageCable Slot Through TrenchlokJoel MontoyaNo ratings yet

- Intze TankDocument20 pagesIntze Tankrascad111No ratings yet

- ASHRAE Basement VentilationDocument6 pagesASHRAE Basement VentilationRohit VermaNo ratings yet

- Isolated Footing - 02Document22 pagesIsolated Footing - 02SS INFRAZONENo ratings yet

- Structural Mechanics Tutorial 1Document3 pagesStructural Mechanics Tutorial 1Rajkamal AroraNo ratings yet

- Design Analysis and Optimization of Offshore ModuleDocument116 pagesDesign Analysis and Optimization of Offshore ModuleMirceaNo ratings yet

- Low Speed Aerodynamics: by Jackie BerryDocument12 pagesLow Speed Aerodynamics: by Jackie Berrymkashkooli_scribdNo ratings yet

- Macro & Mini PilesDocument1 pageMacro & Mini PilesAnonymous JZFSB3D0% (1)

- Knauf GifafloorDocument4 pagesKnauf GifafloorRichard Aldeen VerzosaNo ratings yet

- Drymet LFDocument6 pagesDrymet LFHenrique SantosNo ratings yet

- BOQDocument37 pagesBOQKota Rajesh ReddyNo ratings yet

- HVAC Absorption Chillers Vs Electric ChillersDocument8 pagesHVAC Absorption Chillers Vs Electric ChillersOcchitya MudgalNo ratings yet

- 2R SquatDocument11 pages2R SquatInsan Ahammad100% (1)

- Nib CalculationDocument1 pageNib CalculationKen LuuNo ratings yet

- Properties of Philippine Woods LoadsDocument2 pagesProperties of Philippine Woods LoadsJoshua VicenteNo ratings yet

- Advanced Earthquake Resistant DesignDocument17 pagesAdvanced Earthquake Resistant Designraju619No ratings yet

- Water 15 03288Document18 pagesWater 15 03288amirsabry4.10No ratings yet

- Mini Chiller Daikin UALDocument34 pagesMini Chiller Daikin UALBismar wafiqNo ratings yet

- Part 5 Soil Report ADocument15 pagesPart 5 Soil Report Ashashirajhans2140No ratings yet

- Module 1 Introduction To Civil EngineeeringDocument6 pagesModule 1 Introduction To Civil EngineeeringMadhavan SowrirajanNo ratings yet

- CofferdamDocument46 pagesCofferdamPreeti 1026100% (1)

- Plandoc 22 3465Document1 pagePlandoc 22 3465mohdnazirNo ratings yet

- Slab Manual DesignDocument1 pageSlab Manual DesignAtul ShrivastavaNo ratings yet

- UPVC DOORS & WINDOW NewDocument14 pagesUPVC DOORS & WINDOW NewRUSHALI SRIVASTAVANo ratings yet

- 1 Stress & StrainsDocument55 pages1 Stress & StrainsTechnautsNo ratings yet

- Perencanaan HVAC LaboratoriumDocument38 pagesPerencanaan HVAC Laboratoriumheru sutonoNo ratings yet

- Precast BrochureDocument12 pagesPrecast BrochureNicholasOmodingNo ratings yet

- Longmeadow Rail Crossing Diagnostic Review, May 2017Document3 pagesLongmeadow Rail Crossing Diagnostic Review, May 2017Greg SaulmonNo ratings yet

- RCE076 Railways, Airports & Water WaysDocument2 pagesRCE076 Railways, Airports & Water WaysShubham Kesarwani50% (2)

- Lecture 3 Constative Models (Plaxis) PDFDocument119 pagesLecture 3 Constative Models (Plaxis) PDFMohamed OudaNo ratings yet