Professional Documents

Culture Documents

9323a262g Data

9323a262g Data

Uploaded by

LIONN ONESOLUTIONOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

9323a262g Data

9323a262g Data

Uploaded by

LIONN ONESOLUTIONCopyright:

Available Formats

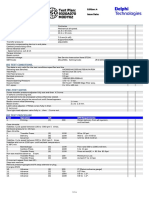

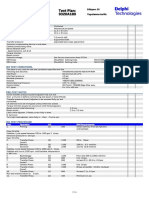

9323A260 Issue No: 5

Test Plan

JCB 68.5 KW @ 2200 RPM (TC) Date: 00/00/00

PUMP SPECIFICATION

Rotation: Anti-Clockwise.

Governor type: Mechanical all-speed.

Gov. Link Length: 41.5 ± 0.5 mm.

Gov. Link Length: 10.1 ± 0.5 mm.

(DP210 Workshop Manual Section 4.6.4)

Plunger Diameter: 7.0 mm (4 off).

Drive Type: Supported shaft.

Transfer pressure: adjustable.

Viscosity compensating device in end plate.

Cambox pressurising valve.

Servo Advance with:

- Speed advance, LLA & CA

Torque trimmer.

Boost control.

Solenoid voltage: See Service Instruction Note DT294.

OEM Code: 320/06738 Setting Code: .......

OEM Code: 320/06754 Setting Code: ....

ISO TEST CONDITIONS.

This data is only valid for the test conditions specified and the

following test benches: HA3000/HA2500/HA700/AVM/PGM

Test Fluid: ISO 4113 at 40 ± 2°C.

Inlet feed pressure: 5.0 psi

Backleak pressure: 0.0 psi

Nozzles: YDB286 (BDL0S6844)

Nozzle Opening Pressure: 172 + 3 - 0 bar.

Nozzle Holder: ISO 7440 + YDB288 Edge filter assy.

H.P. pipes: 6 x 1.8 x 450 mm

PRE-TEST NOTES

Screw transfer pressure adjuster fully in and then 4.0 turns

out before commencing test

CA solenoid to be de-energised unless otherwise stated.

Torque trimmer plug to be wound out until thread appears.

Boost control initial shimming: 0.5 mm.

Boost stroke : 2.9 to 3.1 mm.

Latch valve adjuster, if fitted, screw fully in then

8 turns out

Turn light load adjuster valve fully in ,then 2 turns out.

ISO TEST PROCEDURE

Test Operation S/C RPM Requirements

1. Priming (C) 200 Obtain delivery from all injectors

and backleak.

Close throttle.

Stabilise. Cycle speed between 100 to 400 rpm 3 times.

Open throttle.

Set boost pressure to 15.0 psi.

2. Transfer Press. (S) 1100 84 to 86 psi

3. Delivery (S) 1150 84.3 ± 0.5 mm3/st.

4. Governor (S) 1280 12.0 to 16.0 mm3/st.

Stabilise. Cycle speed between 100 to 1260 rpm 2 times.

Stabilise and run at 1150 rpm until backleak temperature

is 38°C min.

5. Backleakage (C) 1100 Flow rate 450 to 950 cm3/min.

6. Cambox Press. (C) 1100 6 to 11 psi.

7. Transfer Press. (S) 1100 Press at test(6 ) + 78to 79psi

Run test machine down to 0 rpm.

8. Transfer Press. (C) 100 Minimum 12 psi.

9. Transfer Press (C) 1100 As test (7 ) ± 1.0 psi

If incorrect repeat from test (6 ).

Stop test machine.

Remove pressure gauges and fit stop solenoid or plug.

10. Advance (S) 500 0° (Datum advance gauge)

11. Advance (C) 750 0.5° Max.

12. Advance (C) 1050 1.8 to 2.2°.

13. Advance (C) 1100 1.8 to 2.2°.

Stop test machine.

Energise CA solenoid.

14. Advance (C) 700 7.0 to 9.5°.

De-energise CA solenoid.

15. Advance - (S) 1100 4.8to 5.2° 36.0to 40.0mm3/st.

Light load Adjust throttle/torque screw

& LLA valve.

Run test machine down to 0 rpm.

16. Advance - (C) 1100 4.8to 5.2° 38.0 ± 2.0mm3/st.

Light load Use throttle/Torque screw.

17. Advance - (C) 1100 1.0to 4.0° 51.5 ± 1.5mm3/st.

Light load Use throttle/Torque screw.

18. Advance - (C) 1100 7.3to 7.7° 30.0 ± 7.0mm3/st.

Light load Use throttle/Torque screw.

19. Advance - (C) 650 1.8to 2.2° 53.0 ± 8.0mm3/st.

Light load Use throttle/Torque screw.

Open throttle.

Stop test machine.

Fit CPS tool

Set boost pressure to 15.0 psi.

20. Torque Trimmer (S) 1200 Datum CPS reading to 0.0mm.

21. Torque Trimmer (S) 550 Adjust CPS to 0.05 to 0.15mm

CPS

22. Torque Trimmer (S) 640 Adjust CPS to -0.48 to -0.52mm

CPS

Run test machine down to 0 rpm.

23. Torque Trimmer (C) 1250 As test (20) ± 0.05 mm

CPS

24. Torque Trimmer (C) 700 Check CPS is -0.7 to -1.5mm

CPS

25. Torque Trimmer (C) 450 Check CPS is 0.8 to 1.6mm

CPS

26. Torque Trimmer (C) 1200 As test (23) ± 0.2 mm

CPS

Set boost pressure to zero.

27. Torque Trimmer (C) 1200 Check CPS is 1.8 to 2.4mm

CPS

Set boost pressure to 5.5 psi.

28. Torque Trimmer (C) 1200 As test (26) ± 0.2 mm

CPS

Set boost pressure to 1.0 psi.

29. Torque Trimmer (C) 1200 As test (27) ± 0.2 mm

CPS

Set boost pressure to zero.

Screw latch valve adjuster fully in.

30. Latch Valve S/C 260 CPS = 2.5 to 4.5 mm

If incorrect, adjust LV pre-load

& repeat test.

Run test machine down to 0 rpm.

31. Torque Trimmer (C) 220 Check CPS is -0.5 to -2.5mm

CPS

32. Torque Trimmer (C) 280 Check CPS is 2.5 to 4.5mm

CPS

If incorrect or adjusted, stop machine and repeat from test (30).

33. Delivery (C) 100 Minimum 75.0 mm3/st.

34. Shut-off - (C) 500 De-energise solenoid, wait 5 seconds.

Solenoid Max. 2.0 mm3/st.

Stop test machine.

Energise ESOS

Close throttle.

35. Idle delivery (S) 420 12.0 to 16.0 mm3/st. Throttle closed.

36. Delivery (C) 540 Maximum 3.0 mm3/st.

Stop test machine.

Fit Max Fuel adjuster tool

Open throttle.

Set boost pressure to 15.0 psi.

37. Max. Delivery (S) 1150 84.3 ± 0.3 mm3/st.

Max. spread 5.0 mm3/st.

38. Delivery (C) 700 As test (37) + 9 ± 3 mm3/st.

39. Delivery (C) 1150 As test (37) ± 1.0 mm3/st.

Set boost pressure to zero.

40. Delivery (C) 1200 As test (39) - 13.0 ± 5.0 mm3/st.

Set boost pressure to 15.0 ± 0.5 psi.

41. Dynamic timing Refer to SIN DT339

Piezo sensor, outlet U

Off-set angle 274.0°

speed (S) 1150 Trigger level 25 %

42. Delivery (C) 1100 Record delivery mm3/st.

43. Governor (S) 1235 12.0 to 16.0 mm3/st.

44. Gov. cut-off (C) 1320 Maximum 3.0 mm3/st.

45. Delivery (C) 1100 Throttle as test (43).

Minimum as test (42) - 1.0 mm3/st.

.

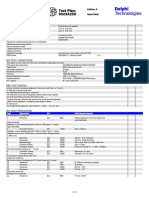

ISO OVERCHECK PROCEDURE

.

The Overcheck section of this plan has been developed in

conjunction with the Original Equipment Manufacturer.

Providing all values are achieved, the pump settings will

maintain the original homologated engine performance. Failure to

attain any one of the values will indicate a pump setting or

function failure and require further investigation.

.

PRE-OVERCHECK NOTES

Dynamic timing - record zero angle - (refer to DT339)

Drive shaft lock bolt to remain locked until zero angle

recorded.

CA advance motor to be de-energised unless otherwise stated.

No adjustments to be made unless otherwise stated.

Close throttle.

Stabilise. Cycle speed between 100 to 500 rpm 3 times.

Set boost pressure to 15.0 psi.

Open throttle.

Stabilise. Cycle speed between 100 to 1280 rpm 5 times.

Stabilise and run at 1100 rpm until backleak temperature

is 38°C min.

46. Gov. cut-off (C) 1320 Maximum 3.0 mm3/st.

Fully unscrew the Maximum speed adjusting screw.

47. Advance (S) 500 0° (Datum advance gauge)

48. Advance (C) 1100 1.7 to 2.3°.

49. Advance (C) 750 0.7° Max.

50. Advance - (C) 1100 4.8to 5.2° 38.0 ± 4.0mm3/st.

Light load Use throttle/Torque screw.

51. Advance - (C) 1100 7.3to 7.7° 30.0 ± 9.0mm3/st.

Light load Use throttle/Torque screw.

52. Advance - (C) 650 1.8to 2.2° 53.0 ± 10mm3/st.

Light load Use throttle/Torque screw.

Stop test machine.

Energise CA solenoid.

53. Advance (C) 700 6 to 10°.

De-energise CA solenoid.

Open throttle.

Fit CPS tool

Set boost pressure to 15.0 psi.

54. Torque Trimmer (S) 1150 Datum CPS reading to 0.0mm.

55. Torque Trimmer (C) 725 Check CPS is -0.7 to -1.5mm

CPS

56. Torque Trimmer (C) 425 Check CPS is 0.8 to 1.6mm

CPS

Set boost pressure to zero.

57. Torque Trimmer (C) 1150 As test (54) + 2.1 ± 0.4 mm

CPS

Close throttle.

58. Delivery (C) 540 Maximum 3.0 mm3/st.

Open throttle.

59. Delivery (C) 100 Minimum 75.0 mm3/st.

60. Shut-off - (C) 500 De-energise solenoid, wait 5 seconds.

Solenoid Max. 3.0 mm3/st.

Run test machine down to 0 rpm.

Energise ESOS

Set boost pressure to 15.0 psi.

61. Delivery (C) 1100 81.0 to 87.0 mm3/st.

62. Delivery (C) 700 As test (61) + 9.0 ± 4.0 mm3/st.

63. Dynamic timing Refer to SIN DT339

Piezo sensor, outlet U

Off-set angle 274.0°

speed (S) 1150 Trigger level 25 %

64. Delivery (C) 1100 Record delivery mm3/st.

65. Governor (S) 1235 12.0 to 16.0 mm3/st.

66. Gov. cut-off (C) 1320 Maximum 3.0 mm3/st.

67. Delivery (C) 1100 Throttle as test (65).

Minimum as test (64) - 1.0 mm3/st.

You might also like

- Ram PickupDocument27 pagesRam PickupFelix50% (4)

- Manual de Taller Mazda Serie B b2500 Con Motor WLDocument118 pagesManual de Taller Mazda Serie B b2500 Con Motor WLIgnacio Schwerter100% (3)

- Sample Preventative Maintenance Inspection Sheet: Fixed Route Vehicle InspectionDocument4 pagesSample Preventative Maintenance Inspection Sheet: Fixed Route Vehicle InspectionVin BdsNo ratings yet

- CG932H Chenggong or Hakata Parts CatalogDocument252 pagesCG932H Chenggong or Hakata Parts CatalogJoemar Revelo100% (3)

- Manual Nissan Murano 2010Document134 pagesManual Nissan Murano 2010Jorge Vargas100% (2)

- Brake Work Sheet 1Document2 pagesBrake Work Sheet 1VimleshNo ratings yet

- 9521A030H DATA CatalogDocument3 pages9521A030H DATA CatalogLIONN SOFTWARES100% (1)

- 9521A030H DATA CatalogDocument3 pages9521A030H DATA CatalogLIONN SOFTWARES100% (1)

- Test Plan: 9320A070 MODY02: Pump SpecificationDocument7 pagesTest Plan: 9320A070 MODY02: Pump SpecificationUserfabian215No ratings yet

- Test Plan: 9320A210: Pump Specification Iso Test ProcedureDocument3 pagesTest Plan: 9320A210: Pump Specification Iso Test ProcedureBaytolga100% (1)

- Test Plan: 9320A210: Pump SpecificationDocument7 pagesTest Plan: 9320A210: Pump SpecificationBaytolgaNo ratings yet

- Delphi 9322a000Document5 pagesDelphi 9322a000BaytolgaNo ratings yet

- Test Plan Delphi TechnologiesDocument2 pagesTest Plan Delphi TechnologiesFRANCISCONo ratings yet

- 3042f843 Plano de TesteDocument1 page3042f843 Plano de TesteJose Alexandre Sunhega100% (1)

- Das q50Document621 pagesDas q50alex100% (1)

- 3239F592TDocument2 pages3239F592TAnderson London67% (3)

- Test Plan: 8923A050: Pump SpecificationDocument2 pagesTest Plan: 8923A050: Pump Specificationveshat100% (1)

- 6T40-Vac Test LocationsDocument4 pages6T40-Vac Test LocationsPedroMecanico100% (4)

- 8520A060A TestplanDocument2 pages8520A060A TestplanBaytolga can100% (1)

- 928F 2XL PDFDocument2 pages928F 2XL PDFCarolina GilNo ratings yet

- 9320a075g Test DataDocument4 pages9320a075g Test DataPedro AbellanNo ratings yet

- Test Plan: Pump SpecificationDocument3 pagesTest Plan: Pump SpecificationBaytolgaNo ratings yet

- 9320a217 TabelaDocument4 pages9320a217 TabelaLIONN SOFTWARESNo ratings yet

- 9320a217 TabelaDocument4 pages9320a217 TabelaLIONN SOFTWARESNo ratings yet

- Basf Total Fluid Management enDocument12 pagesBasf Total Fluid Management enapi-233668671No ratings yet

- Test Plan: Pump SpecificationDocument4 pagesTest Plan: Pump SpecificationBaytolgaNo ratings yet

- Test Plan: 9521A030: Pump SpecificationDocument3 pagesTest Plan: 9521A030: Pump Specificationjohnny sabinNo ratings yet

- 7fbe10-20 (1) 303Document8 pages7fbe10-20 (1) 303johnNo ratings yet

- Bomba Dpa 3340f371g - TesteDocument2 pagesBomba Dpa 3340f371g - TesteOseasJuniorNo ratings yet

- 9520A192G - PlanDocument3 pages9520A192G - PlanMihai-Eugen Popa100% (1)

- 3349F330Document2 pages3349F330marco rod100% (1)

- Injection Pump Specification ©Document4 pagesInjection Pump Specification ©LIONN SOFTWARESNo ratings yet

- 9323a251g PTDocument3 pages9323a251g PTClarice Alves de FreitasNo ratings yet

- 9320A093GDocument4 pages9320A093GKevin TtitoNo ratings yet

- 9323A271G CatalogDocument8 pages9323A271G CatalogLIONN SOFTWARESNo ratings yet

- 3340F401G Plano de Teste DelphiDocument2 pages3340F401G Plano de Teste DelphiJunior Iung100% (1)

- Test Plan: 9320A530: Pump SpecificationDocument4 pagesTest Plan: 9320A530: Pump SpecificationVyacheslav ShatalovNo ratings yet

- 9320a225g Plano LHDocument3 pages9320a225g Plano LHForteLubNo ratings yet

- 9320A020GDocument6 pages9320A020GBaytolgaNo ratings yet

- Ambra-Akcela Oil Specs PDFDocument1 pageAmbra-Akcela Oil Specs PDFJUNA RUSANDI S100% (1)

- 8920A360 - New Holland 7740 TractorDocument13 pages8920A360 - New Holland 7740 TractorBaytolgaNo ratings yet

- Toyota QuestionnaireDocument5 pagesToyota QuestionnairePanit Poonsuwan75% (4)

- 9320A185H TestplanDocument4 pages9320A185H TestplanBaytolga canNo ratings yet

- 9520a950 Lionn Auto SoftwaresDocument4 pages9520a950 Lionn Auto SoftwaresLIONN SOFTWARESNo ratings yet

- 9320A380 TestDocument4 pages9320A380 TestVyacheslav ShatalovNo ratings yet

- TP 9320a210gDocument4 pagesTP 9320a210gVyacheslav ShatalovNo ratings yet

- 823A593T DATA CatalogDocument2 pages823A593T DATA CatalogMilanNo ratings yet

- 8961A020WDocument2 pages8961A020WLTurboNo ratings yet

- Test Plan: 3349330: Pump SpecificationDocument2 pagesTest Plan: 3349330: Pump SpecificationLIONN SOFTWARESNo ratings yet

- Test Plan: Pump SpecificationDocument2 pagesTest Plan: Pump SpecificationClarice Alves de FreitasNo ratings yet

- Testplan 3239590Document2 pagesTestplan 3239590Fx_2050% (1)

- 8921A091WDocument2 pages8921A091WLTurboNo ratings yet

- 9320A070GDocument7 pages9320A070GBaytolgaNo ratings yet

- Testplan 9521A330TDocument3 pagesTestplan 9521A330TMilanNo ratings yet

- 8924A141WDocument2 pages8924A141WLTurboNo ratings yet

- Test Plan: Pump SpecificationDocument2 pagesTest Plan: Pump SpecificationClarice Alves de FreitasNo ratings yet

- Test Plan: Pump SpecificationDocument2 pagesTest Plan: Pump Specificationmecanik.veracruzNo ratings yet

- 3230f582T PTDocument2 pages3230f582T PTHeitor Gael Alves de FreitasNo ratings yet

- 3340F322 Lionn Auto SoftwaresDocument2 pages3340F322 Lionn Auto SoftwaresLIONN ONESOLUTIONNo ratings yet

- TestplanDocument3 pagesTestplanGiorgio Di CesareNo ratings yet

- 3662F871 TablaDocument1 page3662F871 TablaLIONN SOFTWARESNo ratings yet

- Testplan 3238360Document1 pageTestplan 3238360Fx_205No ratings yet

- Test Plan 8523a320Document2 pagesTest Plan 8523a320taniaNo ratings yet

- 8550A223ADocument2 pages8550A223ALTurboNo ratings yet

- 9322A010Document5 pages9322A010BaytolgaNo ratings yet

- Test Plan: 8522A130: Pump SpecificationDocument2 pagesTest Plan: 8522A130: Pump SpecificationJose Alexandre SunhegaNo ratings yet

- Test Plan 8925A150Document2 pagesTest Plan 8925A150MilanNo ratings yet

- 821A661X DATA CatalogDocument2 pages821A661X DATA CatalogMilanNo ratings yet

- 3249F532 TabelaDocument1 page3249F532 TabelaLIONN SOFTWARESNo ratings yet

- 8520A020A TestplanDocument2 pages8520A020A TestplanBaytolga canNo ratings yet

- 8443A260EDocument2 pages8443A260EMiguel ChaconNo ratings yet

- 3042F331 DATA CatalogDocument2 pages3042F331 DATA CatalogMilanNo ratings yet

- Test Plan 3340f370gDocument1 pageTest Plan 3340f370gLIONN SOFTWARESNo ratings yet

- Testplan 3242920Document1 pageTestplan 3242920Fx_205No ratings yet

- 3230F250 DATA CatalogDocument1 page3230F250 DATA CatalogLIONN TESTE2021No ratings yet

- Testplan 3343010Document1 pageTestplan 3343010Fx_205No ratings yet

- 0 400 075 995 Pag1Document1 page0 400 075 995 Pag1LIONN SOFTWARESNo ratings yet

- 0 400 075 995 Pag2Document1 page0 400 075 995 Pag2LIONN SOFTWARESNo ratings yet

- TABELADocument4 pagesTABELALIONN SOFTWARESNo ratings yet

- Test Plan 3340f370gDocument1 pageTest Plan 3340f370gLIONN SOFTWARESNo ratings yet

- PAG1Document1 pagePAG1LIONN SOFTWARESNo ratings yet

- 0460494032Document1 page0460494032LIONN SOFTWARESNo ratings yet

- 9521A300T Parts CatalogDocument7 pages9521A300T Parts CatalogLIONN SOFTWARESNo ratings yet

- 7050Document7 pages7050LIONN SOFTWARESNo ratings yet

- Parts List 3717Document2 pagesParts List 3717LIONN SOFTWARESNo ratings yet

- 3239F600 DataDocument2 pages3239F600 DataLIONN SOFTWARESNo ratings yet

- The Mercedes Amg SL 43 Roadster BrochureDocument20 pagesThe Mercedes Amg SL 43 Roadster Brochurerudhrudy714No ratings yet

- Goodyear's Radial Tyre For Wheel Loaders and Graders.: The Goodyear RT-3BDocument2 pagesGoodyear's Radial Tyre For Wheel Loaders and Graders.: The Goodyear RT-3BRasoolKhadibiNo ratings yet

- The Engine With Integrated Water Cooling TAD734GE: Green Power Volvo Diesel EngineDocument4 pagesThe Engine With Integrated Water Cooling TAD734GE: Green Power Volvo Diesel Enginehonafa- R.O.N.ONo ratings yet

- Atlas Copco Rental: 100% Oll-Free Air Compressor Diesel DrivenDocument1 pageAtlas Copco Rental: 100% Oll-Free Air Compressor Diesel DrivenpowermanagerNo ratings yet

- VM Motori MR700 Manual en PDFDocument62 pagesVM Motori MR700 Manual en PDFZarul AshraffNo ratings yet

- Seminar Report On Disc Brake: Submitted byDocument34 pagesSeminar Report On Disc Brake: Submitted bySouraj PatelNo ratings yet

- Briggs and Stratton 133412 - 0059 01 PartsMan (EN)Document31 pagesBriggs and Stratton 133412 - 0059 01 PartsMan (EN)Gisell ZapataNo ratings yet

- Actuators and Output DevicesDocument59 pagesActuators and Output DevicesvishnusankarNo ratings yet

- This Kit Is The Flybarless Version of The Kasama Srimok 90 ElectricDocument4 pagesThis Kit Is The Flybarless Version of The Kasama Srimok 90 Electrickkm10No ratings yet

- 2009-02-16Document16 pages2009-02-16CoolerAdsNo ratings yet

- LT 20Document138 pagesLT 20Andrej Sobolev100% (1)

- 5 - Brake Shoe Identification 4515Q Vs 4707Q-2Document1 page5 - Brake Shoe Identification 4515Q Vs 4707Q-2Jose Luis DominguezNo ratings yet

- One Way Clutch Brochure From ZENDocument23 pagesOne Way Clutch Brochure From ZENvivekpattniNo ratings yet

- Embedded Systems in Automobile Seminar ReportDocument39 pagesEmbedded Systems in Automobile Seminar ReportbharathNo ratings yet

- Motorsport Pistons and Cylinders Kits: PP98-013 PP80-001 Slipper Skirt Forging DesignDocument6 pagesMotorsport Pistons and Cylinders Kits: PP98-013 PP80-001 Slipper Skirt Forging DesignAllen ChenNo ratings yet

- GR00003800 35C PDFDocument286 pagesGR00003800 35C PDFToponari MedveNo ratings yet

- 2015-SAE-Prediction of High Altitude Performance For UAV Engine PDFDocument6 pages2015-SAE-Prediction of High Altitude Performance For UAV Engine PDF128mansouriNo ratings yet